Home » lithium ion battery knowledge » Battery structure- understand the internal of battery

Battery structure- understand the internal of battery

This article will take you to explore different battery structures. By reading this article, most of your questions about batteries will be answered.

What is battery structure?

The battery structure refers to the arrangement and installation of the internal components of the battery.Different needs and applications require corresponding adjustments to the battery structure to meet actual needs.

For example, positive electrode materials differ between ternary lithium batteries and lithium iron phosphate batteries. These two batteries’ differing performance and application scenarios are a result of the distinct positive electrode materials used in each.

In addition to the positive electrode material, the adjustment of the battery structure is also to pursue better performance and lower cost.

For example, in recent years, the use of silicon-based materials to replace traditional carbon-based materials can increase the energy density of batteries, but the cost of silicon-based materials is higher than that of carbon-based materials, so a trade-off is required in practical applications.

In short, the adjustment of battery structure is to meet different needs and applications, while pursuing better performance and lower cost.

Understanding these differences helps us better understand battery performance and application scenarios.

Lead-acid battery structure VS lithium battery structure

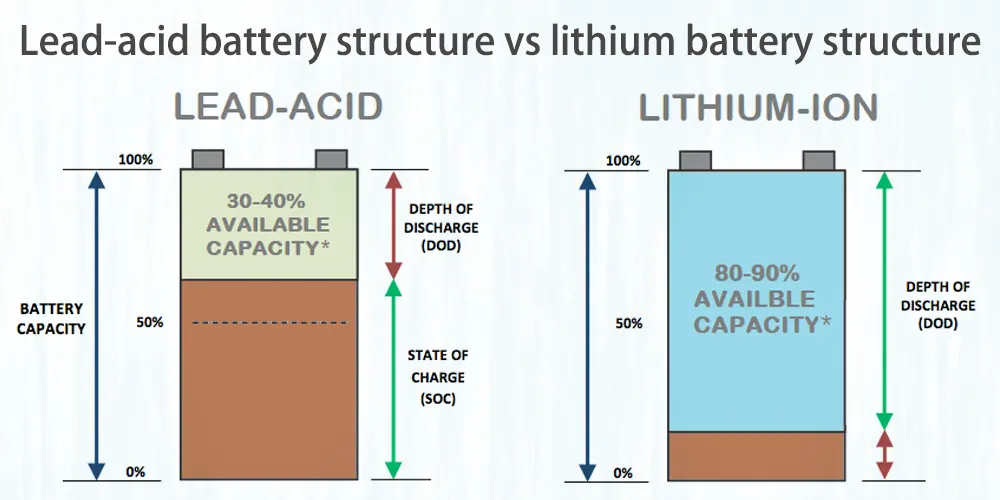

Lead-acid battery is a traditional battery technology, which is composed of positive plate group, negative plate group, separator, container and so on.

The positive plate pack is usually made of lead dioxide, while the negative plate pack is made of lead. The container is made of hard rubber or plastic and contains an electrolyte, usually sulfuric acid.

Lithium battery structure consists of positive electrode, negative electrode, separator, electrolyte, etc. The positive electrode is usually made of lithium metal oxide, while the negative electrode is made of graphite. The electrolyte is usually a lithium salt dissolved in an organic solvent.

Although the structure of the two is similar, due to the weight, volume and energy density of lead-acid batteries, their application fields are limited. Lithium-ion batteries are made of lighter materials, which can be applied to compact designs.

Therefore, it has broad application prospects in mobile devices, electric vehicles and other fields. In addition, lithium batteries can also be used in energy storage systems, solar and wind power generation and other fields.

Lithium battery is one of the development directions of battery technology in the future, and will play a more important role in future energy storage solutions.

Different types of lithium battery structure

Cylindrical battery structure

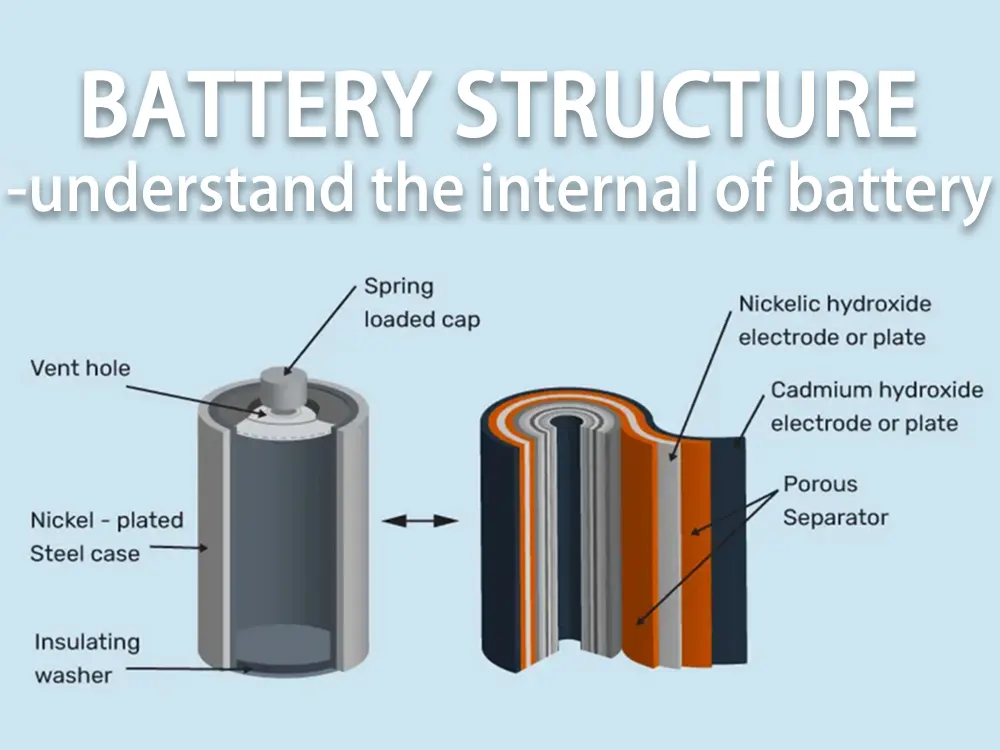

A typical cylindrical battery structure mainly includes a casing, a cap, a positive electrode, a negative electrode, a separator, an electrolyte, a PTC element, a gasket, and a safety valve.

Usually the shell is the negative pole of the cylindrical battery, the cap is the positive pole of the battery, and the battery shell is made of nickel-plated steel plate.

Advantage:

● The monomer itself possesses strong mechanical qualities and a good consistency. The closed cylinder battery may achieve the highest bending strength under the approximate size when compared to the square and pouch batteries.

● The winding technology is mature and the cost is low, but at the same time, the space for cost optimization has been almost consumed.

● The energy of the monomer is small, and the form is easy to control when an accident occurs.

Shortcoming:

● The number of cylindrical cells in the battery system is large, which greatly increases the complexity of the battery system.

● The cost of cylindrical batteries at the system level is high;

● There is little room for energy density improvement.

Pouch battery structure

Pouch lithium batteries generally use aluminum-plastic packaging film materials, which are usually divided into three layers, namely the outer resistance layer, the barrier layer and the inner layer.

The pouch battery is thinner and the lightest in the same volume because of the stacking method.

Advantage:

● Good security. The structure of the soft-pack lithium battery is packaged with aluminum-plastic film.

In the event of a safety hazard, the soft-pack lithium battery is generally inflated first, or cracked to release energy from the seal, while the metal shell cell is more likely to produce a large explosion due to internal pressure.

● Good electrochemical performance and long life. The internal resistance of the soft-pack lithium battery is small, which can greatly reduce the self-consumption of the battery.

● Flexible design. Custom lithium battery manufacturers can customize the size and shape of soft-pack lithium batteries according to customer needs.

Shortcoming:

● Questions of standardization and cost. Since there are so many models of pouch lithium batteries, the degree of automation in the middle and back stages is not as good as that of the cylindrical battery production line, which makes it impossible for pouch batteries to achieve mass production.

● High cost. High-end aluminum-plastic films rely heavily on imports.

● Consistency problem. The degree of automation in the production process of soft pack power batteries is relatively low.

Square battery structure

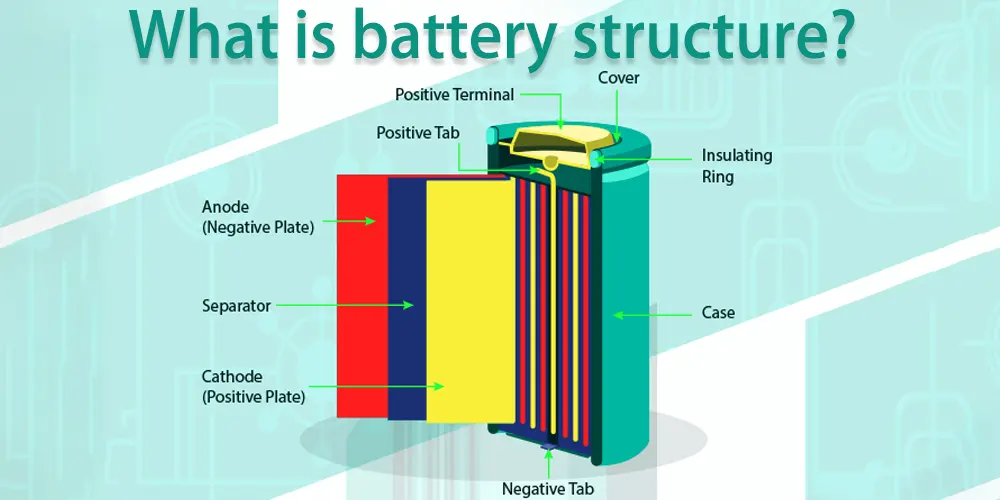

The main components of a typical prismatic lithium battery include: a top cover, a casing, a positive plate, a negative plate, a stack or winding of separators, insulating parts, safety components, etc.

Advantage:

● The packaging reliability of the square lithium battery is high, and the energy efficiency of the system is high.

● Relatively light weight, high energy density.

● The structure is relatively simple, and the expansion is relatively convenient. It is currently an important option to increase the energy density by increasing the capacity of the monomer.

If the monomer capacity is large, the system structure is relatively simple, making it possible to monitor the monomers one by one; another benefit brought by the simplicity of the system is relatively good stability.

Shortcoming:

● The level of production automation is not high, and the differences between monomers are large.

● In large-scale applications, there is a problem that the lifetime of the system is much lower than that of the monomer.

Future development of battery structure

With the growing demand for more efficient and durable batteries, researchers and scientists are exploring different approaches to battery structure design.

A promising area for the development of battery structures is the use of solid-state electrolytes instead of conventional liquid electrolytes.

Solid-state electrolytes offer multiple advantages, including higher energy density, longer cycle life, and improved safety.

The use of solid-state electrolytes also enables the use of lithium metal anodes, which have higher energy densities than the traditional graphite anodes used in most batteries today.

Another area of development is the use of nanomaterials in battery electrodes. Nanomaterials have unique properties that can improve battery performance, such as faster charge and discharge rates, higher energy density and longer cycle life.

The researchers are also exploring the use of 3D electrode structures, which could increase the surface area of the electrodes for more efficient energy transfer.

Overall, the future of battery architecture development looks promising with advances in solid-state electrolytes, nanomaterials, and other technologies.