Home » lead acid battery » The Ultimate guide of AGM battery

The Ultimate guide of AGM battery

Overview of the AGM battery

What is AGM battery

The full name of AGM Battery is valve-controlled AGM lead-acid Battery (VRLA-AGM-Battery). It is a kind of valve-controlled maintenance-free lead-acid Battery with a brand new battery technology whose electrolyte is adsorbed on the AGM separator. It is mainly used in cars equipped with start-stop system.

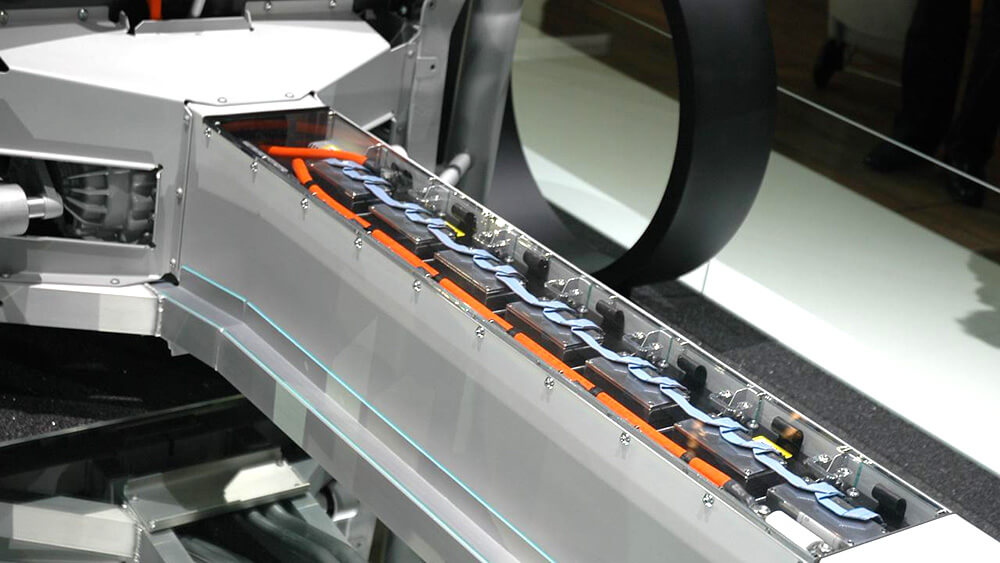

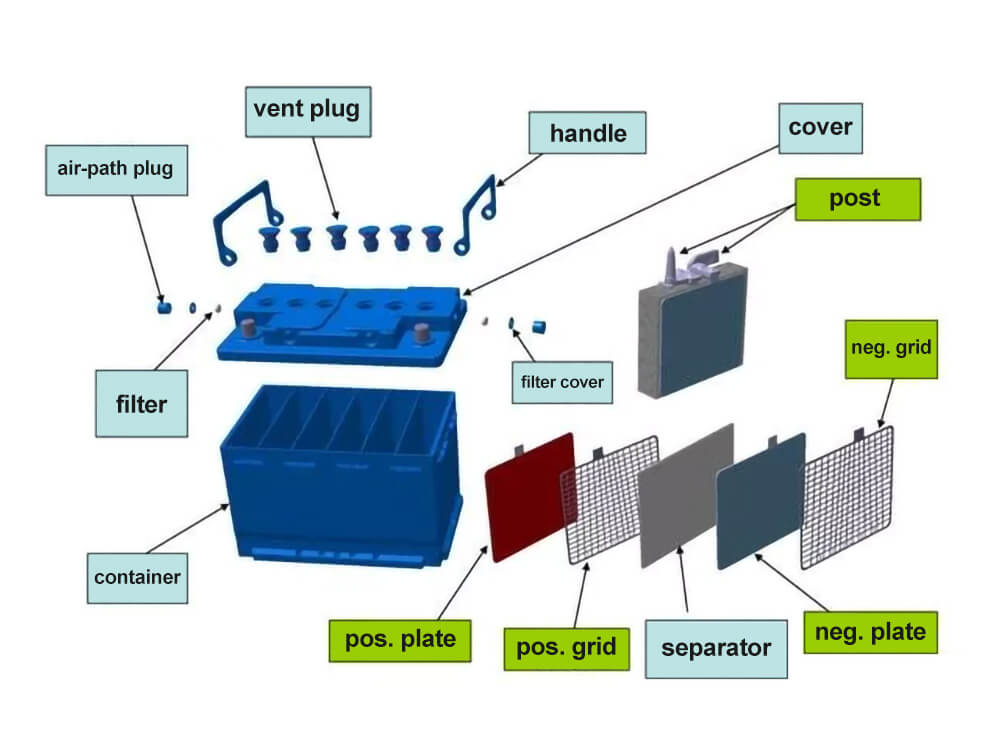

Internal structure of AGM battery

Anatomical diagram of AGM battery

Main technical characteristics of AGM battery

①Technology of AGM : the battery electrolyte is permanently adsorbed in the glass fiber partition, and there is no flowing electrolyte. The capillary action of AGM separator can effectively relieve the stratification of electrolyte and reduce the self-discharge of battery.

②There is oxygen recombination reaction inside the battery, reduce the water consumption in the cycle life of the battery, effectively protect the plate grid to alleviate corrosion.

③The pole group pressure assembly, the mechanical and chemical properties of the plate is more stable, avoid the active substance shedding and performance attenuating in the cycle process, , effectively prolong the life of AGM battery.

④The electrolyte is completely adsorbed in the AGM separator, and the upper part of the electrode group does not need extra electrolyte. The electrode plate can be higher and larger than the traditional battery design, which makes the AGM battery have better cold start performance.

⑤Unique through-wall welding connection can increase the conduction capacity of current and improve the anti-vibration performance of the battery.

The features of the AGM battery

Performance features

The AGM lead-acid battery is of lean liquid design. The electrolyte is adsorbed in the AGM partition, and there is no flowing electrolyte in the battery. Due to the advanced materials and design process of AGM, water loss is small in the process of use. So there is no need to add water, and AGM battery also has the following advantages at the same time:

ø Low self-discharge, can still be used after a long time storage (3 months)

ø High low-temperature starting power, suitable for frequent starting

ø Better charging reception

Ø No acid mist is discharged when charging

ø Long service life (3 ~ 5 years)

ø Explosion-proof safety

ø Less water loss

Structural features

When the ordinary battery is near the period of the end of charging, due to the decomposition of water, a large amount of water is separated out. Make the electrolyte liquid level down, if the charging current is too large, there will be more water loss. Due to the AGM battery adopts lead-calcium alloy grid, AGM separator and innovative design, the recombination reaction of gas exists in the charging and use process of the battery, which reduces the water loss of the battery. Another reason why AGM battery does not need to add water in use is the use of sealed valve control design, which greatly reduces the evaporation and leakage of water. At the same time, the use of AGM separator and the use of “tight assembly” can play a protective role in the cathode active substance, which can effectively prevent the active substance from softening and falling off, and extend the service life of the battery.

Because the maintenance-free lead acid storage battery adopts sealed design, it will not corrode pole and car body. A new safety ventilation system is designed for the battery vent hole. The filter plate in the airway plug can prevent acid mist discharge and external spark from entering the battery, and prevent the battery from bursting.

Usage features

Low self discharge, long service life. AGM lead-acid battery can use commonly 3-5 years, average battery plate gate is lead antimony alloy, antimony in the charging and discharging cycle to transfer from the plate gate to the cathode and anode active material and electrolyte, which increases the self-discharge of battery, shorten the service life of the battery. And AGM battery uses lead calcium alloy, excluding antimony alloy, so the self-discharge can be reduced to a minimum level, and the service life of the battery has been extended. AGM battery has the advantages of large starting power, low internal resistance, high battery output voltage, large low temperature starting current and long service life compared with ordinary flooded battery due to the use of new materials and new design.

The difference between AGM battery and ordinary flooded battery

AGM batteries compared to ordinary lead acid batteries:

| AGM battery | Ordinary lead acid battery |

| Contains 6 vent plug | No vent plug |

| Use AGM separator | Use Envelope separator (PVC) |

| Use new special alloy | Use normal lead calcium alloy |

| There is no flowing acid in the battery | There is flowing acid in the battery |

| Service life (generally 3-5 years) | Service life (generally 2-3 years) |

The difference between AGM and EFB batteries and precautions

Engine start/stop systems are becoming more common. They require special batteries, which are more advanced and last longer than normal batteries, but certainly cost a lot more.

Cars with stop-start systems can’t use normal batteries, even with large capacitors, they can’t withstand larger current when charged, and they have a limited lifespan.

For cars with smart alternator management, ordinary batteries can’t do the job, because charging is done when decelerating and braking, which makes the battery withstand larger current.

Two types of battery are used in cars equipped with a start-stop system: Enhanched flooded Battery (EFB) and AGM battery .

While EFB cells are detailed improvements over conventional batteries, AGM is more advanced. Instead of soaking the electrodes in an electrolyte (diluted sulfuric acid), most of the electrolyte in AGM battery is adsorbed on a porous fiberglass partition. In addition, gases produced during the charging process of the AGM are attracted by a chemical reaction, and the battery is completely sealed, so it can be installed in the cockpit.

But the AGM battery has its drawbacks. It can’t withstand high temperatures, so avoid placing it near the engine or keep it well-ventilated.

EFB batteries are suitable for start-stop vehicles without intelligent charging management. When equipped with an alternator intelligent management system (such as BMW Efficient Dynamics), AGM batteries should be used because they can withstand high charging currents thanks to technology that reduces internal resistance, such as special isolation devices, thinner grids and special mixtures of plates.

Moreover, unlike conventional batteries, the single substance that makes up an AGM battery is compressed before it enters the electrolytic cell, making it effective against vibrations. Manufacturers have incorporated many of these techniques into EFB batteries, increasing their charge and discharge times and allowing them to withstand intense charging, although EFBs are still not up to the level of AGM batteries.

Storage of the AGM battery

AGM batteries require no additional maintenance during use. But it needs to be maintained during storage.

ø AGM battery is forbidden to be stored in loss of power (voltage cannot be lower than 12.65V)

ø AGM battery is strictly prohibited to be stored under the condition of exposure to sunlight and no ventilation

ø Do not invert the AGM battery during storage

ø AGM battery needs to be recharged once every 3 months after being shelved for a long time.

How to charge the AGM battery

Charging method

Compared with ordinary lead-acid battery, AGM battery is also characterized by charging in constant voltage and current limiting. As we know, the terminal voltage of ordinary battery can reach 2.6-2.8 V/single cell at the end of constant current charging. Under such high charging voltage, a large amount of gas will be generated in the battery. The AGM battery has gas recombination reaction, which is exothermic reaction. A large amount of gas combination will raise the temperature of the battery and affect the service life of the battery. In serious cases, the battery will lose thermal control, resulting in the abandonment of the battery.

Setting of charging value

The charging voltage is 14.8V, and the charging current is less than or equal to 5I20 (I20 is the rated capacity of the battery divided by 20, for example, AGM70Ah battery, I20= 3.5A). The temperature change of the battery should be detected during the charging process, and the battery response should be accurately observed every 2 hours. Theoretically, the battery surface temperature should not exceed 45℃. If the temperature is too high, you should stop charging immediately.

AGM battery failure detection

Compared with ordinary lead-acid batteries, the failure rate of AGM batteries is very low. In addition to the use of new materials, this has a great relationship with its manufacturing process. However, there is no absolute 100% of any product, so AGM batteries also have relative quality problems. The following is a brief introduction to the detection method of maintenance-free lead-acid batteries:

Appearance determination method

ø First, check whether there is any scratch or damage on the battery appearance that leads to air leakage

ø Next, tilt the battery on all sides to see whether the battery shell has “bulge” or shrinkage

Voltage detection method

ø Test whether the battery voltage is normal. For example, the battery voltage above 12.8V is sufficient, the 12.6V battery is slightly deficient, the 12V battery is deficient, and the 10V battery may have a short circuit problem.

Charging detection method

Check the battery less than 12V according to the charging requirements. If the battery fails to reach 12 to 18 hours, there may be a short circuit. Analyze the cause and proceed to parallel processing. If the battery reaches 14V during charging, continue charging until the battery is fully charged.

Faqs about AGM battery

What are the advantages and disadvantages of AGM and EFB?

AGM battery refers to the battery whose separator is made of superfine glass wool material. At present, AGM technology is mainly promoted by German and American. Compared with ordinary battery, the price is more than three times expensive, but it has the following advantages :(1) cycle charging capacity is three times higher than lead-calcium battery, with longer service life. (2) In the whole service life (about three years) , it has higher capacitance stability. (3) Low temperature starting is more reliable. (4) Reduce accident risk, no acid leakage to reduce environmental pollution.

Disadvantages: AGM battery is not high temperature resistant, generally can not be installed in the engine compartment! EFB battery is flooded enhanced start-stop battery, developed on the basis of the original ordinary lead-acid battery. So it can withstand high temperature, can be installed in the engine compartment, and can fully meet the requirements of the start-stop system. Compared with ordinary battery, the life performance is three times higher. It is cost-effective, more than two times more expensive than ordinary battery. At present, Japanese manufacturers mainly promote EFB technology.

Will the battery self-discharge after starting and stopping?

Even if the battery is not connected to an external circuit to discharge, it slowly loses power itself, a phenomenon called self-discharge. The quality of active substance is more than that of ordinary battery, and the self-discharge is faster.

How to replenish the battery after starting and stopping?

When charging, there are two ways that the battery can replenish its charge.

① Constant current charging: According to the open circuit voltage, specific gravity (20℃), according to the following table.

Note: When using this method to replenish power, control the charge time to prevent overcharging of the battery.

② Constant voltage charging (i.e. constant voltage current limiting charging).

Exhaust type with constant voltage 16.0V, the limited current is 2.5, charging for 16 hours.

Note: The battery voltage may be artificially high after this method is used. Therefore, let the battery rest for 4 hours after charging, the measured voltage value will be more accurate.

Whether the start-stop battery and ordinary battery can be intergenerational?

The battery of the start-stop system vehicle cannot be replaced by ordinary batteries.

Since the performance of the start-stop battery is designed to be higher than that of ordinary batteries, the service life of ordinary batteries will be reduced. Extrapolating from experimental data, the endurance life is generally only one-third of start-stop.

Since the high temperature resistance of AGM batteries is not as good as that of ordinary lead-acid batteries, they are mostly installed in the trunk or compartment. In the charging and discharging process of ordinary lead-acid batteries, it is inevitable that there will be acid fog and electrolytic hydrogen discharge, which is bound to affect the health and safety of drivers and passengers in the carriage.

And they have different charging modes. The charging procedures of different types of batteries are not the same, especially the charging mode of ordinary wet lead-acid batteries and the charging mode of AGM batteries with start-stop mode are very different. Because of the high current discharge, energy management, deep charging current, not only will lead to premature damage of the battery, but also may lead to the normal operation of the whole system.

Some models with the smart battery management control module, EFB or AGM battery if convert into ordinary battery, the battery management control module in the system are generally no corresponding program with ordinary lead-acid batteries, unable to complete initialization of battery, that is to say, deny ordinary lead-acid batteries, battery management control module At the same time, the control network and power system of these cars are complicated, which means that the car does not accept ordinary lead-acid batteries, which will cause many of the systems on the car to not work properly.

For some vehicles with the start and stop system, even if the original car requirements of the battery, if there is no matching or matching data problems, will lead to the vehicle system error, hidden problems did not occur.

But the batteries of ordinary high-powered vehicles can be replaced with start-stop batteries.