Top 10 lithium battery aluminum-plastic film manufacturers in China in 2022

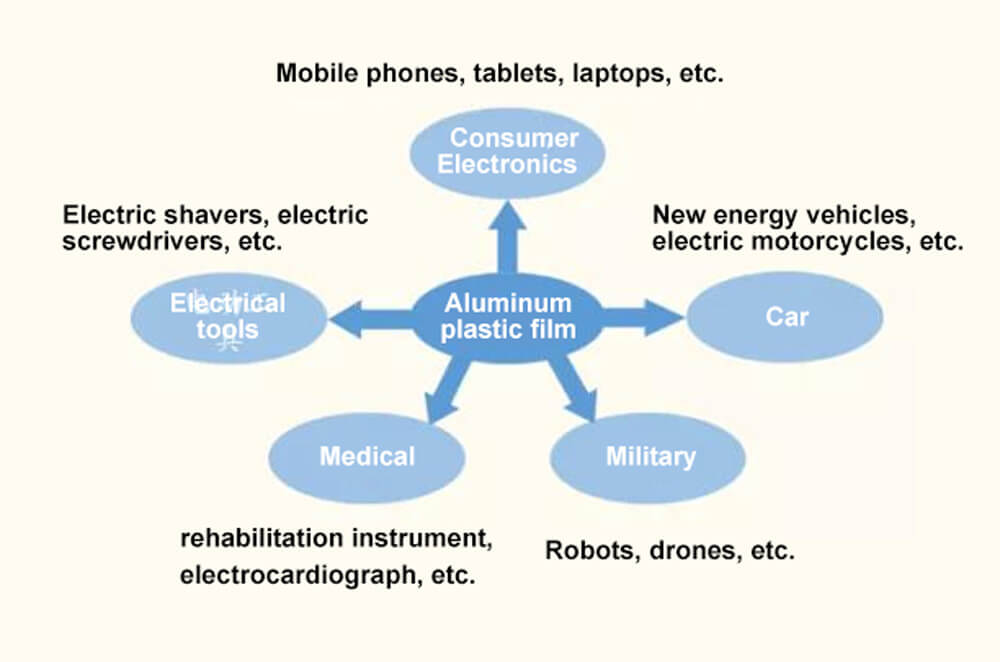

According to the different packaging forms, lithium batteries can be divided into square batteries, cylindrical batteries and pouch batteries. Square and cylindrical batteries are mostly packaged with steel or aluminum shells, and pouch batteries are mostly packaged with aluminum-plastic film.

Due to the presence of electrolyte inside the battery, the aluminum-plastic film of the pouchage material is required to be able to resist the swelling, dissolution and absorption of organic solvents (electrolyte), while ensuring strict barrier of oxygen and moisture.

Aluminum plastic film is generally composed of nylon layer, adhesive layer, aluminum foil, protective layer, adhesive layer, and CPP layer. After the single cell battery is assembled, it is sealed with an aluminum-plastic film to form a battery, and the aluminum-plastic film plays a role in protecting the contents.

The advantage of the pouch battery lies in its high energy density. The energy density of the ternary pouch cell is 260wh/kg, while the ternary square and cylindrical cells are 240wh/kg and 250wh/kg respectively; A security problem will only bulge but not explode. But the pouch battery also has the disadvantage of high cost, which is about 50% higher than the equivalent square and cylindrical batteries.

However, the advantages of high energy density and thinness still make pouch batteries shine in the 3C consumer market. As of 2020, the global consumer lithium battery market size is 92.1GWh, and the pouch lithium battery penetration rate is 81.1%.

As far as the power market is concerned, pouch batteries are used more countrys, which are very popular among European car companies. In the global installed capacity ranking in 2020, the top ten power battery companies such as LG Chem, SKI, Envision AESC, etc. are mainly pouch batteries. In 2020, 15 of the top 20 electric vehicles sold in Europe use pouch batteries. However, the current China share of pouch batteries is relatively low.

In the first quarter of 2021, the China battery factory’s pouch machines accounted for 3.5GWh, accounting for 8%, and the absolute value and proportion of installed capacity were low.

However, China power battery companies have also begun to implement the pouch model. BYD announced at the DMI press conference that it will start to use pouch lithium iron phosphate (also known as small blades) and use secondary sealing technology, that is, the cells are made of pouch (aluminum-plastic film) package, the blade battery is packaged in a duralumin case.

Even under the current penetration rate, the global demand for aluminum-plastic film will be 260 million square meters in 2021, and will reach 820 million square meters in 2025, corresponding to a market space of 6.6 billion yuan in 2021 and 14.7 billion yuan in 2025.

From the perspective of the aluminum-plastic film industry chain, upstream materials include calendered aluminum foil, nylon, adhesives, polypropylene and other materials, and the midstream includes processing equipment, testing equipment, etc., and related industries will usher in development opportunities.

At present, the aluminum-plastic film market is mostly occupied by many companies, especially in the power and high-end consumer markets. With the rapid growth of the global electric vehicle market and the relatively conservative expansion of Japanese-style companies, it may bring alternatives to China aluminum-plastic film companies. Chance.

Top 10 lithium battery aluminum-plastic film manufacturers in China in 2022

So, what are the main aluminum-plastic film manufacturers in China? We briefly sorted out 11 companies for your reference. (names not listed in order)

1. Selen Technology

Company Profile:Selen New Materials Co., Ltd. (stock code 002341) was founded in 2002 and is headquartered in Shenzhen. Selen Technology’s aluminum-plastic film business includes Selen New Energy Materials (Changzhou) Co., Ltd. and Synlun Materials (Japan) Co., Ltd., and currently has two production bases in Changzhou and Japan, and the total production capacity of Changzhou Phase I and Phase II aluminum-plastic film 6 million square meters/month, and the monthly production capacity of the Japanese base is 2 million square meters/month. Lines 4 and 5 of the Changzhou base under construction are expected to have an annual production capacity of 72 million square meters.

Main products:Selen New Materials takes high-end precision coating technology as the core, and its business covers electronic functional materials, optoelectronic display materials, silicone optical materials, new energy materials, precision manufacturing and other fields. It has more than 20 holding subsidiaries with total assets exceeding 7.7 billion. Yuan. It has three industrial bases in Shenzhen, Suzhou and Changzhou.

In 2016, Selen Technology acquired the aluminum-plastic film business of Japan Toppan Printing Co., Ltd.; in 2017, it signed a supply agreement with mainstream power battery manufacturers such as Gateway, Dofluoroduo, and Funeng, and entered the power battery industry chain; in 2019, Reached a supply agreement with LG. According to the statistics of China Chemical and Physical Power Industry Association, Selen Science and Technology has reached 87% of the China power-type aluminum-plastic film market share in 2020, and is the largest China power-type aluminum-plastic film supplier.

Company website: www.szselen.com

2. Shanghai Zijiang

Company Profile:Founded in 1989, Shanghai Zijiang Group has rich experience in R&D, manufacturing and processing in the flexible packaging industry. In 2011, Zijiang Enterprise Group Co., Ltd. and New Shanghai International (Hong Kong) Co., Ltd. jointly established Shanghai Zijiang New Material Technology Co., Ltd.

Zijiang Enterprise is an old-fashioned composite film enterprise, which has been deeply engaged in aluminum-plastic film for more than ten years. The company began to set up an aluminum-plastic film team in 2004, developed the first-generation product in 2007, and updated it to the fourth-generation in 2017. It is the earliest China enterprise that develops aluminum-plastic film technology and has mass production capabilities.

Main products:At present, the company’s power aluminum-plastic film and polyfluoride, Henan Lidong have batch cooperation; cooperation with Guoxuan Hi-Tech and Funeng Technology has also begun to send samples; and Yiwei Lithium Energy and Gateway have entered the stage of review and negotiation. In the first half of 2021, the company achieved sales of 10.46 million square meters of aluminum-plastic film, of which the sales volume of power aluminum-plastic film was 5.09 million square meters, accounting for 48%.

Company website: www.zjnmt.com

3. DM new material

Company Profile:Zhejiang DM Optoelectronics Technology Co., Ltd. is a wholly-owned subsidiary of Daoming Optical Co., Ltd., located in Yongkang, Zhejiang. Daoming Optical Co., Ltd. was founded in 2002. It has now formed the main business of reflective materials, the business of optical and electronic materials, and other The functional polymer material is an extended industrial structure, and it is currently the world’s leading manufacturer of reflective materials on the market.

In 2013, based on the research results and accumulation in the fields of precision coating, composite technology and micro-nano replication and transfer technology, the company invested in the construction of production lines for micro-nano prism reflective materials and lithium-ion battery packaging materials. In 2015, the first-phase production base with a production capacity of 15 million square meters was built. In the second quarter of 2021, the company’s second-phase project with an annual output of 35 million square meters will be completed and put into operation.

DM aluminum-plastic film covers high-performance, high-quality lithium battery aluminum-plastic composite film for digital, energy storage, and power applications.

Main products:The products are mainly divided into aluminum-plastic composite film silver film and aluminum-plastic composite film black film. The performance indicators have been Reached and partially surpassed the international advanced level. At present, the company has developed a series of products with thickness of 86μm, 113μm, 152μm, 90μm (black film).

At the beginning of 2019, DM and Tianjin Lishen signed the “Annual Framework Agreement” to form a practical cooperation framework, representing that the quality and performance of DM’s aluminum-plastic film products have been recognized by leading China battery manufacturers. In 2019, Daoming Optical’s aluminum-plastic film achieved sales revenue of 51.09 million yuan.

Company website: www.chinadaoming.com

4. Putailai

Company Profile:Dongguan Zhuoyue New Material Technology Co., Ltd. was established in 2015 and is a subsidiary of Putailai. The company is committed to providing aluminum-plastic film, copper-plastic film, stainless steel plastic film and other battery packaging materials for global medium and high-end lithium polymer battery manufacturers.

Main products:At present, the company has 23 invention patents and 9 utility model patents. The main products are: 113μm aluminum plastic film (silver), 88μm aluminum plastic film (silver), 115μm aluminum plastic film (black), 90μm aluminum plastic film (black), copper plastic film (for ultra-thin batteries), stainless steel plastic film ( power battery) etc.

Excellent New Materials took the lead in realizing the technological breakthrough and import substitution of high-end thermal aluminum-plastic packaging film products in China, and successfully developed steel-plastic film products for electric vehicle batteries. The performance index of the product is close to that of the international mainstream Japanese aluminum-plastic film products.

Using the self-developed thermal compounding process and secondary compounding process, the problem of the adhesion between the CPP layer of the aluminum-plastic film and the aluminum metal foil layer has been successfully solved, and a special CPP for lithium-ion batteries that is resistant to electrolyte corrosion has been independently developed. It solves the problem that ordinary CPP materials are not resistant to corrosion and high temperature.

Company website: www.putailai.com

5. Crown Material

Company Profile:Crown Materials Co., Ltd. was established in 2007 and is located in Yichun, Jiangxi. Mainly engaged in new energy and new composite film materials.

Main products: Solar cell backsheets, POE films for photovoltaic modules, PVB films, aluminum-plastic films for lithium batteries, special protective films and other new composite films. The products are mainly used in the field of photovoltaics and lithium batteries. field. Service customers include SPIC, CECEP, LG, REC, Hanwha, BYD and other China and foreign companies.

The aluminum-plastic film project of Mingguan New Materials was established in 2010 and started mass production in 2016. There are two main production processes of aluminum-plastic film: one is dry method, which has the advantage of better shell flushing performance and weaker resistance to electrolyte; the other is thermal method, which has the advantages of resistance to electrolyte and hydrolysis. The performance is relatively good, but the punching performance is not very good due to residual thermal stress in the molding process. Mingguan New Materials pioneered the dry-heat composite process, which combines the advantages of dry and thermal methods to improve the performance of aluminum-plastic film.

The company is the first China aluminum-plastic film enterprise that can be used in the field of power batteries, and it is also the deputy team leader unit that drafted national standards in this field. Aluminum plastic film products are widely used in digital, power, energy storage and other fields. The company’s aluminum-plastic film project has a planned total production capacity of 100 million square meters, which will be implemented in three phases. At present, the annual production capacity of 50 million square meters has been achieved, and it is expected to be fully put into production in 2022.

Company website: www.mg-crown.com

6. Leeden

Company Profile:Suzhou Leeden Energy Storage Materials Technology Co., Ltd. was established in 2015. It is an enterprise invested by China Huarong Assets and Hubei High Investment.

Main product:At present, the company’s pouch battery packaging aluminum-plastic film has formed three series of nine products, with excellent deep drawing performance, electrical safety performance and long-term high barrier corrosion resistance.

The company’s independent research and development of MicrolayerTM non-polar microwave anchoring method interface technology innovative application “12-layer multi-phase interface microwave anchoring technology”, realizes the whole series of pouch battery packaging materials, processes, equipment and other technologies made in China, filling China’s high-end aluminum The blank of plastic film R&D industrialization technology. A special aluminum-plastic film for lithium-ion batteries with high capacity and high power density has been developed. The deep drawing of single pit can reach more than 10mm, and the double pit can reach 24mm.

Company website: www.leadermaterial.cn

7. Jysuda

Company Profile:Founded in 2008, Jiangyin Suda Huicheng Composite Materials Co., Ltd. is an innovative enterprise dedicated to the R&D and production of composite materials for lithium batteries. In 2015, the company introduced several sets (sets) of equipment including coating, dry lamination, extrusion lamination production lines from Japan, and entered the aluminum-plastic film industry, the core material of pouch batteries.

Main products:Suda Huicheng currently has an aluminum-plastic film production line with a production capacity of 1.2 million square meters per month.

Company website: www.jysuda.com

8. Wazam

Company Profile:Zhejiang Wazam Energy Materials Co., Ltd. was established in 2017 and is a subsidiary of Zhejiang Wazam New Materials Co., Ltd. It is a high-tech enterprise focusing on the research and development, production and sales of aluminum-plastic composite film materials.

The company has China top technical talents, has independent research and development capabilities, and introduces high-end coating and testing equipment from some country, adopts new and improved coating processes and high-quality and high-precision surface inspection and control systems, and comprehensively establishes intelligent data-based dust-free workshops.

Main products: W1C-113, W1T-113, W1S-118, W1P-113, W3C-153, W3S-158, W3P-153, W5C-88, W5B-91, etc. Specifically: W1 series digital aluminum-plastic film, W3 series power aluminum-plastic film, W5 series ultra-thin aluminum-plastic film, and S series and P series that have strict requirements on the corrosion resistance of the outer layer of lithium battery packaging.

Company website: www.wazam.com.cn

9. Jiangsu Huagu

Company Profile:“Jiangsu Huagu New Material Co., Ltd.” (formerly Wuxi Huaying Lithium Energy New Material Co., Ltd.) was founded in 2014, and the company is located in Wuxi.

Main products:The company is engaged in the research and development, production and sales of aluminum-plastic film (ALF) for pouch lithium batteries.

It has now become a modern professional factory producing aluminum-plastic film for lithium batteries. At present, it has formed a production scale of aluminum-plastic film with an annual production capacity of 12 million square meters.

Company website: www.jshgcl.com

10. FSPG

Company profile:Foshan Fosu Technology Group Co., Ltd. (stock code 000973) was established in 1988. The controlling shareholder is Guangdong Guangxin Holding Group Co., Ltd., which was listed on the Shenzhen Stock Exchange in May 2000.

Main products:It is a leading enterprise and industry leader in the development and production of new materials for advanced polymer functional films. It has gradually formed an industrial layout with dialysis materials, optoelectronic materials and barrier materials as the framework.

FSPG uses the thermal process to produce the aluminum-plastic composite film. Compared with the dry process, the composite between CPP/Al does not need adhesive bonding, and has better electrolyte resistance, durability and high and low temperature resistance. Excellent, while guaranteeing good drawing and insulating properties.

Company website: www.fspg.com.cn

11. Hangzhou First

Company profile:Hangzhou First Applied Materials Co., Ltd. was established in 2003 and is located in Hangzhou City, Zhejiang Province. It is a high-tech enterprise focusing on the research and development, production and sales of new materials. The company has a number of subsidiaries in Zhejiang, Jiangsu, Anhui, Hong Kong, Thailand and other places, which are engaged in the R&D.

Main products:production of new materials such as photovoltaics, electronic circuits, and lithium batteries, international trade, and intelligent equipment.

First adopts advanced dry process to produce aluminum-plastic film for pouch lithium battery, which can match the different performance requirements of 3C consumer batteries, energy storage batteries, power batteries, etc. to the greatest extent. , Lighter weight, more diverse shape design services.

Company website: www.firstpvm.com

The 11 companies reviewed above have developed rapidly in the aluminum-plastic film industry, and basically have a layout in the field of pouch lithium batteries. Of course, there are other aluminum-plastic film companies, but not all of them are included. Welcome to contact the editor for discussion.

We predict that the aluminum-plastic film market will continue to grow rapidly in the future, and competition will continue to intensify.