Latest analysis of the development of aluminum air battery

Lead-acid batteries composed of lead, lead oxide and sulfuric acid have long been the mainstream rechargeable electrochemical battery technology and are widely used in the automotive industry. The expansion of solar and wind power generation in recent years has created a need for large-scale energy storage technologies. Several advances have been made in electrochemical energy storage technologies for stationary grid-scale applications.

Aluminum air battery is an inexpensive, lightweight and powerful battery technology. Oxygen in the air reacts with aluminum to create an electrical charge that generates electricity that is used to power passenger cars.

Some large electrochemical, grid-scale battery technologies already operate inside shipping containers. Such is the case with aluminum air battery technology from Israel, which can store 4,800 kWh and deliver a steady 240 kW (320 hp) output in a standard 20-foot container. At the same weight and volume, aluminum air battery can store more energy than vanadium flow, liquid metal or zinc-bromine-gel technologies.

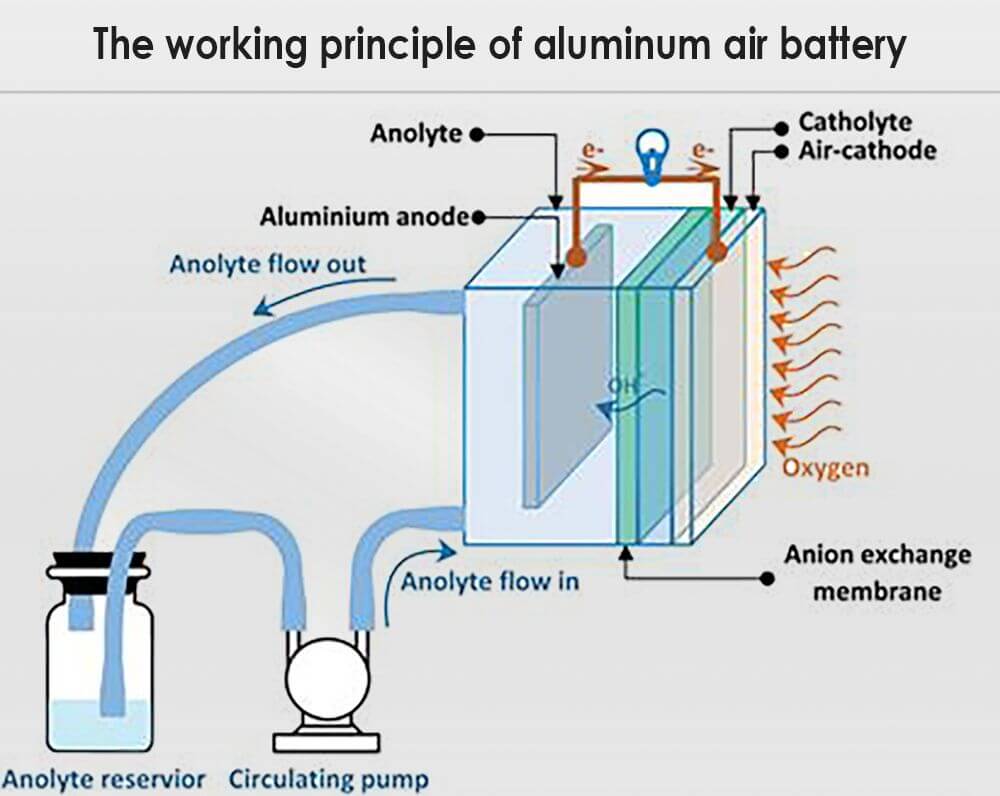

The working principle of aluminum air battery

The structure of a dc battery consists of an anode and a cathode. The anode typically accounts for 70% of the battery’s weight, while the cathode accounts for about 5% of the total weight. aluminum air battery consist of an anode made of pure lightweight aluminum combined with an air cathode. The combination of light weight and chemistry enables it to deliver three times the energy density of more expensive lithium-ion batteries.

Aluminum air battery generate aluminum hydroxide, namely Al(OH)3 or H3AlO3, during use. Aluminum air battery are not rechargeable, but are fully recyclable. When the aluminum-air battery is depleted, there are various chemical methods to extract pure aluminum from the aluminum hydroxide, which allows the continuous recycling of the aluminum-air battery.

In this process, the chemical reaction of the aluminum-air battery is similar to that of the zinc-air battery. The aluminum-air battery uses high-purity aluminum Al (containing 99.99% aluminum) as the negative electrode and oxygen as the positive electrode, and uses potassium hydroxide (KOH) or sodium hydroxide ( NaOH) aqueous solution is the electrolyte.

Aluminum absorbs oxygen in the air, and a chemical reaction occurs when the battery is discharged, and the aluminum and oxygen are converted into aluminum oxide.

The cost and recyclability of aluminum air battery make them competitive with lithium-ion batteries, which are the best rechargeable batteries. Grouped container aluminum air battery can operate with stable output for a longer period of time.

In offshore operations, battery containers need to be quickly and easily used, installed and replaced, making it possible to use aluminum air battery for tugboats and barges serving inland and coastal services.

Advantages and disadvantages of aluminum air battery

The advantages of aluminum air battery are mainly reflected in the following aspects:

- High specific energy, the theoretical specific energy of aluminum-air battery can reach 8100Wh/kg;

- Light weight, the total mass of the aluminum-air battery with the same energy is only 12% of the mass of the lead-acid battery;

- Non-toxic and dangerous, can be recycled and used;

- Aluminum raw materials are abundant.

The disadvantages of aluminum air battery are also obvious:

- It is a chemical reaction device that releases electrical energy. It cannot be recharged repeatedly, and the aluminum electrode needs to be replaced to continue to work;

- Although the aluminum air battery contains high specific energy, the specific power is low;

- The charging and discharging speed is relatively slow, the voltage lags, and the self-discharge rate is relatively large;

- A thermal management system is required to prevent overheating of the aluminum air battery during operation.

The prospect of aluminum air battery

China’s aluminum air battery is currently developing very fast, but there are always some obstacles.

First, no breakthrough has been made in key technologies. Problems such as air electrode polarization and aluminum hydroxide precipitation are important obstacles that affect the marketization of metal-air batteries. The improvement of aluminum-air battery performance has encountered a big bottleneck, and it is still in the laboratory.

Second, China does not yet have the conditions for commercializing aluminum air battery. At present, there are relatively few companies making aluminum air battery in China, and these companies can not support the entire industrial chain at all.

The use of aluminum air battery in passenger cars is just the beginning. Since aluminum air battery can generate enormous amounts of energy, this opens up a wider range of uses for them. Aluminum air battery pack can also be used in sectors such as marine, for example in container ships and cruise ships, ground support equipment at airports, and as a power source for rural microgrids.

Aluminum air battery can also be used for transportation and power local grids, providing modern services for communications, schools and medical facilities in remote areas.

Summary

It is still a non-rechargeable battery for the time being. The voltage of each battery is 1.2 volts. The principle is to use the oxygen in the atmosphere to generate electricity by chemical reaction with aluminum. The extremely high energy density level of kg, after actual testing, its equivalent fuel efficiency has reached 15%, which is equivalent to 13% of internal combustion engine vehicles.

This advantage has made it the first to be applied to the military field. For example, some meters that are inconvenient to disassemble and replace the battery frequently, or the standby power supply of radar or radar, will use aluminum air battery.

Although aluminum air battery have many good properties, there are still problems to be solved before large-scale and popularized commercial applications. For example, the anode of pure aluminum is easily corroded by the electrolyte, and the hydrated alumina after the reaction of aluminum ions will form a gel-like substance and reduce the power output.

The ideal cathode material is still being explored. For example, Italian scientific research institutions have submitted patents for aluminum-glass batteries, as well as aluminum-sulfur batteries.