Home » electric car battery » How EV works – working principle and characteristics

How EV works - working principle and characteristics

Although EV (electric vehicle) has been around for many years, people are still relatively unfamiliar with them compared to traditional fuel vehicles.

How does EV work? And how are is it structurally different from fuel vehicle? Can EV be simply understood as a combination of batteries and the car? This article takes pure EVs as an example to tell you the working principles and structural characteristics of how EV works.

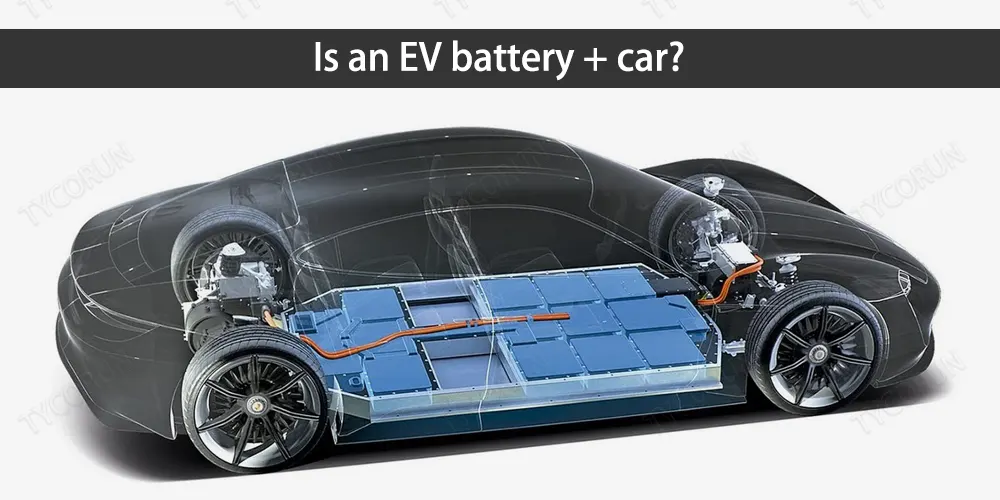

Is an EV battery + car?

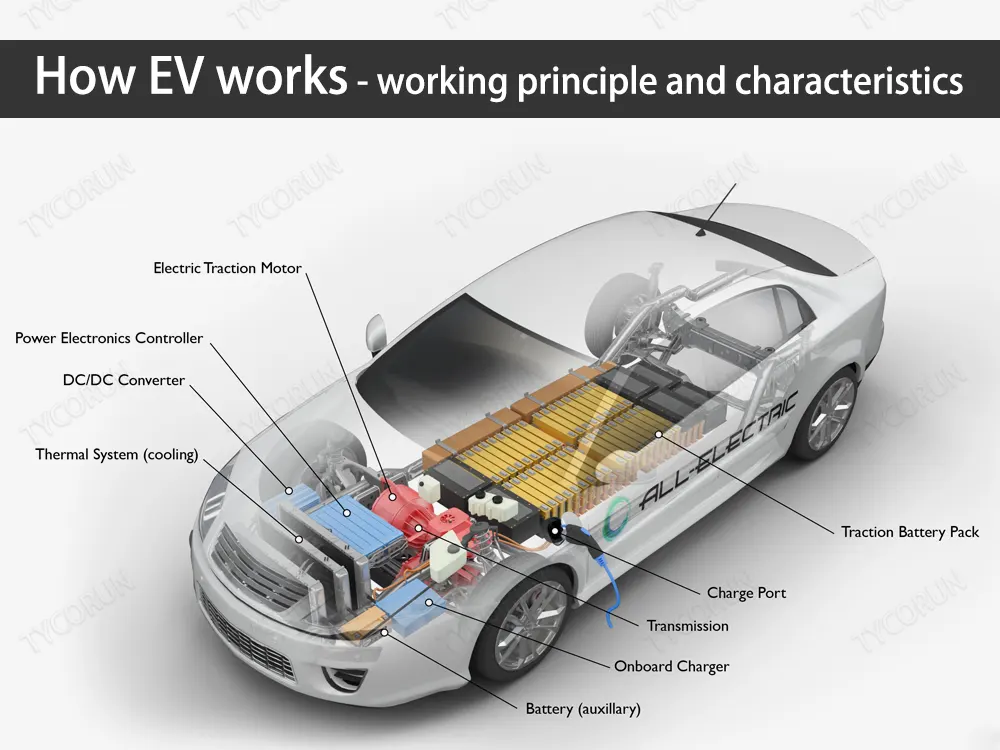

Pure EVs are not simply composed of batteries and the car. Pure EVs are mainly composed of three parts: electric drive system, power supply system and auxiliary system. Electric drive systems include controllers, power converters, electric motors, mechanical transmissions, and wheels, etc., and they all affect how EV works.

Electric motor: The electric motor is like an engine in the traditional fuel vehicle. Its main task is to efficiently convert the electrical energy stored in the power battery into the kinetic energy of the wheels to drive the vehicle under the control of the driver, or to convert the kinetic energy on the wheels during braking. It is converted into electrical energy and fed back into the power battery to realize braking energy recovery of the vehicle.

Controller: The controller is like the nerve center of the human body. EVs must coordinate and control each subsystem through a vehicle control system to achieve the best performance of the vehicle.

Power system: The power system includes battery pack, battery management system (BMS), etc.

Auxiliary systems: An auxiliary system includes auxiliary power sources, power steering systems, air conditioners, lighting devices, etc.

The working principle of how EV works is: battery pack (provide electrical energy) → controller, power converter (control the speed) → drive the motor → transmission system (drive the wheels) → drive the car.

Structural difference between EV and fuel vehicle

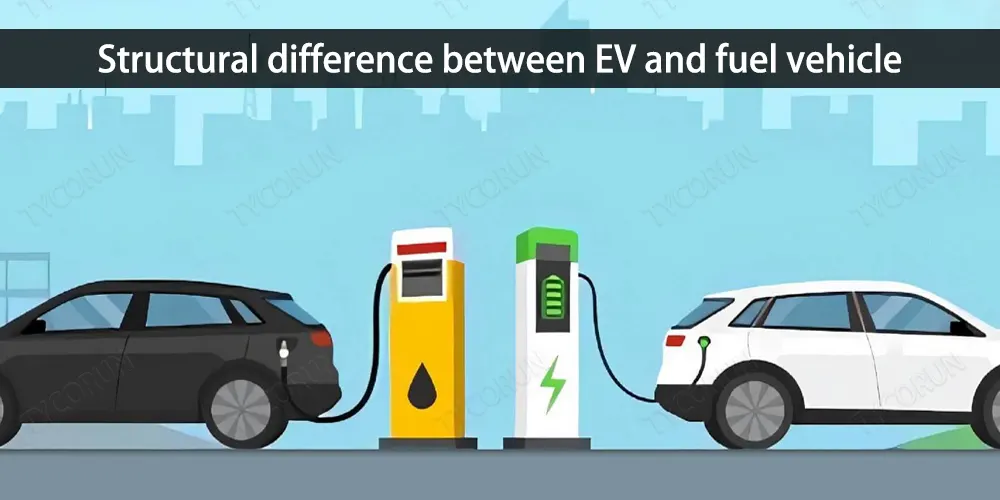

The biggest structural difference between pure EVs and fuel vehicles lies in the power system and energy supply system. Compared with fuel vehicles, the most important change of how EV works is to replace the internal combustion engine and fuel tank of fuel vehicles with matching batteries, electric motors, speed regulators and other related equipment.

Pure EVs do not have an engine to support how EV works, so engine-related parts on fuel vehicles are eliminated. For how EV works, there is no need for parts such as engine, transmission, fuel tank, fuel supply device, fuel injection device, spark plug, intake pipe, exhaust pipe, three-way catalytic converter, muffler, or even the air intake grille on the front of the car.

The electrical components added to pure EVs mainly include batteries, motors, controllers, etc. Pure EVs use electric motors instead of engines, and use controllers to control vehicle operation.

A comparison found that there is no visible difference in appearance between pure EVs and fuel vehicles (except for the exhaust pipe), but the internal structure of pure EVs is relatively simple, with much fewer parts than fuel vehicles, making maintenance easier.

How EV works – speed change

Different from the complicated gear change process of a fuel vehicle, the speed change of an EV is somewhat similar to the volume of the sound on a mobile phone. By adjusting the volume button, the sound of the mobile phone can be made louder or smaller. In electric vehicles, the driver also changes the vehicle speed by manipulating the brake pedal and accelerator pedal, which actually controls the amount of electric energy.

The process of how EV works on the speed change is as below:

The driver presses the accelerator pedal → the sensor detects the movement of the pedal → the value is transmitted to the electronic control system → the electronic control system issues instructions to the motor controller → the motor controller calculates various indicators of the motor → controls the operation of the motor.

When the accelerator pedal is pressed lightly, the battery discharges less current. When the accelerator pedal is pressed hard, the discharge current of the battery will be large. The same is true when decelerating, as all demands are ultimately transferred between components within the car in the form of controllable electrical energy.

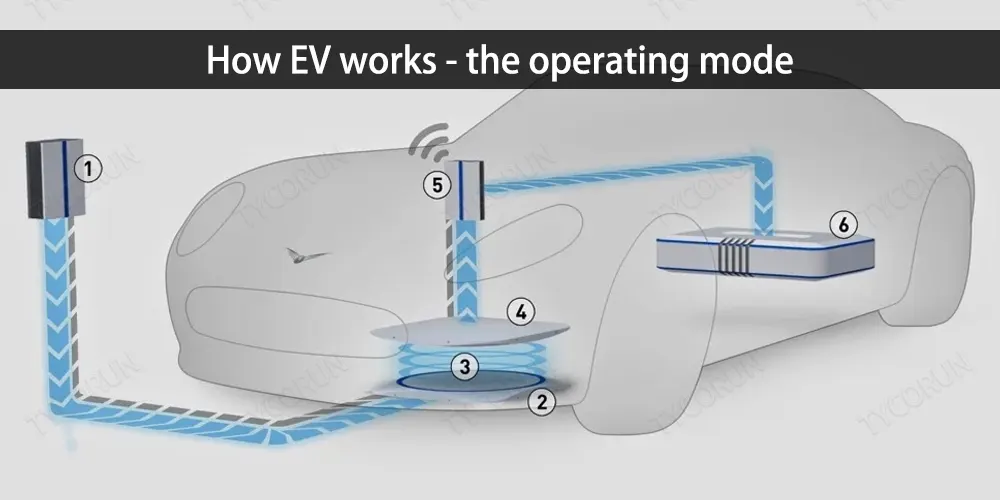

How EV works – the operating mode

Drive the motor

The configuration of the electric drive unit of a pure EV is the same as that of a full hybrid vehicle. The high voltage battery supplies energy to the power electronic components, which convert DC voltage into AC voltage to drive the motor.

Regenerative braking

If a pure EV “coasts” (the vehicle moves without drive torque from the electric motor), part of the thermal energy is converted into electrical energy by the electric motor acting as an alternator and charging the high-voltage battery.

External charging

The high-voltage battery is charged via charging contacts on the vehicle. When an external charging power source is connected, the vehicle will automatically charge according to the previously set value. The process is completed automatically. If electrical devices are used during charging, they will be powered by the charging voltage.

Vehicle temperature control

If a pure EV is in a traffic jam, there is no need for the motor to output energy. A high-pressure heating system and a high-pressure air conditioning compressor will meet the comfort needs of the occupants.

How EV works – the power battery

As the energy source of EVs, power battery technology has been one of the key factors affecting how EV works since its birth. Improving power density, energy density, service life and reducing costs have always been the core of the research and development of electric vehicle power battery technology.

After power batteries have experienced the development and exploration of various types such as lead-acid batteries, nickel-cadmium batteries, and nickel-hydrogen batteries, lithium-ion power batteries have gradually become more popular due to their high energy density, strong high-power charging and discharging capabilities, and no pollution to the environment, becoming the first choice for the power of how EV works.

The current lithium-ion power battery is a new concept battery developed on the basis of secondary lithium battery technology. It solves the two technical problems of poor safety and short charge and discharge life of secondary lithium batteries in principle. Currently, many EV manufacturers around the world are using lithium-ion batteries.

At present, the recycling and utilization of power batteries mainly includes two aspects: the cascade utilization of power batteries and the resource recycling of used batteries.

EVs have high requirements for power wheels battery performance. Generally, when the energy stored in the battery is only about 80% left of the factory state, it is no longer suitable for high-performance electric vehicles.

However, these batteries can continue to be used in low-speed electric vehicles or as energy storage batteries in power plants, especially in the fields of wind power generation, solar power generation and new energy generation, and can also be used for storage in homes or other buildings.

When the battery can no longer be used at all, it will enter the scrapping process. The content of non-ferrous metals in used power batteries is much higher than the industrial quality of primary ores, so the resource recycling of used batteries has very important economic and social significance.

Can solar batteries work with an EV?

Replacing traditional fuel-driven vehicles with clean and renewable solar power has been the dream of generations of car designers, and there have been various experimental attempts.

However, it will take some more time to realize this battery solution. Because under the current technical level, the power generation of solar photovoltaic cells is about 180 watts/square meter. If calculated based on 8 hours of sunlight per day, the daily power generation of solar cells per square meter is only 1440 kilowatt hours. And the impact of azimuth, tilt angle and shadow at which solar panels can obtain the best sunlight has not been calculated here.

Therefore, based on the current technical level, solar power generation cannot be used as the main energy source supporting how EV works. But it is possible to use solar energy as an auxiliary energy source for cars. For example, the solar device installed on the car can be used to provide electric energy for on-board appliances, or the solar skylight control system can be used to automatically adjust the temperature inside the car when parking.