Home » Battery Materials » The introduction of sodium ion battery industry chain

The introduction of sodium ion battery industry chain

Panorama of sodium-ion battery industry chain

Na-ion batteries first appeared in the early 1980s, and then due to the better performance of lithium-ion batteries, the research on sodium-ion batteries was stagnant.

After 2010, with the increasing demand in the field of power batteries, the supply of materials for lithium-ion batteries is in short supply, and the research on room-temperature sodium-ion batteries has re-emerged.

According to different application scenarios, sodium-ion batteries can be mainly divided into power and energy storage. Compared with the commercialization level of mature lithium-ion batteries.

The commercialization of sodium-ion batteries is only in its infancy. Only a few companies have carried out preliminary commercialization of sodium-ion batteries, and a complete and mature industrial chain has not yet been formed.

Upstream of the industrial chain

Battery raw materials

Because sodium-ion batteries work similarly to lithium-ion batteries, many materials and processes can be reused, even from a raw material perspective.

In terms of raw materials, the first and most obvious difference between sodium-ion batteries and lithium-ion batteries is the difference in working ions. Lithium-ion batteries generally use lithium carbonate as a raw material, while the cathode materials for sodium-ion batteries are currently synthesized in the laboratory.

Sources of sodium are very wide, including sodium carbonate, sodium bicarbonate, sodium acetate, sodium oxalate, sodium citrate, sodium nitrate, sodium hydroxide and even the occasional discussion of sodium metal,

However, large-scale industrial production has certain requirements for cost, process safety, acidity and alkalinity, and sodium carbonate (ie soda ash) is most likely to become the raw material for industrial production.

Other materials have more or less certain defects due to cost, safety or physical and chemical indicators. Contrary to the uneven and scarce global distribution of lithium resources, sodium resources are widely distributed globally, and its abundance in the earth’s crust ranks sixth, the most common type of sodium salt we eat is sodium chloride. The most common sources of sodium chloride are sea salt, lake salt, and rock salt (mineral salt).

Other raw materials include manganese, iron, cobalt, copper, nickel, etc. as the positive electrode material, carbon, titanium, phosphorus, etc. as the negative electrode material, and aluminum as the current collector material.

The structure of sodium ion battery

It mainly includes five parts: positive electrode material, negative electrode material, electrolyte, current collector and separator.

Positive electrode material

Cathode and anode materials affect key performance indicators such as energy density, power density, cycle life, and safety of Na-ion batteries, and are critical to battery performance.

Different from the technical route of lithium-ion battery cathode, there are more than 100 kinds of cathode materials related to sodium-ion battery, and the technical route is still in the process of evolution.

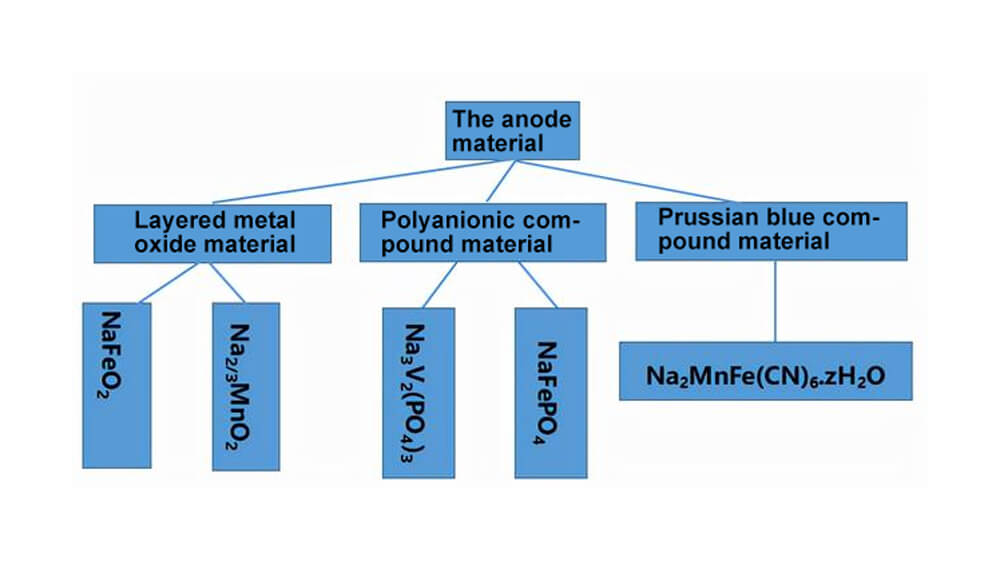

According to the composition, mainstream sodium-ion battery cathode materials can be divided into layered metal oxides, polyanionic compounds and Prussian blue-like compound systems. Since the industrial system is in the early stage of commercialization, the competitive landscape still needs to be tracked, and relevant leading companies still have the first-mover advantage.

Some manufacturers of cathode materials

GEM, Betri, Huayang, Rongbai Technology.

Anode material

Different from the graphite material negative electrode used in lithium-ion batteries, due to the too small spacing between the graphite layers, the intercalation of sodium ions with a larger radius between the graphite layers requires more energy, and reversible deintercalation cannot be performed within the effective potential window.

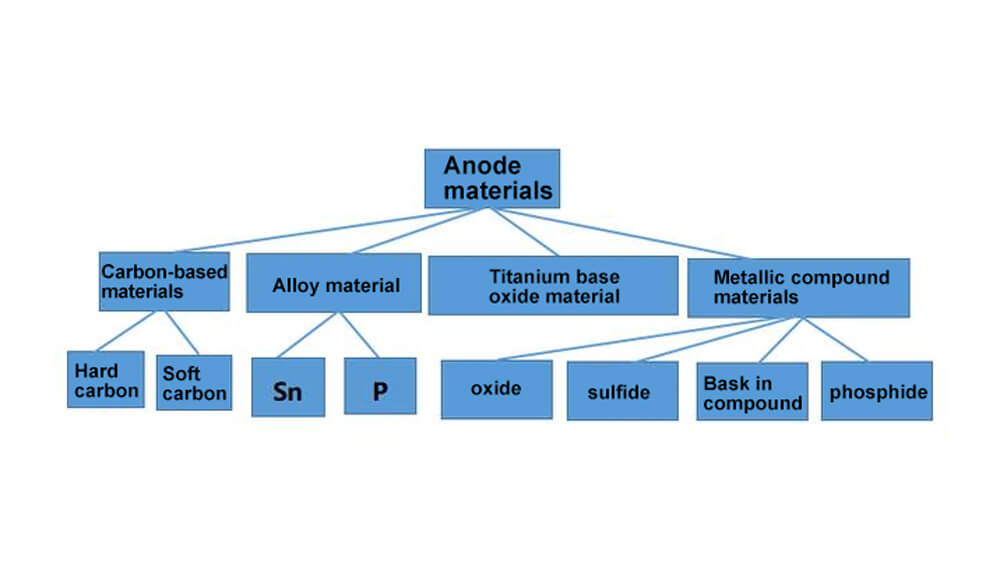

Therefore, it is considered that traditional graphite cannot be used as the negative electrode of sodium-ion battery. The research directions of anode materials for sodium ion batteries include hard carbon, soft carbon, titanium-based oxides and alloys, etc. The research on hard carbon is the most, and the current commercial sodium ion batteries also use hard carbon materials as negative electrodes.

Some manufacturers of negative electrode materials

Shanshan Co., Ltd., Putailai, Zhongke Electric, Xiangfenghua, Beterui, Huayang Co., Ltd.

Diaphragm

At present, the electrolyte composition of the most common organic electrolyte-based sodium-ion battery is very similar to that of lithium-ion battery, and the solvent remains unchanged.

Only the solute salt is changed from lithium hexafluorophosphate to sodium hexafluorophosphate, and the separator can use the same separator as the lithium-ion battery.

The separator is used to isolate the positive and negative electrodes of sodium-ion batteries, preventing short-circuit phenomena, and at the same time acting as an ion channel. The United States, Japan, and South Korea are in the leading position in diaphragm production,

After years of development, China’s diaphragm industry has gradually entered the international market, becoming the fourth largest diaphragm producer. The commonly used diaphragms are:

Diaphragm part manufacturers

Enjie, Xingyuan Material, Mingzhu Plastic, Jieli, Zhongxing New Material, Hongtu, Huiqiang, Zhongli, Yiteng, Yuntianhua New Rice.

Electrolyte

Electrolytes are ionic charge carriers necessary for electrochemical reactions to occur, and are the key to improving the power characteristics of Na-ion batteries. Electrolytes are mainly composed of solvents, solutions, additives and the like.

The most common electrolyte for sodium-ion batteries is an organic liquid electrolyte. The organic solvent portion of the organic electrolyte is similar to the corresponding composition of lithium-ion batteries.

Some manufacturers of electrolyte salts

Polyfluoride, Godsend material

Current collector material

Unlike lithium, since aluminum and sodium do not undergo alloying reactions at low potentials, both cathode and anode current collectors for sodium-ion batteries can use inexpensive aluminum foils instead of higher-cost copper foils. It is judged that the current collector aluminum foil of sodium ion battery is basically the same as that of lithium battery, and the performance requirements are basically similar.

Some manufacturers of aluminum foil for batteries

Dingsheng New Materials, Nanshan Aluminum Industry, Wanshun New Materials

Material cost ratio

Production equipment

Mixing equipment, sintering equipment, crushing equipment, washing equipment, coating equipment, packaging equipment, testing equipment, etc.

Midstream of the industry chain: sodium-ion batteries

Introduction

Working principle

It mainly relies on the movement of sodium ions between the positive electrode and the negative electrode to work: during charging, sodium ions are deintercalated from the positive electrode, and swim through the separator in the electrolyte to embed the negative electrode, and the negative electrode is in a sodium-rich state; during discharge, the opposite is true.

Performance advantage

High energy density, high safety in use (can be discharged to 0V), environmental protection (without lead, cadmium, mercury and other elements that pollute the environment), wide resource sources, and low cost.

Battery type

The types of cells are classified in terms of structure, mainly including soft pack batteries and cylindrical batteries; from the classification of material systems, they include solid-state sodium-ion batteries, sodium-sulfur batteries, room-temperature sodium-ion batteries, and zebra batteries.

Battery production

Due to the working principle of sodium-ion batteries and the high similarity of battery materials to lithium-ion batteries, the process and equipment for battery production can be reused.

Battery system

Since the commercialization level of sodium-ion batteries is only in its infancy, there are relatively few studies on battery systems. CATL has developed AB battery system solutions in battery system integration

That is, the sodium-ion battery and the lithium-ion battery are mixed and matched in a certain proportion, integrated into the same battery system, and the balance control of different battery systems is carried out through the BMS accurate algorithm.

Some sodium-ion battery manufacturers

Ningde Times, Zhongke Haina, Na Innovation Energy, Penghui Energy, Sacred Sun, Mengshi Technology, Xinwangda, Shandong Zhanggu.

Downstream of the industrial chain: application market

In the current secondary battery market, lithium-ion batteries are the absolute main force and core. Based on the continued growth in demand for new energy vehicles, although lithium-ion batteries have relatively no obvious performance limitations, the source of raw materials such as lithium carbonate and lithium cobalt oxide is becoming more and more difficult.

After 2010, as the size and installed quantity of battery packs increased, it became increasingly difficult for lithium resources to meet demand. Because sodium-ion batteries inherently have the potential to best match the performance of lithium-ion batteries, sodium-ion research has been reintroduced.

Although the original intention of sodium-ion battery research and development is to supplement and replace the application of lithium-ion batteries in the field of power batteries, the current energy density of sodium-ion batteries is not as good as that of lithium-ion batteries.

In the field of high-speed electric vehicles, the dominance of lithium-ion batteries cannot be shaken at present; in terms of stationary energy storage, due to the low requirements for volume and quality, sodium-ion batteries have broad prospects.

Since the commercialization of sodium-ion batteries is in its infancy, the analysis of the downstream of the industrial chain is more about forecasting and outlook.

Electric vehicle

At present, the power batteries of commercial new energy vehicles are mainly lithium-ion batteries and a small amount of fuel cells. The use of sodium-ion batteries for electric vehicles is still in the experimental stage.

Due to the low energy density of sodium-ion batteries, they can only be used in low-speed electric vehicles and some low-endurance passenger vehicles. Zhongke Haina has produced a sodium-ion battery backup battery pack for low-speed electric vehicles, the model is DZ72V60Ah-6P24S.

Electric bicycle

Sodium-ion batteries are an upper-level substitute for lead-acid batteries used in the field of electric bicycles, and are expected to replace lithium-ion batteries in this field in the future. There are two types of sodium-ion battery packs for electric bicycles produced by Zhongke Haina, namely DZ48V12Ah-4P16S and DZ48V12Ah-2P16S.

Stationary energy storage

Na-ion batteries will play an important role in the field of stationary energy storage in the future. In the field of energy storage in Japan, there have been practical applications of sodium-sulfur batteries, which are high-temperature sodium-ion batteries. In terms of room temperature sodium ion, Zhongke Hai Na has produced a sodium ion battery for energy storage, the model is DZ48V36Ah-6P16S.

Product advantages

The diameter of the sodium sheet is 15.6 mm, the thickness is 0.4~0.5 mm, and the purity is more than 99.7%. It is specially used for button batteries (2032, 2025, 2016).

The size of the sodium sheet is uniform, the surface is smooth and bright, and it can be stored for a long time. are inconsistent, there will be burrs and scratches on the surface, which will affect the consistency of battery performance.

Packaging Shipping Storage

Using the quadruple protection packaging technology, the sodium sheet is covered with aluminum foil on one side, which acts as a support and current collector, and also plays the role of protecting the sodium. In addition, both sides are covered with a protective film, which can protect the sodium sheet and avoid oxidation.

Put the sodium flakes into plastic bottles, then put them into aluminum plastic bags, and then put them into iron tins for storage, so as to ensure long-term preservation and safety.

Product Descriptions and Recommendations

1. Remove the protective film on the surface (both sides) of the sodium sheet and use it. One side of the aluminum foil is a blue protective film, and one side of the sodium sheet is a transparent protective film, which can facilitate the observation of the surface of the sodium sheet.

2. First peel off the blue protective film on one side of the aluminum foil, then peel off the transparent protective film on the side of the sodium sheet, and first clamp the entire sodium sheet with widened flat tweezers, so that the sodium sheet will not be seriously deformed when peeling off the film.

3. Then use stainless steel pointed tweezers or round-tipped tweezers to clamp a point on the edge of the sodium sheet and pull it outwards, start up, and then extend it along the edge, and then remove the protective film, and the entire film can be removed. When installing the battery, the aluminum foil is facing the battery case and the sodium sheet is facing the separator to assemble the button battery.