CATL sodium ion battery-a introduction of chemical and structural innovation

The CATL sodium ion battery is not only used to improve energy density and layout the supply chain, but also used in three scenarios of electric two wheeled vehicles, electric vehicles and energy storage, as well as low temperature and high power scenarios. This article will mainly discuss the chemical innovation and structural innovation of CATL sodium ion battery.

The production capacity of CATL sodium ion battery and lithium ion battery is compatible

Sodium and lithium are located adjacent to the alkali metal group on the periodic table, with only one electron in the outermost layer of the atom, and their chemical properties are very similar. Batteries with their ions as carriers also have similar principles and structures. Most of the production systems of lithium ion batteries can be reused on CATL sodium ion batteries, and the production capacity can be partially compatible.

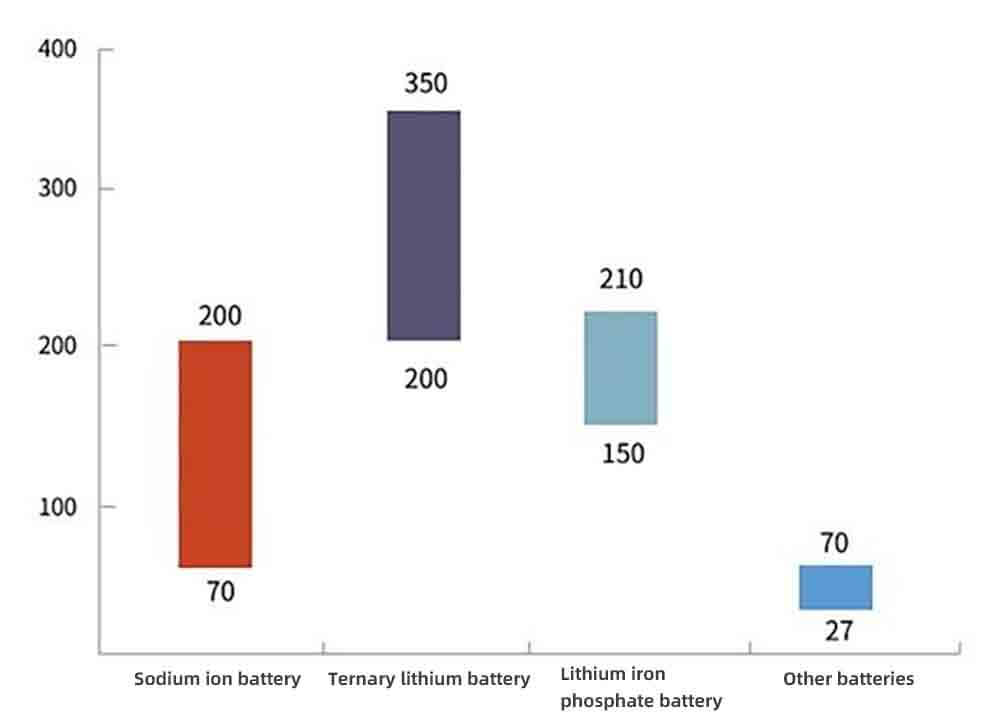

The energy density of single CATL sodium ion battery overlaps with that of lithium iron phosphate battery:

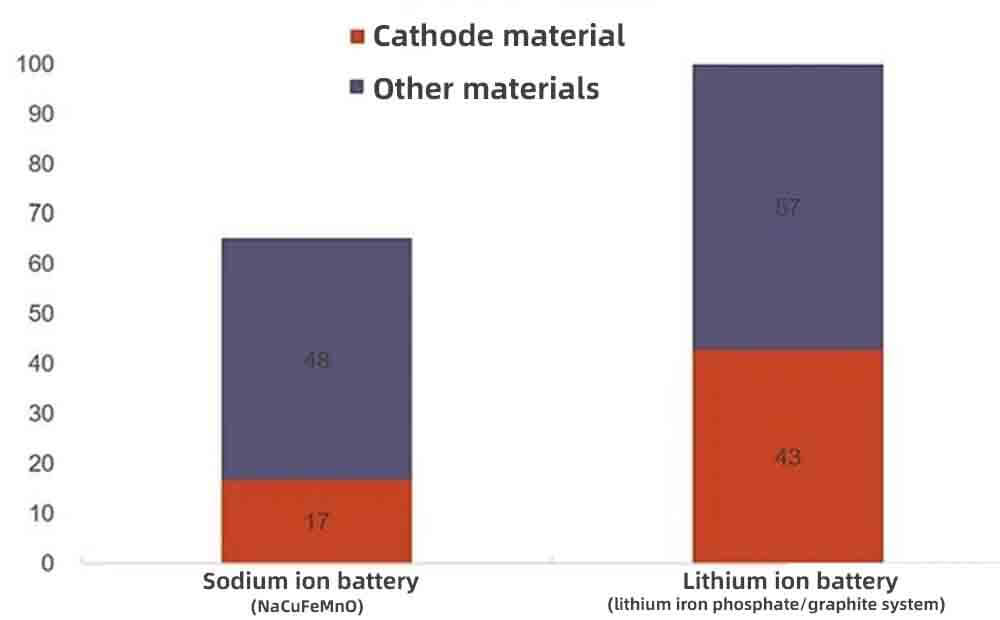

The theoretical cost advantage of catl sodium ion battery is outstanding. According to the watt hour cost conversion of soft pack battery with the same capacity, the theoretical cost of sodium ion battery BOM is about 30% lower than that of lithium ion battery.

The safety and performance of CATL sodium ion battery is no less than that of lithium iron, thanks to:

● Relatively low energy density and exothermic enthalpy

● It is not easy to release oxygen and there is no risk of flammability

● Short time relatively small instantaneous current and temperature rise

At present, CATL sodium ion battery is free from fire and explosion due to overcharge, over discharge, short circuit, acupuncture and extrusion. At low temperatures, thanks to:

● Better interface ion diffusion ability due to the lower solvation energy of sodium ions

● Large aperture transmission channel brought by the open frame three-dimensional framework of Prussian blue and other special positive materials

● At present, the micro nano structure and carbon coating greatly improve the electronic conductivity and discharge power.

CATL sodium ion battery follows the PBA derivative route

Unlike HiNa Battery’s Li doped transition metal O3 type Nax oxides, CATL sodium ion batteries follow the PBA derivative route. Both have the advantage of high gram capacity and voltage platform, which is high energy density. The difference is the high dynamic advantage of PBA due to its special crystal structure.

The open frame structure and three-dimensional huge channels of face centered cubes are very conducive to the rapid migration of sodium ions, and can maintain the structural stability reversibly after a certain amount of deinking. Of course, the sodium content and crystal water content are different due to different preparation processes, so the final crystal will be distorted to form single crystal or rhombohedral system.

In 2015, several cutting-edge laboratories in the United States worked closely with J.B. Goodenough to develop a sodium ion battery cathode material called Prussian white: Na1.92Fe, which is actually a specific component of sodium Prussian blue. Because the sodium content is up to 1.92, the powder appears white, so it is called Prussian white.

First, too much crystal water in the crystal will occupy the sodium ion site and block the migration channel of adjacent sodium ions, and will also be free into the electrolyte, and have side reactions with it, causing electrolyte consumption, instability of negative electrode SEI film, and increased impedance.

Second, too many vacancies in the crystal will not only hinder the migration of electrons, but also cause lattice distortion and damage the Ma C|N Mb bridge bond, which will lead to the collapse of the three-dimensional skeleton structure of PBA and the degradation of battery performance.

CATL sodium ion battery has been designed and improved

CATL sodium ion battery has been innovatively designed and improved from the material and electrode process levels.

Material level

In the process of synthesizing Prussian white materials, CATL research team used exchange reaction to add one or more neutral ligands L to partially or completely replace the crystal water, thus reducing or even removing the content of crystal water at the powder level, and its water absorption can be reduced by up to 60% after verification.

The CATL sodium ion battery research team introduced sodium carboxymethyl cellulose into the preparation of Prussian white materials to adjust the viscosity and precipitation rate of mother liquor, and formed particles with suitable particle size and specific surface area, obtaining relatively optimized magnification and circulation performance.

At the same time, CATL sodium ion battery has made the most appropriate design for particle size and porosity, and guaranteed the cycle stability.

During the charging and discharging process of the sodium ion battery, the cation will preferentially embed and detach from the PBA material because the cation has a small charge/radius ratio.

Therefore, it has less damage to the structure of Prussian blue materials in the process of insertion and removal, which can stabilize the three-dimensional skeleton structure of Prussian blue materials and make the sodium ion battery have good cycle performance.

Polar slice level

The CATL sodium ion battery introduces a one-dimensional carbon nano material with a diameter of 5nm~100nm and good flexibility in a proper proportion, which greatly reduces the resistance of the membrane, so that the positive plate has good conductivity.

CATL sodium ion battery optimized the ratio of conductive polymer and conductive agent, reduced the membrane resistance by 70% and obtained very excellent 2C ratio performance. In addition, the mixing and coating process of Prussian white cathode paste was improved, the ratio of active material thickness d1 to collector fluid thickness d2 was optimized, and excellent cycle performance of CATL sodium ion battery was obtained.

In order to solve the problem of low compaction density inherent in small particle powder, CATL sodium ion battery adopts a unique bimodal mixing and matching method to increase the compaction density of Prussian white positive electrode to 2.0g/cc, which greatly improves the volume and mass energy density.

Chemical system level

In terms of chemical system matching, CATL sodium ion battery controls the capacity loss in the first charge and discharge of the battery, and achieves higher charging and discharge performance at high magnification, so that the sodium ion battery has higher first coulomb efficiency and magnification performance.

Advantages of CATL sodium ion battery

On the basis of integrating highly innovative technical capabilities, CATL has developed a sodium ion battery with unique advantages:

● Energy density of single cell: 160Wh/kg, current global head level;

● Charge at room temperature for 15 minutes, and the power can reach more than 80%, with excellent fast charging characteristics;

● In a low temperature environment of – 20 ℃, maintain a discharge retention rate of more than 90% and excellent low temperature power;

● System integration efficiency can reach more than 80%;

● Excellent thermal stability, and exceeding the safety requirements of China’s strong power battery standard.

Therefore, the energy density of CATL sodium ion battery is slightly lower than that of commercial lifepo4 battery developed by lithium ion battery manufacturers, but its obvious advantages in low temperature performance and fast charging are very suitable for high power application scenarios in high cold regions.

CATL sodium ion battery adopts AB battery structure

AB battery structure is adopted, which is the structural innovation of CATL sodium ion battery. The integration of two types of batteries in series and in parallel can quickly solve the problem of low energy density of the first generation sodium ion battery, which also challenges the BMS system.

The combination of AB’s two swords can make up for the energy density shortage of Gen1 sodium battery. The energy density of its battery pack is increased by 25%, giving play to its advantages of high power and low temperature performance, and can be adapted to more scenarios.

According to the route plan published by CATL, Gen2 sodium electric products will break into 200Wh/kg. In fact, the working principle of the sodium ion battery is the same as that of the lithium ion battery. The processing properties can fully refer to the physical and chemical indicators of the chemical materials of the lithium ion battery, and their mass production lines can be fully compatible.

Carbon neutralization has given birth to the demand for TWh class batteries, and diversified application scenarios are emerging. The generation of CATL sodium ion batteries will jointly guarantee the long-term stable development of the industry with lithium batteries.