Home » lithium ion battery knowledge » Materials and lightweight development of electric bicycles

Materials and lightweight development of electric bicycles

The development of electric bicycles

In fact, the history of electric-assisted bicycles can be traced back to the 1890s. In 1895, Ogden Bolton Jr. applied for a patent for the first battery-powered bicycle with a DC hub motor equipped with a 6-pole brush commutator on the rear wheel. This e-bike has a 10-volt battery that can produce 100 amps, but it’s so bulky that it’s almost impossible to ride.

As the battery and motor processes took shape, the true electric-assisted bicycle was born. In 1989, Yamaha built one of the earliest prototypes, which looked very similar to a modern e-bike.

Power control and torque sensors for electric mopeds were developed in the 1990s. In 1992, Vector Service Limited launched the first electric-assist bicycle called the Zike, which featured a nickel-chromium battery built into the frame and an 850-gram magnet motor. However, sales were very low, the reason for which is unclear, possibly due to high production costs.

In 1993, Yamaha invented the first pedal assist system. Meanwhile, American automotive icon Lee Iacocca founded EV Global motors in 1997. EV Global produces an electric assist bicycle called the e-bike SX, which was one of the first concepts used to promote electric assist. While the bulky electric-assist bicycles of the day used lead-acid batteries, newer models use nickel-metal hydride, nickel-cadmium and lithium-ion batteries. The application of lithium-ion batteries is one of the most important breakthroughs in electric bicycle technology. Higher energy density greatly improves ease of use.

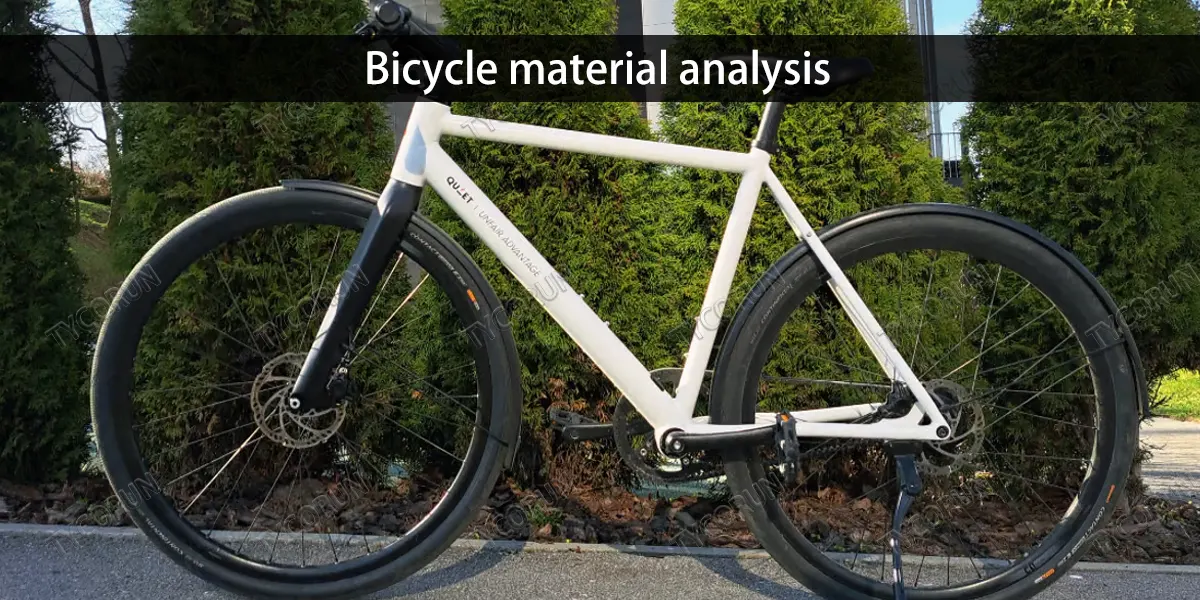

Bicycle material analysis

- Steel frame

The steel frame structure has strong load-bearing capacity and obvious price advantages, so it is still widely used in some station wagons. The high strength and rigidity of the steel frame allows it to bear greater weight, making it suitable for long-distance travel and carrying large items. Additionally, steel frames are relatively inexpensive, making them an affordable option. The main materials used in the steel frame are 4130 chromium molybdenum steel and Reynolds steel. - Aluminum alloy

Aluminum alloy has relatively balanced performance in all aspects and its price is relatively low, so it is very common in daily use. The aluminum alloy frame has good lightweight properties, making the bike more flexible and easier to maneuver. However, aluminum alloys have weak rigidity and strength and a relatively short service life, so they may not be suitable for use in scenarios that require higher load-bearing capacity and durability. Aluminum alloy frames mainly use 6000 series and 7000 series aluminum materials. - Carbon fiber

Carbon fiber is currently the mainstream frame material for high-end road and mountain bikes. It has the characteristics of light weight, good shock absorption and high strength. The lightweight design of the carbon fiber frame makes the bike more flexible and faster, making it ideal for competitive riding. However, carbon fiber structures are prone to fracture when subjected to lateral force, which remains a technical problem to be solved. The manufacturing process of carbon fiber frames is very complex and the price is high, so it has become the material of choice for high-end bicycles.

The current mainstream top-level frames usually use materials such as T700 or T800 as the main body of the frame, while T1000 is mainly used to improve key parts of rigidity, such as the bottom bracket and chainstays, to obtain maximum benefits.

Titanium alloy

Titanium alloy is a lightweight material, second only to carbon fiber, with excellent strength and corrosion resistance among materials, slightly lower than the strength of steel. The fatigue life of a titanium alloy frame is five times longer than that of ordinary steel frames and aluminum frames, which means the service life of the bicycle will be extended. The lightweight design of the titanium alloy frame makes the bike lighter and more flexible, making it ideal for cyclists pursuing high performance. However, due to the complexity of the manufacturing process and welding technology, the price and cost of titanium alloy frames are very high, so titanium alloy frames are only chosen in the high-end bicycle market.There are currently two main types of mainstream titanium alloy frames, namely 6-4 titanium alloy and 3-2.5 titanium alloy.

Magnesium alloy

Magnesium alloys have a unique position in the bicycle world. It is an emerging material that has attracted human attention and exploration since the 1980s. Famous bicycle manufacturers such as Cannondale and Pinarello have also joined the magnesium alloy bicycle manufacturing boom. However, although the magnesium alloy bicycles trial produced by Pinarello and Merida achieved extraordinary results in the Tour de France, they were not successfully commercialized due to the difficulty of manufacturing technology and quality problems of finished products, leading to the abandonment of magnesium alloy frames.Comparing carbon fiber, we will find that there are many manual components in the carbon fiber production process and it is not as suitable for mass production as magnesium alloy. Therefore, it costs more, takes longer, and has higher process requirements. Therefore, with the development of integrated die-casting technology and magnesium alloy technology, the market has once again begun to try magnesium alloy bicycles.

Electric power assist technology development

Electric assist technology is the core technology of electric assist bicycles, which mainly includes three aspects: motor, battery and control system. The technical level and performance indicators of these three aspects directly affect important factors such as the cruising range, power output, intelligence and cost of electric power-assisted bicycles. In recent years, with the advancement of science and technology and market demand, electric assist technology has continued to make breakthroughs and innovations.

In terms of complete vehicles, the main players include Japan’s Yamaha, the United States’ Trek, China’s Giant, etc. These companies have strong competitiveness in the design, manufacturing and sales of electric-assisted bicycles, providing a variety of types and grades of products to meet the needs of different consumers.

In terms of batteries, lightweight, high energy density, long life and low cost are the main directions for the development of battery technology. At present, lithium-ion batteries represented by small cylindrical ternary lithium batteries have become the mainstream battery type for electric bicycles. They have the advantages of light weight, large capacity, long cycle life, and high safety.

According to statistics, global lithium-ion battery production reached 150 million kilowatt-hours in 2019, of which about 10% was used in the field of electric-assisted bicycles. In the future, with the improvement of lithium-ion battery materials and processes, as well as the development and application of new lithium batteries such as solid-state lithium batteries, the endurance of electric-assisted bicycles will be further improved.

In terms of motors, high efficiency, low noise, small size and intelligence are the main directions for the development of motor technology. At present, brushless motors represented by high-speed permanent magnet brushless DC motors have gradually replaced brushed and toothed DC motors and become the mainstream motor type for electric power-assisted bicycles. They have high efficiency, low noise, small size, and long service life.

According to statistics, global brushless DC motor production reached 240 million units in 2019, about 15% of which were used in the field of electric-assisted bicycles. In the future, with the optimization of brushless DC motor performance and the promotion and application of new brushless motors such as brushless self-aligning machines, the power output of electric-assisted bicycles will be further enhanced.

Electric assist bicycle market overview

An electric-assisted bicycle is a new type of transportation that combines a motor, battery and smart sensor system. It can automatically adjust the output power of the motor according to the rider’s pedaling force and speed, thereby providing a more comfortable and efficient riding experience. Electric-assisted bicycles are favored by more and more consumers and governments around the world, and their market size and sales are showing a rapid growth trend.

According to data, the global electric-assisted bicycle market will reach US$27.22 billion in 2021, an increase of 13.9% compared to 2020. It is expected that by 2029, the global market size will be close to 225.5 billion yuan, with a compound annual growth rate (CAGR) of 12.2% in the next six years.

Major manufacturers in the global electric-assisted bicycle market include Giant, Accell Group, Pon and Riese & Müller. These four major manufacturers account for approximately 27% of the global market share. Touring electric bicycles are the largest product segment in the global electric-assisted bicycle market, accounting for approximately 36% of the market share. In the future, with the development of battery swapping and the application of battery swapping station business model, the electric bicycle market will expand in the future.