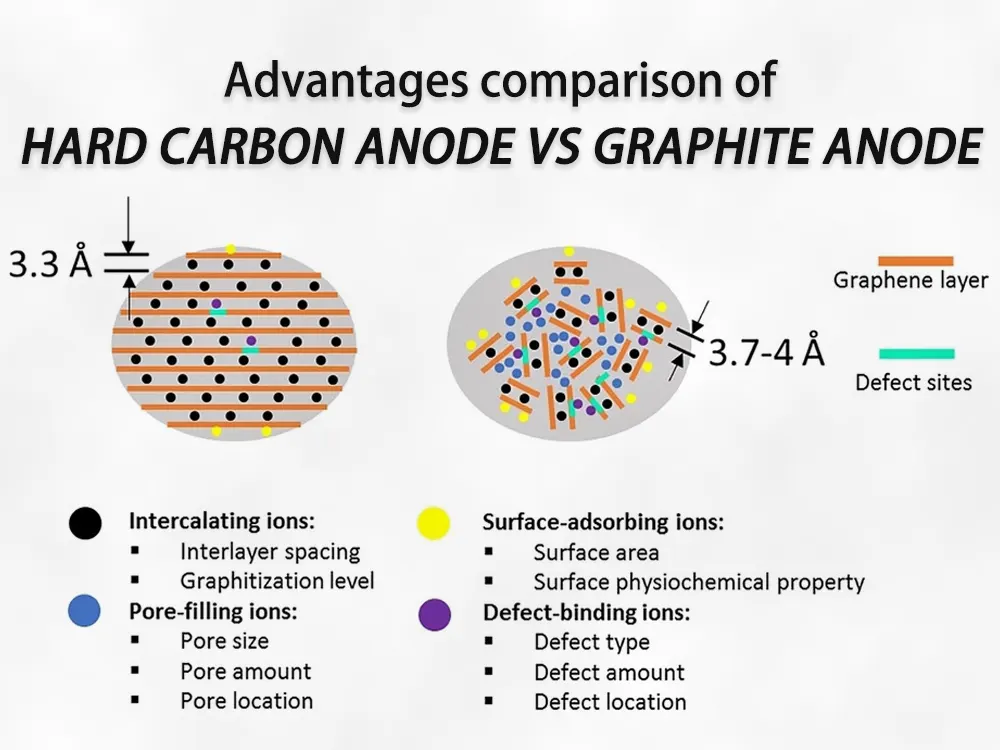

Advantages comparison of hard carbon anode vs graphite anode

In the selection of anode materials, hard carbon anode and graphite anode are two commonly used materials. In this article, comparing the advantages of hard carbon anode and graphite anode, their applicability in sodium batteries will be analyzed.

Advantages of hard carbon anode

Hard carbon anode, a carbon material produced by high-temperature pyrolysis, has been widely used in batteries because of its open pore structure, high specific surface area, and good electrical conductivity. Compared with graphite anode, the main advantages of hard carbon anode include the following points:

Higher specific capacity

The hard carbon anode has a higher specific capacity, that is, the material per unit mass can store more sodium ions. This feature allows the hard carbon anode to store more charge in the same volume, increasing the energy density of the battery.

Better cycle stability

Due to the open pore structure of hard carbon, which can accommodate more sodium ions, the expansion/shrinkage of the electrode during charge/discharge is more uniform, thereby improving the cycle stability and lifespan of hard carbon anode.

Lower cost

Compared with graphite, the production cost of hard carbon anode is lower, and the raw materials are easier to obtain, which makes the hard carbon anode have lower cost and stronger market competitiveness in the production of sodium batteries.

Advantages of graphite anode

Graphite is a natural carbon material that is also widely used in batteries due to its high electrical conductivity and high chemical stability. Compared with hard carbon anode, the main advantages of graphite anode include the following:

Higher specific conductivity

Graphite has a higher specific conductivity and can transport charges faster, which means that graphite anodes can support higher charging rates and faster charge/discharge responses, thereby increasing the output power of sodium batteries.

Better physical stability

Compared with hard carbon anode, graphite anode has better physical strength and stability, so it is less prone to deformation and fragmentation, thereby improving the safety and service life of batteries.

Hard carbon anode vs graphite anode – which one is better for sodium batteries?

In general, both hard carbon anode and graphite anode have their unique advantages, so choosing which material to use as the anode of sodium batteries needs to consider multiple factors. Generally speaking, if higher energy density and better cycle stability are required, hard carbon anode is more suitable. If higher output power and better physical stability are required, graphite anodes are more suitable.

In addition, factors such as material cost and sustainability need to be considered. As mentioned earlier, the production cost of hard carbon anode is lower, and the raw materials are easier to obtain, so it is more sustainable in the production process. Therefore, in some application scenarios that pursue low cost and sustainability, hard carbon anode may have more advantages .

It should be pointed out that the choice between hard carbon anode and graphite anode is not an either-or relationship, but needs to be considered comprehensively according to specific application scenarios and needs. For example, in some demanding applications, a hard carbon anode can be combined with a graphite anode to achieve better battery performance.

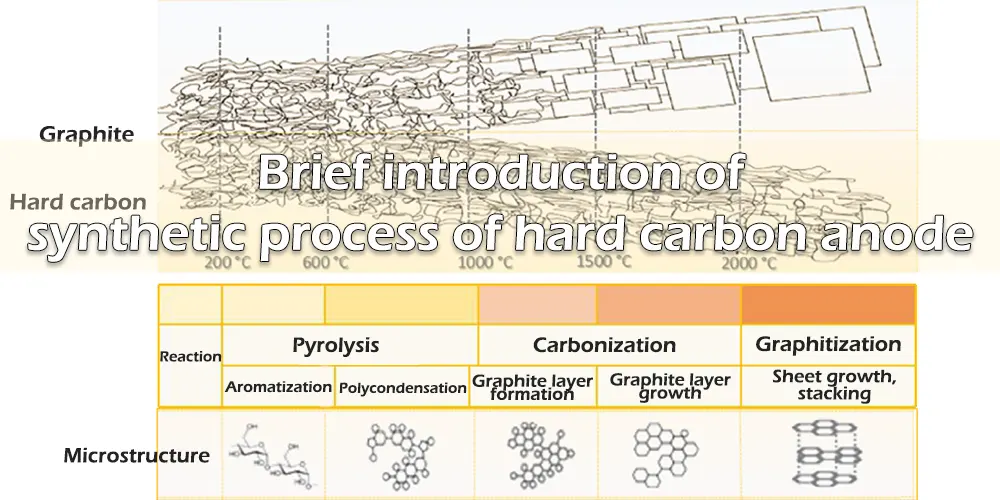

Brief introduction of synthetic process of hard carbon anode

Different from the synthesis of lithium ion batteries such as lithium ion golf cart batteries, lithium ion motorcycle battery, etc. anode material graphite, the synthesis of hard carbon anode needs to go through processes such as aromatization, polycondensation, graphite layer formation, graphite layer growth, and sheet growth stacking.

Artificial graphite mainly uses chemical raw materials such as needle coke, petroleum coke and pitch. These raw materials can appear in a molten state in a wide temperature range during the carbonization process, so that the carbon layers can be rearranged to form a long-range ordered sheet structure.

The organic precursors used in hard carbon anode mostly have branched chain structures containing groups such as oxygen, sulfur, and nitrogen. In the process of carbonization, cross-linking forms a new network structure, which is not conducive to the rearrangement of carbon layers, so it is impossible to form a long-range ordered graphite sheet structure. The precursor raw materials used in hard carbon anode are mainly biomass, resins and polymer precursors.

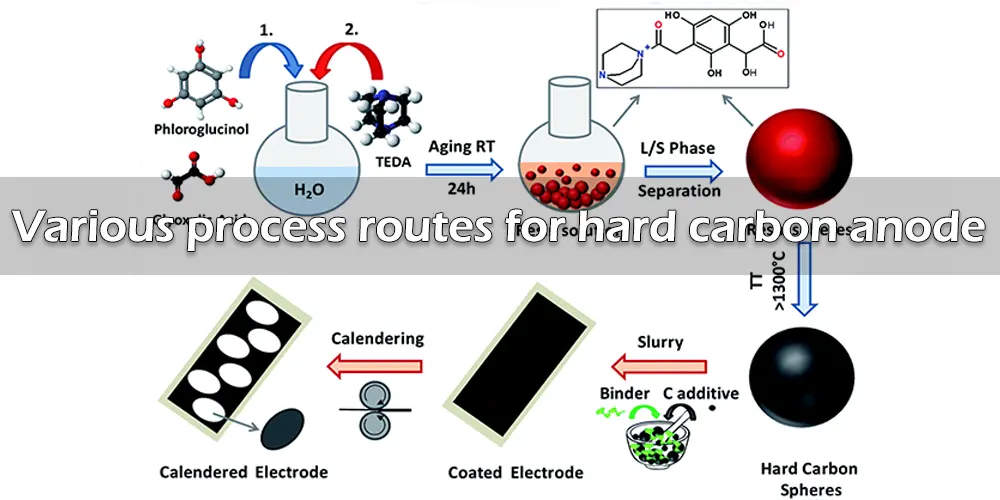

Various process routes for hard carbon anode

At present, the commonly used hard carbon anode precursors are mainly bio-based polymer materials, such as moso bamboo, coconut shell, starch, walnut shell, etc. At the same time, chemical raw materials such as anthracite, pitch, and phenolic resin can also be used.

The hard carbon anode products obtained from different precursors have significant performance differences, and the source of raw materials is different, and the cost structure is also significantly different. The hard carbon anode process is multi-channel parallel, and the anode companies each show their capabilities.

The hard carbon anode precursor used by Kuraray is coconut shell, a biomass material. The hard carbon anode processes of Chinese traditional top 10 anode manufacturers BTR, Shanshan, SHINZOOM and Shenzhen Xfh Technology include bio-based materials, resin-based materials and asphalt-based materials, realizing a systematic patent layout.

BEST GRAPHIET, as a hard carbon anode company that benchmarks against Kuraray, focuses on the preparation of hard carbon materials from biomass materials such as glucose, starch, lignin, and coconut shell. Yuanli uses raw materials such as moso bamboo, coconut shells and rice husks. SQ GROUP uses straw.

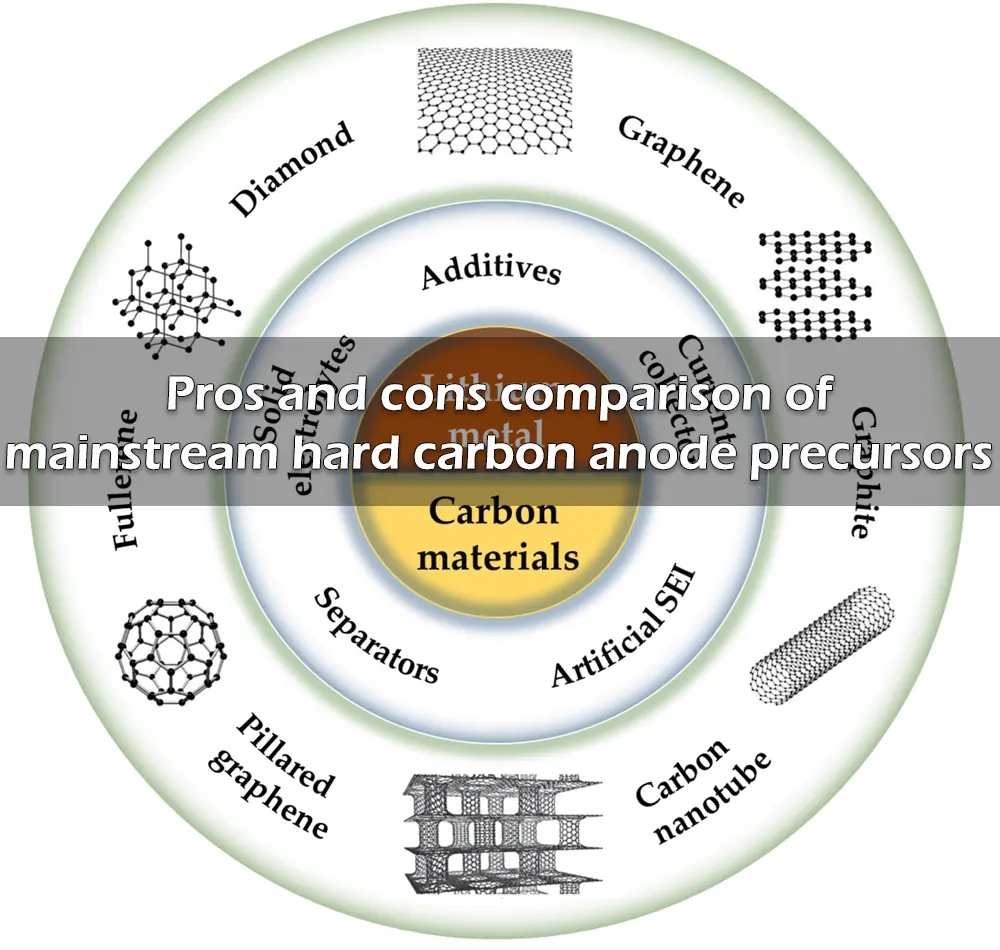

Pros and cons comparison of mainstream hard carbon anode precursors

Coconut shell biomass material is one of the earliest hard carbon anode precursors to be industrialized. This kind of material exists widely in nature, and has less impurities, and its own strength is relatively high, which can bring a stable structure to hard carbon anode products. However, China currently has insufficient supply of coconut shell raw materials for the production of hard carbon anode and needs to rely on imports.

Polysaccharide biomass materials such as starch are widely used as raw materials, low in price, and can be naturally degraded. They have an advantage in environmental protection. At present, the main problem is that the process cost is high, and additional additives such as cross-linking agents or hydrogenation modification are required.

The hard carbon products obtained from phenolic resin precursors have better uniformity and higher purity. The products are generally spherical particles, and because the raw materials are controllable, the design of the process is strong, but the disadvantage is that the cost is high.

The sources of asphalt-based materials are very wide and the price is low, and both coal-based asphalt and oil-based asphalt can be used. But the disadvantage is that there are more volatiles in the asphalt, which requires additional tail gas treatment, which increases the cost, and the current process is not yet mature, and the capacity of the product is low.