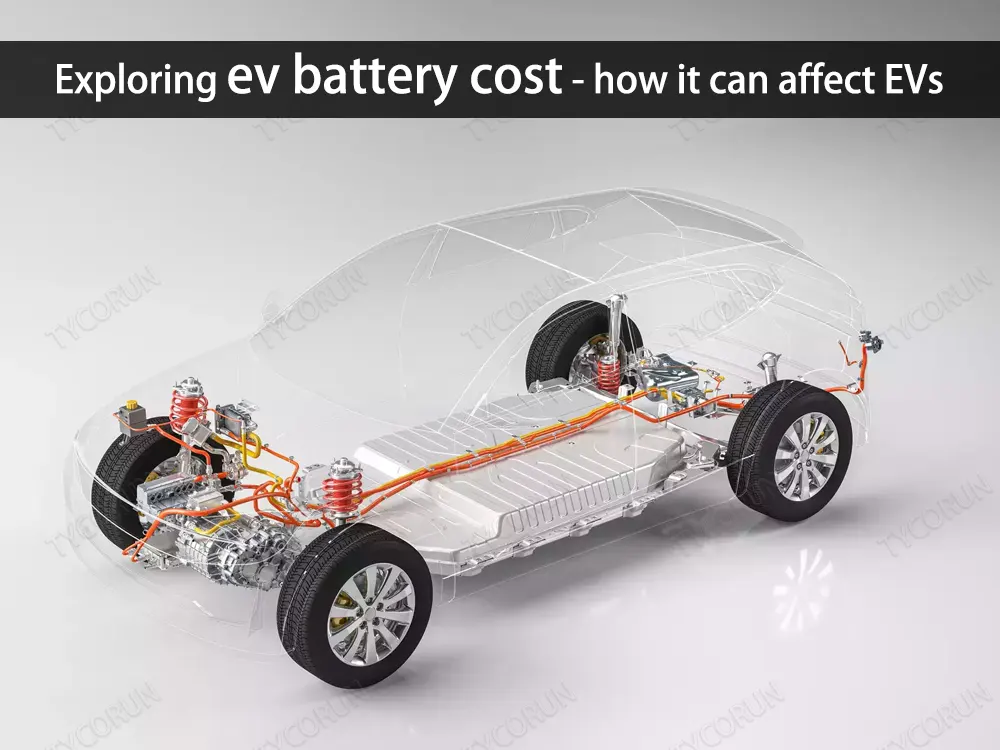

Home » electric car battery » Exploring ev battery cost – how it can affect EVs

Exploring ev battery cost - how it can affect EVs

EV battery cost

It is shown that the average single-part ratio coefficient of electric vehicle power battery packs is 48.85%.

The so-called part-to- whole ratio refers to the ratio of the sum of the prices of all accessories of the vehicle to the sales price of the vehicle.

The larger the ratio, the higher the price of parts and components, which means the higher the cost for consumers to repair and maintain their cars.

According to reports, the average battery cost of Samsung, Panasonic, LG and other power battery manufacturers among the top 10 power battery companies in the world is US$160/kW·h.

This means that a battery with a range of 700 kilometers costs close to $100,000. If you trade it in, it will probably be no less than $60,000.

Even if prices in China are relatively cheaper, perhaps the battery cost of an electric car priced at about 150,000 RMB can be reduced to about 70,000 RMB. But replacing a battery is equivalent to buying an 80% new used car, which is still difficult for some people to accept.

Why electric car battery cost so much?

While the high cost of electric vehicle batteries is concerning, there are many factors that contribute to this cost.

One of the main reasons for the high cost is the expense of the materials used in battery production, particularly raw materials such as cobalt and lithium.

It is undeniable that there are certain objective factors for the high EV battery cost. In particular, the skyrocketing lithium price is an important reason for the sharp increase in EV battery costs.

The expensiveness of positive electrode materials comes from the fact that they determine important indicators such as battery performance and safety, accounting for 50% of the battery cost.

Lithium ions and electrons are stored in the positive electrode of the battery and flow to the negative electrode to complete charging. This means that the positive electrode directly determines the battery performance, and indirectly determines the endurance of the electric vehicle itself.

Compared with lithium iron phosphate batteries, the cost of positive electrode materials for ternary lithium battery is more expensive.

The main reason is that the price of ternary lithium materials is relatively expensive due to the scarcity of nickel, cobalt, manganese, and lithium precious metal raw materials, and the decrease is relatively small.

In addition, battery technology also affects EV battery cost, because different companies have different battery packaging designs and assembly modes. Currently, only some battery companies in the world are able to master higher efficiency and cost-saving assembly methods.

How ev battery cost affects EVs?

Excessive EV battery cost will cause the vehicle pricing to rise, which will cause damage to the car brand and lose a certain proportion of intended customers.

As we all know, since electric vehicles do not need to replace oil, filters, ignition parts, engines and other related parts, maintenance parts are significantly reduced.

In addition, electric vehicles often use energy recovery braking functions to reduce wear on brake discs and brake pads, and the frequency of replacement of the braking system is also reduced.

Therefore, electric vehicles have always been superior to traditional fuel vehicles in terms of maintenance frequency and cost, which has become one of the important factors that attract consumers to buy them.

However, with the rapid expansion of the electric vehicle market and the increase in vehicle service life, consumers have found that when the battery is damaged and malfunctions, the maintenance cost of electric vehicles is significantly higher than that of fuel vehicles.

At a time when the electric vehicle market is still expanding rapidly, the cost of battery repair or replacement is too high, which will reduce the reputation and experience of electric vehicles, thereby affecting consumers’ purchasing decisions.

Secondly, customers may give up on repairs, resulting in a greater waste of resources.

It is even possible to find some informal repair manufacturers to replace batteries obtained through illegal channels, which will greatly increase the possibility of subsequent product failures and accidents, posing a huge hidden danger to safe driving.

How to reduce ev battery cost?

For car companies, they need to take the initiative to find technical ways to reduce costs.

For example, material innovation can be achieved, including high nickel and monocrystalline ternary cathodes, manganese elements inserted into the iron-lithium cathode to increase the voltage, silicon-doped negative electrode materials to supplement lithium, and the use of sodium-ion batteries.

It can also strengthen system innovation and improve production efficiency. Or focus on structural innovation, improving energy density and reducing system costs by designing the cell structure and size, optimizing the assembly structure of modules and battery packs, and reducing the amount of consumables.

In terms of reducing EV battery costs, it is not enough to rely on automobile companies alone.

On the one hand, financial companies and institutions should actively participate in the practice of battery swapping station business model, which can not only reduce consumers’ purchase costs, but also reduce battery maintenance and replacement problems.

On the other hand, power battery recycling companies should also take action to work with battery companies or vehicle companies to promote the recycling and reuse of power batteries and improve the reuse rate of lithium, cobalt and other resources, which can reduce EV battery cost to a certain extent.

In addition, unifying battery pack specifications is also one of the important means to reduce EV battery cost.

This requires industry organizations to revise power battery specifications and size standards as soon as possible, reduce specifications, and achieve large-scale automated production through modular applications, thereby effectively reducing battery production costs.

Summary

Currently, the cost of power batteries remains high and remains one of the bottlenecks restricting the development of electric vehicles.

For electric vehicles to continue to maintain a steady development momentum, it is crucial to continuously improve consumption and user experience.

With the joint efforts of the upstream and downstream of the industry chain, vehicle companies can only be more active and proactive in reducing ev battery cost. Only in this way can car companies improve their own profitability and win more users.