Ways of battery formation and difference comparison

What is battery formation?

Lithium batteries are dead when assembled and must be charged to activate. The first charge is called battery formation and is used to activate the active materials in the battery body. Battery formation is a very complicated process, and it is also an important process that affects battery performance. Because in the process of charging the battery for the first time, it is inevitable to form a passivation thin layer covering the surface of the carbon electrode on the phase interface between the carbon anode and the electrolyte, which is called a solid electrolyte interface film or SEI film.

The battery capacity division is to charge and discharge the battery, and detect the discharge capacity when the capacity division is full to determine the capacity of the battery. Only batteries whose tested capacity meets or exceeds the design capacity are qualified. This process of screening qualified batteries through capacity testing is called capacity division.

The role of battery formation and capacity division

The battery formation and capacity separation and detection system are the most critical links in the back-end process. The formation of a lithium battery cell is to realize the initialization of the battery by charging and discharging, and activate the active material of the cell, which is a process of energy conversion.

The lithium battery formation principle is relatively complicated, but it is also a very important process that affects battery performance. The power connector acts as a switch between the battery and the external connection, which also affects the performance of the battery. High-quality battery terminals allow lithium batteries to be used effectively.

Battery formation is just a charging process, and there is no need to discharge the battery cells, so a separate charger can be used during formation, so the charger is often called a battery formation machine or a battery formation cabinet. Although battery formation does not require discharge, some battery formation processes require more than one charge, followed by the capacity separation process after formation, which requires charging and then discharging the battery cell.

After the battery is formed and charged, the battery cell must be discharged. This technical requirement has also led many battery manufacturers such as lithium top 100 to directly use a charge-discharge machine with charging and discharging functions for battery formation. The significance of battery capacity classification is to screen out qualified batteries and group them. Due to the technical reasons in the battery manufacturing process, the actual capacity of the battery cannot be completely consistent.

After a certain specification, the “full charge-discharge” cycle is carried out. The cycle time multiplied by the discharge current is the capacity of the battery. As long as the capacity obtained by the test meets or exceeds the design capacity, the battery is qualified. By sorting cells of different capacities, battery pack consistency can be optimized. As a device for activating and checking whether the battery is qualified, the selection of the connector for the battery forming device is also critical.

Three ways of battery formation

With the rapid development of the industry, the industry has gradually begun to pursue energy saving and consumption reduction and improve product consistency, followed by the gradual evolution from traditional single-point formation to serial formation and compound formation. The battery formation methods include single point battery formation, composite battery formation and serial battery formation.

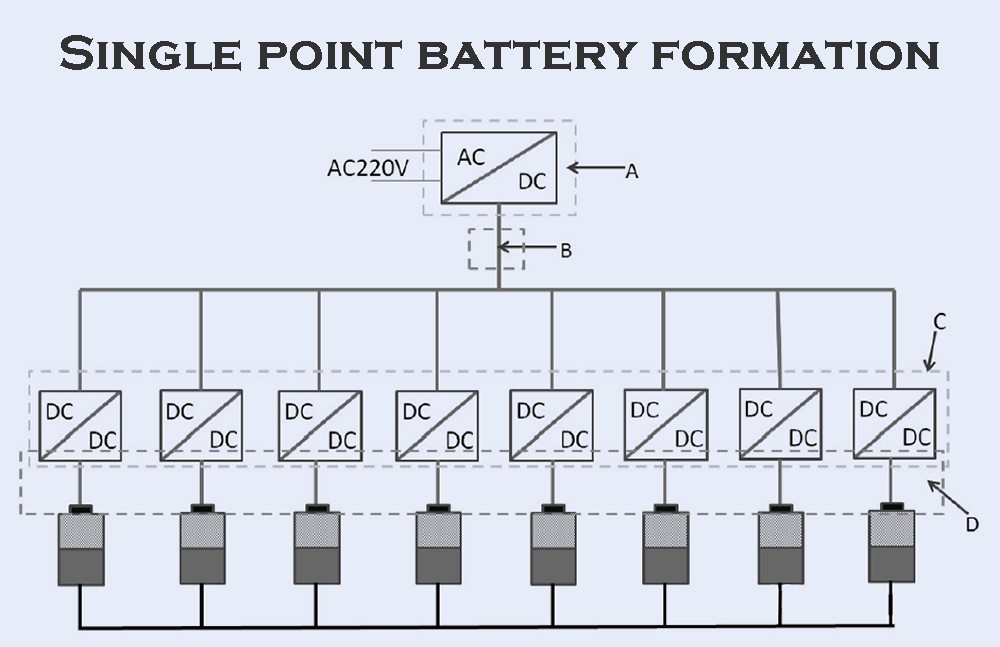

● Single point battery formation

Single point battery formation is the most traditional application method. The basic principle is that each battery has a separate charge and discharge module for separate charge and discharge, and there is basically no influence between the single cells.

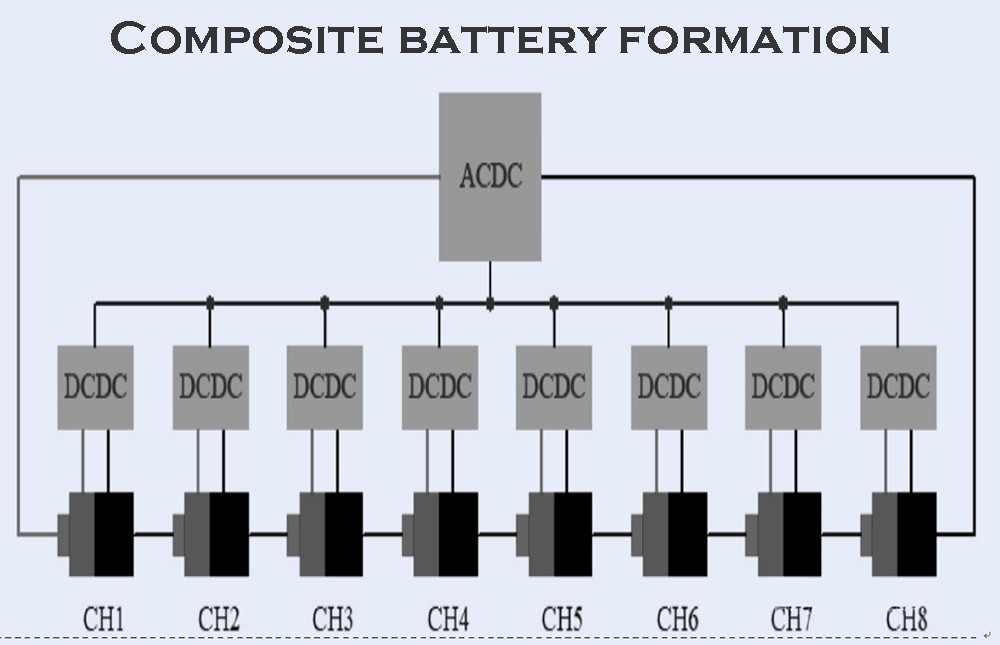

● Composite battery formation

The original intention of compound battery formation is to control the cost of input while providing product consistency. The basic principle of composite battery formation is to charge all the batteries in series by connecting a series of batteries (the specific number varies according to different designs) to ensure that the current of each battery is exactly the same. At the same time, in order to meet the traditional charging and discharging control of a single battery and the battery constant voltage function, a bypass control module is added at both ends of each battery.

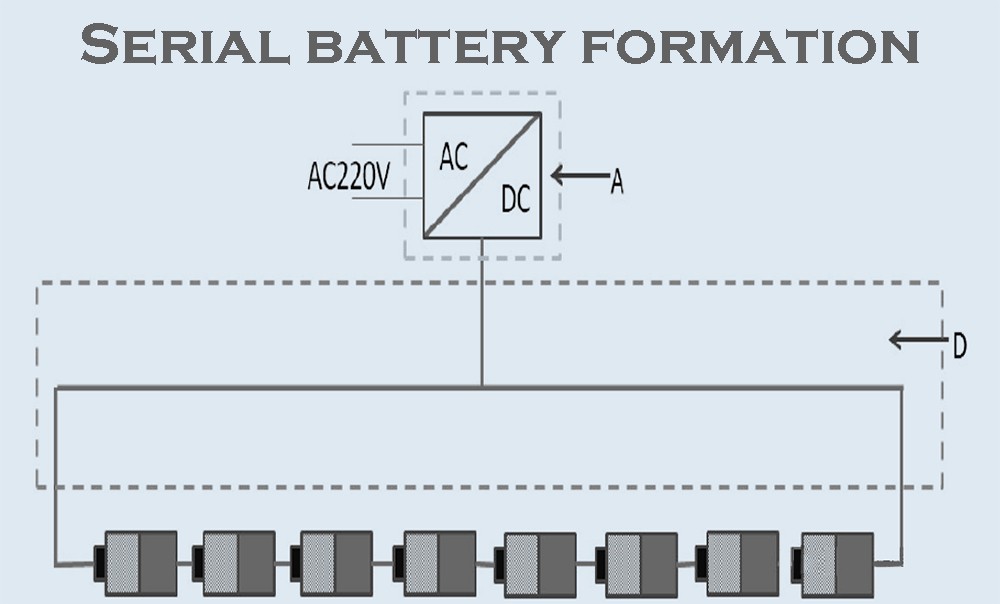

● Serial battery formation

The serial battery formation is an application method that the industry has explored and compromised. The achievement of series battery is to simply connect the whole series of batteries in series and then charge and discharge. For example, you can get 24v voltage by connecting 12v lithium ion battery, just connecting two batteries in series. This method cannot realize the constant voltage charge and discharge function of the battery.

Strictly speaking, the Serial battery formation can be divided into two methods. One is the simplest way to connect all batteries in series. If a single battery is abnormal, the whole series of batteries will stop. Another way is to perform bypass control on a single battery on the basis of series connection. When a single battery is abnormal, the abnormal battery is skipped through the bypass version, and other batteries are charged and discharged normally.

Comparison of three types of battery formation

| Compare items | Serial battery formation | Single point battery formation | Composite battery formation |

|---|---|---|---|

| Maturity | In the past three years, it has been maturely used in major companies. | The most mature and has been in use for many years. | Low maturity, less application. |

| Efficiency | Charging efficiency ≥ 75% Discharge efficiency ≥ 75% | Charging efficiency ≥ 65% Discharge efficiency ≥ 60% | Charging efficiency ≥ 75% Discharge efficiency ≥ 75% |

| Functions | Without constant voltage function, single channel stop. | Satisfies various functions. | With constant voltage function, single-channel constant current is not possible, and the stability is poor. |

| Current and voltage accuracy | Overall accuracy can be improved to 0.025%. | The stability accuracy can be up to 0.05%. | Overall accuracy can be improved to 0.025%. |

| Cost | Lowest | Higher | Highest |