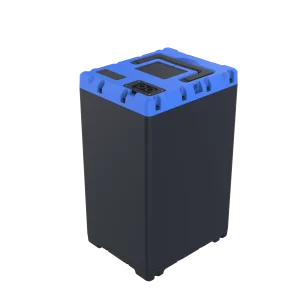

12V 100AH LITHIUM ION BATTERY BASIC REQUIREMENT | |

| ITEM | 12V100Ah |

| SERIES | 4(3.2V x 4 = 12.8V) |

| PARALLEL | 17(6Ah x 17 = 102Ah) |

| SIZE | 328MM*172MM*215MM*220MM |

| CYCLELIFE | 0.5C CHARGE 1C DISCHARGE, 1000 WEEKS ≥80% OR 36 MONTHS |

| LIFETIME | 25±2℃≥6 YEARS |

| IP GRADE | IP67 |

| RATED CHARGE CURRENT | 5A |

| MAX CHARGE CURRENT | 50A |

| RATED DISCHARGE CURRENT | 100A |

| MAX DISCHARGE CURRENT | 200A |

| SURGE CURRENT/TIME | CUSTOM |

| HEATING FILE(INCL.BMS RE-DESIGN) | OPTIONAL |

| WEIGHT | 12.5KG |

| ENCLOSURE | MALE MOLD PLASTIC SHELL |

| HANDLE | OPTIONAL |

| TERMINAL | M8 TERMINAL MORE THAN 1.5C OF BATTERY CAPACITY) |

| CHARGE & DISCHARGE PORT | SAME PORT |

| TRACK BACK QR CODE | LASER CODE (PROTECTION:PEARL COTTON THICKNESS 20MM ) |

| LABEL | NEUTRAL LABEL |

| FRAGILE LABEL | ✔ |

| PACKAGE | CERTIFICATE FOR PACKING OF DANGEROUS GOODS |

| BMS REQUIREMENT | |

| TYPE OF BMS BOARD | HARDWARE VERSION |

| BALANCE FUNCTION OF BMS BOARD | ✔ |

| MAX SERIES QTY OF BATTERY | 4 |

| MAX PARALLEL QTY OF BATTERY | 4 |

| COMMUNICATION | SUCH AS RS485, CAN AND SO ON |

| LCD SCREEN SHOW SOC% | ✔ |

| BUZZER ALARM | ✔ |

| GPS/GPRS | ✔ |

| BLUETOOTH | ✔ |

| TEST REQUIREMENT | |

|---|---|

| CAPACITY | LG Chem ≥104Ah (UNDER THE CONDITION OF AMBIENT TEMPERATURE OF 25℃±2℃ WITH BMS, FULLY CHARGE AT 0.33C CURRENT, STAND FOR 0.5H, DISCHARGE AT 1C TO THE FINAL VOLTAGE, AND STAND FOR 0.5H AFTER DISCHARGE, THE CAPACITY SHOULD BE GREATER THAN THE NOMINAL CAPACITY) |

| NORMAL CYCLELIFE | SATISFY 1000 TIMES AT LEAST 80%DOD (PERFORMANCE REQUIREMENTS: AT AN AMBIENT TEMPERATURE OF 25℃±2℃, CHARGE AT 0.5C AND DISCHARGE AT 1C FOR 100 CYCLES ATTENUATION RATE <2%) |

| HIGH TEMP.CYCLELIFE | SATISFY THE CYCLE OF 600 TIMES AND NOT LESS THAN 80%DOD (PERFORMANCE REQUIREMENTS: AT AN AMBIENT TEMPERATURE OF 55℃±2℃, CHARGE AT 0.2C, DISCHARGE AT 1C FOR 100 CYCLES, ATTENUATION RATE <3.3%) |

| LOW TEMP.CYCLELIFE | SATISFY 500 CYCLES AT LEAST 80%DOD (PERFORMANCE REQUIREMENTS: AT AN AMBIENT TEMPERATURE OF -10℃±2℃, CHARGE AT 0.2C AND DISCHARGE AT 1C FOR 100 CYCLES. ATTENUATION RATE <4%) |

| CAPACITY PRESERVATION RATE | CAPACITY RETENTION RATE IS NOT LESS THAN 95% (AFTER THE BATTERY IS FULLY CHARGED, THE BATTERY PACK IS PLACED UNDER THE CONDITION OF BMS AT AN AMBIENT TEMPERATURE OF 25°C ± 2°C, AND THE BATTERY PACK IS ALLOWED TO STAND FOR 28 DAYS AND THEN CONDUCT A 3H RATE DISCHARGE CAPACITY TEST. DISCHARGE TO THE BATTERY TERMINATION VOLTAGE TO OBTAIN THE BATTERY PACK’S CAPACITY AFTER STANDING FOR 28 DAYS.) |

| SOAK TEST | 1.2M DROP, SOAK FOR 3 HOURS WITHOUT LEAKAGE,SMOKE & FIRE |

| ANTI-DROP | THERE IS NO OBVIOUS DAMAGE TO THE APPEARANCE OF THE BATTERY WHEN DROPPED FROM SIX ANGLES FROM A HEIGHT OF 1 METER, NO LEAKAGE, SHELL RUPTURE, FIRE OR EXPLOSION |

| VIBRATION TEST | AFTER THE BATTERY PACK IS FULLY CHARGED, IT HAS BEEN FIXED ON THE VIBRATION TABLE IN A LARGE PLANE DIRECTION. THE AMPLITUDE OF THE BATTERY PACK IS 5MM, THE MAXIMUM STROKE IS 10MM, THE VIBRATION FREQUENCY IS 10HZ-55HZ, AND THE VIBRATION TEST IS ON THE X, Y, AND Z OF THE BATTERY PACK. THE TEST TIME IS 90MIN IN EACH DIRECTION WITH A FREQUENCY SWEEP CYCLE BETWEEN 10HZ-55HZ. AFTER THE TEST, IT IS LEFT FOR 1 HOUR. THE SHELL IS NOT DEFORMED, SHAKES UP AND DOWN WITHOUT DISPLACEMENT, THE BATTERY PACK HAS NO LEAKAGE, NO FIRE, AND NO EXPLOSION. |

| OTHERS | |

| USE AREA | RECOMMENDED ANNUAL MINIMUM TEMPERATURE ≥-10℃ AREA |

| CERTIFICATION | UN38.3 |

| INSURANCE | PRODUCT LIABILITY INSURANCE |

A. Yes, we welcome sample order to test and check quality.

A. Sample needs 5-10 days, mass production time needs 3-5 weeks, it depends on order quantity.

A. Yes, we have MOQ for mass production, it depends on the different part numbers. 1~10pcs sample order is available. Low MOQ, 1pc for sample checking is available.

A. We usually ship by DHL, UPS, FedEx or TNT. It usually takes 3-5 days to arrive. Airline and sea shipping is also optional.

A. Firstly let us know your requirements or application. Secondly, We quote according to your requirements or our suggestions for the power inverter 3000w.Thirdly customer confirms the power inverter 3000w samples and places a deposit for formal order. Fourthly We arrange the production.

A. Yes. Please inform us formally before our production and confirm the design firstly based on our sample.

A. All of batteries are 2000 cycles life beyond 80% DOD. with 2 years warranty.

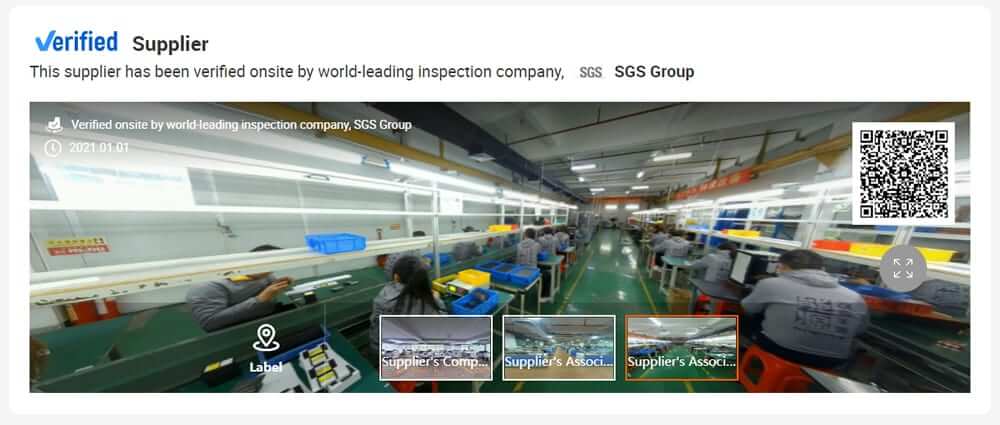

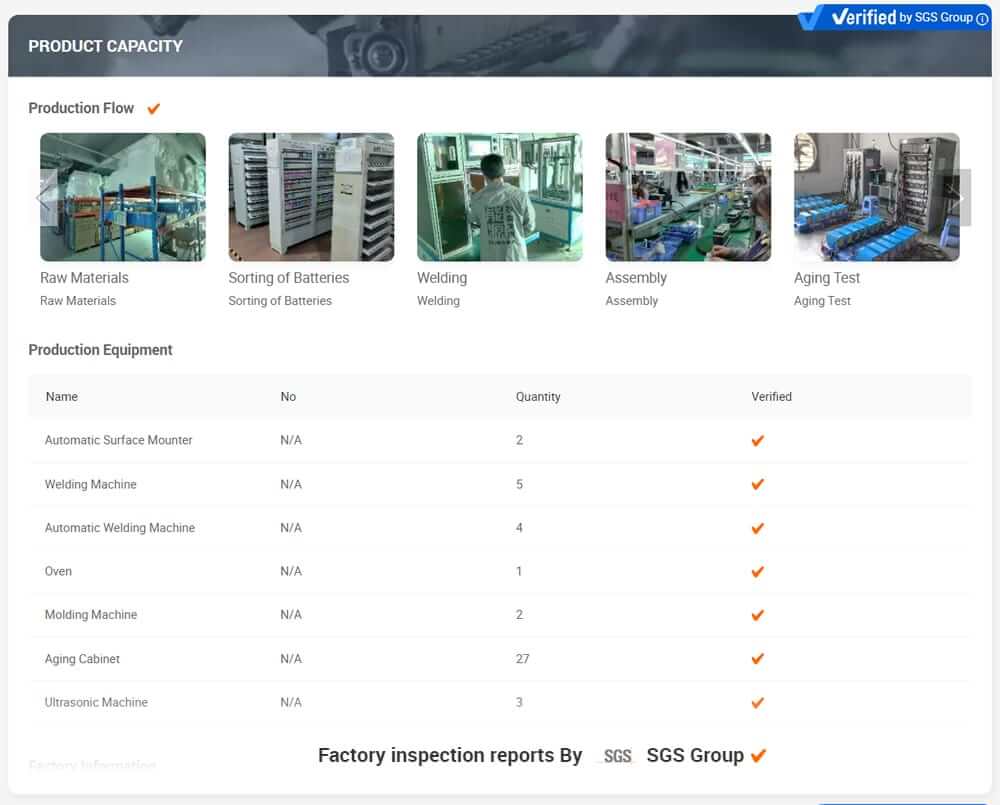

lithium ion battery manufacturing SGS

lithium ion battery factory SGS

TYCORUN BATTERY SGS

Asima –

Everything went great , highly recommend this lithium battery manufacturer. Good product good service. This time went with shipping by boat, saved a lot of money if you have a bit of time to wait. Very satisfied.

zoritoler imol –

Hello there, just turned into alert to your weblog via Google, and found that it’s really informative. I’m going to watch out for brussels. I will appreciate when you proceed this in future. Many people might be benefited from your writing. Cheers!

graliontorile –

I’d incessantly want to be update on new blog posts on this site, bookmarked! .