Home » Battery Materials » Formation mechanism and prevention of lithium dendrite

Formation mechanism and prevention of lithium dendrite

- What cause dendrites in lithium batteries

- What are the characteristics of lithium dendrite

- Factors that affect lithium dendrites

- How to avoid the lithium ion battery dendrite formation

- Control the flatness of the positive and negative current collectors after coating

- The size of the negative electrode particles should be smaller than the critical thermodynamic radius

- Add electrolyte additives to stabilize the anode-electrolyte interface

- Replace liquid electrolyte with high strength gel

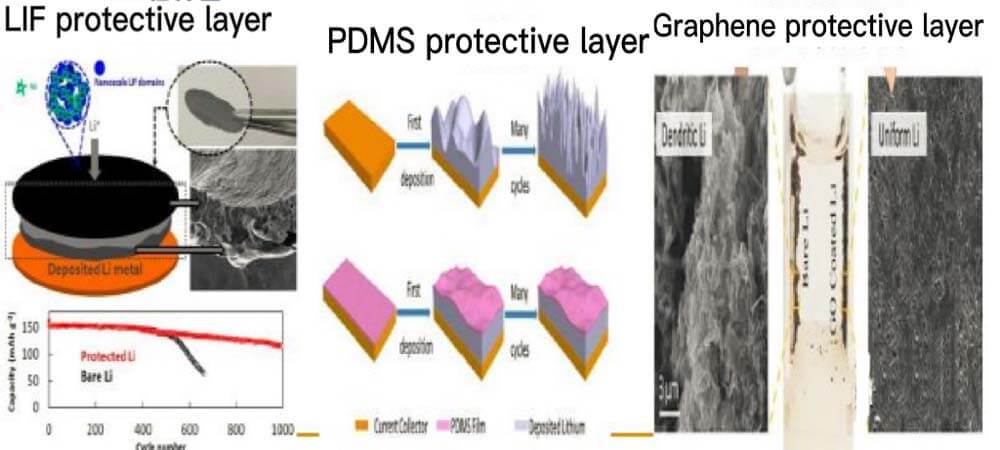

- Establish high-strength lithium anode surface protection layer

Everyone knows that lithium batteries can be used as power tool batteries, power wall battery and so on. Do you know the relationship between lithium ion batteries and lithium dendrite? One of the main reasons for the reduction of the capacity of lithium ion battery is the irreversible loss of lithium elements (compounds and ions), that is, the formation of irreversible lithium compounds or lithium metal.

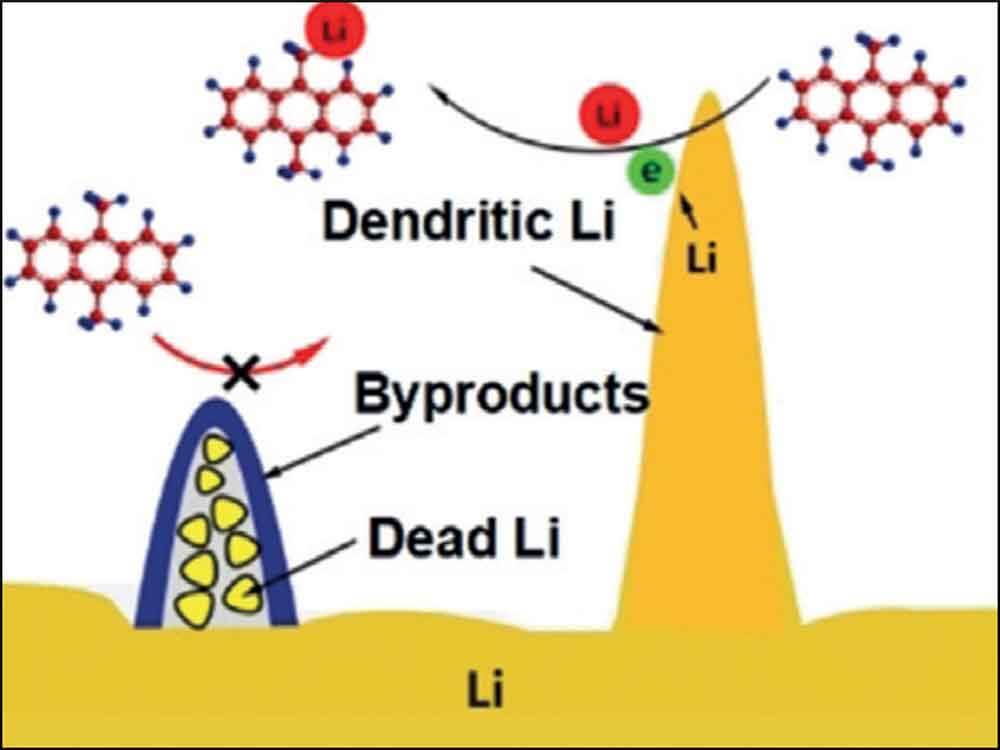

The irreversible lithium compound is one of the main components to form the SEI film, and the irreversible lithium metal mainly forms lithium dendrite and dead lithium.

What cause dendrites in lithium batteries

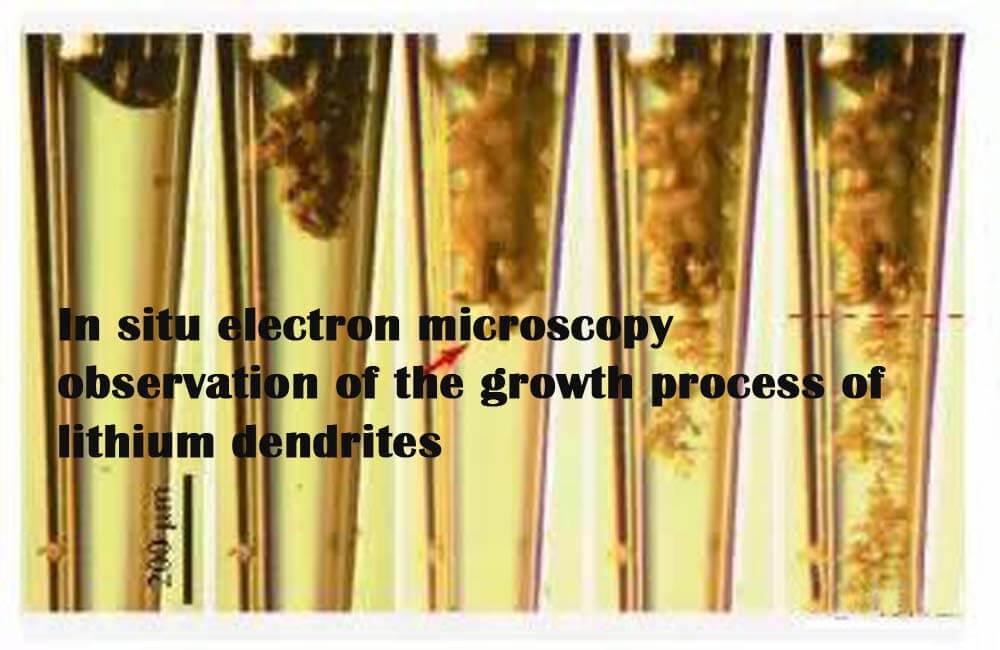

As early as the 1970s, researchers made detailed observations of the deposition of metallic lithium. However, the growth mechanism of lithium dendrite involves the fields of electrochemistry, crystallography, kinetics, thermodynamics, etc., and is very complicated, so there is no universal theory of dendrite growth so far.

The lithium dendrite problem in batteries is similar to electroplating production in the electrochemical industry, such as electroplating Cu, Ni and Zn, etc., and also faces the problem of metal dendrite growth. Therefore, the experience accumulated in the electroplating process can be used as a reference for understanding the growth of lithium technology crystals. Previous experience has shown that during electroplating, there is a cation concentration gradient in the electrolyte, limited by the diffusion rate of lithium ions.

When the current density reaches a certain value, the current can only be maintained for a period of time, which is called the beach time, and then the cations are exhausted in the electrolyte near the deposition electrode. This breaks the electroneutrality balance on the surface of the deposition electrode and forms a local space charge, which leads to the lithium ion battery dendrite formation during electroplating.

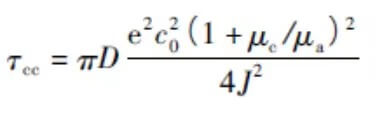

With the help of electroplating experience and previous research, M. Rosso et al. considered the influence of deposition rate, ion concentration, current density, overpotential and surface tension on the intercalation and ion deposition process, and proposed a Monroe-Newman model for lithium dendrite.

Where e is the basic charge unit; Co is the initial concentration; D is the diffusion constant; J is the current density; μc is the cation concentration; μa is the anion concentration. Experiments show that τcc becomes smaller when J2 increases.

In addition, some theories believe that due to the uneven surface of the metal lithium negative electrode, there are many protrusions, which leads to an increase in the distribution of electrons and charges at the protrusions, resulting in more Li+ being attracted and deposited to form lithium dendrite.

In conclusion, the growth of lithium dendrite is a complex electrochemical problem involving many factors, so it is difficult to describe with a single model or theory. However, the research and exploration of the theoretical model of Li dendrite nucleation and growth is still going on.

What are the characteristics of lithium dendrite

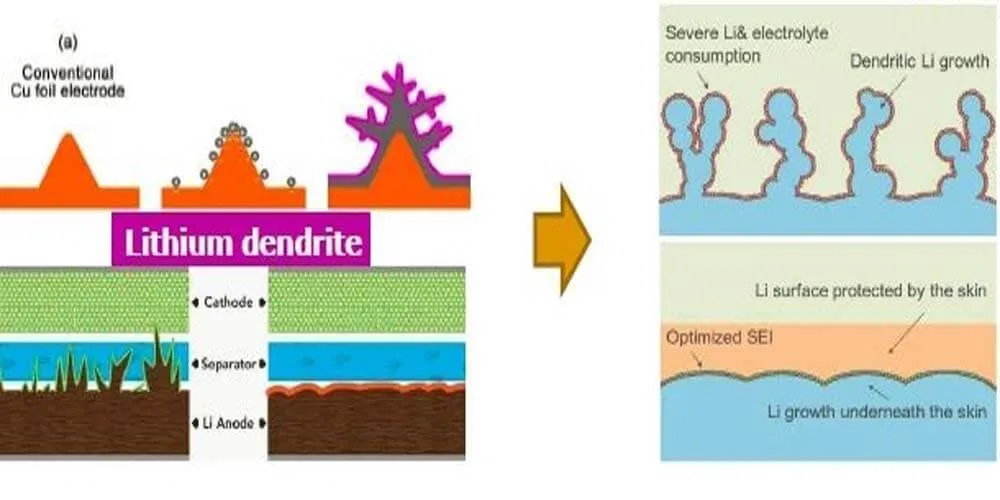

The morphology of lithium dendrite is different in different battery environments and at different times, such as moss-like lithium, filamentous lithium, needle-like lithium, whisker-like lithium, bush-like lithium, and dendritic lithium. This diversification of names is due to the different descriptions of them by various researchers. It can be briefly divided into 3 categories:

①No bifurcation, single growth, such as filamentous lithium, needle-like lithium, whisker-like lithium.

② Clustered, similar to the fermentation process of dough when growing, such as moss-like lithium, shrub-like lithium.

③ obvious bifurcation structure, sparse branches, the most dangerous dendrite structure, easily pierced separator, such as dendritic lithium.

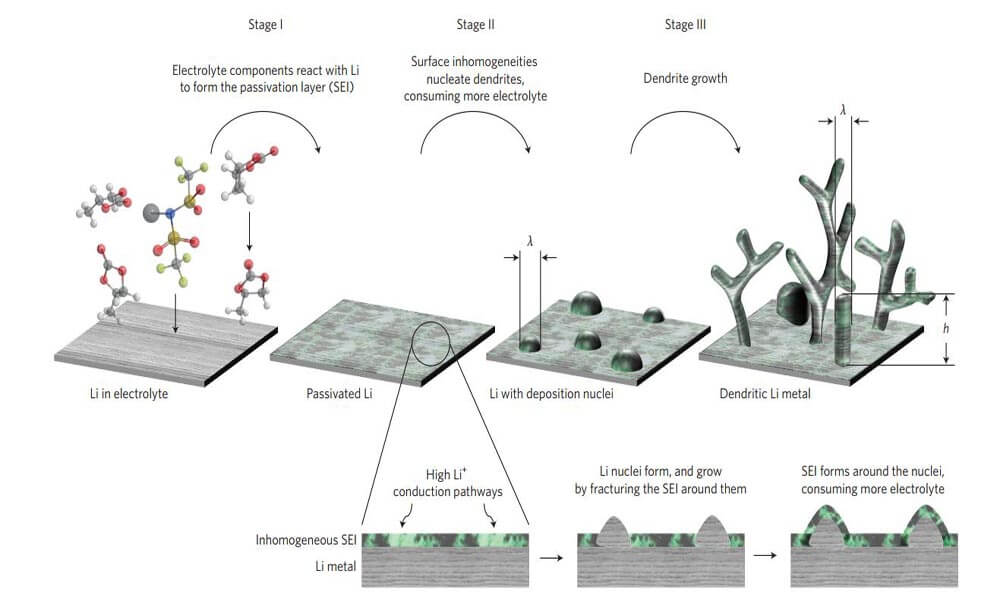

The initial nucleation and growth of lithium dendrite can be divided into three stages.

In the first stage, after the battery is assembled, due to the high activity of metallic lithium, a transient reaction can occur when it comes into contact with components such as organic solvents in the electrolyte to form an SEI film, that is, the formation of the SEI film is earlier than the generation of dendrites.

The dense SEI film prevents the electrolyte from further reacting with metallic lithium and is a good ionic conductor, but an electronic insulator. Li+ can be deposited on the electrode surface through this SEI film, but its deposition distribution is not uniform due to the influence of lithium, electrolyte, SEI film’s own characteristics and charging and discharging conditions.

The second stage, the nucleation stage, that is, the continuous accumulation of non-uniform precipitation, leads to bulges in some places until the original SEI film is burst.

Finally, it enters the growth stage, and continues to grow in the length direction after piercing the original SEI film, becoming visible lithium dendrite. At the same time, the SEI film also continuously reacts and proliferates with the growth of metal lithium dendrite, but always coats the metal lithium surface.

Generally speaking, the number of lithium dendrite is mainly determined by the nucleation stage, while the morphology of dendrites is mainly determined by the growth stage.

Factors that affect lithium dendrites

According to the Monroe-Newman model and actual work experience, the reasons for the easy occurrence of lithium precipitation are summarized as follows:

① When overcharged, the negative electrode lithium is saturated, and the excess lithium has been precipitated by metal

② In the place where the negative electrode leaks copper foil, due to the small polarization, it is easy to alloy with lithium, and it is easy to precipitate lithium.

③ When charging with a large current, the lithium on the surface of the negative electrode has no time to diffuse into the interior, and precipitates on the surface of the electrode

④ The edge of the electrode, especially when the electrodes are aligned, is affected by the edge effect, the current density is large, and the negative electrode is easy to precipitate lithium

In addition, the redundancy design of the positive and negative electrodes is insufficient, the battery is charged at low temperature, the gas contact between the positive and negative plates is not good, and the negative electrode electrolyte is not infiltrated well. Factors such as distance may lead to lithium precipitation in the negative electrode.

The surface of the positive and negative electrodes is uneven

There are many reasons for the uneven surface of positive and negative electrodes, such as: uneven coating, heavy positive coating or light negative coating, active material mixed with impurities, super thick positive or negative head, etc.

Lithium ion concentration gradient and distribution

During the charging process, the lithium ion concentration of the positive electrode gradually increases, and the lithium ion concentration of the negative electrode decreases due to the continuous acceptance of electrons. In a dilute solution with a high current density, the ion concentration will become 0.

The Monroe-Newman model shows that when the ion concentration decreases to 0, the negative electrode will form a local space charge and form a lithium dendrite structure, and the growth rate of the lithium dendrite structure is the same as the ion migration rate in the electrolyte.

According to the theory of self-healing electrostatic field, metal cations will be adsorbed on the bulge to form a positive electric field, thereby repelling lithium ions of the same charge and reducing bulge.

Current density

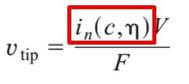

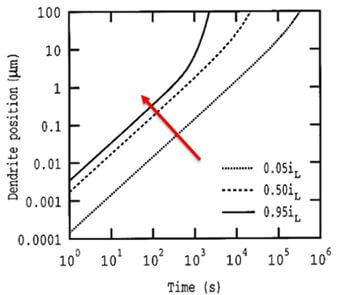

In the article Dendrite Growth in Lithium/Polymer Systems, the author believes that the tip growth rate of dendritic lithium is closely related to the current density, as shown in the following formula:

If the current density is reduced, the growth of lithium dendrite can be delayed to a certain extent, as shown in the following figure:

How to avoid the lithium ion battery dendrite formation

According to the lithium ion battery dendrite formation and influencing factors of lithium dendrite, the lithium ion battery dendrite formation can be avoided from the following aspects:

Control the flatness of the positive and negative current collectors after coating

This has been mentioned before.

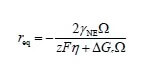

The size of the negative electrode particles should be smaller than the critical thermodynamic radius

In the process of lithium dendrite growth, the formation of lithium nuclei has a thermodynamic critical radius raq and a kinetic critical radius rk:

Add electrolyte additives to stabilize the anode-electrolyte interface

Additives are decomposed, polymerized or adsorbed on the surface of the lithium negative electrode, and participate in the formation of the SEI film as a reactant to change the composition and structure of the SEI film and modify the physical and chemical properties of the SEI.

In addition, it can also be used as a surfactant to change the reactivity of the surface of the lithium negative electrode, adjust the current distribution during the lithium deposition process, and uniformly deposit the lithium.

Additives can improve Li deposition morphology and cycling efficiency even at ppm levels in the electrolyte. Therefore, the use of electrolyte additives to modify the lithium anode is the most economical and convenient method.

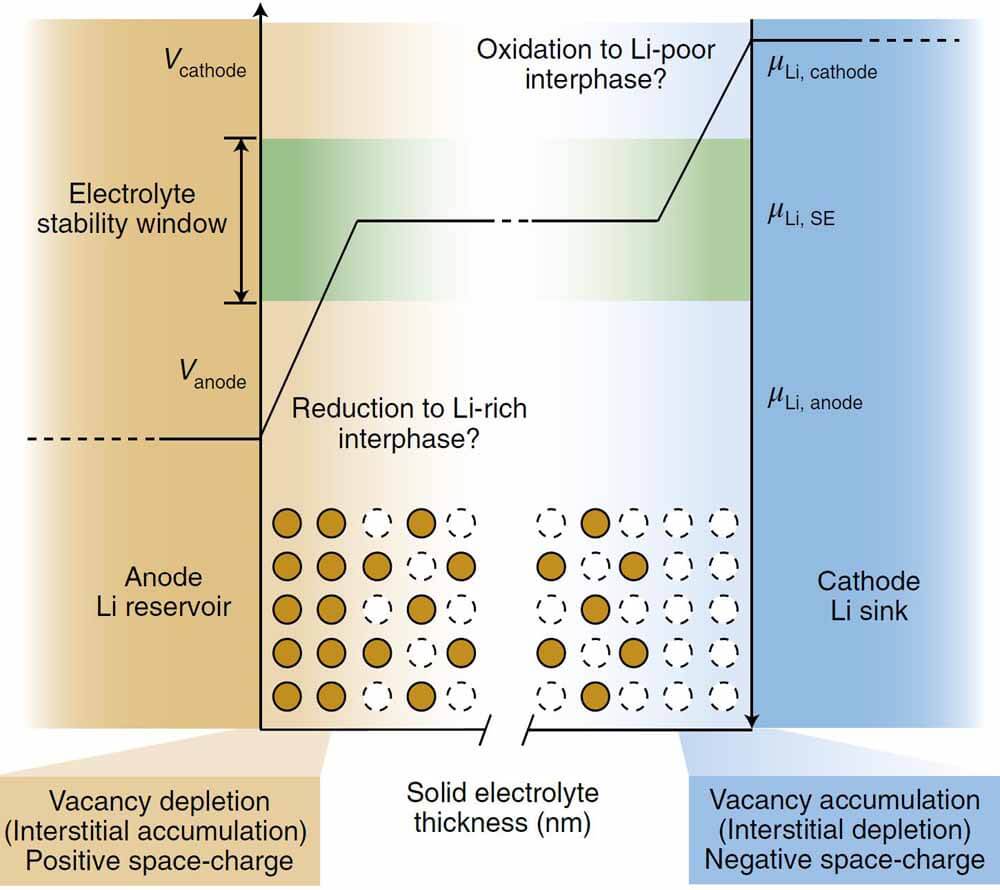

Replace liquid electrolyte with high strength gel

The solid electrolyte has a high modulus, which can prevent the growth and spread of lithium dendrite. It is difficult for lithium dendrite to pierce the electrolyte to conduct the positive and negative electrodes, and the safety is greatly improved. Therefore, it is considered to be the best choice for lithium metal batteries.

Establish high-strength lithium anode surface protection layer

The modulus of inorganic ceramic solid electrolytes is generally high, which can prevent the growth and spread of lithium dendrite, but it is worth noting that inorganic ceramics with high modulus, it means that its contact is poor, which will lead to poor contact with the electrode and excessive interface resistance. Therefore, when selecting inorganic ceramic materials, a balance must be struck between high modulus and surface contact.

The modulus of inorganic ceramic solid electrolytes is generally high, which can prevent the growth and spread of lithium dendrite, but it is worth noting that inorganic ceramics with high modulus, it means that its contact is poor, which will lead to poor contact with the electrode and excessive interface resistance. Therefore, when selecting inorganic ceramic materials, a balance must be struck between high modulus and surface contact.