Zinc manganese battery types and application

What is zinc manganese battery

Zinc manganese battery, also known as dry batteries, unlike rechargeable aa batteries, it is refer to primary batteries that use manganese dioxide as the cathode, zinc as the anode, and ammonium chloride aqueous solution as the electrolyte. Zinc-manganese batteries have the advantages of low temperature resistance, long storage time, large capacity, and suitable for high-current discharge.

According to different structures, zinc-manganese batteries can be divided into three types: cardboard batteries, paste batteries and thin-film batteries. Paste batteries have been used as early as the early 20th century, and are currently one of the widely used zinc manganese battery varieties.

Mainly used in home appliance remote controls, flashlights, toys and semiconductor radios, tape recorders, clocks, electronic scales and other small household electronic equipment. The starting voltage of zinc-manganese batteries varies with the type of MnO2 used, the composition of the electrolyte, and the pH value, etc., generally between 1.55 and 1.75V, and the nominal voltage is 1.5V. The most suitable temperature for use is 15-30°C.

Types of zinc-manganese batteries

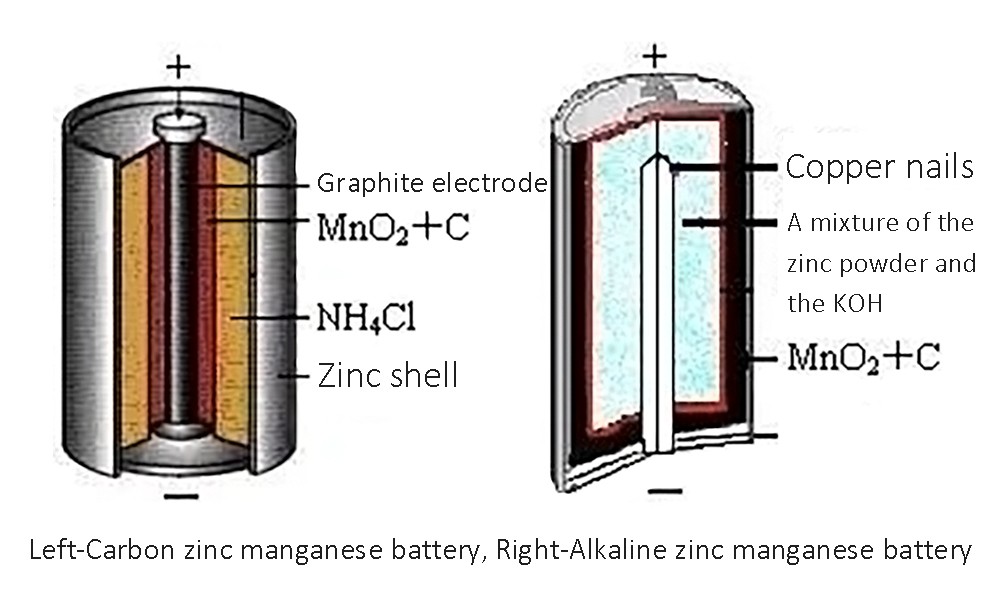

Zinc-manganese batteries can be divided into carbon zinc-manganese batteries and alkaline zinc-manganese batteries.

Carbon zinc manganese battery: the cathode is graphite rod and manganese dioxide (MnO2), the anode material is zinc flakes, and the electrolyte is starch paste of ammonium chloride (NH4Cl) and zinc chloride (ZnCl2). Because the cathode has graphite rods.

Alkaline zinc manganese battery: the cathode is manganese dioxide, the anode is zinc, and the electrolyte is more commonly potassium hydrochloride (KOH). Alkaline zinc manganese battery can be said to be an upgraded product of carbon zinc manganese battery.

Alkaline zinc manganese battery vs carbon zinc manganese battery

According to the different electrolyte and electrode structure, zinc manganese batteries are mainly divided into carbon zinc manganese battery and alkaline zinc-manganese batteries. The overall performance of carbon zinc manganese battery is higher than that of carbon zinc manganese battery.

● The capacity of alkaline batteries is significantly higher than that of carbon batteries, about 3-8 times that of the latter

● The discharge capacity of alkaline batteries is significantly higher than that of carbon batteries, and is more suitable for high-current discharge

● The storage period of alkaline batteries can reach 3-7 years, which is 3-7 times that of carbon batteries

● Alkaline batteries have a higher utilization rate of raw materials, for example, the utilization rate of zinc is 3-8 times that of carbon batteries

Due to the large discharge capacity of alkaline batteries, high-current electrical appliances, such as cameras, shavers, and electric toys, can use alkaline batteries. And low-current electrical appliances, such as quartz clocks, alarm clocks, remote controls, radios, etc., can use carbon batteries.

Application of zinc manganese battery

Battery performance complies with national industry standards. Due to the advantages of heavy load, large current discharge, large capacitance, good low temperature performance and leakage resistance, and high cost performance, it is widely used in civil and industrial applications.

Especially suitable for flash cameras, miniature recorders, video cameras, walkie-talkies, BP machines, shavers, palm-type color TVs and game consoles, toys, telemeters, alarms, calculators, hearing aids, flashlights and electric clocks and other equipment.

For example, AA-type (No. 5) alkaline zinc-manganese batteries can be used in flash cameras to continuously shoot 8-10 films, while dry batteries can only shoot 1-2 films, and nickel-cadmium batteries cannot be used. It can be said that all dry batteries and nickel-cadmium batteries can be replaced by alkaline zinc-manganese batteries.

Zinc manganese battery industry chain

The upstream suppliers of the zinc manganese battery industry are mainly manufacturers of electrolytic manganese dioxide powder, zinc powder, release paper, steel case, carbon rod, zinc cylinder and copper needle. The main metal raw materials required for the production of zinc-manganese batteries are zinc powder and electrolytic manganese dioxide powder.

| Upstream raw materials | Midstream products | Downstream applications |

●Manganese powder ●Zinc powder, zinc cylinder ●Separator paper ●Carbon rod, steel shell ●Copper Needle | ●Alkaline zinc manganese battery ●Carbon zinc manganese battery | ●Electric toys ●Household appliances ●Smart home ●Household medicine ●Outdoor electronic equipment |

Zinc manganese battery market in China

Driven by scientific and technological innovation, China’s zinc manganese battery industry has developed rapidly and has gradually replaced traditional dry batteries. China is the world’s largest producer of zinc-manganese batteries. In recent years, China’s zinc manganese battery market has maintained a stable supply and output has shown a slight growth trend.

In recent years, the production of zinc-manganese batteries in China no longer uses mercury as a protective agent, greatly reducing environmental pollution. Driven by the awareness of environmental protection, the demand for zinc-manganese batteries in other countries has become increasingly strong, and China has become the world’s largest exporter of zinc-manganese batteries.

With the continuous deepening of national environmental protection policies and supply-side structural reforms, green and environmentally friendly zinc-manganese batteries will gradually become the mainstream of the market.

Some small and medium-sized manufactueres whose battery products fail to meet the quality standards are gradually eliminated by the market, and the concentration of the zinc manganese battery industry is expected to increase. According to industry insiders, zinc-manganese batteries, as a substitute for traditional polluting dry batteries, have achieved rapid development driven by technological innovation.

As the world’s largest producer and exporter of zinc-manganese batteries, China’s zinc manganese battery industry has developed steadily in recent years, and the scale of exports has continued to expand, achieving a trade surplus in the industry. With the support of national policies, the market space of China’s leading zinc manganese battery companies will be expanded, and green and environmentally friendly zinc-manganese batteries will receive widespread attention. Leading companies in China are Nanfu, Sonluk, Mustang, etc. also are top 10 zinc manganese battery manufacturers in the world.

Waste zinc manganese battery recycling

Alkaline zinc-manganese batteries are the most used primary batteries. Waste alkaline zinc-manganese batteries will pollute the environment after being discarded, and people pay more and more attention to their recycling.

Research on the process of water immersion-calcination-vacuum aluminothermic reduction treatment of waste alkaline zinc-manganese batteries, through the phase and element content analysis, the phase existence form of the treated materials and the recovery rate of potassium and zinc.

This study shows that 99% of potassium hydroxide can be recovered by immersion of waste alkaline zinc manganese battery materials; The main phases of the calcined slag obtained after the water leaching slag is calcined are ZnO and ZnMn2O4; The calcined slag is vacuum aluminothermic reduction, which can reduce zinc and manganese, and recover 98% of zinc. The main phase of the reduced slag is alumina and aluminum-manganese alloy.