Benefits of deep cycle electric bus battery and the FAQ guide

12v lithium electric bus battery manufacturers

14-year professional lithium electric bus battery manufacturers, 10-year warranty on battery packs, using the best BMS protection board, protecting the lithium electric bus battery pack from overcharge, overdischarge, overcurrent, short circuit, etc, with excellent self-discharge rate. Configurable Bluetooth, can be connected in series and parallel. The heating function and other special functions can also be customized. Enough stock for the 10 series of 12v lithium ion battery. Can be shipped within 3 days.

-

12v lithium ion battery

12v 200ah lithium ion battery

-

12v lithium ion battery

12v 150ah lithium ion battery

-

12v lithium ion battery

12v 84ah lithium ion battery

-

12v lithium ion battery

12v 75ah lithium ion battery

-

12v lithium ion battery

12v 60ah lithium ion battery

-

12v lithium ion battery

12v 50ah lithium ion battery

-

12v lithium ion battery

12v 42ah lithium ion battery

-

12v lithium ion battery

12v 30ah lithium ion battery

- Does an electric bus have an engine

- Which type of battery is used in an electric bus

- How big is the battery in an electric bus

- How long does electric bus battery last

- How many batteries does a bus have

- How far can an electric bus go on one charge

- How to charge electric bus battery

- Do electric bus use lithium batteries

- Is an lithium electric bus battery deep cycle

- Is an electric bus battery safe

- How much do electric bus battery cost

- Is a lithium electric bus battery worth it

Electric vehicles are becoming more and more popular every year, and there are more and more power battery manufacturers. The most important ones are Top 10 power battery companies. And every major automaker in the world either has an all-electric vehicle, or at least a hybrid. This transition is no different with mass transit buses as electric buses are becoming a common sight on city streets and highways.

This is more common, especially in places like China, The US and Europe. Powering a bus of this size requires an electric bus battery and this battery is the key component that separates an electric bus from a combustion engine bus. An electric bus battery in place of a fossil fuel engine is what makes an electric bus Eco-friendly as it has zero carbon emissions as well reduced cost spent on fuel. Electric buses are being used as school buses, private transit companies, and public transport systems all to replace conventional fuel-powered buses.

Thanks to the electric bus battery, these buses now run more smoothly and quietly having no fossil fuel engine with active moving parts that can constitute noise and facilitate breakdown mid-transit. Reports have it that nearly 50% of the world’s buses will be fully electric by 2030 and this is already evident in China which constitutes over 90% of all-electric buses in the world today.

To better understand what makes these electric buses a good alternative, we need to understand the driving force of the bus which is the electric bus battery. In this article, we’ve answered some of the most commonly asked questions about electric bus battery.

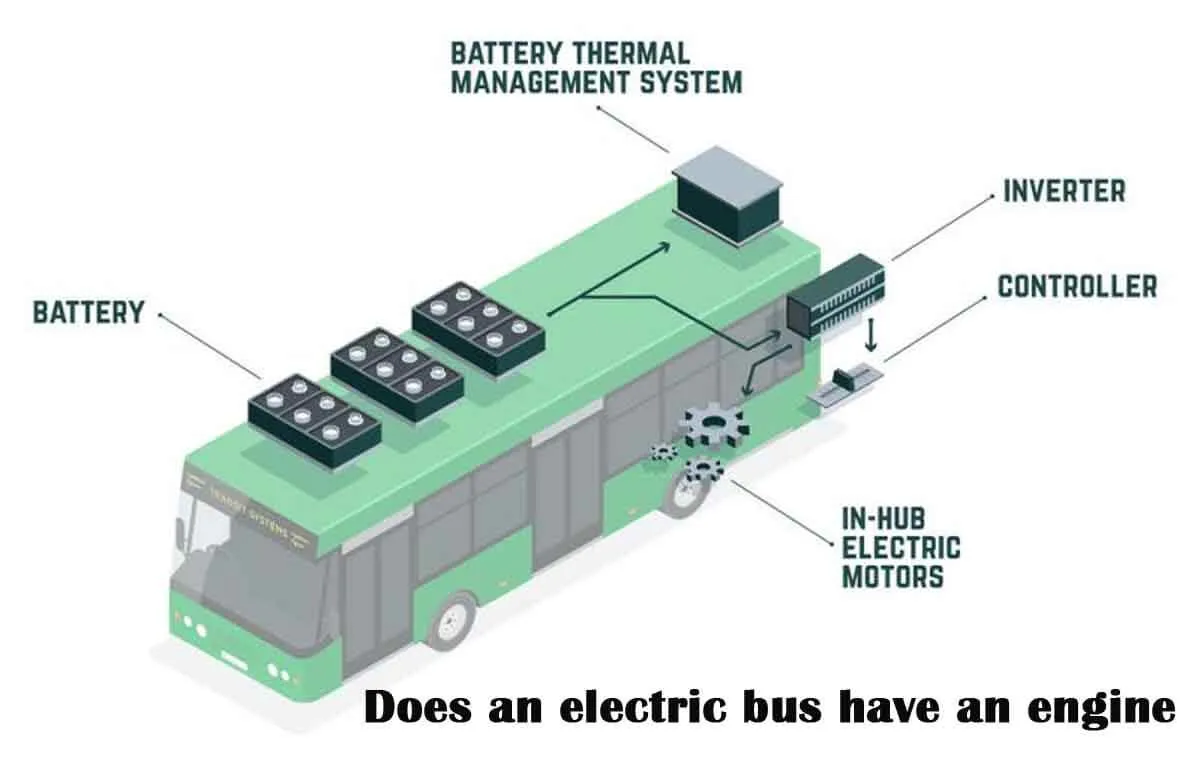

Does an electric bus have an engine

By definition, an electric bus is a vehicle powered by an electric current supplied by an electric bus battery that effectively replaces an engine. With the presence of an electric bus battery, there is no need for an engine or a fuel tank, rather the battery now serves as the fuel alternative supplying electricity to the transmission and wheels.

When the driver starts the bus, a signal is transmitted to the powertrain which in turn powers up the electric bus battery making power avail to the rest of the bus. This battery not only powers the wheels but also other components within the bus such as the headlights, air conditioning, heater, USB charge ports, and all others.

Which type of battery is used in an electric bus

As we’ve established, an electric bus is powered by an battery pack and battery comes in different types all of which offer varied levels of performance and capacity. But in all the battery technology available today, lithium-ion batteries are the best available to be used as an electric bus battery.

Lithium batteries offer some really impressive capabilities that other batteries are yet to achieve. A lithium electric bus battery offers the best energy density among other batteries and also has the lowest weight to volume ratio of any battery.

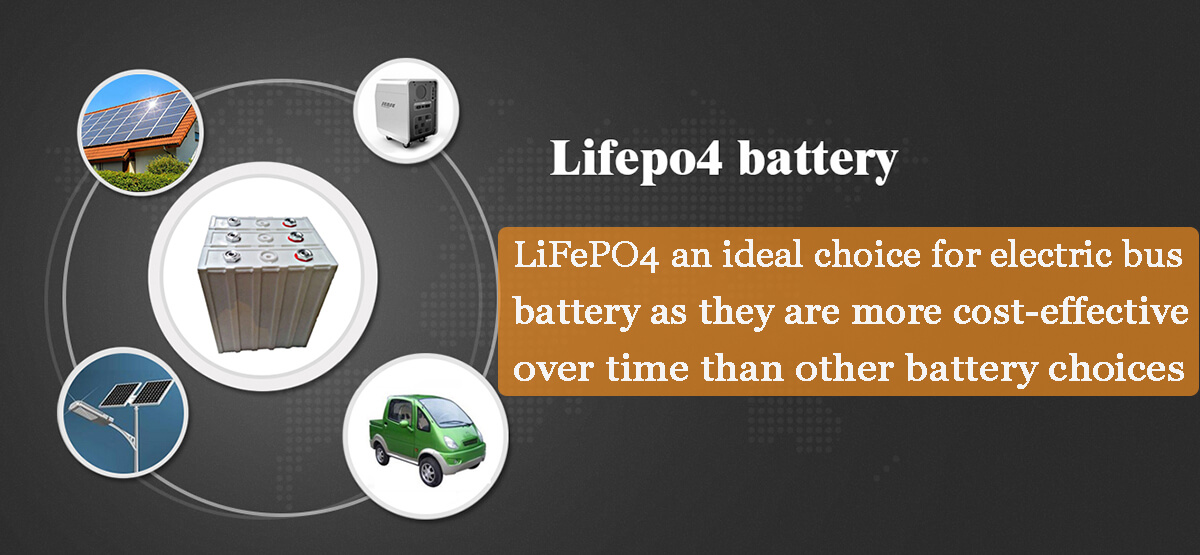

Lithium electric bus battery also come in different types with their chemical composition being the major difference amongst them. Lithium Iron Phosphate or (LiFePO4) batteries are the most commonly used of all lithium batteries for several reasons. They are regarded as the safest and most stable lithium battery available having a relatively long life span than all the battery types reaching up to 4000 cycles in active use.

These batteries are maintenance free, have fast charge speed and have no memory effect. This makes LiFePO4 an ideal choice for electric bus battery as they are more cost-effective over time than other battery choices. Lithium iron phosphate battery can be used not only as a good choice for electric bus battery, but also as lithium RV battery, electric skateboard battery, etc.

How big is the battery in an electric bus

Much like every electronic device or appliance that relies on a battery to function, the size of the battery is dependent on the demand of the device in question and the total runtime that said battery is required to work for.

The size of an electric bus battery is dependent on the size of the bus it is meant to power as well as the load said bus carries for some time. Most electric buses come in 10 to 18-meter sizes all with varying demand for power as the size increase. A standard 12-meter bus can run on a 360 kWh electric bus battery. For example, a 12-meter-long BYD electric bus weighs 13.8 tons, and uses a lithium battery voltage of 540V and a battery capacity of 600AH.

How long does electric bus battery last

An electric bus battery comes in different sizes all with different capacities and energy densities. How long a standard electric bus battery will last depends on several factors such as the size and type of the battery as well as the energy demand of the bus with regards to wheels, air conditioning, headlights, and many others.

The duration an electric bus battery will lay can be calculated on basis of kWh/km. Taking, for instance, a standard bus running on a 360 kWh electric bus battery, and it uses 1.8 kWh of energy for 1 mile, we simply need to factor in the energy usage of the bus into the size of the battery. This would be ( 360 kWh ÷ 1.8 kWh) which would give us 200.

In essence, this bus would run a 360kWh battery at 1.8 kWh for 200 miles. This doesn’t take into account discharge depth and battery efficiency but a simply gives a rough estimate of how an electric bus battery works and how long it would last in ideal conditions

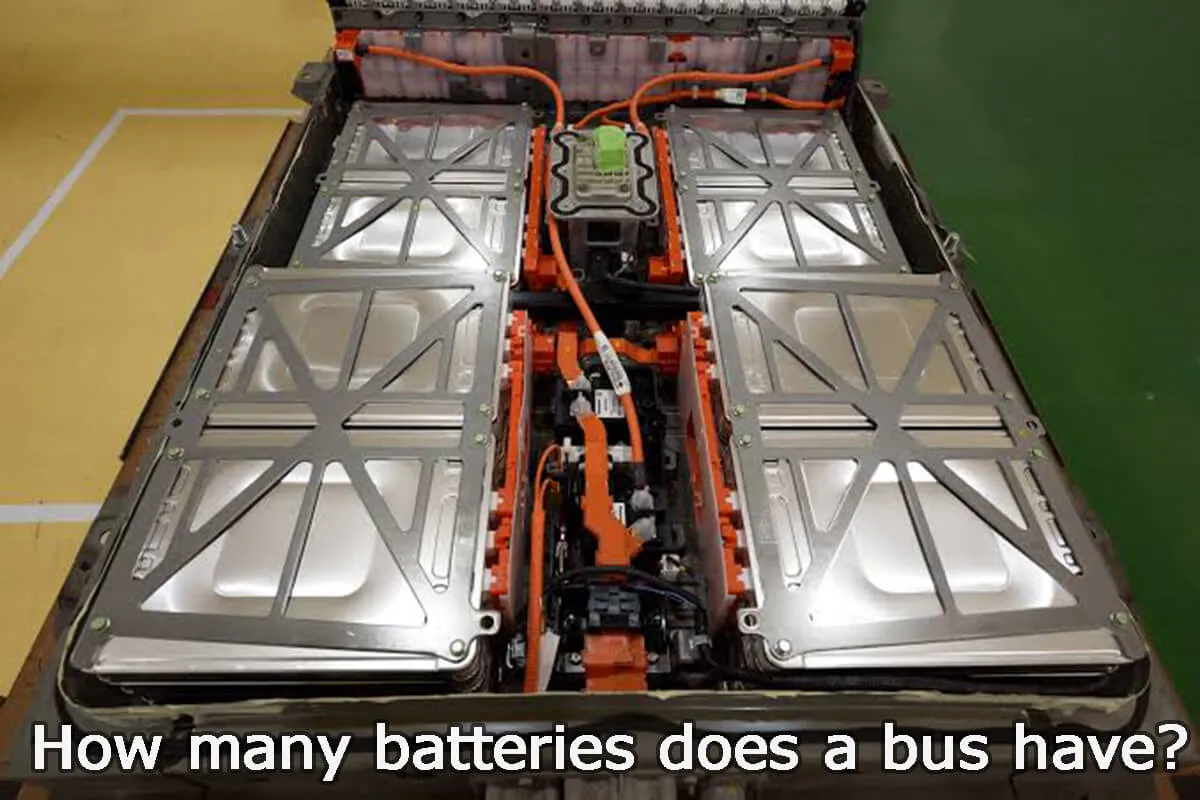

How many batteries does a bus have

A standard electric bus, usually needs a combination of multiple battery packs to function. Depending on the size of the electric bus battery, the number of batteries sufficient to power a bus can be calculated.

For example, a 58.1kWh bus battery pack is composed of 14 modules with a 12S01P, a nominal voltage of 618V and a nominal capacity of 94AH.

How far can an electric bus go on one charge

Much like how long an electric bus battery would last when supplying energy to a bus, the relative distance said bus can go on a single charge also depends on several contributing factors. Many electric buses usually have a dedicated route they are meant to run, so the question would be if the electric bus battery can complete the required route before needing a charge?

With factors like the weight of the bus and passengers onboard, temperature, topography(hills and slopes), bus system usage, and others into consideration, a standard 350 kWh electric bus battery on a 12-meter bus should be able to cover a 200-mile range, all things considered.

How to charge electric bus battery

Charging an electric bus battery is an important aspect of maintaining the bus’s performance as well as its schedule. This is because electric buses are mostly used for mass transportation and commonly used by the public, so any interruption in schedule could be an inconvenience for a lot of people.

Hence, there are two basic modes of charging an electric bus battery which are Pantograph and plug-in charging.

Using a pantograph method of charging, the electric bus pulls in at a layover point where a charge station is located usually along its dedicated route. This station commonly has a robot hand stationed just above the roof level of the electric bus. Upon reaching this point, the robotic arm docks with the charging port of the electric bus placed on the roof of the bus and charging commences.

The electric bus battery would ideally receive an hour’s worth of energy in under 5 minutes while passengers board and exit the bus. Once the time for charging is up, both ports will automatically detach from each other, while the system notes the amount of energy received, the driver pulls out of the station and heads to his next stop/charge station.

Using a plug-in station is relatively straightforward as it is the principle that applies to electric cars and other chargeable appliances. The electric bus battery can be charged by pulling the electric bus into a charge station commonly at night after the bus is done with service for the day.

Electric buses are usually fitted with a standard charge receptacle which can be paired with a level 1 or level 2 charger. Both levels denote the speed at which the electric bus battery can be charged with level 2 being the fastest charging of the two. The electric bus can be charged overnight with charge taking between 3 to 8 hours depending on the battery size, charge C-rate and charge station available.

Do electric bus use lithium batteries

Electric buses are just like most electric vehicles and would function depending on the quality of the battery being used. If a high-performance electric bus battery isn’t used, the electric bus would also perform poorly slowly declining alongside the battery.

This is why most electric buses today make use of lithium batteries as their go-to electric bus battery because they offer the best performance over a long lifespan. Lithium batteries have the best technology in terms of energy density, C-rate, charge cycle, maintenance, weight to size ratio, and much more.

With new strides in battery technology being made constantly, the price of a lithium electric bus battery will continue to drop which favors electric bus owners in the long run.

Is an lithium electric bus battery deep cycle

Ideally, a deep cycle battery is a battery that can be discharged to a lower depth/percentage than other batteries and has a high charge cycle. Most lithium ion batteries are deep cycle batteries and a lithium electric bus battery can be classified as a deep cycle battery.

For a lithium electric bus battery it usually has a discharge depth greater than 95% and for such a power battery, anything lower than 80% means the battery is bad. This means, the lower the discharge depth, the lower the capacity of the battery and eventually this would lower the battery performance as well. To preserve and prolong the performance of a deep cycle lithium electric bus battery, it is advised that the battery not be charged to 100% or allowed to discharged completely to 0%.

Is an electric bus battery safe

A lithium battery used as an electric bus battery is generally considered to be stable and therefore, safe to use. But this isn’t always the case as even lithium batteries can have certain safety risks attached to them. These risks commonly include fire hazards which although, not common are a real danger to bus fleets if not properly handled.

When a lithium electric bus battery is exposed to high temperatures either due to overcharging, mechanical failures, or internally generated heat from a short circuit. This can trigger a cascade of chemical reactions within the battery cell that could lead to explosion and emission of toxic gases like carbon monoxide and Sulphur dioxide.

This why a properly installed lithium electric car battery comes with a battery thermal management system (BTMS) which helps regulate the temperature of the battery to prevent such fire hazards fro occurring. And the lithium battery itself is equipped with BMS which ensures safety in the use process to an extent.

How much do electric bus battery cost

With most electric buses, the electric bus battery makes up a considerable amount of the overall purchase price, much like the engine does for a combustion engine bus. Nevertheless, the price of lithium electric bus batters has been on a slow but steady decline over the last decade or so.

The average cost of a lithium electric bus battery has dropped to about $150 per kWh which if multiples by a standard 360 kWh battery should only to roughly $54,000. This makes up about 30% to 40% of the initial purchase price of a 12-meter electric bus but prices may vary accordingly.

Is a lithium electric bus battery worth it

With the plethora of advantages, they come with a lithium electric bus battery, it is safe to say they are well worth it. With a higher energy density, better performance, longer lifespan, and zero maintenance required, a lithium electric battery is the recommended choice for any electric bus.

About lithium electric bus battery manufacturers

TYCORUN® has more than 14 years of experience in the lithium electric bus battery industry and is a Chinese high-tech enterprise that develops, produces and sells various new energy battery products.

12V electric bus battery production capacity accounts for 80% of our lithium battery manufacturing products

High quality assurance

TYCORUN is determined to become a leader in the lithium electric bus battery industry, quality is our culture!

Professional manufacturers

With lithium ion electric bus battery pack as the core, integrating channels and technologies

Factory wholesale price

We promise to let customers get the most cost-effective lithium electric bus battery products

Reliable Service Assurance

Provide lithium ion electric bus battery OEM, ODM, 1 MOQ.Full Set of Certificate

Professional China Lithium Battery Companies

As a professional China lithium battery companies, TYCORUN ENERGY Adopt AAA Lithium ion battery cells design and production, provides upstream suppliers consultant for your lithium ion battery pack solutions.

Safety lithium battery pack high cost-effective, up to 10% – 25% cost savings.

FAQ About Buying Lithium Batteries

Most common applications for lithium battery

Lithium battery is widely used in many industries, ranging from powering the vehicles, scooters, bicycles to energy storage in home use, commercial use and outdoor power supply, etc. Generally speaking, lithium ion battery manufacturers make 2 kinds of lithium batteries: ternary lithium battery is applied for powering to move because of its high energy density and discharge rate, while LFP lithium battery is more popular with energy storage for its stable chemistry components and longer cycles. Some of the most popular application of lithium battery cover EV, RV, golf cart, forklift, camping power supply, kayak, scooter, solar power system, home Energy storage system, UPS Data center, telecom and IT backup, Industrial Equipment, etc.

What Factores should you Consider When Buying lithium ion battery?

Professionals from lithium ion battery manufacturers advise you that you need to provide the following information when buying lithium batteries. you need to provide the following information:

Rated voltage(V)

Operating voltage range(V)

Capacity(Ah)

Charging current (A)(Rated current/ Maximum continuous current/Peak current)

Discharge current (A)(Rated current/Maximum continuous current/Peak current)

whether it needs to be in series or parallel, and if so, how many in series or parallel.

Our lithium ion battery factory engineers will recommend the most suitable and cost-effective lithium ion battery packs

What certifications are required for lithium batteries?

Commonly used certifications for lithium batteries are dedicated for transportation and certification of product quality. Not too many lithium ion battery manufacturers will apply for those certifications because of the high cost. Fortunately we have some of them and in the future we will apply all of them for our worldwide market. The certifications as per below:

Transportation unique qualification: generally MSDS, UN38.3, report for sea as well as air transportation of goods

MSDS is a chemical safety and security technical spec, a file utilized by chemical producers and importers to clarify the physical as well as chemical residential properties of chemicals as well as the possible damage to the health of users.

The UN38.3 is specifically created by the United Nations for the transport of lithium battery by sea or by air.

Identification and classification report for sea and air transport of goods: It is a report that needs to be provided when batteries and products with batteries are transported by air or by sea.

Product quality certification: Different countries have different product quality certifications. Commonly are:

European Union: CE, ROHS

North America: FCC, UL

India: BIS certification

How to ship the lithium ion batteries?

For purchases from China lithium ion battery factory, We have three shipment way to ship out the goods,

Option 1: SEA WAY, we can ship out the lithium battery to every country via sea way. And We have UN38.3 & MSDS certification. Here’s the range time for the shipment date.

USA: 30-40 days

Europe: 30-40 days.

Australia: 35-45 days.

Option 2: AIR WAY, If the single parcel less than 68KG, that we can use the air way.

USA: 12-15 days

Europe: 12-15 days.

Australia:15-18 days.

Opyion 3: TRAIN WAY, We can ship out the lithium battery to Europe via Train way.

USA: 30-40 days

Europe: 30-40 days.

Australia: 35-45 days.

Because the lithium battery material is dangerous material. Our lithium ion battery suppliers have passed UN38.3 & MSDS & Dangerous packing certificate, As a lithium ion battery manufacturer, TYCORUN® can ship out the lithium battery!

Receive an accurate quote within 3-5 days when you fill out this form. Or, give us a call: +1(405) 283-8396

Lithium ion Battery News

One-stop Africa battery swap solution – new energy electric motorcycle intelligent operation management

This article will cover the current situation of Africa’s market, the rapid development of the Africa battery swap industrial chain and Tycorun’s battery swap solution.

Top 6 high-rate cell companies in China

Among the manufacturer producing high rate battery, BAK, EVE, LISHEN, MOLICEL, SAMSUNG SDI, and SunPower stand out for their outstanding products.

Top 10 solid state battery manufacturers in China

China’s solid state battery development is in the accelerated stage, the top 10 solid state battery manufacturers mainly have the following

New Ganfeng battery – ultra safe semi-solid battery with high performance

This article details Ganfeng Lithium’s solid-state battery development, technological innovations, and the performance of the ganfeng battery in safety tests.

Top 5 electric cargo tricycle in China

This review presents the top 5 electric cargo tricycles in China, featuring detailed specifications and performance insights. Evaluating criteria such as load capacity, battery efficiency, and safety features, this guide assists buyers in selecting the ideal tricycle based on individual requirements.

Materials and lightweight development of electric bicycles

This article provides an insightful exploration into the development of electric bicycles, focusing on advancements in materials and lightweighting techniques. It delves into the historical evolution of electric bicycles, analyzes various bicycle frame materials, discusses the development of electric power assist technology, and offers an overview of the electric assist bicycle market. Through detailed examination and analysis, it highlights the importance of lightweighting for electric bicycles and identifies key trends shaping the industry’s future.