12V lithium ion battery manufacturers

12v lithium ion battery factory

12v lithium ion battery: The Ultimate FAQ Guide

- What is a 12V lithium ion battery?

- Brief history of the 12V lithium-ion batteries

- What is the technology used to develop the 12V lithium ion battery?

- 12V lithium ion battery applications

- Advantages of 12V lithium ion battery over other types of batteries

- How to make a 12V lithium ion battery

- How many cells in a 12V lithium ion battery?

- How do you connect your 12V lithium ion batteries (series or parallel)

- What is the size and weight of the 12V lithium-ion battery

- What is the charging and discharge rate of the 12v lithium ion battery

- How long does a 12V lithium ion battery last?

- Quality standards and differences of 12V lithium ion battery

- What are 12V lithium ion batteries used for?

- Are 12 volt lithium-ion batteries safe?

- What are the disadvantages of 12V lithium-ion batteries?

- What certification is required for a 12V lithium ion battery?

- How many Amp Hours can you really get from a 12v lithium battery(300ah, 100ah,500ah, 200ah)?

- How to select the right 12V lithium ion batteries for your application(200ah, 300ah,500ah, 100ah)?

- Is it right to leave my lithium ion batteries to charge overnight?

- Will the 12volt lithium-ion batteries be damaged if left unused for a long time?

- How to maintain the 12volt lithium ion batteries

- Industrial application of the 12V lithium-ion batteries( in cars and electric vehicle)

- What the future holds for lithium ion batteries? (technological advancements in the field)

1.What is a 12v lithium ion battery?

lithium ion batteries get the advantage of the uttermost attention among many battery chemistries.They are widely employed to use owing to their reduced cost per cycle and lofty energy density relative to the other battery chemistries. Though tagged “lithium ion batteries”, it is obtainable in about six chemistries, each steeply completely different from another.

Lead-acid batteries are one of the oldest and most widely used secondary batteries and have a wide range of applications in the field of energy storage.Their name comes from the positive and negative electrodes made of lead sheets and sulfuric acid electrolytes. Because lead and sulfuric acid are harmful substances, it will cause great harm to the environment and after the reaction will produce a certain amount of gas left in the electrolyte, so it is necessary to check and replace the electrolyte frequently. In addition to environmental concerns, confusion over the size of lead-acid batteries is a controversial issue, but they still have a high market due to low material and manufacturing costs and high recovery rates.

Compared with lead-acid batteries, lithium-ion batteries have high energy density, long cycle life and are relatively friendly to the environment. All batteries are made of cells; conventionally these are usually about four or more. Any cell has its nominal voltage, a minimum voltage which it can safely discharge, referred to as its nominal voltage. lithium ion batteries usually has a nominal cell voltage of 3.2Volts whereas the lead-acid battery has each cell featuring a nominal voltage of 2volt per cell.

A 12-volt lithium cell is attained by combining four cells. This cell combination is quite popular and is usually used in most electronic gadgets. The nominal voltage of any 4 cell battery now becomes 12.8V. When eight of the cells are joined in series, the nominal charge is 25.6, although it would be referred to as a 24Volt battery. In the same manner, a 48V battery has a nominal voltage of 51.2V and is made up of sixteen cells connected in series.

2.Brief history of the 12v lithium-ion batteries

1n 1912, the first developmental stride in the lithium ion batteries was started by G.N. Lewis but only became successful later. In the early 1970s, the batteries were made commercially available in the markets. This battery could not be recharged, therefore, researches to develop a rechargeable lithium ion batteries continued. This followed the inability to curtail the safety concerns during its recharge. The lightest metal on the Earth’s surface yet known by man is Lithium. Its electrochemical reactivity is a property that offers it the advantage of possessing the highest energy density per unit weight.

The inherent instability of lithium metal, especially during recharge, led to research on lithium ions, a non-metallic component, in a bid to manufacture a non-metallic lithium ion batteries safe for charging. Lithium-ion has a lower energy density than lithium metal but possessed the unique characteristics of lithium needed for an efficient battery. It was safer than its metallic variant although safety measures are still required during its charging.

An Englishman, Stanley Whittingham first started research works on making a lithium-ion battery. He made use of titanium disulfide and lithium metal. However, when the combination was unsuccessful and he discontinued the research. John B. Goodenough took off from where Whittingham left in the 1980s. Rather than titanium disulfide as cathode, he used lithium cobalt oxide. This was successful to a certain scale: the energy potential of the battery increased by a factor of two.

Another development was made to the battery five years later. Akira Yoshino at the Meijo University in Nagoya, Japan replaced the lithium metal at the anode with petroleum coke. This combination made the battery safer. By 1991, Sony Corporation became the first known manufacturer of rechargeable batteries. From the 1990s onward, the lithium ion batteries is the acceptable and fastest-growing battery chemistry.

As outlined above, Lithium and Lithium-ion batteries are of two kinds; they are dissimilar. Nevertheless, they do share some commonalities. Being batteries, they both provide electricity and are quite portable. Their chemical composition stores the electric charge provided during charging. Electricity capable of powering any device to the battery is transmitted when a connection is made between its electrodes to form a circuit. The charges are from the cathode to the anode.

Even after the trying yet successful endeavor to produce what is known today as the lithium-ion battery, why is the lithium batteries still engaged to use today? lithium batteries are not rechargeable. However, it does have a higher capacity than lithium-ion batteries. This ability to retain charge for a long time is possible because of its high energy density. Besides, lithium metal is a common element on Earth thus making a battery with lithium at its anode easy and less expensive to create. However, with the lithium-ion battery, various materials are needed to combine to get the anode, and these materials are not usually cheap to come by.

3.What is the technology used to develop the 12v lithium ion battery?

12V Lithium-ion battery comes in various chemistries unique to one another. They are named after their active components. An example of such could be demonstrated with the popularly used lit-ions – Lithium cobalt. The full name of the ion is Lithium cobalt, although, for ease, it could either be represented by its chemistry notation or abbreviation. The chemical denotation of Lithium cobalt is LiCo(O2) while its acronym is LCO. Presenting them this way makes it easier for them to be pronounced and memorized. Cobalt is the prominent constituent of this battery. Generally, for the six other prevalent lithium-ion batteries that would be discussed in this section, their names point to the key element used in its manufacture.

Lithium Cobalt Oxide(LiCo(O2)) [LCO]

Commonly used in powering in telecommunicating devices, cameras, and computers, the Li-cobalt has an advantage over the others due to its high specific energy. At its anode is graphite whereas the cathode is made up of oxide of cobalt. During the discharge, ions moves from the anode towards the cathode due to the layered nature of cathode. Meanwhile, during the charging process, the flow is from cathode to anode. There are several disadvantages with the Lithium-cobalt battery. One is the concern of short life span. It is also known to be very unstable, and has a restricted load capacity.

Lithium Manganese Oxide (LiMn2O4) [LMO]

The first Lithium-ion cell employing the use of lithium manganese oxide debuted in 1996. The cell was manufactured by Moli Energy. This followed a paper on lithium-ion using manganese spinel in 1983 published in the Materials Research Bulletin. Lithium manganese oxide is the material of the cathode. The cell works on a basis that a three-dimensional spinel structure is created on the electrode leading to more ion flow, efficient current handling, and decreased internal resistance.

Lithium Nickel Manganese Cobalt Oxide (LiNiMnCoO2) [NMC]

A combination of manganese and cobalt at the cathode makes for cells denoted as Lithium Nickel Manganese Cobalt Oxide (NMC). Each cell, if developed, as do the Li-Manganese can offer more energy and power. To give an instance, NMC in a 18650 cell operating at a capacity of around 2,800mAh should be able to produce a current of about 4A and 5A; and an NMC in a similar cell if optimized for particular power could deliver 2,000mAh with a continuous current discharge of 20A. In some cases, it can surpass 4,000MAH although this is at the expense of cycle life and loading capabilities. Adding silicon with graphite to form the anode comes at a risk. With each charging and discharging, the anode would expand and contract, rendering the cell unstable.

Lithium Iron Phosphate(LiFePO4) [LFP]

Phosphate was identified as a material for the cathode of rechargeable lithium ion batteries in 1996 at the University of Texas. In collaboration with other contributors, it was found out that Li-phosphate had a good electrochemical performance with low resistance. Its design to make the cell chemistry comprised of phosphate at the cathode. The current realized is adequately high. Its high thermal stability, tolerance, and increased safety are some of the main advantages. An advantage that makes it preferred among other Li-ion systems is its good tolerance. If sustained at high voltage for an extended period, Li-phosphate can tolerate full charge conditions and undergoes lesser stress compared to systems of other lithium-ion.

The 12V lithium-ion batteries works due to the movement of lithium ions from the anode to the cathode. With the Lithium Cobalt Oxide battery as an example, neutral lithium is transformed into Li+ at the lithium-graphite anode. From the anode, the ions travel to the cathode and form LiCoO2. Co(IV) is reduced to Co(III) at this electrode. This change in oxidation state is given by the equation:

Li1-xCoO2 (s) + x Li + + x e LiCoO2à- (s).

During the discharge process, a process where the Lithium in the Lithium-graphite anode is oxidized from 0 to 1, the equation for such reaction is as follows:

6 C(graphite) + LiàC6Li + + e.

Conversely, during recharge, the process is reversed; the equations also reverse. The lithium-ion at the lithium-cobalt oxide cathode goes to the anode where they take up a neutral lithium form within the lithium-graphite as before. Unlike most other battery chemistry, the lithium ion batteries is more stable across charge/recharge cycles. This is due to the minute lithium ion size which leads to fewer disturbances during ion transfer within an electrode structure.

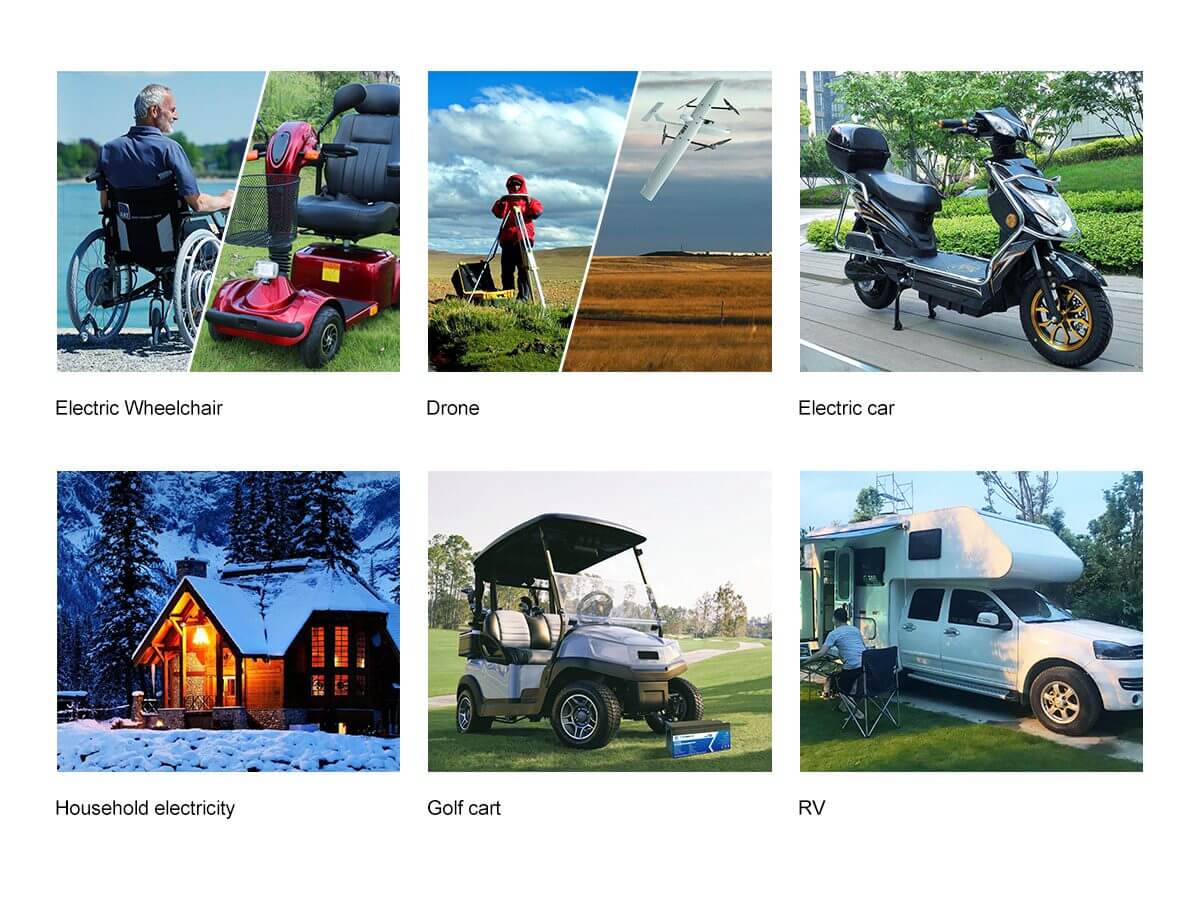

4.12v lithium ion battery applications

lithium ion batteries, as a commonly used type of lithium ion batteries, has large range of applications. A lot of electronic devices choose 12V lithium-ion batteries as the power supply. Many customers are particularly concerned about the specific application of 12V lithium-ion batteries in what aspects? Although this article does not cover the all range of lithium ion batteries applications, it is still intended to provide customers with as many 12V lithium-ion batteries applications as possible.

Applications in personal transportation:

This sector is the most popularmarket in the global electric transportation sector, which includes electric bicycles, motorcycles, electric golf vehicle, electric wheelchairs, electric balance vehicles, scooters, balance vehicles, RVs, campers, electric scooters and so on

Automotive applications:

There are four main types of battery applications in the area of motor vehicle:

- Micro hybrid electric vehicle

- Hybrid electric vehicles

- Plug-in hybrid electric vehicles

- Electric Vehicles

- Robotics and automation applications:

The application of batteries in automation equipment, robotics and unmanned driving applications is also increasing. Examples include hand-held vacuum cleaners and floor cleaners

Industrial applications:

- forklifts, baggage carriers and ground handling vehicles are often used in large warehouses

- Navigation and Marine applications: such as trawlers, submarines, yachts, electric boats, etc.

- Grid Applications: Fixed energy storage devices and grid systems are very large, encompassing a variety of applications and energy storage technologies. For example, base station batteries, solar systems, etc.

- Aerospace applications: Lithium-ion batteries and advanced battery systems have promoted the aerospace sector, such as aircraft, satellite equipment, etc.

- other aspects such as: hardware tools, small refrigerator, fishing machine, fascia gun, disinfection light, children’s electric toy car, children’s toys, lawn mower, dry cleaning machine, outdoor stereo, pull rod speakers, 3D printer, etc.

5.Advantages of 12V lithium ion battery over other types of batteries

| Advantages of 12V lithium ion batteries over other types of batteries | |||||

| Battery components | Lithium iron Phosphate | Lithium cobalt oxides | Lithium manganate | Lead- acid | Ni-mh |

| Lifespan | 3000cycles | 500cycles | 400cycles | 150cycles | 500cycles |

| Energy density (wh/kg) | 100-150 | 120-150 | 105-120 | 40-50 | 40-70 |

| Long run cost | The most economic | High | Relatively high | Relatively high | Relatively high |

| high-temperature resistance | Excellent | Average | Poor | Poor | Average |

| self discharge(%/month) | <1% | 1%-5% | 5% | 3%-4% | 25~35% |

| operating temperature (℃) | -20-60 | -20-60 | -20-60 | -40-60 | -15-40 |

This table summarizes the information about the types of batteries commonly used in 12V lithium ion batteries and the chemical properties of the batteries. The cell includes lithium iron phosphate, lithium cobalt acid, lithium manganese acid, lead acid, nickel hydride, etc

1、Compared with nickel-metal hydride battery and lead-acid battery, lithium ion batteries has higher working voltage. Nickel-metal hydride and lead-acid batteries generally operate at a voltage of 1.2-1.5V, while lithium-ion batteries operate at a voltage of 3.2-3.8v Higher operating voltages mean fewer cells are needed for the same assembly voltage. For example, if we need a 350V assembly voltage, the nickel-metal hydride battery needs about 292 cells in series (350V/1.2 V) and the lithium-ion battery only needs 98 cells (350V/3.6V).

2、In addition to high pressure and high energy density, lithium ion batteries have a low self-discharge rate. What is the self-discharge rate? Self-discharge rate, also known as charge retention ability, refers to the battery in the open state, the battery stored in the capacity to maintain under certain conditions. In other words, lithium-ion batteries lose much less capacity than other batteries after being stored for a while.

Depending on the type of lithium-ion battery, the average self-discharge rate is about 1 to 5 percent per month. The loss of capacity can be divided into two kinds: reversible capacity loss and permanent capacity loss; The loss of reversible capacity can be recovered by charging, while the permanent loss cannot be recovered. Compared with other batteries, lithium ion has a relatively good cycle life. Lead-acid batteries have a lifespan of about 300-500 cycles. A lithium-ion battery can do thousands of times.

6.How to make a 12V lithium ion battery

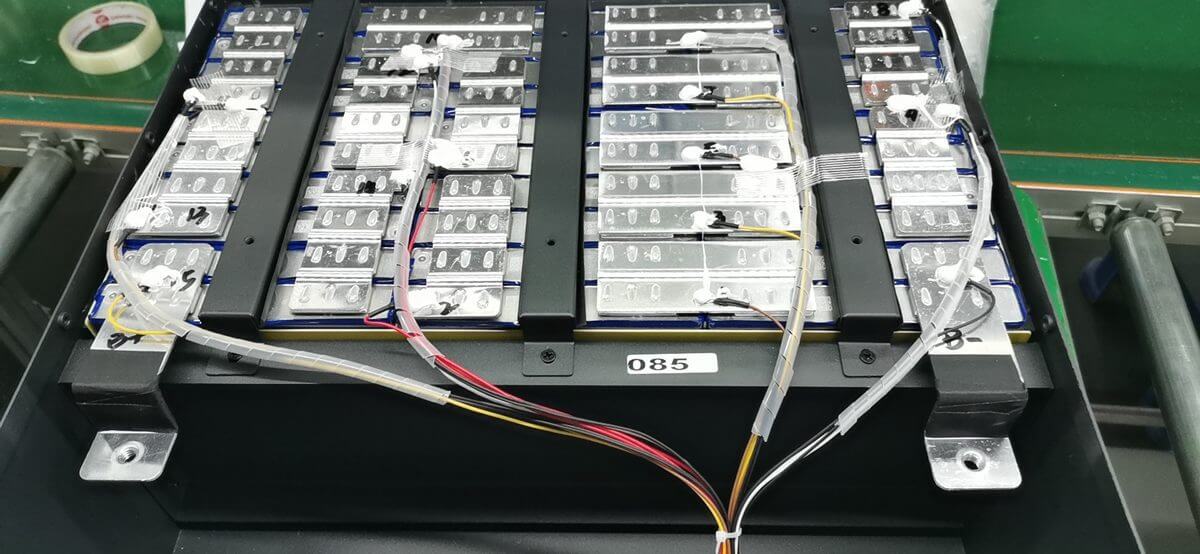

Now that we’ve seen how lithium ion batteries work in series and parallels to get to 12 volts, let’s talk about what lithium ion batteries are made of. lithium ion batteries is a very complex system, but lithium ion batteries cell components are relatively small, only five parts, and about 12-20 kinds of materials related to the cell.

The composition of the cell is:

1 、Cathode, also known as the positive electrode, is composed of some positive electrode materials covered on the conductive matrix. In lithium-ion batteries, the substrate is usually ultra-thin aluminum foil.

2、The anode, also known as the negative electrode, usually consists of the negative electrode active material and auxiliary materials covered on the copper foil.

3、Separator, a thin film of conductive ions between the positive and negative poles, used to prevent short circuits in contact between the positive and negative poles. The positive and negative electrodes are sandwiched with the diaphragm, which is then assembled (laminated or wound) to form a cell. Winding is a commonly used cell assembly technology, that is, the battery positive, negative and diaphragm material flat laminated into a thin sheet and then rolled up, and then stuffed into a metal container or aluminum plastic film. The technology maximizes the surface area of the battery electrode and has a relatively minimum volume. At the same time, the electrons and ions in the battery can move freely to ensure the power performance of the battery.

4、Packaging materials. The assembled cell needs outer packaging to be encapsulated. The packaging materials are mainly metal shell, plastic shell and composite film.

5、The electrolyte, which is an ion transport medium, allows ions to travel between the positive and negative electrodes. The final step after the initial packaging of the battery is to inject an electrolyte. In addition, the battery has a number of components, such as CID(Current Interrupt Device) pressure relief valve, PTC(Positive Temperature Coefficien) thermistor, etc. But not all types of batteries are available.

7.How many cells in a 12V lithium ion battery?

In explaining how to get a voltage of 12 V through series and parallel circuits, we need to know that the voltage is the same everywhere in series circuits, and the current is the same everywhere in parallel circuits. For example, to get a 12.8V 100Ah battery pack, we need four 3.2V 50Ah prismatic lithium iron phosphate cells (12.8 v/3.2v) in series and two 3.2V 50Ah prismatic lithium iron phosphate cells in parallel. For the next example, to get a 12.8V 200Ah battery pack, we need four 3.2V 50Ah prismatic LiFePO4 cells (12.8v/3.2v) in series and four 3.2V 50Ah prismatic LiFePO4 cells in parallel.

8.How do you connect your 12V lithium ion batteries (series or parallel)

Batteries are connected in series or parallel depending on the use it is put to. Power banks, a portable charger designed to recharge electronic devices are made of connection of two or more batteries. By connecting a battery in series or parallel, you either increase the amp-hour or voltage capacity and in few cases, both are raised for a specific value. When the positive terminal of a battery is connected to the negative terminal of another, they are in series. Connecting batteries in series increase the cumulative voltage but retains the same amp-hour value.

A 12V lithium-ion batteries can be safely connected in series with another battery, but, both batteries needs to be of the same voltage and amp-hour rating. Additionally, the batteries when connected in series need to be recharged with a charger with a suitable voltage rating. For example, a 12V lithium-ion batteries connected to another 12V battery should be recharged with a voltage of about 24V. Batteries are connected in parallel by linking the positive terminal of a battery to another, and the negative terminal of the battery to the negative terminal of the other battery. This connection increase the amp-hour rating of system but the voltage rating stays the same. Parallel connection ensures the battery system powers equipment for an increased duration. The recharging duration is however also increased. The 12V lithium-ion batteries could be connected in series or parallel depending on the application to which it is to be used. However, it is recommended the batteries connected on parallel are not more than 4.

9.What is the size and weight of the 12V lithium-ion battery

lithium ion batteries are efficient and reliable. They also take up less space and weight. On average, below are the weight and dimensions of 12V lithium ion batteries. Their sizes are proportional to their amp-hour ratings.

Amp Hours: 5Ah

Length: 5.9 in (151 mm)

Width: 2.6 in (65 mm)

Height: 3.9 in (99 mm)

Weight: 2 lbs (0.9 kg)

Amp Hours: 10Ah

Length: 5.9 in (151 mm)

Width: 3.9 in (98 mm)

Height: 4 in (101 mm)

Weight: 3.6 lbs (1.65 kg)

Amp Hours: 20Ah

Length: 7.1 in (181 mm)

Width: 3 in (76 mm)

Height: 6.6 in (166.5 mm)

Weight: 6.1 lbs (2.75 kg)

Amp Hours: 50Ah

Length: 7.8 in (197 mm)

Width: 6.5 in (166 mm)

Height: 6.8 in (173 mm)

Weight: 14.1 lbs (6.38 kg)

Amp Hours: 100Ah

Length: 13 in (329 mm)

Width: 6.8 in (172 mm)

Height: 8.8 in (223 mm)

Weight: 26.4 lbs (11.98 kg)

Amp Hours: 200Ah

Width: 10.5 in (267 mm)

Height: 9 in (228 mm)

Weight: 61.1 lbs (27.7 kg)

Length: 20.5 in (520 mm)

Amp Hours: 300Ah

Length: 20.5 in (520 mm)

Width: 10.5 in (267 mm)

Height: 9 in (228 mm)

Weight: 75.8 lbs (34.36 kg)

10.What is the charging and discharge rate of the 12v lithium ion battery

Charging rates of batteries are designated by ‘C’, signifying charge current. A battery with. Charge current of 1, i.e 1C could go from 0% to 100% in about an hour. Most NMC lithium ion batteries are so rated. Lithium iron phosphate batteries have a lesser charge current being between 0.5 and 0.8. With a charge rate of 1C, a 1000mAh battery could provide a constant charge current of 1000mA in an hour.

Similarly, the discharge rate of a 1C, 1000mAh rated battery could provide discharge current of 1000mA in one hour. This battery could provide power for 5 hours if 200mA is expended each hour. Generally, the charging rate of a 12Vlithium-ion battery is about 1C, although advances in battery technology have enabled the production of batteries with the rate of 50 or so. The discharge rate is much lower. What is the charging and discharge rate of the 12V lithium-ion batteries.

Similarly, the discharge rate of a 1C, 1000mAh rated battery could provide discharge current of 1000mA in one hour. This battery could provide power for 5 hours if 200mA is expended each hour. Generally, the charging rate of a 12Vlithium-ion battery is about 1C, although advances in battery technology have enabled the production of batteries with the rate of 50 or so. The discharge rate is much lower.

11.How long does a 12V lithium ion battery last?

I believe most consumers have heard that more than the number of cycles of lithium ion batteries, the battery is useless. Many customers in order to be able to extend the life of the battery, each time when the battery power is completely exhausted before charging, so the life of the battery really extend ? The answer is no. If the life of a lithium ion batteries is 2000 times, referring to not the number of charges, but a charge and discharge cycle. A charging cycle means that all the power in the battery is transferred from full to empty and then back to full, which is not equivalent to a charge.

A lithium-ion battery, for example, uses only half of its charge on the first day, and then recharges it. If the next day is like this, you can use half of it and charge it for two times in total, which counts as one charge cycle, not two. So the correct answer is: lithium-ion battery life is related to the number of charging cycles, not directly related to the number of charging cycles. In fact, shallow charging is more beneficial for lithium-ion batteries, and is only necessary if the product’s power module is calibrated for lithium.

So how long does a fully charged lithium-ion battery last? For example, a 12V, 400Ah lithium-ion battery can last up to 2 hours (12v*400ah/2400w) or longer on a home load of 2400 watts.

lithium ion batteries maintenance method:

1, Each fully charged use, reduce the number of charging, improve the service life of lithium ion batteries.

2, Do not fully discharge the lithium ion batteries, usually less than 10% of the power need to charge.

3, Use the original charger to charge, do not use universal charging.

4, Lithium ion batteries charging process, do not use lithium ion batteries.

5, Do not charge the lithium ion batteriestoo much. Stop charging the lithium ion batterieswhen it is full. According to the experimental results, the life of lithium ion batteries is continuously attenuated with the increase of charging times. Generally, the charging times of lithium ion batteries are over 2000 times

12.Quality standards and differences of 12V lithium ion battery

When we introduce the cell to our customers, we often mention grade A or grade B,Grade T. What does it mean? This is the battery industry a conventional naming method, there may be a lot of enterprises do not name, here is just a general method to explain about the power industry we often heard of the concept of A,B,T Grade.

What is A grade A cell? cell factory according to the factory’s own production capacity, technical ability, to arrange production, through a series of battery cell manufacturing process, the final production of batteries, delivered to customers. Battery production factories in full accordance with the order of the standard battery capacity, thickness, length, width and other parameters produced by the battery is called grade A cell.

What is a grade B cell? Any factory that produces a product is bound to have a defect rate. Then this defect rate determines the vitality of a factory .First line manufacturers can do about 2%, and the second, third line is likely to do 5-10%. It is because of this defect rate that a B grade is created. In fact, grade B has only a slight difference in capacity, or length, width, thickness.It does not meet the order requirements, but the performance is the same as grade A, but the price is cheaper than grade A.

What is a echelon battery? Echelon battery refers to the downgrading of the battery.It is for the battery pack. That is, the capacity of the new battery pack decreases after a certain amount of time, which is not enough to meet the power demand of the current equipment application. However, the battery is not broken. After some repair and adjustment, it can be used on the equipment with lower power requirements. For example, the original equipment uses 200Ah and 72V electricity, but the echelon battery only has 120Ah and 62V after repair and adjustment, so it can only be applied to other electric equipment.

13.What are 12V lithium ion batteries used for?

lithium ion batteries are often used to directly replace the lead-acid batteries because they have very similar charging voltages. Lithium-ion batteries are widely used in energy storage power systems such as hydraulic power, thermal power, wind power and solar power stations, uninterruptible power for post and telecommunications, power tools, electric bicycles, electric motorcycles, electric vehicles, military equipment, aerospace and other fields. Lithium-ion batteries have been widely used in portable electrical appliances such as laptop computers, video cameras and mobile communications due to their unique performance advantages.

The large-capacity lithium-ion battery developed at present has been tested in electric vehicles, and is expected to become one of the main power sources for electric vehicles in the 21st century, and will be used in artificial satellites, aerospace and energy storage. With the shortage of energy and the pressure of the world’s environmental protection. Lithium-ion battery is now widely used in the electric vehicle industry, especially the appearance of lithium iron phosphate battery material, more promote the development and application of lithium ion batteries industry.

14.Are 12 volt lithium-ion batteries safe?

The safety of lithium-ion batteries has always been a problem of user relations. Lithium-ion batteries have the risk of explosion, but the safety is controllable, and most safety problems are caused by product defects and abuse . A few years ago, we paid attention to the explosion and fire problems of lithium ion batteries. These accidents were mainly caused by improper temperature control of lithium ion batteries, which also had a bad impact on lithium ion batteries. For example, when Tesla electric cars caught fire in recent years, we checked relevant information of Tesla and found that Tesla mainly uses NCA batteries. NCA batteries and NCM batteries are ternary lithium ion batteries, and are the main battery types of power batteries, especially in the field of passenger cars. Compared with lithium iron phosphate battery, it has higher energy power, more in line with the needs of passenger cars.

So why did the Tesla catch fire? One of the disadvantages of NCA batteries is: Its poor thermal stability under the state of charge leads to the decrease of battery safety, which makes battery manufacturers and end-product users worry about the safety of NCA batteries.That’s why the Tesla caught fire. According to statistics, there have been about 50 reported fire accidents in Tesla electric vehicles around the world in 2020. So how many Teslas are there in the world? In 2020, Tesla produced 509,700 cars worldwide and sell 499,500 cars. That works out to about 1 in 10,000, which is a very small probability.

So you don’t have to worry about the safety of lithium batteries. As the technology matures, our lithium-ion batteries are getting safer. All lithium ion batteries include a battery management system (BMS). The main function of BMS is to solve the problem of overcharge and overdischarge of batteries. If the battery voltage falls below certain voltage, the BMS protects the lithium-ion battery; The BMS also provides protection if the battery voltage exceeds certain voltage. Is that why these batteries have thermal stability and long cycle life.

15.What are the disadvantages of 12V lithium-ion batteries?

We know that everything has its pros and cons, and our lithium-ion batteries are no exception. But having shortcomings does not mean that we cannot overcome , on the contrary, we can have a comprehensive understanding of lithium ion batteries,.For our next design lithium ion batteries ,it provides thinking direction.

The disadvantages of lithium ion batteries are:

1.Protection requirements:

lithium ion batteries need integrated protection circuit to prevent over-charging and over-discharging. The integrated circuit also prevents the lithium ion batteries from getting too hot during rapid discharges, when the temperature becomes high.

2.Poor conductivity:

lithium ion diffusion rate is slow. At high power charge and discharge, the actual specific capacity of charge and discharge is low.

3.Transportation:

Air transportation has restrictions on the number of lithium ion batteries, and special protection devices are needed to prevent short circuit in the transportation process, which leads to the need for large quantities of lithium ion batteries by sea, and the transportation time becomes longer.

4. Temperature:

lithium ion batteries low temperature performance is poor.

5. The development of technology:

the modern society has appeared the trend of lithium ion batteries to replace lead acid batteries, but the development of technology is still flawed, with the more developed technology now, these problems will be gradually solved.

6. Life:

Single lithium ion cell life is long, prismatic lithium ion cell charging and discharging times in about 4000 times, but the life of lithium ion batteries pack is shorter, generally over 2000 times. And the cylindrical lithium ion batteries discharge times in about 2000 times, but the life of the cylindrical lithium ion batteries pack is shorter, generally over 500 times. 7.The cost of production requirements, high cost.

16.What certification is required for a 12V lithium ion battery?

International logistics of lithium ion batteries must be the focus of the industry. What certification is required for the export of lithium ion batteries? We have sorted out some information, to facilitate everyone to do a comprehensive understanding of the lithium ion batteries certification!

1.Certification of UN38.3.

Certification of UN38.3 almost involved in the global scope , belongs to the safety and performance test, as long as it is involved in air shipment package contains lithium ion batteries.whether it’s a small button battery, installed on the device’s battery, or with the device packaging together of electricity, require UN38.3 test and air transport to identify rear can through empty inspection report. The certification period varies from one machine to one month. Certification fees range from several thousand yuan to more than ten thousand yuan.

2.CE certification

CE certification is suitable for the European Union area, divided into safety and performance testing, certification cycle from a few days to a year, certification fees from thousands of yuan to tens of thousands of yuan. CE certification relative to UL certification, the probability of passing is relatively high. In our opinion, the size of the EU member states more attracted most manufacturers to CE recognition. But even because of the huge size of the European Union, the speed of its standard update is also amazing, so many manufacturers have been in a confused state, almost difficult to keep up with the update of the standard. CE certification is a self-declaration, if the manufacturer has the ability to test, it can be completed by itself. However, in the EU market, products that fail to pass the spot check will be recalled and subject to a serious fine. Therefore, many domestic manufacturers entrust a third party to conduct the test, so the risk of recall is avoided to a large extent.

17.How many Amp Hours can you really get from a 12v lithium battery(300ah, 100ah,500ah, 200ah)?

A 300Ah rated battery would ordinarily sustain a 30A rated appliance for ten hours. This same battery could last for about 25 hours powering a 12A appliance. For a 100Ah, 12V lithium-ion batteries, a 100A rated device could be powered for an hour with it. Similarly, a 500Ah and 200Ah battery could power 500A and 200A rated devices respectively for an hour.

18.How to select the right 12V lithium ion batteries for your application(200ah, 300ah,500ah, 100ah)?

When considering your choice for a lithium ion batteries, aside from capacity, the energy content of it is also considered. The energy content is calculated by multiplying the battery capacity which is in mAh by the battery’s voltage. For a 12V battery with a capacity of 100Ah, the energy content is 1200Wh. To obtain more energy, a battery of higher capacity is used. A battery with high energy content typically drains fast and is required in applications like igniting a car and in power tools.

19.Is it right to leave my lithium ion batteries to charge overnight?

Some modern batteries are provisioned with a protective circuit to restrain them from taking charges after it reaches 100%. This makes for less worry of overcharge as the battery wouldn’t surpass the recommended voltage limit. However for the many lithium ion batteries without a protective circuit to guide against such, charging it overnight is unrecommended. Charging a battery above its voltage limit leads to heat generation and this eventually leads to a reduction in the capacity of such a battery. Lithium-ion batteries like other secondary batteries are susceptible to deterioration over time. And charging them doesn’t help. When lithium ion batteries are charged after their capacity is filled, the time they spend plugged into power adds to their overall charging time. This deteriorates the battery further. Conclusively, charging a battery overnight hinders the battery’s effectiveness.

20.Will the 12volt lithium-ion batteries be damaged if left unused for a long time?

A lithium ion batteries would be harmed if left unused for a very long period without charging. When the self-discharge of the battery is made to continue, eventually draining all energy from the battery, the battery might be unable to take in charge any longer due to the dry up of the battery diaphragm. Usually, the discharge rate of the battery is barely noticeable being about 1-2 mA discharge per day. Upon consistent recharge, this rate is less noticeable.

21.How to maintain the 12volt lithium ion batteries

lithium ion batteries need to be kept charged periodically when not in use. A battery left uncharged or kept at low voltage for long periods would damage it. It is also advised that your 12V lithium-ion batteries be charged with an appropriate charger; one that inputs the adequate voltage to the battery as stated by the manufacturer. Furthermore, lithium ion batteries are less effective when exposed to certain temperatures. Temperature extremes reduces their lifespan, as such, it is advisable to keep your 12V lithium-ion batteries at locations with temperatures between 4C and 32C. Charging the battery at room temperature is also advised.

22.Industrial application of the 12V lithium-ion batteries( in cars and electric vehicle)

Batteries have enjoyed wide applications in cars, and the common battery kind used is the 12V battery. The ignition system of cars needs a battery for the production of considerable current required to start a vehicle. Most cars make use of the lead-acid cell. However, the few that use the lithium ion batteries enjoy more efficiency, zero maintenance, and a much-reduced weight. Electric cars make use of secondary batteries with high ampere-hour capacity. These batteries are chosen for their power-to-weight ratio, energy density, and weight. Light batteries enable the car to be light and less bulky. Lithium-ion batteries are employed in electric cars. In most cases, the lithium-polymer is used. Both batteries are characterized by lightweight and high energy density. Notably, Tesla uses a modified version of the lithium-ion battery for its electric cars.

23.What the future holds for lithium ion batteries? (technological advancements in the field)

With improvements made to smartphones, smart devices and gadgets, the reliance are on batteries to power them. There’re advantages of the lithium-ion battery and there are limitations of it as well. Although chips and microcircuits are made for devices, the battery is only able to power them for about a day or two. Lithium-cobalt batteries are much expensive due to the cobalt used at its cathode. Researchers at the University of Texas hopes to use more abundant element like nickel in the manufacture of lithium-ion batteries. In a separate development, researchers at the university of eastern Finland are looking to improve the stability of the battery during ion transfer by introducing a silicon hybrid at the anode.

Replacing graphite with mesoporous silicon microparticles and carbon nanotubes improves the performance of the battery. Besides, silicon is widely and easily available than graphite. A better replacement to the lithium ion batteries is mulled by IBM research. This battery is touted to outsmart li-ion batteries in key areas like power and energy density, charge rate and speed. The materials to be used in its manufacture are from seawater. lithium ion batteries are expected to pack more power and energy in the years coming due to the combination of various elements. Being the most viable energy source for the future, the lithium-ion battery is undergoing developments to unlock its present limits.

About lithium ion battery manufacturers

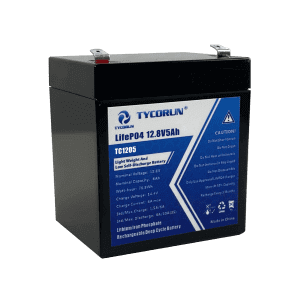

TYCORUN® has more than 14 years of experience in the lithium battery industry and is a Chinese high-tech enterprise that develops, produces and sells various new energy battery products.

12V lithium ion battery production capacity accounts for 80% of our tycorun lithium battery manufacturing products

High quality assurance

TYCORUN is determined to become a leader in the lithium battery industry, quality is our culture!

Professional manufacturers

With lithium ion battery pack as the core, integrating channels and technologies

Factory wholesale price

We promise to let customers get the most cost-effective lithium battery products

Reliable Service Assurance

Provide lithium ion battery OEM, ODM, 1 MOQ.Full Set of Certificate

Video Gallery

Lithium ion Battery News

One-stop Africa battery swap solution – new energy electric motorcycle intelligent operation management

This article will cover the current situation of Africa’s market, the rapid development of the Africa battery swap industrial chain and Tycorun’s battery swap solution.

Top 6 high-rate cell companies in China

Among the manufacturer producing high rate battery, BAK, EVE, LISHEN, MOLICEL, SAMSUNG SDI, and SunPower stand out for their outstanding products.

Top 10 solid state battery manufacturers in China

China’s solid state battery development is in the accelerated stage, the top 10 solid state battery manufacturers mainly have the following

New Ganfeng battery – ultra safe semi-solid battery with high performance

This article details Ganfeng Lithium’s solid-state battery development, technological innovations, and the performance of the ganfeng battery in safety tests.

Top 5 electric cargo tricycle in China

This review presents the top 5 electric cargo tricycles in China, featuring detailed specifications and performance insights. Evaluating criteria such as load capacity, battery efficiency, and safety features, this guide assists buyers in selecting the ideal tricycle based on individual requirements.

Materials and lightweight development of electric bicycles

This article provides an insightful exploration into the development of electric bicycles, focusing on advancements in materials and lightweighting techniques. It delves into the historical evolution of electric bicycles, analyzes various bicycle frame materials, discusses the development of electric power assist technology, and offers an overview of the electric assist bicycle market. Through detailed examination and analysis, it highlights the importance of lightweighting for electric bicycles and identifies key trends shaping the industry’s future.