How to distinguish and choose the battery connector

Have you ever heard about the battery connector of lithium battery packs? This article introduces the classification and comparison of battery connectors and the method of distinguishing the materials of the connectors, so that everyone can better know how to choose the battery connector.

You can refer to the following battery pack production video, battery pack uses battery connector to achieve series and parallel connection.

Types and comparison of battery connectors

There are 5 common types of battery connectors as follows:

| Types | Conductivity/Resistance | Solder spot reliability | Ease of welding | General purpose |

|---|---|---|---|---|

|

Copper connection piece (nickel-plated copper piece) | Good, about 4.2 mΩ | Higher | Difficult welding | Occasions with higher requirements for super high current |

| Pure nickel connecting piece | Average, about 16mΩ | High | Easy welding | Occasions with higher requirements for high current |

| Iron nickel-plated connecting piece | Poor, about 25mΩ | Poor | Difficult welding (more difficult to solder than pure nickel) | Small current and economical products |

| Al-Nickel alloy piece | Better, 3.2~7.2 mΩ | Average | Difficult welding | Special for polymer battery |

| Stainless steel connecting piece | Bad, about 200mΩ | Fine | Easy welding | Small current and low requirement products |

How to distinguish the type of battery connector

In view of the fact that metallic nickel belongs to the more noble metal materials, and metallic nickel also belongs to the category of ferromagnetic materials, pure nickel and nickel-plated iron pieces attract magnets equally, so it is not possible to distinguish pure nickel from nickel-plated iron using a magnet. The following specific methods can basically roughly distinguish the material of the battery connector for customers.

● Color discrimination method

Use a sharper blade to scrape about 5-8 times on the battery connector, and observe the color of the scraped surface of the battery connector. If it appears golden or golden red, battery connector is nickel-plated copper.

● Specific gravity method

In the case of the same size and volume, the connection between pure nickel and nickel-plated iron is about 1.15 times. That is, nickel is heavier than nickel-plated iron, which can be distinguished by electronic scale weight.

● Chemical resolution method

Take a glass cup, put half a tablespoon of refined table salt, add warm water to dissolve it into salt water, cut a few pieces of connecting piece and put it in, let it stand for four to five hours to observe the color of the salt water. The one that turns light green is nickel-plated copper; the one that turns yellow is nickel-plated iron;

Those that do not change color or slightly turn yellow are pure nickel pieces (pure nickel pieces contain a small amount of impurities such as iron due to the classification of different purity grades)

● Resistance measurement method

Take a few meters long (compared with the resistance value that can be measured by the multimeter resistance file), use a 4-digit digital multimeter (can distinguish 0.01Ω minimum), measure the resistance value of the connecting piece, comparing different types of connectors with the same thickness, width and length, the one with the smallest resistance value is pure nickel, and the one with the largest resistance value is nickel-plated. The resistance value multiple of nickel-plated iron piece and pure nickel piece is about 1.4 times.

● Visual resolution method

The production process of pure nickel piece does not require electroplating process, so its surface is relatively neat and smooth, but the color is slightly dull; The nickel-plated piece is electroplated, and its surface layer presents micro-sand grains, and at the same time has a more shining silvery white luster.

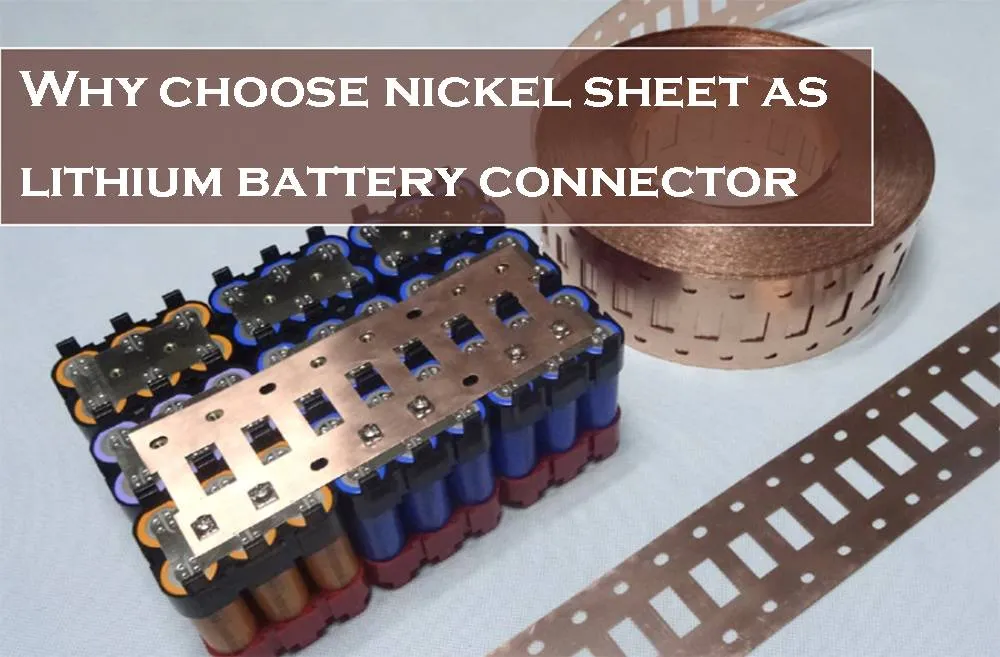

Why choose nickel piece as lithium battery connector

Why odm lithium ion battery pack manufacturer prefers nickel piece as battery connector? The advantages of nickel pieces are as follows:

- Nickel piece is resistant to high temperature, low internal resistance and easy to spot weld

- Nickel pieces are cheap, and the shapes of nickel pieces can be varied according to the actual PACK structure requirements.

- Spot welding technology is mature, and spot welding machines on the market are cheap.

- The spot welding of combined lithium battery pack can basically ignore the production tools, which saves a lot of cost.

- It is also more convenient to maintain and disassemble after welding. Some disassembled batteries only need to polish the welding surface of the battery core to be reused.

The battery nickel connector spot welding effect is good, the internal resistance is lower, oxidation resistance, corrosion resistance, the discharge time of battery pack is longer, and battery spot welding is stronger. The price is more economical than copper piece, and copper has a disadvantage that it is easy to oxidize in the air.

How to choose the size of the battery connector

There are two reasons for choosing the length (thickness and length) of the battery connection piece:

1. The magnitude of the current flowing through the battery connector is usually determined by the highest output discharge current of the battery during product operation. For example: in an electric bicycle (10AH battery pack), the maximum output current of battery is 7 to 8 amperes (the car starting battery is about 20 to 30 amperes); In the power tool battery pack, the maximum output current of the power tool battery is around 10-15 amperes;

2.The application length of battery connector is usually determined by the fact that the voltage drop (line loss) caused by the current passing through battery connector is lower than 1%~1.5% of the total voltage of the battery pack. To put it simply, the longer the length is, the longer the length is selected, and the “wire loss” of the battery connector is reduced by widening.

For example: in the electric vehicle battery pack, the short connector used for connecting two adjacent batteries in series can use a 0.2x6mm connector, however, for long-distance battery series connection and battery pack terminal output long battery connector, a 0.2x10mm battery connector is required.

The greater the resistance of the battery connector, the greater the line loss generated by battery connector, the maximum output capacity of battery will be reduced, and even heat will be generated when the battery pack is working, which will reduce product safety.

Calculation of resistance value of battery connector

Copper resistivity: 1.694uΩ.cm

Pure nickel resistivity: 6.9 uΩ.cm

Pure iron resistivity: 9.78 uΩ.cm

Al-Ni alloy resistivity: 1.6~3.6 uΩ.cm

According to R=ρL/S, that is, resistance=resistivity×length÷cross-sectional area, the resistance value of various battery connectors can be calculated, and then according to the size of the current to be passed. The two factors of mechanical tensile strength are used to select a suitable battery conductive connector. Of course, the cost factor also needs to be considered. In the above formula, the unit of R is Ω; ρ is the resistivity; L is the length in meters; S is the cross-sectional area of the conductor in mm².

The conductivity of a metal is inversely proportional to its resistivity, the greater the resistivity and resistance, the worse the conductivity. Moreover, the actual resistance of the metal material will increase compared to the theoretically calculated value due to its different purity, and the conductivity is the key factor of the connector.

Theoretical calculation of battery connector selection

When the 0.1x5x100mm long connecting piece flows through 5A and 10A current, the voltage drop generated by it is as follows:

| Battery connector types | Resistance value | 5A current voltage drop | 10A current voltage drop | Loss in parallel use | Loss in series use |

|---|---|---|---|---|---|

| Copper connector | 4.2mΩ | 0.21V | 0.42V | Very small | N series loss |

| Pure nickel connector | 16mΩ | 0.8V | 1.6 V | Comparatively small | N series loss |

| Nickel-plated connector | 25mΩ | 1.25V | 2.5 V | Small | N series loss |

| Al-Nickel alloy piece | 3.2~7.2 mΩ | 0.16~0.36 V | 0.32~0.72V | Very small | N series loss |

| Stainless steel connectors | 200mΩ | 1V | 2V | Larger | N series loss |

Example: 36V/10AH electric vehicle battery pack, if 10 pieces of nickel-plated iron pieces of 0.15x8mmx3cm are used for series connection, the total resistance of the battery connector is about 45mΩ. When the battery pack is working, if it is calculated with a discharge current of 10A.

It can be calculated that the total voltage drop line loss is about 0.45V, and the voltage drop value accounts for about 1% of the total voltage value, which is a reasonable choice. However, the loss calculated above does not include the loss of the parallel connection pads of each battery group, so the actual total loss of the whole group is about 1~1.5 times larger than the above value.

At the same time, the above assumptions are based on the average current value. In fact, when battery is used in quite a few occasions, the peak current flowing out is often several times or even ten times the average value. Therefore, attention should be paid when considering loss and instantaneous voltage drop, otherwise it will cause adverse effects on the startup of the product.

As can be seen from the above table, a battery connector with a smaller section size can be selected for parallel connection, but a battery connector with a larger section size must be selected for series connection.