Influence of carbon coated aluminum foil on battery and market development

It can improve battery performance and has the advantages of increasing battery energy density, inhibiting battery polarization, reducing battery internal resistance, increasing battery cycle life, and improving battery material processing performance. In recent years, with the increase in battery energy density requirements, the market demand for carbon coated aluminum foil has been continuously released. At present, nearly 90% of power lithium batteries have used carbon coated aluminum foil.

Advantages of carbon coated aluminum foil in lithium battery applications

Carbon coated aluminum foil uses functional coatings to treat the surface of battery conductive substrates. It is a breakthrough technological innovation. Carbon coated aluminum foil is to coat dispersed nano-conductive graphite and carbon-coated particles on aluminum foil evenly and delicately. Carbon coated aluminum foil can provide static electrical conductivity and collect the micro-current of active materials, which can greatly reduce the contact resistance between cathode and anode materials and current collectors.

Carbon coated aluminum foil can improve the adhesion between the two, reduce the amount of binder used, and improve the overall performance of the battery. Advantages of carbon coated aluminum foil in lithium battery applications:

● Inhibit battery polarization, reduce thermal effects, and improve rate performance;

● Reduce the internal resistance of the battery, and significantly reduce the dynamic internal resistance increase during the cycle;

● Improve the consistency and increase the cycle life of the battery;

● Improve the adhesion between the active material and the current collector, and reduce the manufacturing cost of the pole piece;

● Protect the current collector from being corroded by the electrolyte;

Improve the processing performance of lithium iron phosphate and lithium titanate materials.

Influence of carbon coated aluminum foil on battery

The influence of carbon coated aluminum foil on the battery includes the influence on the electrochemical impedance of the battery, the power performance of the battery, the low temperature performance of the battery and the cycle performance of the battery, etc.

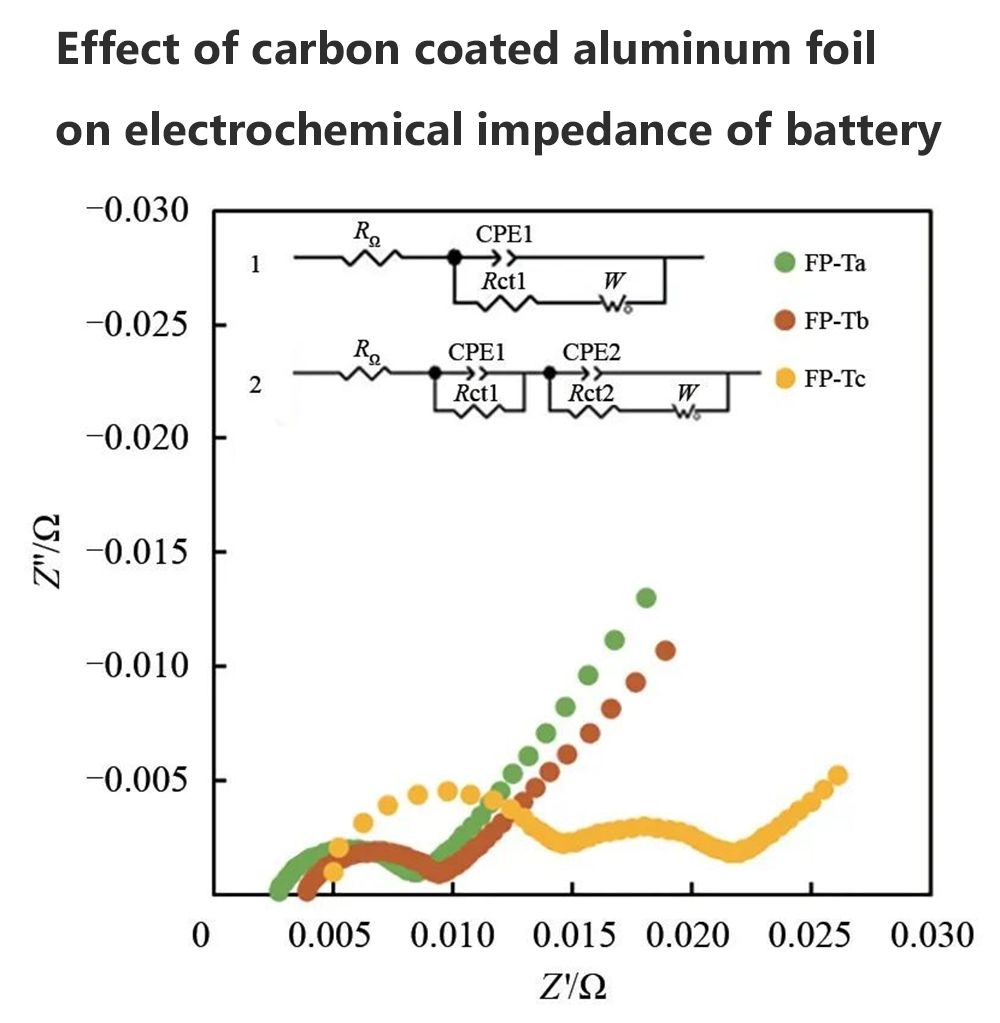

Effect of carbon coated aluminum foil on electrochemical impedance of battery

The electrochemical impedance spectrum of light aluminum foil consists of two semi-circular arcs in the high-frequency region and a slanted line in the low-frequency region. Compared with carbon black and graphene, there is one more capacitive reactance arc. This is caused by the electric double layer capacitance at the interface gap between the aluminum foil and the active material. The ohmic internal resistance of carbon black and graphene are 2.5 mΩ and 3.7 mΩ, respectively, while the ohmic internal resistance of aluminum foil is 5.0 mΩ.

It can be seen that the carbon coating has a significant effect on reducing the internal resistance of the battery. The EIS spectra of carbon black, graphene and aluminum foil were fitted with equivalent circuits. Carbon coated aluminum foil can improve the contact mode between the active material and the aluminum foil: the elastic carbon layer relieves the stress between the rigid material particles and the foil, and improves the adhesion of the material. And effectively fill the gap between the spherical particles and the foil without direct contact to improve the conductivity.

Effect of carbon coated aluminum foil on battery power performance

The 1 C discharge capacity of carbon black, graphene, and bare aluminum foil is 6.5 Ah. As the charge-discharge rate increases, the charge curve and discharge curve shift to high voltage and low voltage respectively, which is a polarization phenomenon. This process includes ohmic polarization, electrochemical polarization and concentration polarization. The smaller the internal resistance, the smaller the polarization.

When charging at a high rate, the voltage platform rises, and when the battery is charged to the cut-off voltage with a constant current, it will not be fully charged. At this time, the unfulfilled capacity will be replenished by the constant voltage charging process. The 4 C constant current charging ratio of carbon black and graphene is both 93%, and the fast charging performance is good. The 4 C constant current charge ratio of bare aluminum foil is only 84%, which cannot meet the actual use needs.

With the increase of the discharge rate, the difference in the discharge median voltage of carbon black, graphene and aluminum foil is enlarged. At 4 C, the discharge median voltages of carbon black, graphene and bare aluminum foil are 3.00 V, 3.05 V and 2.97 V, respectively, the polarization of graphene is small, and the polarization of bare aluminum foil is the largest.

Effect of carbon coated aluminum foil on low temperature performance of battery

The chemical activity of the reactants decreases at low temperature, which will lead to an increase in the internal resistance of the battery, a sharp drop in voltage, and a decrease in capacity. Carbon black, graphene and bare aluminum foil have obvious voltage drop at the initial stage of 1C discharge at -20℃, from the initial voltage of 3.36-3.37 V to 2.50-2.60 V, among which the voltage drop of bare aluminum foil is the largest. As the depth of discharge increases, the voltage rebounds slightly, because the internal resistance generates heat during discharge, which improves the electrochemical reactivity of the battery.

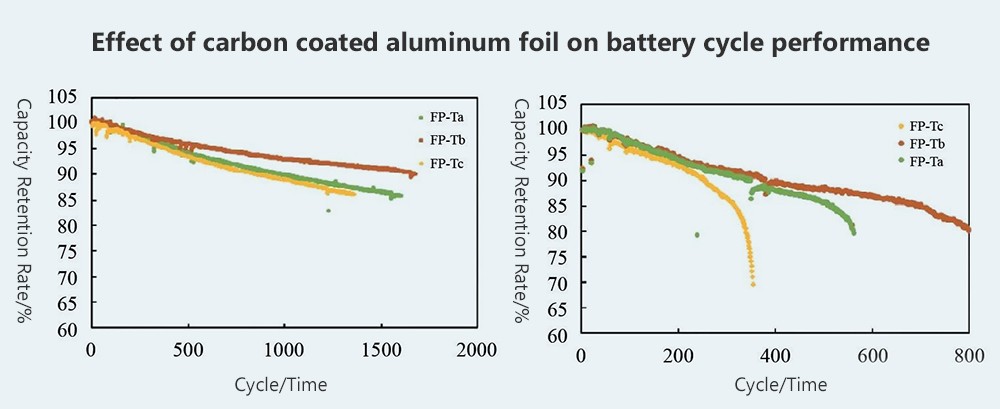

Effect of carbon coated aluminum foil on battery cycle performance

Carbon black, graphene, and light aluminum foil were subjected to charge-discharge cycles at room temperature at 1 C. Carbon black was cycled 1691 times with a capacity retention rate of 85.34%; graphene was cycled 1756 times with a capacity retention rate of 88.48%; light aluminum foil was cycled 1358 times with a capacity retention rate of 86.12%. The 1 C cycle trends of carbon black and bare aluminum foils are similar, and carbon black-coated aluminum foils have little effect on cycle performance at low magnifications.

The 1 C cycle performance of graphene has obvious advantages, and the capacity retention rate is far ahead. The graphene-coated aluminum foil shows good cycle performance at low magnification. When carbon black, graphene and light aluminum foil were tested at room temperature at 3 C, when the capacity retention rate dropped to 80.00%, carbon black, graphene and light aluminum foil were cycled 562 times, 800 times and 338 times respectively, and inflection points had appeared .

The comparison shows that the carbon coated aluminum foil significantly improves the high-current cycle capability of the battery. The graphene-coated aluminum foil has a better effect on improving the high-power cycle capability, thanks to the flat graphene on the surface of the aluminum foil to help the conduction of electrons in the plane direction of the pole piece, which improves the high-current transmission and heat conduction capabilities.

Global carbon coated aluminum foil market analysis

Carbon coated aluminum foil can improve battery performance. With the upgrading of market demand, the application of carbon coated aluminum foil in the battery field continues to expand, and it is expected to cover all power batteries in the future. In the global market, the carbon coated aluminum foil consumption market is mainly concentrated in countries and regions with relatively complete industrial development systems such as North America, Europe, China, and Japan.

Among them, the production scale of carbon coated aluminum foil in China and Japan ranks among the top in the world. In recent years, with the economic development of Southeast Asia and the shift of global industries to the east, the market demand for carbon coated aluminum foil in Malaysia, Indonesia, Thailand and other Southeast Asian countries has accelerated, and the market has great potential for future development.

The global carbon coated aluminum foil market is highly concentrated. At present, carbon-coated aluminum foil manufacturers are mainly distributed in Japan, China and other Asia-Pacific regions. DSXC is a leading manufacturer in battery aluminum foil manufacturers in China. The company’s customers include BYD, CATL, LG, GOTION high-tech and other power battery companies in the world.

The processing cost of carbon coated aluminum foil is relatively high, which is 2-3 times that of ordinary lithium battery aluminum foil. In recent years, with the increase in the density of downstream lithium batteries, the market has put forward higher requirements for the cost, quality, performance, and specifications of carbon coated aluminum foil.

With the active improvement of relevant companies, the specifications of carbon coated aluminum foil have gradually increased, and the functions have become more abundant. In the long run, the carbon-coated aluminum foil industry will continue to upgrade towards diversification, high performance, functionality, and environmental protection.

Conclusion

Professionals say that carbon coated aluminum foil can help improve lithium battery performance. In the context of increasing battery density, the market demand for carbon coated aluminum foil will continue to be released. China is a major producer of lithium batteries, and the market demand for carbon coated aluminum foil is broad. The processing cost of carbon coated aluminum foil is relatively high.

In the era of parity, the processing technology of carbon coated aluminum foil needs to be further optimized. At the same time, the upgrading of market demand will also drive the development of carbon coated aluminum foil in the direction of high performance and functionality.