Home » battery thermal management system » EV battery thermal management – essential for electric vehicles

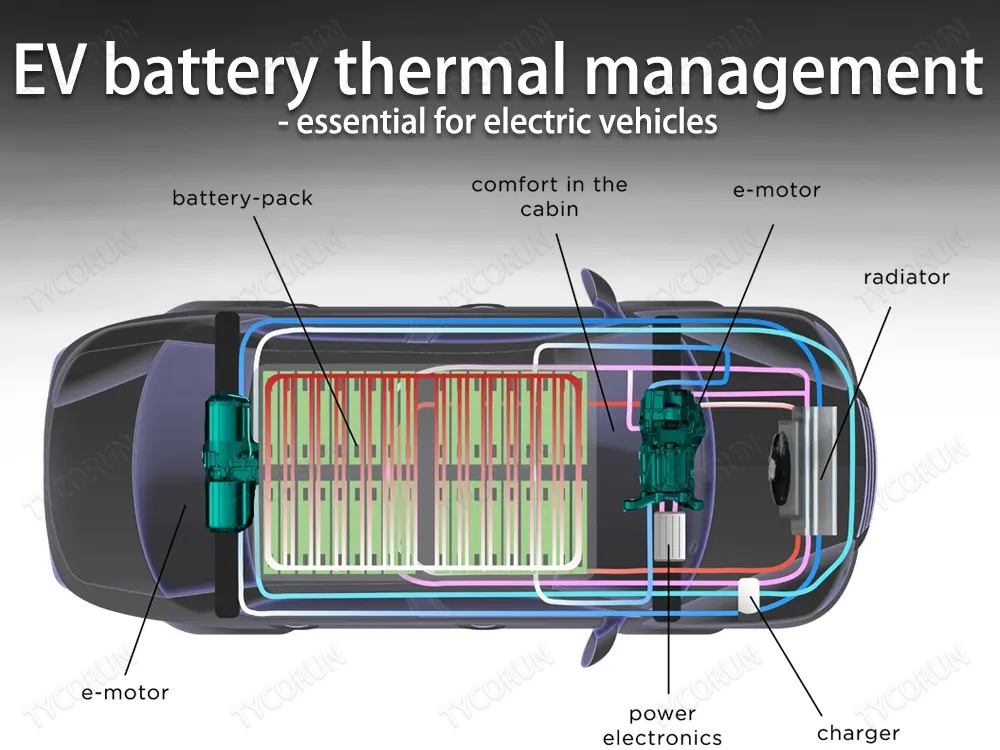

Ev battery thermal management - essential for electric vehicles

After lithium battery replacement lead acid, the development of electric vehicle batteries is getting faster and faster, and people’s improvement of battery thermal management technology is getting deeper and deeper.

In order to let more people understand battery thermal management technology. This article will analyzes and summarizes several common EV battery thermal management systems.

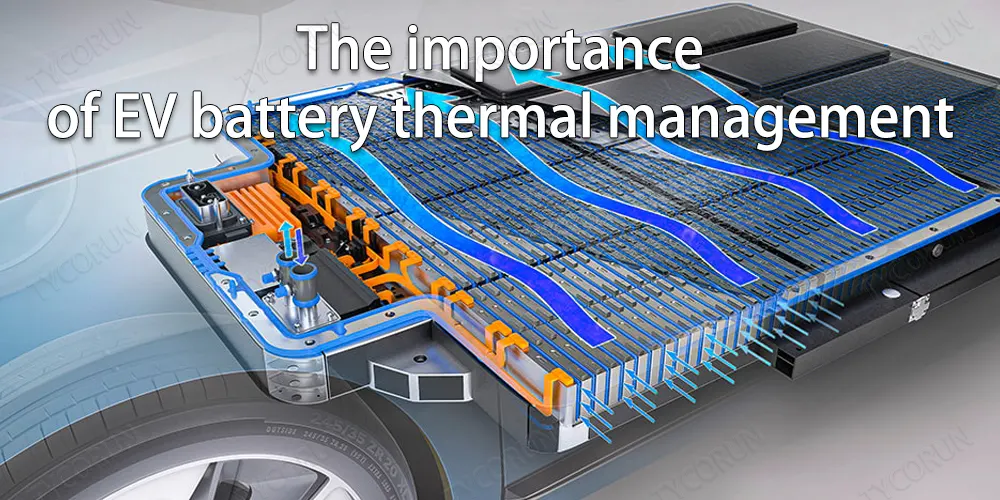

The importance of EV battery thermal management

In electric vehicle battery management, the thermal management system is one of the core components of the battery management system.

During normal operation, the battery of an electric vehicle will generate a lot of heat due to the intercalation and deintercalation of lithium ions inside the battery, the flow of current in the battery and battery pack, and various tiny side reactions in the battery.

If the heat is not discharged as soon as possible, it will accumulate inside the battery pack, which will increase the temperature of the battery. When the time is too long or the temperature exceeds the allowable upper limit, it will seriously affect the life of the battery and even directly cause the battery to short-circuit and explode.

In addition, when the lithium ion battery first charge is in a low temperature environment, lithium dendrites will appear. The growing dendrites risk piercing the separator and shorting the battery.

Therefore, the quality of the EV battery thermal management system is directly related to the safety performance and charging and discharging performance of the battery pack.

EV battery thermal management methods

The research on EV battery thermal management technology is currently mainly focused on how to export the heat generated by the battery during operation, so that the battery can work within the optimal temperature range.

The cooling methods currently applied to pure electric vehicles are mainly air cooling, liquid cooling, and direct cooling.

At the same time, the application of phase change materials in the thermal management of electric vehicle batteries is also a research hotspot. The main battery cooling types and research status are introduced in turn below.

Air cooling

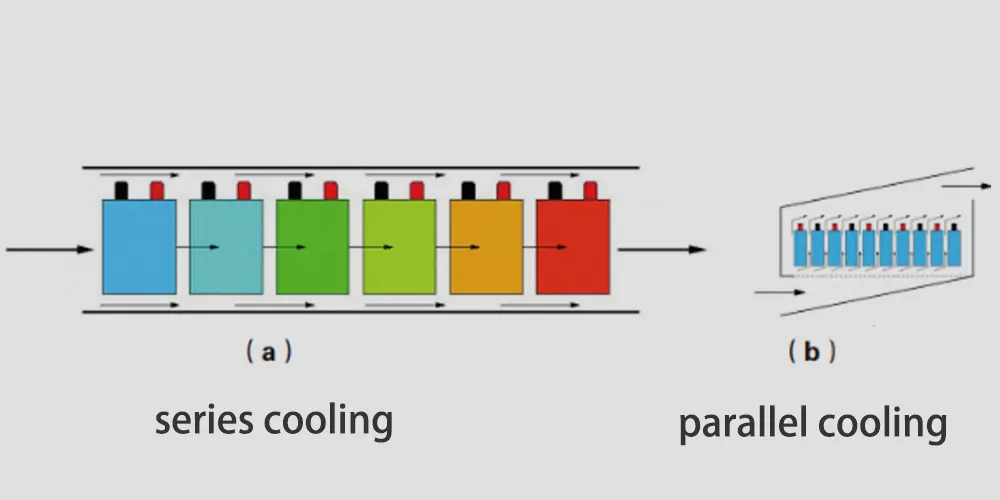

Air cooling is the earliest power battery cooling technology to be used. According to the flow power of the wind, there are two types of natural air cooling and forced air cooling, and based on the air channel of the air cooling system, there are two types of series cooling and parallel cooling, as shown below.

The advantage of the air-cooled system is that it is simpler in structure than liquid-cooled and direct-cooled systems, and has lower power consumption. However, due to the arrangement of its flow channels, the space utilization rate is low, and it is difficult to prevent water and dust.

In addition, when the outside air temperature is too high or too low, the thermal management system is difficult to meet the needs, and the air conditioning system is required to supply air for cooling.

Therefore, the cooling performance of the air-cooled system is difficult to meet the needs of use, and is gradually being replaced by liquid-cooled and direct-cooled systems.

Liquid cooling

Liquid cooling is the cooling method with the best overall performance. According to the structure, liquid cooling can be divided into direct contact and indirect contact. The direct contact type is to immerse the battery in the cooling liquid.

The advantage is that the heat exchange effect is excellent and the temperature uniformity is good, but the disadvantage is that it puts forward high requirements on the sealing and insulation performance of the inside and outside of the battery pack.

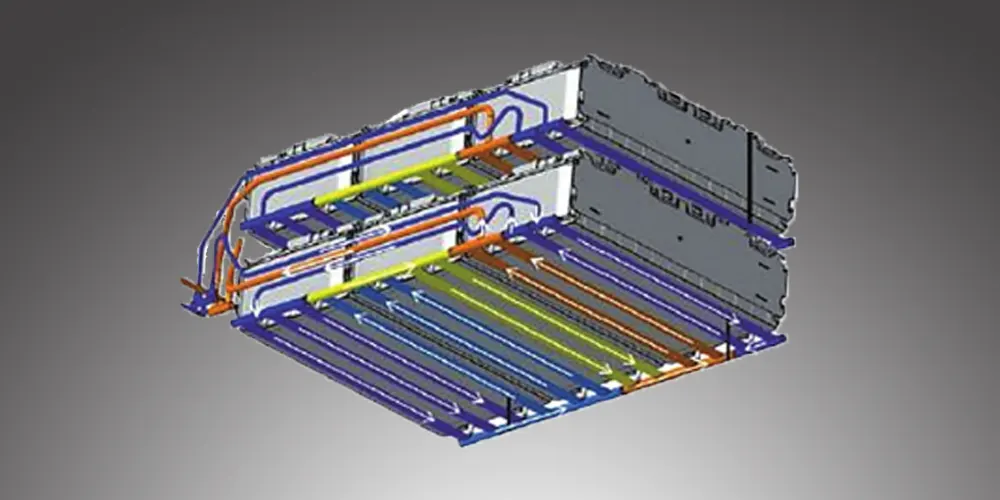

The indirect contact type is to lay a flow channel in the battery pack to make the coolant flow in the flow channel. The advantage is that it reduces the requirements for sealing and insulation performance.

The current research on the liquid cooling system mainly focuses on the optimization of the cooling plate and the arrangement of the cooling plate and the power battery. Top 10 power battery companies in the world have different cooling plate arrangements.

Direct cooling

Direct cooling is to directly introduce the refrigerant of the air conditioning system into the battery pack for cooling, which is equivalent to using the cooling plate in the battery pack as the evaporator of the air conditioning system.

The advantages of the direct cooling system are high efficiency, quick response, and large cooling capacity. Its disadvantage is mainly due to the high dependence on the car air conditioning system.

In summer, both the passenger compartment and the battery system require high-power cooling, resulting in a high load on the air-conditioning system.

In winter, because the passenger compartment needs to be continuously heated, and the battery pack needs to be preheated and then cooled, this poses a challenge to the car’s air-conditioning system.

Phase change material cooling

The thermal management method of the phase change material is to put the phase change material into the battery pack, and use its high phase change latent heat to absorb the heat generated when the battery is discharged.

The biggest advantage of phase change materials is that the structure and operation are the simplest, and only the batteries and phase change materials need to be reasonably arranged in the battery pack.

The whole process requires no external system intervention, and the temperature uniformity is excellent. Moreover, the phase change material has wide sources and low price.

The main disadvantages of phase change materials are: the volume and mass of the required phase change materials are large, which reduces the overall energy density of the battery pack.

Other thermal management systems

In addition to the cooling system mentioned above, heat pipe cooling is also a relatively popular research direction.

The principle of the heat pipe is that the material in the tube absorbs heat and evaporates in the high temperature area, and expands in the low temperature area to produce a volume change, thereby causing the spontaneous flow of the liquid in the tube.

The advantage of the heat pipe is that as long as there is a sufficient temperature difference between the high and low temperature areas, it can continue to carry out spontaneous circulation, and the heat transfer efficiency of the heat pipe is much higher than that of general heat-conducting materials measured in the laboratory.

However, the current application of heat pipes in battery thermal management systems is not perfect, so they have not been widely used in electric vehicles.

Battery pack heating

While studying how to dissipate the excess heat inside the battery, some scholars have noticed that when the electric vehicle is in a severe cold or low temperature environment, the service life and energy density of the battery are greatly affected.

Therefore, some scholars also focus on the research of heat preservation and heating of the battery pack.

The general direction is: wrap the insulation material outside the battery pack, arrange electric heating sheets between the batteries or let the heated coolant flow through the inside of the battery pack to complete the heating of the battery, etc.

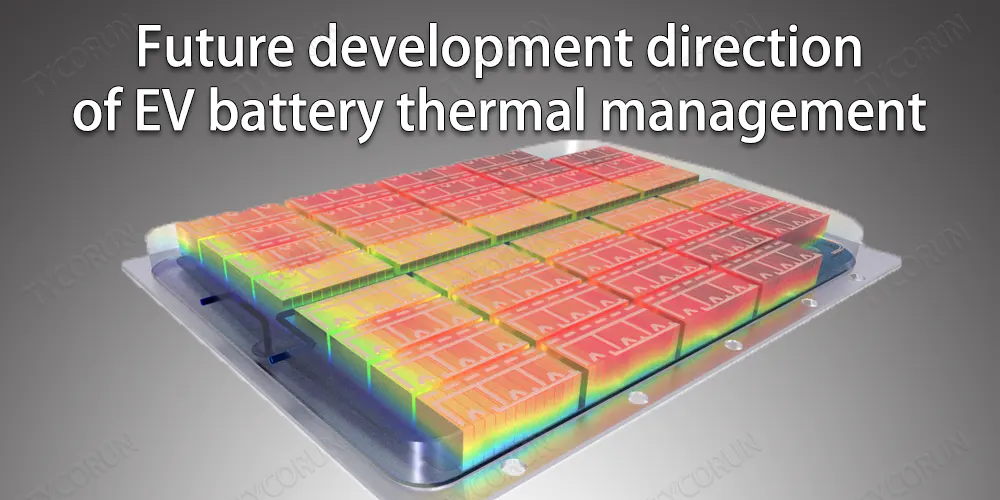

Future development direction of EV battery thermal management

EV battery thermal management system heating and cooling technologies are two important technologies to control the internal temperature of the battery, and are also the focus of research on EV battery thermal management.

The development status and future development direction of EV battery thermal management technology are summarized as follows:

(1) Air cooling technology improves the heat dissipation effect of the air cooling system by controlling the air volume and air pressure, changing the arrangement of the battery pack and the width of the air duct.

(2) When the EV battery thermal management system adopts heat pipe technology, the EV battery thermal management system coupled with heat pipe and liquid cooling has great development potential in the future.

(3) Compared with single phase change materials, the heat dissipation performance of the EV battery thermal management system using composite phase change materials is better. The research on the coupling of phase change materials and other cooling methods has more long-term significance;

(4) For the internal heating technology, the battery heating rate and safety can be improved by in-depth study of the current control strategy.

Summary

To sum up, the development of EV battery thermal management technology is crucial to ensure the safety and performance of electric vehicles.

With the development of various cooling methods such as air cooling, liquid cooling, direct cooling, phase change material cooling, and heat pipe cooling, the thermal management system of electric vehicle batteries can be more efficient and effective.

At the same time, battery pack heating is also an important research direction. In the research and design of the thermal management of electric vehicle batteries in the future.

It is necessary not only to make the thermal management system have better temperature control and temperature uniformity, but also to minimize the mass of the battery pack and reduce energy consumption.