Principles and application scenarios of flywheel energy storage

Flywheel energy storage is an integrated technology, and its future development direction is high-speed, composite material rotor, and internal and external rotation structure. Flywheel energy storage has broad application prospects, but it is currently in the early stage of market development. At present, the global energy storage market is characterized by large scale, fast speed, many policies and a hot market.

China’s demand for energy storage is huge and urgent, and it is in the early stage of development from demonstration to commercialization. The Chinese government has a series of policy support. Flywheel energy storage is a high-power, fast-response, high-frequency, long-life mechanical energy storage technology with broad application prospects.

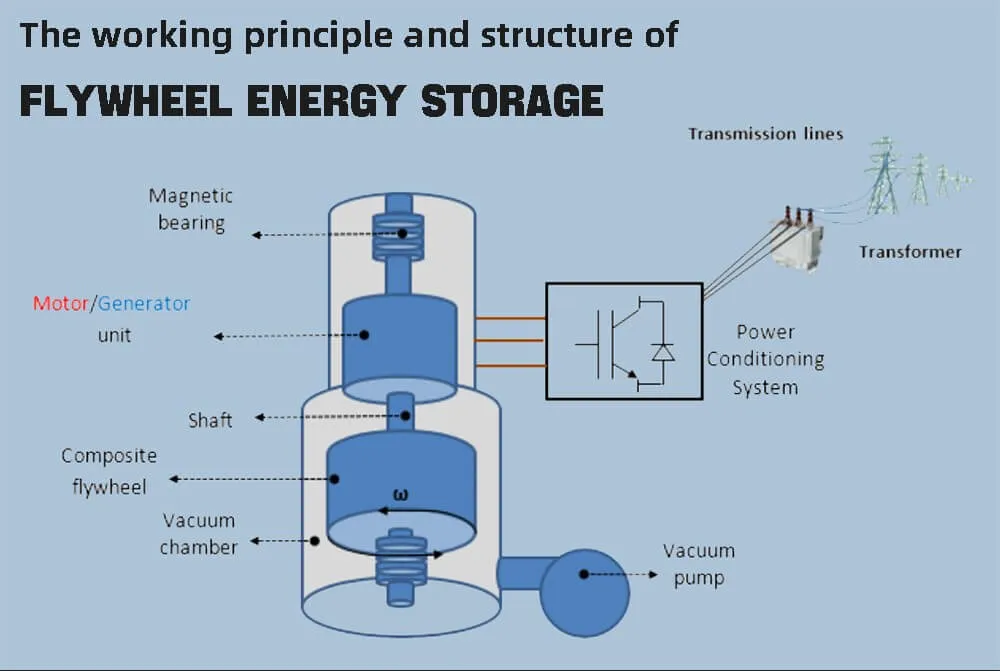

The working principle and structure of flywheel energy storage

The entire flywheel storage device is in a closed casing, providing a high vacuum to reduce drag and protect the rotor system from running. Flywheel energy storage has the advantages of high energy storage density, high energy conversion efficiency (up to 90%), the number of charge and discharge is independent of the depth of charge and discharge, and no pollution. The flywheel system plays an important role in the field of power system (including renewable energy grid connection, frequency regulation, etc.), rail vehicles, UPS, aerospace and other fields.

The flywheel energy storage power system mainly consists of three parts:

- Flywheel;

- Motor: motor + generator;

- Bearings: provide low-loss support for the rotor.

When the flywheel is charged, the motor will start to accelerate the flywheel, converting electrical energy into mechanical energy for storage. When electricity is needed, the speed of the flywheel decreases, and the mechanical energy is converted into electrical energy through the generator to supply external power.

Features and pros and cons of flywheel energy storage technology

Technical features of flywheel energy storage

Flywheel energy storage is a high-power, long-life and high-efficiency power energy storage technology. Compared with other energy storage technology, flywheel energy storage is characterized by almost no friction loss and low wind resistance. The specific power of flywheel energy storage can reach more than 8kW/kg, which is much higher than that of traditional electrochemical energy storage technology.

The life of the flywheel energy storage mainly depends on the fatigue life of the flywheel material and the life of the electronic components in the system. At present, the service life of flywheel energy storage can reach more than 2 million times, and the service life is not affected by the depth of charge and discharge. No harmful substances are produced during the operation of the flywheel energy storage and almost no maintenance is required during the operation. It has good adaptability to working conditions and environment, and can work normally under -20 ~ 50 ℃.

Technical characteristics and applications of flywheel energy storage

| Technical advantages | High power density, high efficiency, long life, no pollution |

|---|---|

| Technical disadvantage | Low energy density and high self-discharge rate |

| Application scenarios | UPS, energy recovery, power grid frequency regulation, micro-grid peak regulation, etc. |

Advantages and disadvantages of flywheel energy storage

Advantages of flywheel energy storage

- Good power characteristics, fast response speed, can achieve millisecond-level high-power charge and discharge, and high reliability;

- High efficiency, maintenance-free, no friction loss due to magnetic levitation support, and long system maintenance cycle;

- Not affected by the number of repeated deep discharges, the service life is generally more than 20 years;

- The applicable temperature is wide, the capacity characteristics are not affected by high and low temperature, and the working temperature is generally -10 to +40 °C;

- No chemical substances, green environmental protection, no pollution.

Disadvantages of flywheel energy storage:

- Since the speed of the flywheel can reach 40,000 to 50,000 rpm, the flywheel is generally made of carbon fiber, and the cost is high;

- The energy release duration is short, generally only tens of seconds, and the self-discharge rate is high. If charging is stopped, the energy will be completely lost within tens of hours.

Application prospect analysis of flywheel energy storage

Flywheel energy storage is suitable for high-power, fast-response, and high-frequency scenarios. Typical markets include UPS, rail transit, and power grid frequency regulation. In the future, there will be emerging markets such as charging piles and construction machinery.

UPS market

Global data centers, communication base stations, and important activities all have clear requirements for uninterrupted power supply. At present, the combination mode of chemical battery + diesel generator is mainly used.

Compared with the current chemical battery such as UPS lithium battery, the flywheel energy storage has the advantages of faster response, large instantaneous power, small footprint and long service life, and is more suitable for use with diesel generators as UPS power sources.

Rail transit

At present, the electric energy recovered by subway trains entering the station is consumed by means of resistance heat dissipation, which has the problem of waste of resources and impact on the power grid.

The flywheel energy storage will recover electric energy when the train enters the station, and release the electric energy when the train leaves the station, playing the role of energy saving and friendly power grid. Several subway stations in the United States have demonstrated flywheel energy storage, which can save 20% of electricity.

Power grid frequency regulation market

The flywheel frequency modulation power station is earlier than the electrochemical frequency modulation power station. As an energy storage device, flywheel energy storage is different from general energy storage devices. It is a power energy storage device and can be used for short-term support of power.

Unbalanced power generation and power consumption in the power grid will cause the frequency of the power grid to fluctuate. In order to smooth this fluctuation, the power grid needs to be equipped with a frequency modulation power station with 2% of the total power generation capacity.

At present, the frequency regulation of China’s power grid is mainly undertaken by generator sets. In the future, the proportion of new energy entering the grid will increase, and the demand for grid frequency regulation will be greater.

The flywheel energy storage has the characteristics of high power, fast response speed, and strong circulation ability. It can quickly and effectively perform active/reactive power compensation with the changes of the power grid, stabilize fluctuating loads, buffer power generation output transients, and support power grid frequency and voltage. Flywheel energy storage has good application prospects.

Energy storage electric vehicle charging pile

Different from battery swapping, Energy storage electric vehicle charging piles are mainly used in high-power and fast-charging applications for electric vehicles. Limited by the capacity of the existing grid framework, the construction of an electric vehicle charging station involves a series of problems such as the capacity increase of the grid and the adjustment of urban planning.

The high-power electric vehicle fast charging pile system with an energy storage link can reduce the pressure of the charging pile on the capacity increase of the power grid. The magnetic levitation energy storage flywheel is used as the energy storage device, and the energy storage flywheel is fully used for slow charging and fast discharging, that is, the typical operating characteristics of low-power charging and high-power output.

It can not only meet the requirements of fast charging of electric vehicles, but also avoid the constraints of grid capacity expansion. At the same time, because the energy storage flywheel has high power density, small size, flexible layout, green environmental protection and no pollution, it can be arranged underground, which eliminates the impact of the construction of charging stations on the city appearance and reduces the pressure of urban construction work.

Current application status of global flywheel energy storage

The technical threshold of flywheel energy storage system is relatively high, and there are still some urgent problems to be solved in composite material structure technology, magnetic bearing technology, and high-speed and high-efficiency motor technology in vacuum. High-speed, composite material rotor, internal fixed external rotating structure is the future development direction. Chinese companies have basically mastered alloy flywheel technology, but there is a clear gap compared with foreign countries in structural design, composite rotor flywheel and other aspects.

Flywheel energy storage technology has been explored in North America as early as the 1950s and 1960s. A commercial application scenario with relatively rigid demand and a clear profit model was born, that is, the application of power grid frequency regulation. Stable and mature technologies and products have been formed, which have withstood the test of commercial operation, and a leading enterprise in the flywheel energy storage industry has emerged.

Canada’s Temporal Power’s total R&D investment of up to 35 million Canadian dollars. Beacon Power in the United States has invested as much as 250 million US dollars in various types of research and development. The common technical feature of the two companies is that they are developed, designed and manufactured for the commercial application of power grid frequency regulation.

China has independently developed flywheel energy storage technology for decades, mainly based on theoretical research in various universities. At present, there are nearly ten flywheel energy storage manufacturers in China conducting research and development of flywheel energy storage equipment, and there are not many engineering applications that have been deployed. In 2022, flywheel energy storage will gradually heat up, and the entire industry will be in a state of exploration until a benchmark and exemplary flywheel energy storage project is connected to the grid.

Flywheel energy storage equipment is a mechatronics equipment based on precision manufacturing and multi-disciplinary integration. Its main bottleneck lies in the large-scale production capacity of high quality and stability. At present, most of the flywheel production technologies/products in China are still in the stage of prototype trial production, and there is still a long way to go before large-scale production.

From a global perspective, the application of grid-side flywheel energy storage in the field of frequency regulation is mature. In 2011, the first commercial flywheel energy storage frequency regulation power station was connected to the grid and has been in operation for more than ten years, and it is still in operation. Canada’s first commercial flywheel energy storage frequency regulation power station was connected to the grid in 2014, and it is still providing frequency regulation auxiliary services for the local power grid.

Conclusion

Among many energy storage technologies, flywheel energy storage systems have received much attention due to their high efficiency, large capacity, fast response, and environmental friendliness. As a gradually mature energy storage technology, the flywheel energy storage system has been applied to the fields of electric vehicles and electric power, gradually replacing chemical battery energy storage, and has become a force that cannot be ignored in the energy storage industry.

The technical reserve of flywheel energy storage in China has been basically completed, and it is in the early stage of commercialization. Demonstration projects have been promoted in the fields of high-power UPS, power grid frequency regulation, and kinetic energy recovery.