Mainstream production process of lithium iron phosphate

What is lithium iron phosphate

LiFePO4 batteries have outstanding advantages in terms of safety, cost, high-temperature performance, and cycle performance. They are ideal cathode materials for commercial electric vehicle power lithium-ion batteries, and they also widely used in the field of energy storage, such as home backup power supply powerwall battery, portable battery station and large energy storage power station, etc.

The performance of the LiFePO4 cathode material depends to a certain extent on the shape of the material, the size of the particles and the arrangement of atoms, so the preparation process is particularly important.

At present, the mainstream processes for industrial production of lithium iron phosphate include: ferrous oxalate method, Iron oxide red method, full wet method (hydrothermal synthesis), iron phosphate method and autothermal evaporation liquid phase method. Among them, the ferrous oxalate process is the most common preparation process in the early stage, and the cost of LiFePO4 under this route is relatively high.

The full wet process is a relatively advanced preparation process, but this process needs to be reacted under high temperature and high pressure, which is not conducive to industrial production. LiFePO4 prepared by the iron red process usually has poor performance, and the iron phosphate process is most likely to develop into a standard process for the preparation of lithium iron phosphate.

Ferrous oxalate method

The ferrous oxalate method is a common preparation process in the early stage. Lithium carbonate and lithium hydroxide are used as lithium sources, and ferrous oxalate is used as iron source, after ball milling and drying the raw materials, in an inert gas or reducing atmosphere, accelerate heating to a certain temperature with a certain temperature rise, and react for a period of time to cool down.

Advantages: simple process, easy to realize industrialization

Disadvantages: The particle size is not easy to control, the distribution is uneven, the shape is irregular, and the synthesis process requires inert gas protection.

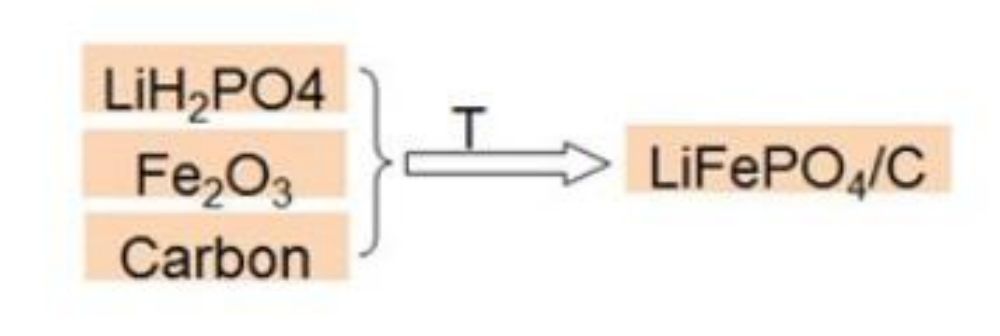

Iron oxide red method

Iron oxide red powder preparation

1. Add sulfuric acid to dissolve scrap iron to obtain FeSO4

2. Add NaOH, react with FeSO4 to get precipitated Fe(OH)2

3. Fe(OH)2 is decomposed into Fe2O3 after sintering

4. Remove Na impurities in Fe2O3 by washing with water

Lithium iron phosphate preparation

1. Disperse and grind iron oxide red powder with ammonium dihydrogen phosphate and lithium carbonate

2. Spray drying

3. High temperature sintering for reaction

4. Grinding to produce LFP

High-speed mixer FRM series

Circulating stirring ball mill QX series

Advantages: low raw material price, improved electrical conductivity of the material

Disadvantages: sulfuric acid is used, which is not easy to control; a large amount of waste water needs to be discharged during the process, and a large amount of ammonia gas is generated at the same time, which is difficult to handle and has great pressure on environmental protection.

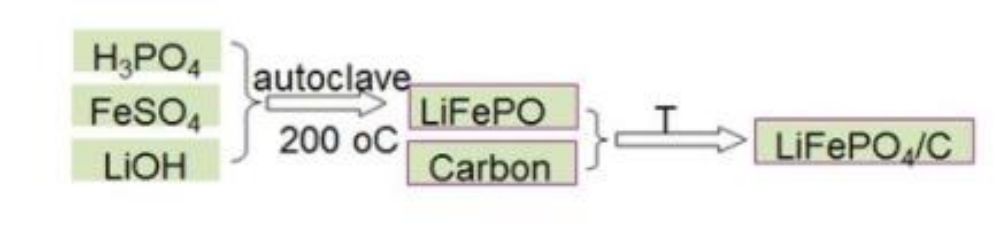

Full wet method

The full wet method (hydrothermal method) is a relatively advanced preparation process. It is a process in which ferrous sulfate, lithium hydroxide and phosphoric acid are dissolved in water or other solvents, and the reaction is carried out through a hydrothermal process to synthesize LiFePO4.

High temperature coating machine VCJ series

Advantages: uniform phase, small powder particle size, easy operation, good batch stability, cheap and easy-to-obtain raw materials, no inert atmosphere required.

Disadvantages: uneven particle size, impure phase, large equipment investment and complicated process

Iron phosphate method

Iron phosphate preparation

1. Add sulfuric acid to dissolve scrap iron to obtain FeSO4

2. Add (NH4) 3PO4 to react with FeSO4 to get precipitated FePO4

Lithium iron phosphate preparation

1. Dispersion and grinding of iron phosphate and lithium carbonate or lithium hydroxide

2. Spray drying

3. High temperature sintering for reaction

4. Grinding to produce LFP

Rod pin dispersing Mill SMLYU series

Advantages: good cycle performance, low price

Disadvantages: long production cycle, high energy consumption, serious pollution, poor batch stability

Autothermal evaporation liquid phase method

1. Preparation of ferric nitrate

● Add nitric acid, react with pure iron to obtain Fe(NO3)3, and discharge nitric oxide

2. Lithium nitrate preparation

● Add nitric acid, react with lithium carbonate to generate lithium nitrate, and discharge a small amount of carbon dioxide

3. Preparation of lithium iron phosphate

● Add iron source and phosphorus source to lithium nitrate, heat and react to generate LiFePO4 NH3, and discharge nitrogen dioxide

● Fluidized bed drying

● Roller kiln sintering, decompose LiFePO4·NH3 to obtain LiFePO4

● Jet crushing

Advantages: excellent low temperature performance, good cycle performance, low energy consumption, good batch stability

Disadvantages: Pure iron has no obvious price advantage, nitric acid has strong oxidizing and corrosive properties, and is difficult to control, and the nitric oxide and nitrogen dioxide discharged from the reaction are toxic gases, and the environmental protection pressure of this process is huge. The process is complicated, which is not conducive to cost control.

Stirring ball mill SX series

Introduction of lithium iron phosphate new technology

At present, the profit margin of LiFePO4 is being continuously compressed, and there is an urgent need for new processes and new products for the preparation of low-cost iron phosphate.

New technology introduction:

1.Preparation of iron phosphate from waste iron and phosphoric acid

Fe+2H3PO4→Fe(H2PO4)2+H2

Fe(H2PO4)2+oxidizing agent→FePO4

2.Preparation of LFP by iron phosphate and lithium source

2FePO4+Li2CO3 +2C→2 LiFePO4+C02+C0

3.Large-scale equipment (such as large-scale sand mill, large-scale spray drying, which helps to increase unit production capacity)

Advantage:

● Wide range of scrap iron sources and low prices

● Phosphoric acid has no strong oxidizing and corrosive properties, and is a relatively safe acid that is easy to control

● No poisonous and harmful gas emissions, low pressure on environmental protection

● The process flow is simple and the production cost advantage is obvious

● The cost of LFP prepared by this process can be controlled at 20,000 RMB/ton

Nanoparticle disperser VSM series

The new process reduces the pressure on environmental protection by changing the iron source preparation process, so that the production cost of iron phosphate is significantly reduced, and the preparation process is simple.

With the characteristics of its products that can realize high-power fast charge and discharge, adapt to ultra-low temperature and harsh conditions, safety, reliability, long life, and relatively low cost, the technological level is in the leading position in the world.