Four new technologies of power battery - CATL vs BYD and SVOLT, EVE

In recent years, in addition to changing the internal chemical structure of the battery, major battery factories have also made great efforts in packaging technology. Today, let’s talk about the new technologies of CATL, SVOLT, BYD, EVE in the TOP 10 lithium Iron phosphate power battery manufacturers.

On April 25th, Leapmotor held the Leapmotor Intelligent Power CTC battery-chassis integration technology conference online. The chairman of Leapmotor Technology said that the intelligent power CTC technology will be freely shared and shared with the whole industry, and the latest achievements of self-research in the whole field will be shared with the whole industry.

At the meeting, the general manager of Leapmotor’s battery product line said that this technology innovated the installation process by redesigning the battery carrying tray, coupling the entire lower body chassis structure with the battery tray structure. By reducing redundant structural design, the number of components can be effectively reduced, and the body and battery structure can be complemented while improving space utilization and system specific energy.

In this way, the vertical space of the vehicle is increased by 10mm, and the battery layout space is increased by 14.5%. In addition, in terms of battery life, the technology is based on the economical management of energy consumption brought by the software application of AI BMS big data battery management system, and comprehensively increases the cruising range of the vehicle by 10%.

In addition, Leapmotor Intelligent Power CTC technology uses the body structure as the external structure of the battery pack, canceling part of the structural design of the battery pack. In this sense, the Leapmotor C01 equipped with Leapmotor’s intelligent power CTC technology will become the world’s first electric vehicle without an independent battery pack.

Taken together, this technology enables a new round of improvements in battery safety, battery life and battery performance. In fact, as early as 2016, Leapmotor began to develop the integrated technology of battery and chassis integration. The release of the intelligent power CTC technology also supplemented the last piece of the puzzle of Leapmotor’s intelligent power.

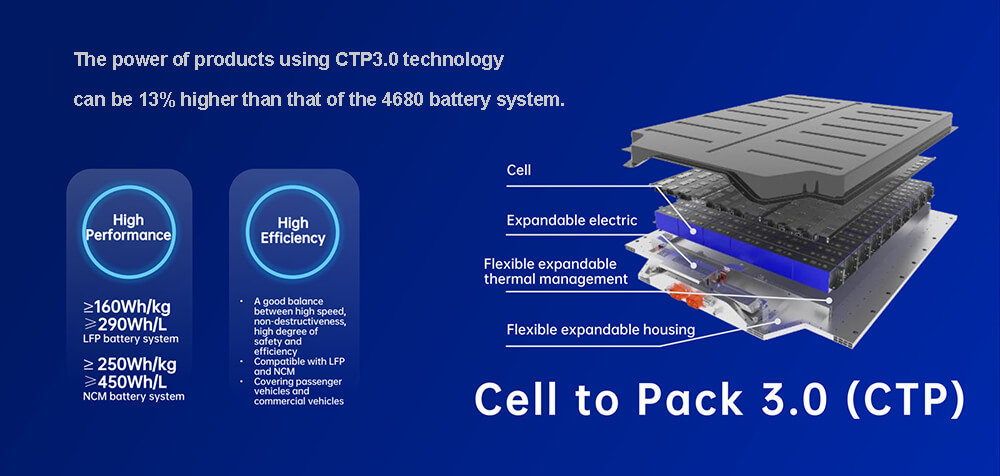

CATL – CTP3.0

In 2019, CATL debuted the CTP battery pack at the Frankfurt Auto Show, and immediately cooperated with BAIC New Energy and realized the first mass production model application.

It is reported that the first-generation CTP technology improves the volume utilization rate of the battery pack by 20%-30% by simplifying the module structure, which can greatly reduce the manufacturing cost of power batteries after being put into application.

In terms of energy density, the average energy density of traditional battery packs is 140-150Wh/kg, and the energy density of CTP battery packs can reach more than 200Wh/kg.

In March, Wu Kai, chief scientist of CATL, said that the third-generation CTP technology is ready for mass production and is expected to be officially launched in April this year. It can be applied to the company’s lithium iron phosphate batteries and ternary batteries, also known as “Kirin batteries”.

It is reported that CTP3.0 consists of a platform cell module, an expandable electrical module, a flexible and expandable thermal management module and a flexible and expandable box module.

Wu Kai also said that the energy density of lithium iron phosphate batteries using CTP3.0 technology can reach 160Wh/kg, and the ternary lithium battery can reach 250Wh/kg.

It is worth mentioning that, under the same conditions, the power of products using CTP3.0 technology can be 13% higher than that of the 4680 battery system.

SVOLT – knife battery

In April 2019, SVOLT publicly displayed a short knife battery with a length of 600mm. This battery has 4 sizes, ranging from L300-L600, can cover the global charging range of 1.6-4C, and can be applied to passenger cars, commercial vehicles, energy storage, construction machinery, non-high-speed trams and other global scenarios. And it can be applied to the global chemical system without cobalt, ternary and lithium iron phosphate.

According to reports, the short knife battery is based on laminated long and thin cells, and adopts the new PACK solution of LCTP. Compared with the traditional module battery pack, the space utilization rate of the matrix battery pack can be increased by 17%, and the volumetric energy density can be increased by 30%. Group efficiency increased by 12%.

The energy density is increased by 9%, the charge of the whole package is increased by 24%, the PACK components are reduced by 20%, and the cost is reduced by 10%. Knife battery has the advantages of high compatibility, high adaptability, high security and long life.

On the Battery Day in 2021, SVOLT announced that it will realize the short-cut of its global products in the future, and released the “Leader 600” strategy, proposing to increase the production capacity target to 600GWh in 2025, and to accelerate the commercialization of new types of short-cut batteries.

In 2021, SVOLT’s first-generation short-knife lithium iron phosphate battery L600 has been mass-produced at the Jintan factory in Changzhou, and the second-generation L600 with higher energy density will be mass-produced in 2022.

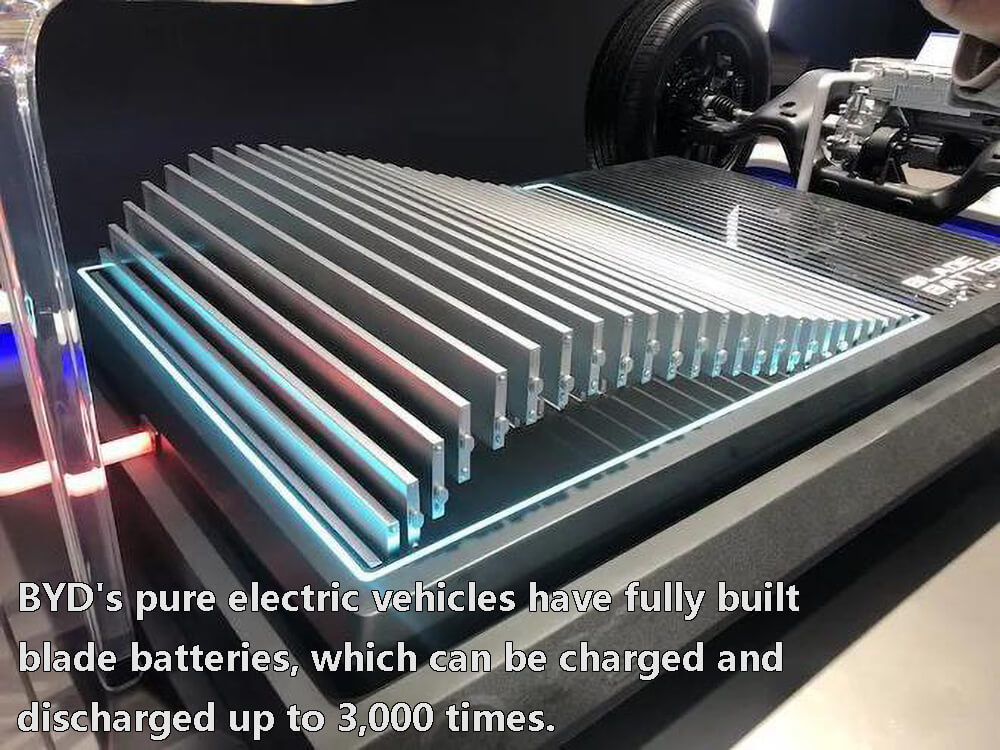

BYD – blade battery

In March 2020, BYD released a new generation of lithium iron phosphate battery products – blade batteries, which were first installed in BYD “Han” models.

Compared with the traditional power battery that produces cells by winding, the blade battery adopts the lamination process. The lamination structure has a more uniform current density and better internal heat dissipation performance, which is more suitable for high-power discharge.

And the attenuation of the battery is less than 20% after 4500 times of charging, and the lifespan is more than 3 times that of the ternary lithium battery.

In terms of performance, compared with the traditional square shell cells with modular battery packs, the blade battery has increased the volume utilization rate by more than 50%, and the volumetric energy density can be close to that of the 811 ternary lithium battery.

In terms of cruising range, according to the test, the blade battery can be charged from 10% to 80% in 33 minutes, and the BYD “Han” model equipped with it can complete the acceleration of 100 kilometers in 3.9 seconds.

In addition, the blade battery can be charged and discharged more than 3,000 times and can travel 1.2 million kilometers.

More importantly, Wang Chuanfu, chairman of BYD, said that the blade battery will completely erase the word “spontaneous combustion” from the dictionary of new energy vehicles.

According to the test video released by BYD, the blade battery has passed the “acupuncture test” perfectly. The acupuncture results show that after the acupuncture of the BYD blade battery, there is no open flame, no smoke, and the surface temperature is only 30-60 ℃, which verifies its high safety. specialty.

Today, BYD’s pure electric vehicles have fully built blade batteries, which can be charged and discharged up to 3,000 times. Up to now, BYD has no less than 10 production bases mass-producing blade batteries.

For customers, the entire FAW Hongqi E-QM5 series has been equipped with blade batteries, and a pure electric model of Changan, Jinkang and two models of BAIC are also equipped with blade batteries. There is also news that BYD may add two new customers of new energy vehicles, Weilai and Xiaopeng, to supply blade batteries for them.

EVE – large cylindrical battery

In April 2021, EVE announced to cooperate with foreign battery companies to provide assistance for the R&D and mass production of the latter’s 4680 batteries.

Then, EVE publicly stated that the company’s large cylindrical batteries include two types of 4680 and 4695, and the company’s large cylindrical materials have reached the extreme level of nickel 9 series. It is estimated that 20GWh of production capacity will be released in 2023, and the production capacity will reach 40GWh in 2024.

In 2021, at the opening ceremony of Jingmen Power Storage Battery Industrial Park, Liu Jincheng, chairman of EVE, said that the company will build a large cylindrical battery project in Jingmen, and Jingmen may be the first in the world to mass-produce 4680 and 4695 battery production base.

In November 2021, EVE plans to invest 6.2 billion yuan to build a 20GWh passenger vehicle large cylindrical battery production line and auxiliary facilities project, and a 16GWh square lithium iron phosphate battery production and auxiliary facilities project in Jingmen. It is estimated that the large cylindrical batteries constructed in this project are the 4680 and 4695 battery production lines.

If you don’t know what’s different about the new technology of 4680 battery, you can refer to the 4680 battery vs 18650 article.

Summarize

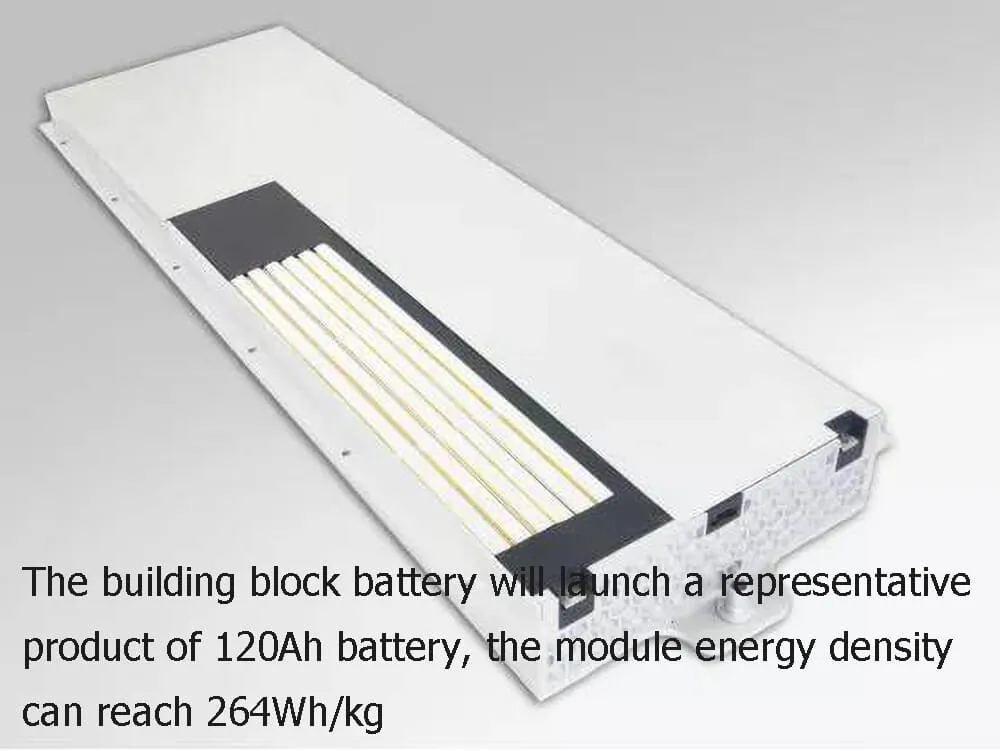

In addition to the above-mentioned four new power battery technologies, there are also building block batteries being developed by Gateway Power, hybrid solid-liquid batteries of Weilan New Energy, etc.

Among them, the building block battery of Gateway Power can achieve 300mm-750mm in length of battery cells and 7mm-18mm in thickness of battery cells according to different needs, which can increase the volume energy density of soft-pack cells by more than 10%, and reduce the cost by 10%-15 %.

According to the plan, the building block battery will launch a representative product of 120Ah battery, the module energy density can reach 264Wh/kg, and the cycle life exceeds 2000 times.

In general, on the basis of not changing the internal chemical composition of the battery, various battery manufacturers have come up with their own tricks, by changing the module technology, production technology and material state, etc.

Continuously improving the space utilization and energy density of batteries has jointly promoted the development of power battery technology and the rapid development of the power battery market.

2 thoughts on “Four new technologies of power battery – CATL vs BYD and SVOLT, EVE”

very good publish, i actually love this website, keep on it

I was recommended this blog by my cousin

You are wonderful! Thanks!