Safety scheme of lithium battery storage safety

- What are the technical routes for liquid-cooled products and what are the differences?

- What is the role of fire protection facilities in the battery storage safety construction?

- What are the early battery storage safety warning and control measures for electrochemical energy storage plants?

- What is the cost of safety facilities for electrochemical energy storage plants?

- What are the causes of fires at energy storage plants?

- The prevention of battery storage safety cases

- What measures can be taken to promote the safe and sustainable development of energy storage?

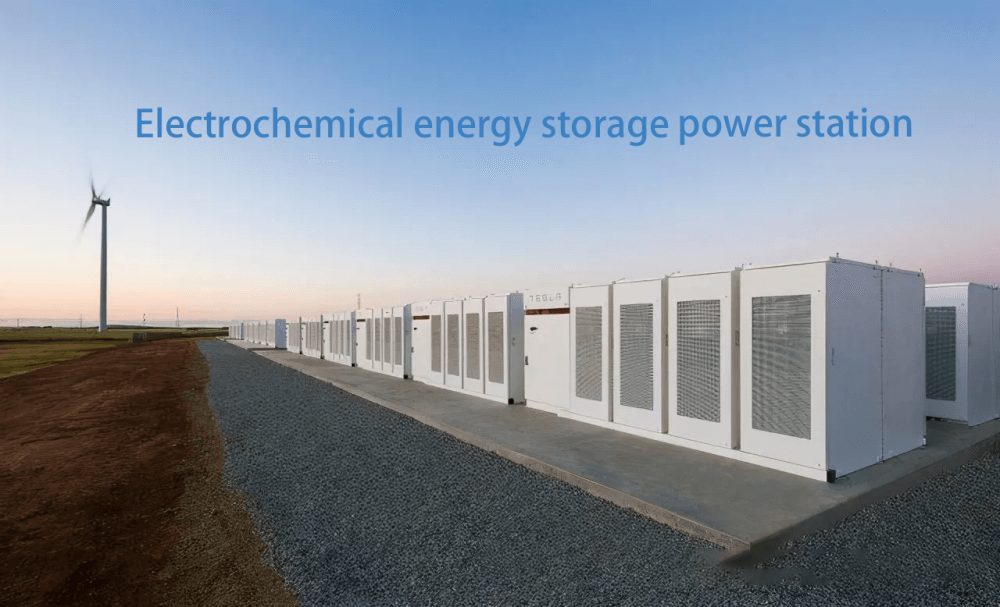

At present, safety accidents of energy storage power station and battery charger occur from time to time. In this paper, the safety risk of electrochemical energy storage power plant is discussed, the known and unknown problems are found and analyzed, and the solution to the lithium battery storage safety is proposed.

1.What are the technical routes for liquid-cooled products and what are the differences?

At present, the liquid-cooled products introduced by many energy storage system integrators are not simply systematic heat dissipation, but high threshold of liquid-cooled energy storage technology. It radiates heat directly to the cell through the convection of coolant. The difficulties also include how to reduce the risk of coolant leakage, it can fully meet the battery storage safety requirements of energy storage power station by considering the multi-dimensional design, environmental conditions, heat dissipation requirements and reliability requirements.

As far as liquid-cooled products are concerned, the technical route taken by both temperature control enterprises and energy storage system integrators can be said to be the same. Different manufacturers apply the same basic principles, differences are mainly reflected in the specific implementation of product design, for example, energy efficiency level, structure layout, core components selection, refrigerant type, electronic and electrical design.

Compared with air-cooled system, liquid-cooled system has obvious advantages in heat conduction, energy density, security, reliability, etc. , especially in solving the problem of uneven battery temperature in air-cooling system, the battery module has a great improvement in cycle life and reliability.

Enterprises should consider the following two aspects in product design: First, the temperature control system’s own fire risk management and flame retardant performance, don’t endanger the safety of energy storage station because of its own problems; Second, the temperature control system should provide a stable and reliable battery cooling scheme for the battery storage safety, to ensure that the battery does not overheat due to temperature control failure and the above two points for temperature control enterprises and energy storage integrators of the technical solutions are the same requirements.

In addition to the requirement for the optimal design and reliable manufacturing of temperature control products according to regulations, the appropriate temperature control solutions should be matched according to the technical characteristics of different energy storage plants.

The focus of liquid cooling products from temperature control companies and energy storage system integrators will vary. Temperature control companies are more focused on the development of liquid-cooled hosts, while energy storage system integrator integrators are more concerned with the temperature control of the entire battery storage safety system, not only including the functions of liquid-cooled hosts, it is also necessary to combine the performance of the liquid-cooled end of the battery, the ultimate goal is to well meet the battery temperature consistency.

At present, some integrators of liquid-cooled solutions, temperature consistency has been achieved within 2.5 degrees C, the battery life span has been greatly improved. Because temperature control enterprises are still the most professional solution providers in the field of temperature control, it is believed that in the future, the joint research and development of liquid cooling systems by temperature control enterprises and system integrators will be the trend of the industry.

For the safety requirements of energy storage plants, keeping the battery temperature well consistent, to some extent, can prevent the battery”Heat out of control”, but barely relying on the temperature control scheme to improve can not effectively solve the potential security risks. The cause of every safety accident of energy storage power station is complicated. In order to ensure the higher safety of energy storage power station, how to avoid, prevent, timely control and minimize the loss of potential safety risk from battery, battery management, temperature control system, fire protection, etc. , will be a healthy development of the industry demand.

At present, there are two main ways of heat storage management: air-cooled and liquid-cooled, each with its own characteristics. However, because the density of antifreeze used in liquid cooling is 1000 times than that of air, and the specific heat is 4 times than that of air, it has the characteristics of large heat carrying capacity and high heat transfer efficiency as a heat carrier compared with air cooling, in the case of higher energy density, faster charging and discharging speed, and larger variation of environmental temperature, the prevention of thermal runaway of battery is more effective.

Nowadays, the liquid-cooled products on the market are in fact a deep combination of the two, there is no big difference from the technical line, basically using the liquid-cooled unit and Pipeline and liquid-cooled box scheme. The function of liquid cooling is to realize the temperature control of the battery through the heat exchange between the refrigerant and the battery, so that the battery can work at a more suitable temperature and prolong the service life of the battery. At the same time, when the battery thermal run away, It can delay the spread of thermal runaway time. However, it can not prevent the occurrence and spread of heat out of control.

The design and test of liquid-cooled products in temperature control enterprises or the use and test of energy storage system integrators are all preconditioned to meet the safety requirements of energy storage power plants. The technical route is the same, but the ideology of the product is different. Before the 2021, battery modules used in Chinese energy storage systems were mainly air-cooled products. Since BYD first introduced liquid-cooled battery modules that meet Chinese standards, at present, the Sungrow Power, Envision Energy, Kehua, Trina Energy Storage Solutions and other lithium ion battery company also have the corresponding product launch.

Energy storage system integrators in the industry to introduce liquid-cooled products mainly refers to the use of liquid-cooled battery modules of the battery storage safety products, undoubtedly, some enterprise energy storage converter products use liquid-cooled refrigeration. Compared with air-cooled refrigeration, liquid-cooled refrigeration has its own advantages, but it also faces new challenges.

The use of liquid-cooled refrigeration for the safety of energy storage power stations requires extra attention to liquid hazard protection, mainly in the presence of condensation in the system during normal use or maintenance, higher pollution level should be considered in the design of corresponding parts, and some measures should be taken to prevent the accumulation of condensate; In the normal operation, equipment maintenance, hose or other system components (such as reservoir) loose or fall off, there must be no liquid leakage to the live part or the impact of electrical insulation. The closed liquid sealing system shall be provided with an overpressure safety device.

The safety device for over-pressure of liquid cooling system should meet the following requirements: the installation position should be as close as possible to the liquid sealing system to be protected; The injection and discharge opening is in place and marked to prevent the release from spilling to anyone; the release opening is in place and marked to ensure that the liquid is not watered when the device is started for components that may cause danger.

There should be no shut-off valve between the cooling device and the protected parts, and the cooling device should have the function of automatic air-water separation and exhaust the battery storage safety system which shall be able to monitor and display on-line the pressure and temperature of the circulating cooling liquid of the liquid cooling device.

2.What is the role of fire protection facilities in the battery storage safety construction?

The effectiveness of fire-fighting facilities can limit the spread of fire types in some parts of the energy storage system, especially the early suppression of thermal runaway of batteries, and minimize the scope and extent of the accident. Fire fighting system is different from the alternation development of fire extinguishing agent, the innovation of different early warning detection and the optimization renewal of different fire fighting control logic, all indicate that fire fighting facilities are paid more and more attention in electrochemical energy storage power plant.

The electrochemical battery storage safety station is different from the conventional building, which has a large number of batteries stored in a limited space, and has a large fire load and a high fire risk. Once the batteries lose control of the heat, it is difficult to put out the fire, it is particularly easy to form a systematic fire, burn the entire container, and even explosion. In view of the particularity of energy storage power station, the setting of fire control system is particularly important. In the fire strategy, the early detection, accurate detection, early and accurate fire-fighting fire should be based on.

Fire-fighting facilities are passive. When a fire occurs in a power station, fire-fighting means are used to restrain and put out the flames, to prevent the fire from spreading, and to minimize the loss of fire and casualties, this is the main role of fire fighting facilities. According to the characteristics of the battery fire, the alarm and fire-extinguishing unit can be sunk to the single energy storage module, which can effectively restrain the rise of the fire level and prevent the spread of the fire, and adopt the gas fire-fighting method of cooling and heat absorption.

Secondly, the influence of fire extinguishing agent on the conductivity of battery should be considered to avoid the damage to the normal operation of the system. In order to ensure the battery storage safety, it is still necessary to install the terminal fire protection facilities in the enclosed large independent energy storage space, which must have the functions of quick fire extinguishing and long-term heat absorption protection, at the same time, it is necessary to prevent the repeated burning of battery fire, to avoid secondary disasters and explosion accidents, and to prevent the spread of fire to a higher level.

In 2019, DNV Det Norske Veritas a study on the safety of lithium-ion batteries, which found that Compressed air foams were effective in fighting fires, in particular, the main fire-fighting performance (including fire-fighting ability, long-term heat absorption rate, short-term heat absorption rate) is superior to other fire-fighting methods, and has excellent anti-reignition performance, in the lithium battery fire fighting will play a crucial role.

Fire-fighting facilities can play a certain role in warning and fire-fighting against electric fire and battery fire in battery storage safety station. A combination of multiple sensors, can battery leakage, thermal runaway to a certain extent of early warning, such as monitoring the battery flammable gas leakage, electrolyte leakage, timely warning; Gas fire extinguishers can effectively extinguish electrical fires and put out or slow down fire spread in the event of a battery fire; water fire extinguishers can be used in a flood extinguishing mode when the fire is not under effective control, avoid causing bigger accidents.

Lithium metal is the most Reactivity series of all known elements (including radioactive ones) , and thermal runaway phenomena are common in lithium-ion battery, it is a potential safety problem for lithium battery in battery storage safety. On the other hand, EMS and PCS are composed of a large number of electrical and electronic components and high and low voltage wiring harness and its connecting parts, but they can not be ignored.

As the last passive defense system, the reasonable design, material selection, layout and construction of fire protection directly affect the healthy development of energy storage industry. The fire-fighting system can detect and alarm the container fire early, extinguish the fire quickly, isolate the fire conduction and radiation, and prevent the loss caused by the expansion of the burning area.

The whole fire-fighting system should cooperate with the requirement of energy-storing fire-fighting water supply, reserve the interface of fire-fighting water supply and fire-fighting, and make the whole energy-storing power station form the three-dimensional system of fire-fighting combination, so as to embody the value of fire-fighting products with the least loss.

The key of electrochemical energy storage fire protection is early detection and disposal. Based on the analysis of the energy storage fire cases that have occurred at present, the hidden dangers of the energy storage fire mostly come from the fire caused by the abnormal battery. This kind of fire goes deep into the hidden dangers and is not easy to be detected by the staff, therefore, early detection of fire information and accurate and effective feedback to the fire disposal unit is particularly important.

Using a complete and targeted electrochemical energy storage fire fighting system, the fire can be extinguished effectively at the initial stage of a fire in an battery storage safety station, and the fire can be restrained for a long time, and the fire information can be reported to the main station, save the firemen valuable time.

The function of fire protection equipment in the battery storage safety is to detect the fire danger signal in time, to ensure the fire extinguishing in time after the fire accident, and to reduce the spread of the fire danger accident. Of course, there are also strict requirements for the selection of fire fighting facilities, the type of detectors, the layout and installation, the control logic, the selection and dosage of fire extinguishing agent, the reliability of the facilities themselves, and the linkage between the fire fighting facilities and the overall control of the energy storage system.

3.What are the early battery storage safety warning and control measures for electrochemical energy storage plants?

In the area of precision detection, the chip’s bottom detection advantages and temperature/smoke/gas detection triad of cross-border, complex capabilities, to create a compact and intensive detector, pre-installed/built-in Battery module so that early detection, early action, early isolation, accurate detection of the specific battery module; The complex scheme of gas fire extinguishing and high-pressure water mist is adopted to prevent reignition for different scenarios, different levels (class, cluster level, pack level) , the need for different energy storage fire solutions.

To detect the hierarchical arrangement of the battery storage safety compartment, battery cluster and battery PACK box, to monitor the real-time data of the battery operation cycle, to collect and analyze the characteristic data of the thermal runaway of the battery, according to the abnormal battery at different stages to make different levels of detection and alarm, and make different prevention and control treatment. Combined with the construction scale and layout of electrochemical battery storage safety plant, multi-stage fire prevention and control.

In terms of safety measures, the battery thermal runaway is extremely early characteristic parameters of the acquisition and signal transmission system, fire suppression equipment, pressure relief devices, active exhaust smoke equipment, alarm equipment and fire display equipment. In terms of prevention and control measures, the starting point is generally to optimize the design of electrochemical energy storage power plants, such as the site selection of electrochemical energy storage power plants, the planning of station areas and the arrangement of certain distance fire protection distances.

It also includes the electrochemical battery storage safety system of electricity, heating, ventilation, air conditioning, and finally the installation of fire facilities and equipment, fire water, fire lanes and so on. Currently electrochemical battery storage safety plant complete system solutions can be provided. The detection results of combustible gas (H2, CO, VOC, etc) are used as early warning signals in the early warning system The alarm system adopts smoke, temperature and combustible gas of three kinds of fire detectors, through the detection of smoke, temperature and combustible gas of three kinds of signals of fire intelligent detection. The automatic fire extinguishing system adopts the combination of “Perfluorohexanone and Compressed air foam” for innovative application.

In PACK-level, cluster-level fire using perfluorohexanone precision targeted fire suppression, multiple releases, continuous cooling, to prevent recurrence. For the cabin fire, the Compressed air foam is used as the ultimate line of defense. The whole cabin is filled, the temperature is lowered for a long time, the fire can be prevented from reburning, and the fire can be controlled in a single cabin. Mobile Compressed air foam fire extinguishing device as an emergency rescue device, with battery compartment reserved filling mouth connected quickly, flexible, cost-effective. The barrier suppression type Compressed air foam spraying device is sprayed on the external wall and the top of the fire battery compartment to form a foam barrier to prevent fire spreading between the compartments.

The early-warning measures of battery storage safety mainly include the early-warning of abnormal operation parameters such as voltage and temperature of battery and electrical equipment, early-warning of fire danger signals (combustible gas, smoke, temperature) , detection and early-warning of insulation fault of battery system, early-warning of abnormal conditions such as fire-fighting System, sensor status, Temperature Control Equipment, communication, flooding, etc.

It is mainly controlled and protected by BMS, PCS and EMS of Energy Storage System. Energy Storage Security Early Warning System is composed of BMS system, fire detection system, infrared camera. BMS system is the earliest one that can sense the index of the cell. By monitoring the single cell voltage, temperature, SOC, SOH, total voltage, current, total positive and negative, the insulation resistance of the case can be safely warned. Fire detection systems sense system indicators, infrared cameras sense surface indicators and fire fighting is through 1,1,1,2,3,3,3-Heptafluoropropane and fire water pipe injection.

4.What is the cost of safety facilities for electrochemical energy storage plants?

Taking the 1MW energy storage container as an example, the traditional energy storage temperature control, safety early warning, fire-fighting scheme accounts for about 1% -4% of the expenditure. In the future, battery storage safety solutions technology upgraded to the precision detection dimension, the proportion of expenditure will increase to 5% -8% . It is understood that the current global cost of battery storage safety between 4% -6% . The cost of a fire-fighting device is related to the scheme used, with the 1,1,1,2,3,3,3-Heptafluoropropane class fire-fighting system costing tens of thousands of Yuan and the perfluorohexanone PACK class, with costs ranging from one hundred thousands to one hundred thousand percent, depending on the scheme.

5.What are the causes of fires at energy storage plants?

Under the influence of internal and external factors such as overcharge, overdischarge, overheat and mechanical collision, it is easy to cause the collapse of battery diaphragm and internal short circuit, which causes the heat to get out of control. Based on the design concept of active safety, three-level explosion protection and three-level fire protection and three-level insulation monitoring and protection are currently adopted, it has six safety designs: Ontology Safety, design safety, structure safety, system safety, management safety and fire safety.

From the global case of energy storage power plant fire, the cause of thermal runaway mostly from the cell temperature. How to solve the problem of heat transfer between the inner of the cell and the outer shell is still worth discussing and studying. Air-cooling technology takes air as cooling medium and convection as heat transfer mode, liquid-cooling technology takes coolant as medium and heat conduction as heat transfer mode. From the point of view of heat transfer, liquid cooling can effectively reduce the risk of thermal runaway to a certain extent.

Facts show that electrolyte leakage, overcharge and overdischarge, short circuit in the cell, insulation failure, cable damage, over-current and so on lead to the battery heat out of control or equipment temperature abnormal fire, battery aging, poor consistency, heat exchange system failure, resulting in high-temperature operation of the system caused by heat accumulation, poor insulation design or external foreign matter (conductive dust, liquid) into, test operation and so on improper operation lead to short-circuit, external encounter open fire, impact, lightning all kinds of accidental factors can cause fire.

The cause of fire in electrochemical battery storage safety plant is complex and multi-sided, but the most common is the thermal runaway of battery, because its thermal runaway development has a certain sustainability and irreversibility. Therefore, simply relying on temperature control cooling mode can not completely prevent the occurrence of thermal runaway, which requires the necessary and effective fire control means with temperature control facilities, joint cooling control of thermal runaway batteries, at the same time suppression and fire fighting.

In contrast, in the local protection unit, the heat absorption capacity is strong, volatile, environmental protection, battery and electrical equipment, non-destructive fire extinguishing agent is more suitable for some, such as perfluorohexanone. In the larger protective space, the need to be able to quickly fill the space, isolation of air, the overall battery system for blocking cooling protection, the comprehensive comparison, fog smart Compressed air foam is a good choice.

To solve this problem, the solutions proposed by the industry are multi-level and multi-dimensional detection methods, such as pyrolysis particle detector, embedded micro-temperature detectors, embedded micro-gas detectors, can achieve very early detection and alarm. Another common type of fire is electrical fire, due to electrical short-circuit, overcurrent heating, aging heating, lightning strike, etc.

In general, it is electrolyte leakage, battery internal or external short-circuit, arc breakdown, battery over-voltage, temperature is too high, current is too large, impact, etc. Electrical fires can generally be put out by fire-fighting devices, but because batteries have energy of their own, they will continue to cause the spread of electrical fires. At the same time, there are a large number of batteries inside battery storage safety plants, after the battery heat out of control, it is easy to cause chain reaction around the battery, the battery to continue to cool down to effectively control the spread of fire.

6.The prevention of battery storage safety cases

Composite detectors can be used to detect the temperature, smoke, combustible gas, VOC and other characteristic data of thermal runaway of lithium-ion battery, which can effectively prevent and control the fire of battery storage safety station caused by thermal runaway of lithium-ion battery, the combination of detection data and Battery BMS data can comprehensively judge the battery storage safety, make early judgment, early warning and early disposal to avoid fire caused by battery heat out of control.

When the battery is out of control, the fire extinguishing agent of gas or liquid is used to directly act on the battery to extinguish the open fire, and the spraying of the fire extinguishing agent needs to have a good cooling effect on the battery, block the thermal expansion of the battery out of control, to prevent the battery from re-burning.

Battery system defects, system protection is not complete, poor operation and management, and fire system is not perfect, etc. . The solution should start with improving the safety of battery, strengthening the safety management of the operation and maintenance of the electrochemical energy storage power station, and establishing a reliable battery fire-fighting system, including the design of battery storage/room fire-fighting, divided into fire detection, classification alarm, fire suppression, remote control; electrical (control) room fire design, for The Substation and distribution cabinets, control cabinets, inverters and other electrical equipment, the use of fire detection tube-type fire extinguishing equipment.

At present, the main causes of fire in battery storage safety plants are mechanical abuse, electrical abuse and thermal abuse, and the lithium-ion battery itself because of its very high energy ratio, very high activity with flammable and explosive basic conditions. Lithium-ion fire is mainly due to overcharge and overdischarge, resulting in thermal runaway of single lithium-ion battery if it can not be put out in time, in serious cases will lead to thermal runaway, because of the combination of multiple batteries pack energy storage plant, the tight packing of a large number of individual cells that can not dissipate heat quickly and effectively results in dangerous diffusion of the lithium-ion pack to the entire battery cluster.

There are mainly the following stages to be prevented:

equipment selection stage: standardize the selection of key equipment and battery storage safety system units, try to select certified products

power station design stage: strengthen the evaluation of power station design scheme, especially for safety design;

equipment procurement stage: strengthen the production process supervision of battery, PCS and system products;

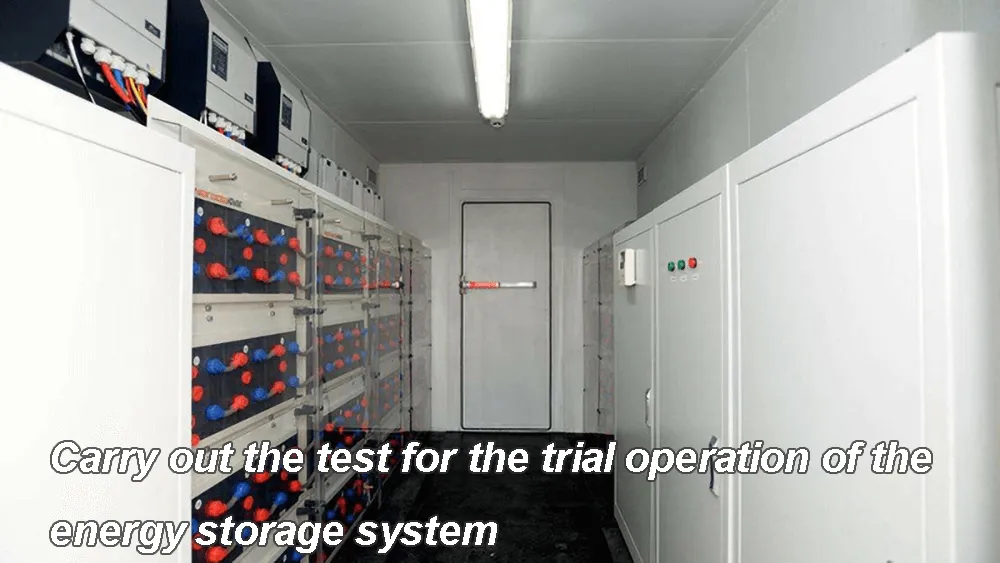

the stage of installation and commissioning: standardizing installation and commissioning procedures, formulating corresponding emergency response procedures, strengthening personnel training and on-site management;

operation and maintenance stage: quality operation and Maintenance Quality Management Manual and Procedure Document; strengthen the management and maintenance of the Operation Environment and the running state of the equipment; start the trial operation and acceptance and regular safety inspection.

Causing a fire at the battery storage safety plant, it mainly includes: high voltage relay adhesion, electrolyte leakage, low and high voltage isolation, battery internal resistance increase, battery diaphragm breakdown internal short circuit, battery overcharge, overdischarge. Software control, testing and protection should be strengthened. Liquid cooling itself is a better choice to solve the problem of battery cooling, liquid cooling is more conducive to battery temperature control, with the charge-discharge rate of the increase in liquid cooling is the electrochemical storage temperature control of the mainstream solutions.

Some companies have liquid-cooled battery systems that have liquid outlet temperature differences in the ± 0.5 ° C range, and battery storage safety systems are designed to keep the battery pack in a balanced and comfortable operating temperature range for long periods of time, eliminate the potential safety hazard caused by runaway battery heat.

7.What measures can be taken to promote the safe and sustainable development of energy storage?

At present, it is necessary to build a market-oriented green energy storage technology innovation system, develop different battery storage safety technologies according to specific application scenarios, and innovate in synergy from many levels, such as materials, devices, systems and applications, the cost of energy storage can be reduced by more than half through the development of subversive technology, and the safety of electrochemical battery storage safety system can be improved to a completely controllable level.

In the future, it is necessary to strengthen the establishment of market-oriented R & D system and personnel training system for green energy storage technology, aiming at the problems of large capacity, low cost, high safety and easy recovery, etc. , we will actively promote innovation in energy storage technologies, reduce the cost of battery storage safety applications, promote the development of battery storage safety technologies and industries, and promote a clean global energy transition.

The safety prevention and control of battery storage safety station runs through many key links in the whole life cycle of battery manufacturing, power station design and construction, Operation Maintenance and accident emergency treatment. With the aid of big data technology, the operation data of the battery are analyzed and mined, the on-line state evaluation and active safety early warning of the battery storage safety system are established, and the operation and maintenance strategy of the battery storage safety station is optimized, it is of great significance to reduce the safety accident risk of battery storage safety plant.

There are three aspects to the battery storage safety system, one is to develop the standard of safety performance test method, the other is to evaluate the harmful gas, and the third is to study the standard of safety performance classification and Comprehensive Evaluation.

Battery storage safety, whether it is ontological safety, active safety, or passive defense measures, it is necessary to conduct joint research on the safety technologies of electrochemical battery storage from battery materials, fireproofing materials, cells, modules, system integration, as well as different institutions such as design institutes, Power Grid Companies, lithium ion battery manufacturer and fire departments, to achieve real innovation and provide security for the development of large-scale battery storage safety industry.

At the stage of equipment selection and procurement, customers should request to participate in the bidding and energy storage products should be certified by the certification body approved by CNCA Carry out trial operation and acceptance test of battery storage safety system; carry out grid-connected battery storage safety and fire acceptance to ensure compliance with grid-connected standards and fire safety requirements; conduct regular operation and maintenance quality evaluation to ensure the operation quality of battery storage safety plants.

The formation mechanism of lithium battery fire and its early out-of-control characteristics can also be discussed through cooperative research, joint testing and establishment of joint laboratories, based on the research of detection mechanism, early warning analysis and suppression disposal, combined with the innovative technology of detection technology, sensor, control system and suppression material, to enhance the battery storage safety system.

At present, the storage forms of the fire extinguishing system of the energy storage fire fighting facilities in use are the pressure storage type, the standby type and the pump group type. There are start-up risk and maintenance risk in fire fighting facilities. It is suggested that multi-valve and multi-pump linkage should be adopted to drive the valve or pump group of fire extinguishing agent Choose non-storage pressure, non-standby pressure, non-pump type maintenance-free fire fighting facilities. The most important thing is to establish strict product technical standards.