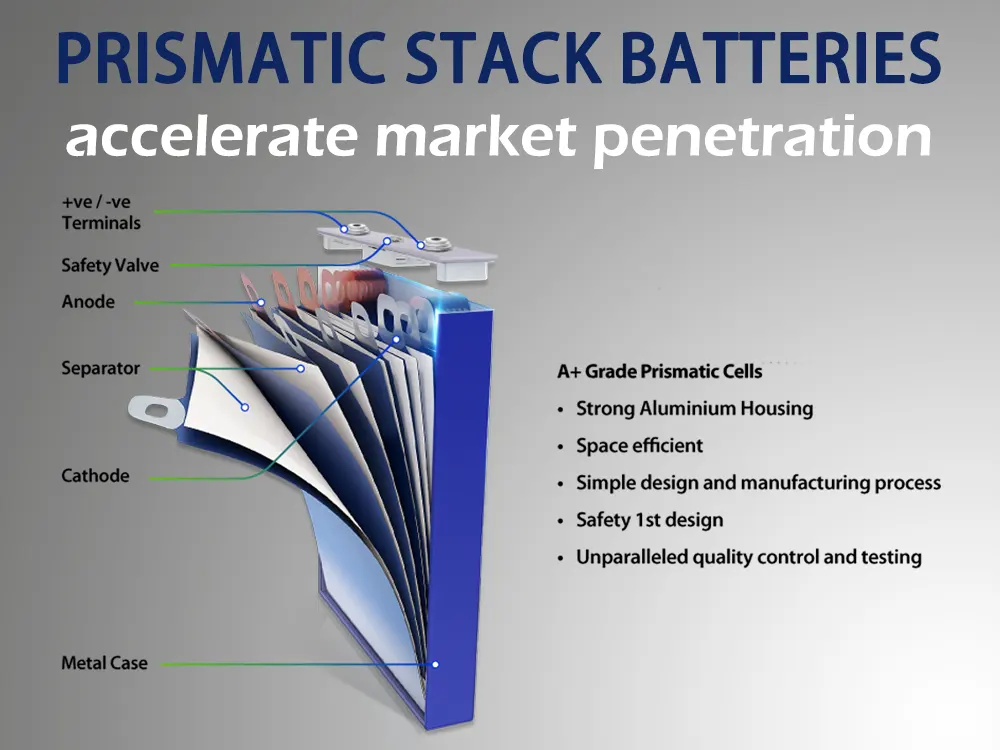

Prismatic stack batteries accelerate market penetration

Development trend of battery technology

In terms of the battery technology route proposition, Tesla particularly respects the 4680 all-tab large cylindrical battery. In a public statement in January this year, Tesla said it would expand the 4680 battery factory in Nevada, with a planned annual production capacity of 100GWh. The 4680 battery is not only used in electric vehicles, but will eventually be used in Tesla’s energy storage products.

Driven by the Tesla effect, all-tab large cylindrical batteries have become one of the mainstreams of emerging battery technology development. At present, battery companies including CATL, EVE, Envision, HITHIUM, etc. are also making layouts around the manufacture and mass production of large cylindrical batteries with full tabs.

At the same time, Chinese power battery companies, which lead the global battery innovation, have also opened up another emerging battery technology development direction – “long and thin batteries + stacking technology”.

Review the development history of prismatic stacking technology, which can be traced back to 2018. At the beginning of its establishment, SVOLT took the lead in applying the lamination process to the manufacture of prismatic batteries, and introduced car-grade standards, thus opening the era of power battery stacks.

At present, among the top 10 power battery companies in the world, prismatic stacking has become the general consensus and mainstream choice of the industry. BYD, SVOLT, CALB, EVE, and Sunwoda, which mainly focus on the square route, are gradually adopting the lamination process.

Like the 4680 large cylinder, the application of prismatic stacking battery also covers multiple application scenarios such as power, energy storage, and fast charging. Two different technical routes will also compete in diversified application scenarios in the future.

The production capacity of prismatic stacking has been accelerated

Compared with large cylindrical batteries, which are still in the early stage of mass production, prismatic stacking batteries are performing faster in terms of market penetration and production expansion speed, and the production capacity of prismatic stacking batteries is growing rapidly.

Among them, some production lines of CALB in Changzhou, Xiamen, Wuhan, Hefei, Jiangmen and other production bases produce One-Stop (referred to as “OS”) batteries and all-tab stacking batteries. The demand for the purchase of stacking equipment for the two product lines is strong. It is worth mentioning that the OS product of CALB’s new product also adopts the stacking process.

SVOLT’s new expansion capacity is mainly “short blade”. At present, SVOLT’s L600 short blade lithium iron phosphate battery has been equipped with some models of Great Wall. On the third battery day, SVOLT released the flying stack based on ultra-high-speed stacking technology 3.0, and the dragon scale battery based on LCTP3.0 of short blade battery.

In addition to the power field, the application of prismatic stacking batteries in the energy storage market is also accelerating. At present, BYD’s energy storage cells are mainly prismatic stacking batteries. BYD has also publicly stated that blade batteries will be used in energy storage products in the future.

The new generation of ultra-large battery cell LF560K released by EVE has solved the technical problems of LF560K energy storage battery in the design and producibility of electronic conductance current collection through a breakthrough in the stacking process.

On the whole, the mass production of new-generation products of CALB using the stacking process, the global short-blade strategy of SVOLT, and the blade battery strategy of BYD’s entire series all indicate that the stacking route has become the mainstream choice of many leading power battery companies.

As the penetration rate of stacking technology continues to increase, the application proportion of long and thin prismatic stacked batteries is expected to tend to the mainstream of the market. The industry predicts that the global demand for long and thin prismatic stacking batteries is expected to exceed 1000GWh in 2025.

Leaps in efficiency of stacking battery process

It is possible to form a major emerging technology route that can compete with the large cylinder with full tabs, and the layout of the “long and thin battery cell + stacking” technology route reflects the forward-looking vision of Chinese power battery companies to gain insight into the industry. At the same time, the reason why the prismatic stacked batteries can be introduced into the market faster than the full tab and large cylinder is mainly due to the leapfrog breakthrough in the stacking process technology.

From the perspective of battery enterprise stacking technology progress, SVOLT has focused on stacking process technology since its inception in order to highlight the differentiated competition route. In 2019, SVOLT took the lead in introducing high-speed stacking technology in the production of prismatic batteries, opening the era of power battery stacking. At that time, it adopted a 45-degree rotating high-speed stacking process to achieve a single-station stacking efficiency of 0.6 seconds per piece.

Since then, SVOLT has continued to promote the upgrading of high-speed stacking technology. In 2020, SVOLT innovatively launched a high-speed lamination process 2.0 with a single-station stacking efficiency of 0.45 seconds/sheet and two sheets at the same time, so that the production efficiency of laminated batteries can be rapidly improved.

In 2022, SVOLT will release the third generation of high-speed stacking technology – “flying stacking technology”, which integrates multi-knife cutting and multi-slice stacking technology, and the lamination efficiency reaches 0.125 seconds/piece.

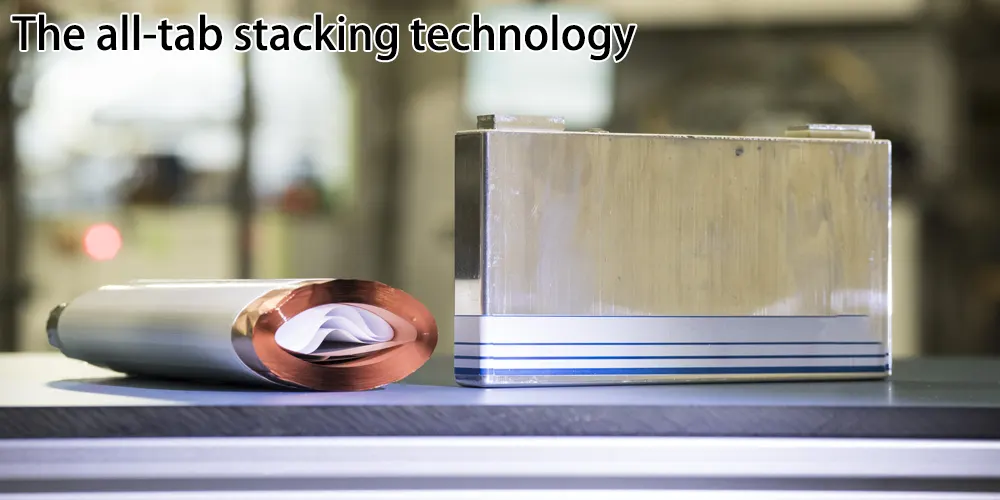

CALB pioneered the all-tab stacking technology in 2019. The battery products using this technology have the characteristics of high specific energy, long life, and all-weather, which fundamentally solves the safety risk of lithium-ion analysis of winding structure products. In 2020, CALB will improve the process and launch the “DBW” full-tab connection technology, which saves the die-cutting process of the tabs and avoids defects such as die-cut residues from the design, thereby improving the strength of the tabs.

In 2021, the battery pack developed by CALB based on the MIR platform and L300 battery products combined with system safety technology can realize that the entire pack of ternary lithium battery will not catch fire when needled.

EVE is also outstanding in the breakthrough of stacking technology. At present, the company’s 3.0 stacking technology can achieve a limit stacking rate of 0.2 seconds/piece, matching the CTT technology. Thanks to the larger pole piece area, the production capacity of a single stacking equipment can reach 1.3GWh.

Conclusion

It can be seen that power battery companies are constantly breaking the constraints brought by the stacking batteries process, and continue to innovate and advance in improving production efficiency, yield, and product performance and quality.