Analysis of the types and needs of BMIC

ICs in BMS are divided into general-purpose and special-purpose types. Common chips include MCU, power management chip, communication interface and other chips. Such chips can use the same or similar models as non-batteries applications, and do not need to be developed separately for BMS. Dedicated chips are specially developed for BMS applications, namely BMIC, to meet the functional requirements of BMS in specific application fields.

Table of Contents

Types and functions of BMIC

BMIC can be divided into Protector BMIC, Charger BMIC, Gauge BMIC, Monitor/AFE BMIC, Balancer BMIC, Authentication BMIC and other types. Charger BMIC can also be classified into switch, linear, and charge pump types. Balancer BMIC can be divided into two types: active equalization and passive equalization.Protector BMIC

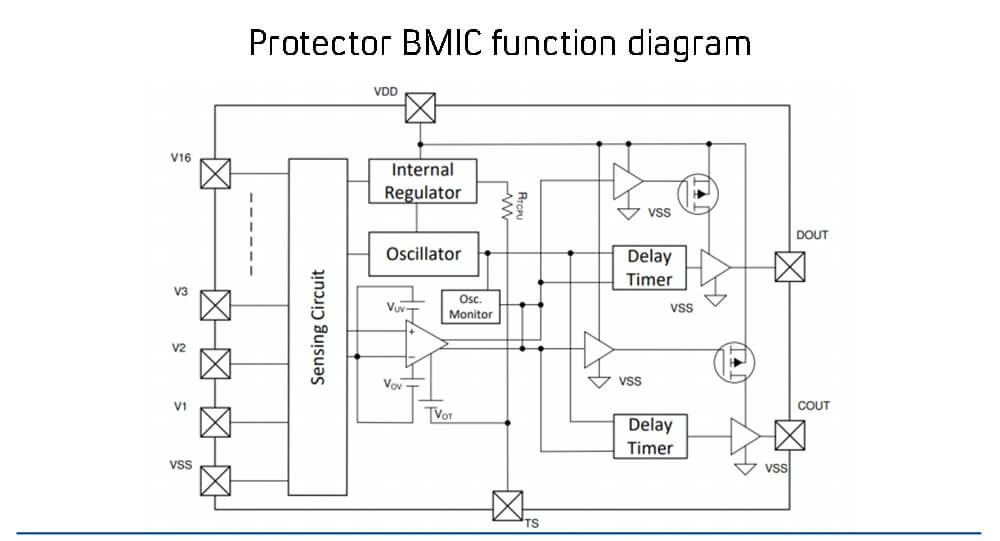

The Protector BMIC is responsible for monitoring the charging and discharging of the batteries cells to ensure that the batteries will not be damaged due to external abuse or failure. Generally speaking, the abnormal conditions that Protector BMIC needs to monitor include overvoltage, overcurrent, discharge overcurrent, charge overcurrent, overheating, etc. When an abnormal situation is detected, the batteries safety chip can cut off the circuit in time to ensure the safety of the batteries system. At present, some BMICs (Charger, Gauge, etc.) will integrate protection functions, but in order to achieve more comprehensive protection, the dedicated Protector BMIC is still an indispensable component in some applications.

Structurally, Protector BMIC is mainly composed of sampling circuit, amplifier circuit and logic circuit. Compared with chips such as Monitor BMIC and Gauge BMIC, since the measurement parameters of Protector BMIC are only used for comparison with thresholds, the sampling accuracy requirements are relatively low, and the logic circuit part is also dominated by comparators, and the structure is relatively simple.

When an abnormal situation is detected, the batteries safety chip can cut off the circuit in time to ensure the safety of the batteries system. At present, some BMICs (Charger, Gauge, etc.) will integrate protection functions, but in order to achieve more comprehensive protection, the dedicated Protector BMIC is still an indispensable component in some applications.

Structurally, Protector BMIC is mainly composed of sampling circuit, amplifier circuit and logic circuit. Compared with chips such as Monitor BMIC and Gauge BMIC, since the measurement parameters of Protector BMIC are only used for comparison with thresholds, the sampling accuracy requirements are relatively low, and the logic circuit part is also dominated by comparators, and the structure is relatively simple.

Charger BMIC

The functions that the Charger BMIC needs to implement are: ● Power Path Management (PPM): Control the power path so that the interruption of the external power supply does not affect the normal operation of the system; ● Charge and discharge control: Appropriately control and manage the charge and discharge of the batteries. The typical batteries charging process is usually divided into a trickle phase, a constant current phase and a constant voltage phase. The switching control between each phase needs to be completed by the Charger BMIC. Limited by the cost, volume and heat dissipation requirements of the chip, the charging chip is generally only used for charging low-power electrical appliances. For high-power application scenarios (such as electric vehicles), a dedicated high-power charging circuit built by discrete devices is generally used. According to the different circuit topologies, Charger BMIC can be divided into linear, switching and charge pump types.

Among them, the linear Charger BMIC is usually used in low-power charging applications, and the switching Charger BMIC is the most widely used, which can support charging applications ranging from tens to hundreds of W. The charge pump Charger BMIC is mainly used in fast charging occasions, which can effectively improve the charging efficiency in the constant current charging stage.

Limited by the cost, volume and heat dissipation requirements of the chip, the charging chip is generally only used for charging low-power electrical appliances. For high-power application scenarios (such as electric vehicles), a dedicated high-power charging circuit built by discrete devices is generally used. According to the different circuit topologies, Charger BMIC can be divided into linear, switching and charge pump types.

Among them, the linear Charger BMIC is usually used in low-power charging applications, and the switching Charger BMIC is the most widely used, which can support charging applications ranging from tens to hundreds of W. The charge pump Charger BMIC is mainly used in fast charging occasions, which can effectively improve the charging efficiency in the constant current charging stage.

Gauge BMIC

The function of the Gauge BMIC is to use a specific algorithm to estimate the battery’s SOC/SOH and other parameters by measuring the external characteristics of the batteries (such as voltage, current, temperature, etc.), and feed the results back to the controller chip. The core competence of Gauge BMIC lies in the design of high-precision sampling circuit and SOX algorithm. To achieve high-precision SOX estimation, high-precision voltage and current sampling is essential. In addition, the commonly used SOC estimation algorithms include the modified discharge termination voltage method and the dynamic voltage correction method.Monitor BMIC and Balancer BMIC

The main function of Monitor BMIC is to monitor batteries parameters with high precision and send relevant data to the main controller through the communication interface. Different from Gauge BMIC, Monitor BMIC only has parameter monitoring function, which is generally used in the occasion of high serial number. Usually, multiple monitoring chips need to be cascaded to form a complete monitoring system. In a high-string-count system, in order to ensure the balance of cell voltage and power, it is necessary to take power-balancing measures. At present, there are two common schemes for power balancing: active balancing and passive balancing.

In a high-string-count system, in order to ensure the balance of cell voltage and power, it is necessary to take power-balancing measures. At present, there are two common schemes for power balancing: active balancing and passive balancing.

Authentication BMIC

Authentication BMIC was mainly used in removable batteries devices in the early days. In order to avoid harm to devices or users caused by mismatched batteries, an Authentication BMIC is generally integrated into the batteries pack, and authentication is performed when the battery is connected to the system. Only the authenticated batteries can supply power to the system. In addition, although most mobile phone batteries are currently non-removable, in order to avoid the potential risks caused by users replacing batteries by themselves, manufacturers generally choose to configure an Authentication BMIC in the built-in batteries of the device.BMIC demand is growing rapidly

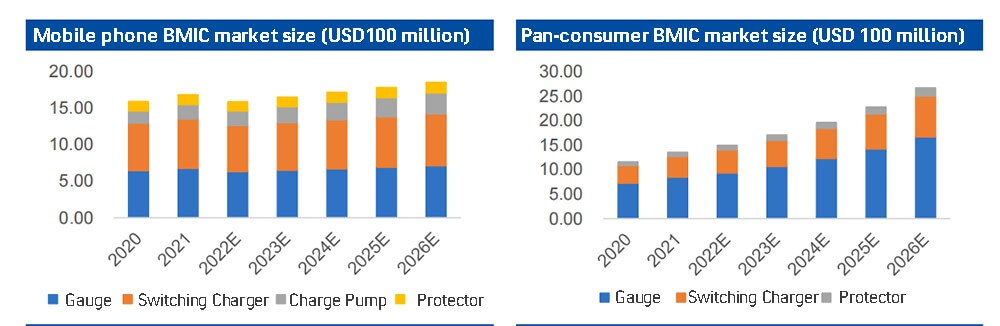

Consumption – the largest downstream segment in the next 3-5 years

The main downstream applications of the lithium batteries consumer market include mobile phones, notebooks, tablet computers, TWS headsets, smart watches, etc. Among them, mobile phones/tablets/TWS headphones/smart watches generally use 3.7V lithium-ion batteries, and notebook computers generally use 3 strings of 12.6V lithium-ion batteries. At present, the BMIC involved in consumer electronic products generally include three types: Charger BMIC, Gauge BMIC, and Protector BMIC. In addition, early mobile phones use removable batteries, so in addition to Charger BMIC, Protector BMIC, and Gauge BMIC, an additional Authentication BMIC is required.

In recent years, with the evolution of smartphone batteries to non-removable technical solutions, Authentication BMIC can only be found on some high-end smartphones. On the whole, as the first terminal to adopt the lithium batteries solution, the consumer field will remain the largest downstream market of BMIC in the next 3-5 years.

At present, the BMIC involved in consumer electronic products generally include three types: Charger BMIC, Gauge BMIC, and Protector BMIC. In addition, early mobile phones use removable batteries, so in addition to Charger BMIC, Protector BMIC, and Gauge BMIC, an additional Authentication BMIC is required.

In recent years, with the evolution of smartphone batteries to non-removable technical solutions, Authentication BMIC can only be found on some high-end smartphones. On the whole, as the first terminal to adopt the lithium batteries solution, the consumer field will remain the largest downstream market of BMIC in the next 3-5 years.

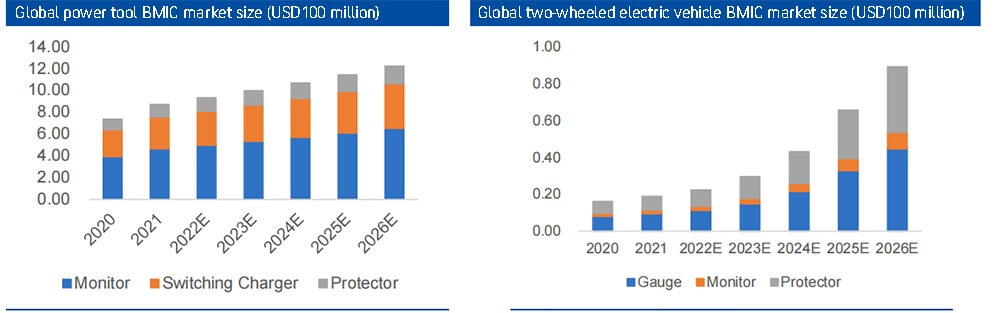

Demand for BMIC for power tool batteries

The BMIC products involved in two-wheeled electric vehicles generally include three BMICs: Gauge BMIC, Monitor BMIC and Protector BMIC. The BMIC products involved in power tool batteries generally include three types: Monitor BMIC, Switch Charger BMIC and Protector BMIC. The penetration rate of lithium-ion batteries for two-wheeled electric vehicles continued to increase. Due to its high energy density and light weight, lithium batteries have more advantages than traditional lead-acid batteries in the field of two-wheeled electric vehicles. The traditional lead-acid batteries has low energy density and limited cruising range, and two-wheeled electric vehicles have begun to accelerate the shift to lithium batteries. The increase in the proportion of lithium batteries solutions drives the continuous growth of BMIC demand. In the traditional two-wheeled electric vehicle with lead-acid batteries as the energy storage device, due to the high stability of lead-acid batteries, except for some high-end models, special BMIC is generally not adopted. The characteristics of lithium batteries are lively, and the requirements for the degree of balance between BMIC are increased, and special Monitor BMIC need to be used. The new national standard recommends that the batteries voltage of two-wheeled electric vehicles is 48V, 60V, 72V, 84V, 96V, and 144V, and the corresponding number of cells in series is more than 16 strings. Therefore, Monitor BMIC generally used in the field of two-wheeled electric vehicles are 16S and 18S models.

In high-end two-wheeled electric vehicle products with high safety requirements, in order to further ensure the safety of the batteries cells, an additional Protector BMIC is required. The batteries structure in the power tool is similar to that of a two-wheeled electric vehicle. It also needs a Protector BMIC, a Monitor BMIC, and a Charger BMIC to meet the battery charging needs.

The characteristics of lithium batteries are lively, and the requirements for the degree of balance between BMIC are increased, and special Monitor BMIC need to be used. The new national standard recommends that the batteries voltage of two-wheeled electric vehicles is 48V, 60V, 72V, 84V, 96V, and 144V, and the corresponding number of cells in series is more than 16 strings. Therefore, Monitor BMIC generally used in the field of two-wheeled electric vehicles are 16S and 18S models.

In high-end two-wheeled electric vehicle products with high safety requirements, in order to further ensure the safety of the batteries cells, an additional Protector BMIC is required. The batteries structure in the power tool is similar to that of a two-wheeled electric vehicle. It also needs a Protector BMIC, a Monitor BMIC, and a Charger BMIC to meet the battery charging needs.

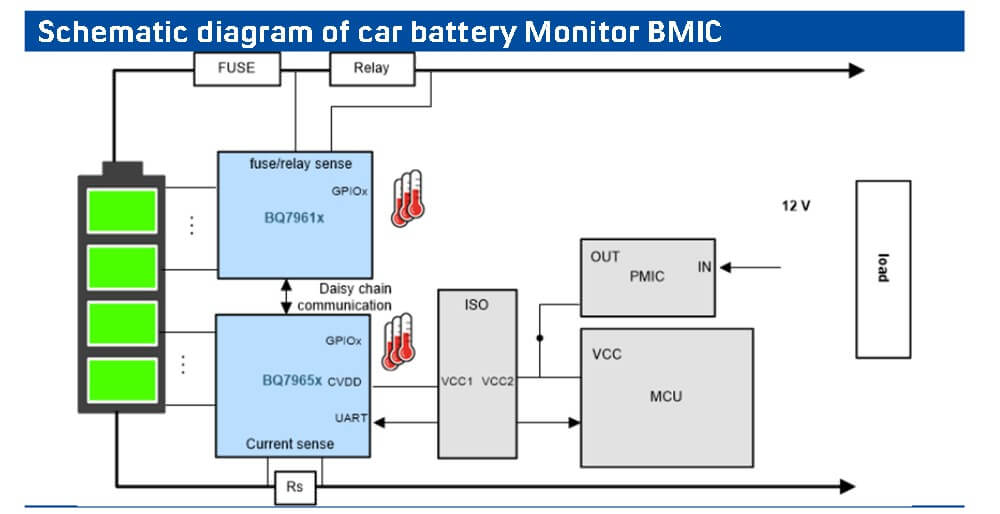

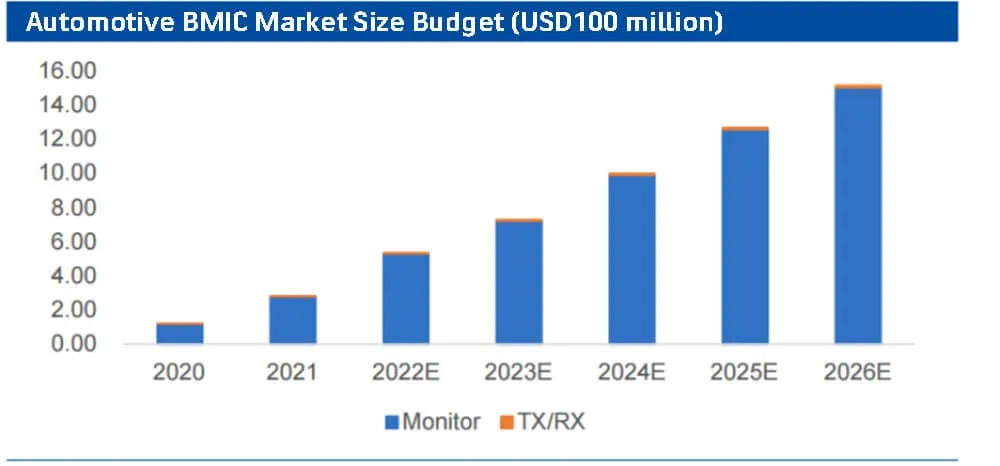

Electric vehicles – the most demanding BMIC track

BMIC is the core component of electric vehicle batteries safety, and early electric vehicles usually use a single battery solution. The Tesla Model S was released in 2012, and it was the first to use a battery pack consisting of more than 7,000 18650 cells in series. The 18650 batteries have large output, low price, and advantages in reliability and energy density. However, in a system consisting of more than 7,000 cells in series and parallel, power imbalances are prone to occur between batteries clusters, posing a huge challenge to BMS. Taking lithium iron phosphate batteries as an example, the voltage range of a single cell is generally between 3.2-3.6V, and the batteries voltage of a 400V system electric vehicle is generally around 360V. In order to achieve the corresponding voltage level, about 120 cells need to be connected in series. The series connection of such a large number of cells puts forward higher requirements for the consistency of the power between the cells. Therefore, it is necessary to use the Monitor BMIC to detect the voltage and current of each cell.

Taking lithium iron phosphate batteries as an example, the voltage range of a single cell is generally between 3.2-3.6V, and the batteries voltage of a 400V system electric vehicle is generally around 360V. In order to achieve the corresponding voltage level, about 120 cells need to be connected in series. The series connection of such a large number of cells puts forward higher requirements for the consistency of the power between the cells. Therefore, it is necessary to use the Monitor BMIC to detect the voltage and current of each cell.

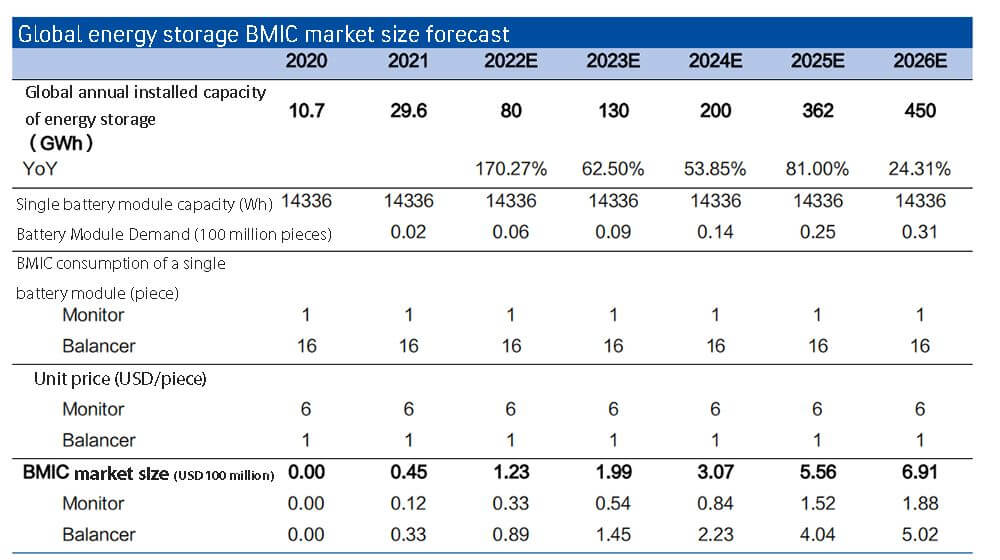

Energy storage – the most resilient BMIC track

With the increase in the installed capacity of new energy power generation, the frequency regulation and peak regulation capabilities of traditional power grids have been challenged. Electrochemical energy storage is an important means to improve the peak and frequency regulation capability of the power grid. With the increase in the installed capacity of new energy power generation, the demand for electrochemical energy storage also continues to grow. The BMIC involved in energy storage generally include three types: Monitor BMIC, Balancer BMIC and isolated communication IC. The application of BMIC in the field of energy storage is mainly energy storage power station. With the increase in the proportion of new energy sources, in order to ensure the stable operation of the power grid, the supporting construction of energy storage power stations has become a rigid need. In electrochemical energy storage power stations, the voltage level is high, the number of batteries in series and parallel is large, and the quality requirements for BMIC are also high. The energy storage power station has a large space and can support complex circuit arrangements. In order to improve the energy conversion efficiency, an active equalization scheme can be adopted. The BMS system of each module of the electrochemical energy storage power station generally includes: Monitor BMIC, Balancer BMIC, isolated communication IC, Gauge BMIC, etc. The information of each rack is uploaded to the central MCU through the isolated communication interface for unified deployment.

Batteries capacity upgrade, 280Ah and larger capacity batteries are becoming the mainstream of the industry. Therefore, at present, 280Ah batteries are accelerating to replace the traditional 50Ah and 100Ah batteries products in the scenarios of wind power generation side, grid side, shared energy storage side and some large-scale mobile energy storage applications that pursue low cost, large capacity and safety.

From the perspective of energy storage batteries capacity planning, the potential scale of the global energy storage BMIC market may be larger. According to relevant data, in 2022Q1, the total scale of energy storage batteries projects announced for expansion in China will reach 166GWh. In the future, the demand for BMIC in the energy storage market is expected to exceed the estimated range, with potential flexibility.

The energy storage power station has a large space and can support complex circuit arrangements. In order to improve the energy conversion efficiency, an active equalization scheme can be adopted. The BMS system of each module of the electrochemical energy storage power station generally includes: Monitor BMIC, Balancer BMIC, isolated communication IC, Gauge BMIC, etc. The information of each rack is uploaded to the central MCU through the isolated communication interface for unified deployment.

Batteries capacity upgrade, 280Ah and larger capacity batteries are becoming the mainstream of the industry. Therefore, at present, 280Ah batteries are accelerating to replace the traditional 50Ah and 100Ah batteries products in the scenarios of wind power generation side, grid side, shared energy storage side and some large-scale mobile energy storage applications that pursue low cost, large capacity and safety.

From the perspective of energy storage batteries capacity planning, the potential scale of the global energy storage BMIC market may be larger. According to relevant data, in 2022Q1, the total scale of energy storage batteries projects announced for expansion in China will reach 166GWh. In the future, the demand for BMIC in the energy storage market is expected to exceed the estimated range, with potential flexibility.

BMIC performance continues to improve

In terms of accuracy and power consumption, China’s BMIC has kept up with the performance indicators of international mainstream brands. The trend of China-made BMIC is even more evident in smartphone applications, and more and more China-made BMIC are entering the supply chain of high-end smartphones. In addition, lithium batteries are also used as UPS battery, power wheels battery, toy batteries, etc. In general, the potential market for BMIC is large. With more and more applications of multi-cell lithium batteries, high-capacity batteries packs have higher and higher requirements for BMIC. On the premise of ensuring the safety of the batteries pack, China-made BMIC needs to continue to innovate and develop towards small packages, high precision, high withstand voltage, low static power consumption, and low internal resistance.

With more and more applications of multi-cell lithium batteries, high-capacity batteries packs have higher and higher requirements for BMIC. On the premise of ensuring the safety of the batteries pack, China-made BMIC needs to continue to innovate and develop towards small packages, high precision, high withstand voltage, low static power consumption, and low internal resistance.

Related posts