18650 battery pack - helpful guide to build 18650 battery pack

What are 18650 cells?

18650 cells are a type of rechargeable lithium-ion battery cell, and multiple 18650 battery cells are used to make a 18650 battery pack, either connected in series or parallel configuration. The name “18650” refers to the battery’s dimensions, with “18” representing the diameter (18mm) and “65” representing the height (65mm). The “0” at the end indicates that the battery is cylindrical.

What is the difference between 18650 cells and other battery cells?

18650 cells, specifically lithium-ion batteries, and 18650 battery pack differ from lead-acid cells in several key aspects:

- Chemistry: 18650 cells use lithium-ion chemistry, whereas lead-acid cells use, as the name suggests, lead-acid chemistry. Lithium-ion batteries have a higher energy density, which means they can store more energy in a smaller and lighter package compared to lead-acid batteries.

- Voltage: 18650 cells typically have a nominal voltage of 3.2 to 3.7 volts per cell, whereas lead-acid cells have a nominal voltage of around 2 volts per cell. 18650 battery pack used with devices that require more voltage or amperage. This means a lithium-ion battery pack requires fewer cells to achieve a specific voltage than a lead-acid battery pack.

- Capacity: 18650 cells generally have higher capacity compared to lead-acid cells. The capacity of a 18650 cell can range from a few hundred milliampere-hours (mAh) to several hundred Ah, depending on the specific model and brand. In contrast, lead-acid batteries typically have lower capacities.

- Cycle life: Lithium-ion batteries, including 18650 cells, generally have a higher cycle life than lead-acid batteries. A cycle refers to one complete charge-discharge cycle. Lithium-ion batteries can endure thousands of cycles before their performance starts to degrade significantly, whereas lead-acid batteries typically have a lower cycle life.

- Self-discharge: 18650 cells have a lower self-discharge rate compared to lead-acid batteries. Self-discharge refers to the rate at which a battery loses its charge when not in use. Lithium-ion batteries have a lower self-discharge rate, allowing them to retain their charge for longer duration.

- Weight and size: 18650 cells are smaller and lighter than lead-acid batteries. This makes them more suitable for applications where weight and size are important factors, such as portable electronics and electric vehicles.

- Maintenance: Lead-acid batteries require regular maintenance, such as checking and replenishing electrolyte levels, while lithium-ion batteries, including 18650 cells, are virtually maintenance-free.

Lithium-ion 18650 cells offer advantages in terms of energy density, voltage, capacity, cycle life, self-discharge rate, and size compared to lead-acid cells.

What is a 18650 battery pack?

A 18650 battery pack is a configuration of multiple 18650 cells connected together to provide higher voltage, capacity, or both. By combining several individual cells, the pack can deliver more power and energy than a single 18650 cell. Constructing a 18650 battery pack involves connecting the cells in series, parallel, or a combination of both.

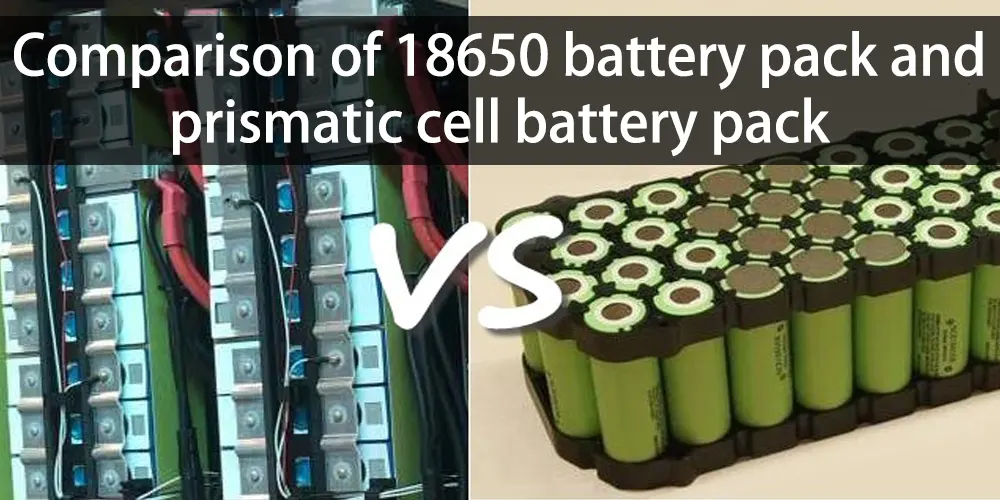

Comparison of 18650 battery pack and prismatic cell battery pack

18650 battery pack and prismatic cell battery pack are two different configurations of lithium-ion batteries, each with its advantages and considerations. Here is a comparison between the two:

- Physical appearance: The main difference between these battery packs is their form factor. 18650 cells are cylindrical, measuring 18mm in diameter and 65mm in height, while prismatic cells are rectangular or square, with varying dimensions depending on the specific model.

- Packaging efficiency: Prismatic cells often have a higher packaging efficiency than 18650 cells. The rectangular shape of prismatic cells allows for better space utilization in specific applications, maximizing the battery’s energy density. On the other hand, the cylindrical shape of 18650 cells may result in some wasted space within the battery pack.

- Heat dissipation: 18650 cells have better heat dissipation characteristics due to their cylindrical design. The cylindrical shape allows for more efficient airflow and heat transfer within the battery pack, reducing the risk of overheating. Prismatic cells may require additional cooling measures due to their less efficient heat dissipation properties.

- Flexibility in configuration: The flexibility of the prismatic cell is higher, because there is no uniform model, so the size and capacity can be designed according to the application requirements. The cylindrical battery, especially the 18650 battery, has a high degree of standardization, its size is fixed, and its flexibility is low.

- Availability and cost: 18650 cells are more commonly available and have been widely used for a longer time, leading to a larger selection from various manufacturers. This greater availability can contribute to lower costs compared to prismatic cells, which may have a more limited range of options and higher manufacturing costs.

- Application suitability: The choice between 18650 battery pack and prismatic cell battery pack often depends on the specific application requirements. The application scenarios of the two have a certain overlap. A single 18650 cell is smaller in size, so it is suitable for relatively small electrical equipment, such as portable electronics, power tools.

However, when the 18650 cells are packed into a battery pack, the 18650 battery pack can also supply power for large power systems, such as electric motorcycles, electric vehicles, energy storage system. The prismatic cell is also easy to expand due to its large capacity, because it is often used in power systems, such as electric vehicles, energy storage system.

It is worth noting that both 18650 cells and prismatic cells are lithium-ion batteries and share many common characteristics, such as energy density, voltage, capacity, and safety considerations. The choice between the two ultimately depends on the specific needs and constraints of the application at hand.

What parts and tools are needed to build a 18650 battery pack

To build a 18650 battery pack, you will need several parts and tools.

Here is a list of the essential components and tools typically required:

Parts:

- 18650 cells

- Battery management system (BMS)

- Battery holder/Spacers

- Wiring

- Connectors

- Insulation material

Tools:

- Soldering iron

- Heat gun or hair dryer

- Wire cutters and strippers

- Multimeter

- Battery spot welder (optional)

- Safety equipment

Remember to follow safety guidelines and proper handling procedures for lithium-ion batteries to avoid accidents or damage.

How to design and build a 18650 battery pack

Designing and building a 18650 battery pack involves considering several factors, such as the desired voltage, capacity, load current, and safety requirements.

Here are some steps to help you with the design and construction process:

Determine the voltage requirement: Determine the voltage needed for your application. This can be done by checking the voltage requirement of the device or system you plan to power with the battery pack. If the voltage requirement is already specified, proceed to the next step. Otherwise, identify the voltage range that your application can accept.

Calculate the number of cells in series: Each 18650 cell typically has a nominal voltage of 3.2 to 3.7 volts. To achieve the desired voltage, divide the required voltage by the nominal voltage of a 18650 cell. If a non-integer is obtained, the integer is taken and added by one. For example, if your desired voltage is 14.4 volts, you need 14.4V / 3.7V ≈ 4 cells in series.

Determine the capacity requirement: Calculate the capacity needed for your application, considering the desired runtime or energy demand. Determine the capacity in milliampere-hours (mAh) or ampere-hours (Ah). This will help you select 18650 cells with the appropriate capacity. Consider that the capacity of the battery pack will be the same as the capacity of an individual cell if the cells are connected in series.

Decide on series and parallel configuration: Based on the calculated number of cells in series and the desired capacity, decide on the series and parallel configuration that meets your requirements. Connecting cells in series increases the voltage while connecting them in parallel increases the capacity.

Calculate the load current: Determine the maximum load current that your battery pack needs to deliver. This information is typically available in the specifications of the device or system you plan to power. Make sure the selected cells and the battery pack as a whole can handle the required load current.

Select cells and battery management system (BMS): Choose high-quality 18650 cells from reputable manufacturers. Consider factors such as capacity, discharge current rating, and cycle life. Ensure the selected cells can handle the load current and voltage requirements. Additionally, select a BMS compatible with the number of cells that meets your safety and protection needs.

Design the physical layout: Plan the physical layout of the battery pack, considering factors such as mechanical stability, space availability, and thermal management. Use battery holders, spacers, or custom-made enclosures to hold and secure the cells in place, ensuring proper insulation and protection.

Assembly and testing: Follow proper safety precautions and assembly techniques while connecting the cells, wiring, and BMS. Solder the connections carefully and insulate exposed terminals. Test the pack using a multimeter to verify proper voltage, cell balance, and connectivity.

Safety considerations: Ensure that the battery pack is protected against overcharging, over-discharging, and short circuits by integrating the appropriate BMS. Adhere to safety guidelines, handle the cells properly, and consider adding features such as fuses, thermal sensors, and protection circuits for enhanced safety.

It is important to note that designing and building a battery pack can involve electrical and safety considerations. If you are not familiar with the process or lack experience, it is advisable to consult experts or seek guidance from professional lithium battery manufacturer who specializes in battery pack assembly to ensure a safe and reliable final product.

What is the most crucial considerate factor in designing a 18650 battery pack?

When designing a 18650 battery pack, the most critical factor to consider is safety. Then, to have a clear understanding of the voltage requirement and capacity requirement. Lithium-ion batteries, including 18650 cells, can be potentially hazardous if not handled and designed properly.

What to consider when choosing the right nickel strip to build the 18650 battery pack

When selecting the right nickel strip for making a 18650 battery pack, several factors should be considered to ensure the strip’s compatibility and reliability.

The following key points are important:

- Thickness

- Width

- Material and coating

- Weldability

- Compatibility with cell size and configuration

- Safety

- Supplier reputation

- Cost

Why need to use 18650 cell holders for 18650 battery pack

Using 18650 cell holders in a 18650 battery pack offers several advantages and benefits. It can provide structural integrity, electrical isolation, and protection for the individual cells within the battery pack.

They contribute to the pack’s safety, reliability, and ease of assembly and maintenance. However, it is vital to choose high-quality cell holders and ensure proper installation to optimize their performance and maximize the lifespan of the battery pack.

The following are some key elements:

- Mechanical stability

- Ease of assembly

- Electrical isolation

- Cell protection

- Flexibility and modularity

- Heat dissipation

- Serviceability

Can I make 12V battery from 18650 cells? How many 18650 cells do I need?

Yes, you can make a 12v lithium ion battery using 18650 cells. To determine the number of 18650 cells needed to achieve a 12V battery, you need to consider the nominal voltage of the 18650 cells and their configuration (series or parallel).

Each 18650 cell typically has a nominal voltage of around 3.2 to 3.7 volts. To create a 12V battery, you can connect the cells in series. When cells are connected in series, the voltages add up. Therefore, you need to connect 4 cells in series to achieve a 12V battery.

Remember that the actual voltage of the 18650 cells can vary depending on factors such as charge level and temperature. It is important to consider the specific voltage range of the cells you are using and ensure that the total voltage of the connected cells falls within the desired range.

While building a battery pack, it is crucial to incorporate a battery management system (BMS) to monitor and protect the cells, balance their voltages, and provide overcharge and over-discharge protection.

How to calculate the running time of a 18650 battery pack

To calculate the running time of a 18650 battery pack, you need to consider the capacity of the battery pack and the load current of the device or system it powers. The following steps will let you calculate the running time.

Determine the capacity: Identify the capacity of the 18650 cells in the battery pack. If you have multiple cells connected in parallel, the capacity of the battery pack will be the sum of the capacities of the individual cells.

Calculate the effective capacity: Consider the efficiency of the battery pack and any losses incurred during discharge. Multiply the total capacity of the battery pack by the efficiency factor to determine the effective capacity. For example, if the battery pack has a measured efficiency of 90%, multiply the total capacity by 0.9.

Determine the load current: Identify the load current, which is the amount of current drawn by the device or system powered by the battery pack. The load current is typically specified in milliamperes (mA) or amperes (A).

Calculate the running time: Divide the effective capacity of the battery pack by the load current to calculate the running time. Convert the capacity and load current to the same unit (mAh or A) before performing the calculation. The result will be the running time in hours.

Running time (hours) = Effective Capacity (mAh or Ah) / Load Current (mA or A)

Note: If the load current is not constant and varies over time, it may be necessary to consider the average or peak load current, depending on your specific application.

It is important to note that the calculated running time is an estimate and may vary depending on factors such as the efficiency of the battery pack, temperature, discharge rate, and the specific discharge profile of the cells. Additionally, the actual running time may decrease over the life of the battery pack as the cells age and their capacity decrease.

Applications of 18650 battery pack

18650 battery pack is widely used in various applications, including power tools, solar energy storage, uninterruptible power supplies, portable lighting, medical devices, robotics, and energy storage systems.

Final thoughts

18650 battery pack has become famous for various applications due to their compact size, high energy density, and ability to deliver reliable power. Whether in consumer electronics, electric vehicles, power tools, solar energy storage, or various other devices, these battery packs provide the necessary portable power solutions.

With their versatility, efficiency, and increasing advancements in technology, 18650 battery pack continues to play a significant role in powering our modern world.

2 thoughts on “18650 battery pack – helpful guide to build 18650 battery pack”

Thank you so much for sharing such an educational article

Hi there, thanks for your comment, you could take a look at our recent article, hope it is also useful to you~!