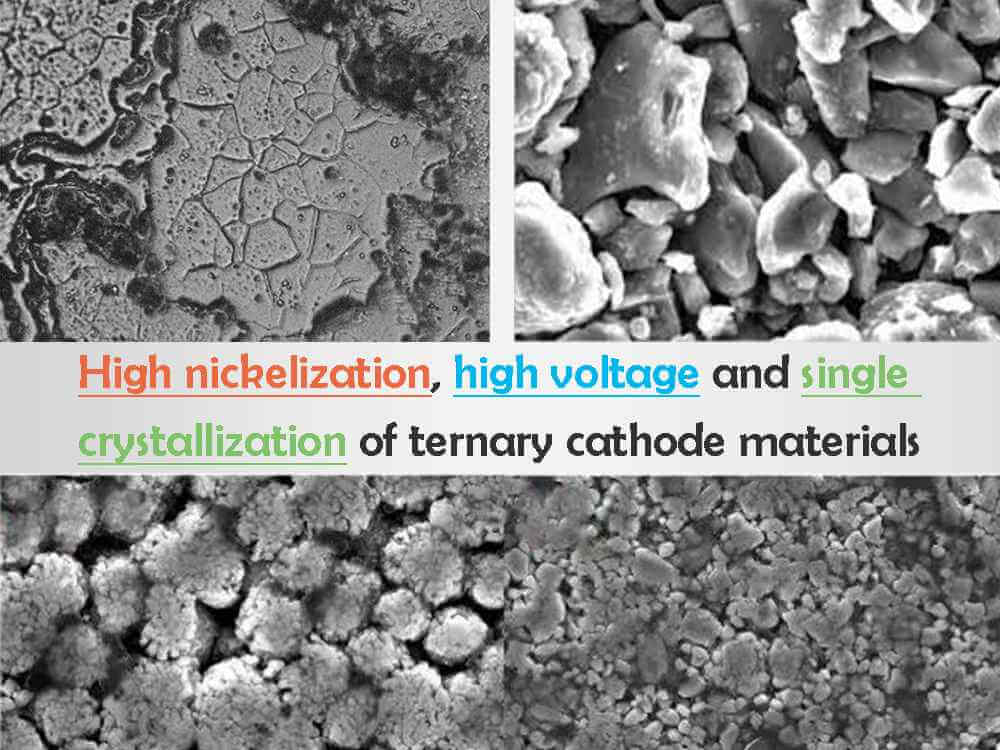

High nickelization, high voltage and single crystallization of ternary cathode materials

The process application of high nickel, high voltage and single crystal chemistry drives the continuous optimization of ternary cathode materials in energy density, safety performance, cost and other aspects. And the top companies with corresponding technical reserves are expected to promote the improvement of industry concentration, such as Top 5 NCM811 high nickel ternary cathode material companies.

Ternary cathode materials improve for a long time

The installed capacity of power batteries is increasing

The global trend of vehicle electrification is obvious. According to data statistics, the global penetration rate of new energy vehicles has steadily increased, with the global penetration rate reaching 8.3% in 2021, 4.1 pct higher than that in 2020. In the first quarter of 2022, the global sales of new energy vehicles reached 2.061 million, among which, China’s overall sales of new energy vehicles reached 1.257 million, up 142.7% year on year, and the penetration rate reached 19.2%.

Under the trend of electric power of vehicles, the global power battery installation capacity is rising rapidly. Benefiting from the rapid promotion of vehicle electrification in the Chinese and European markets, the global sales of new energy vehicles have risen rapidly since 2016, and the installed capacity of power batteries has increased simultaneously. In 2021, the global power battery installed capacity reached 296.8GWh, up 102% year on year; China’s power battery installed capacity reached 154.5GWh, up 144% year on year, faster than the global average growth rate, accounting for more than half of the global battery installed capacity.

Ternary and lithium iron phosphate coexist for a long time

Chinese market ternary battery installed capacity to maintain high growth, lithium iron phosphate installed capacity recovery. Previously, ternary cathode materials with the advantage of high energy density in the new energy passenger vehicle market rapidly increased, accounting for more than 60% of the installed power battery capacity in 2019 and 2020. However, with the launch of CATL CTP technology and BYD blade battery, combined with the decline of Chinese financial subsidies, cost reduction has become the main factor of power battery selection of automobile enterprises, driving the recovery of lithium iron phosphate installed capacity.

In July 2021, the monthly installed capacity of lithium iron phosphate exceeded three yuan, and the annual installed capacity in 2021 was 79.8GWh, accounting for 51.7%, marking the first time since 2018 that its installed capacity has exceeded ternary cathode materials. From January to May 2022, the cumulative installed capacity of power batteries in China was 83.1GWh, up 100.8% year on year; The cumulative installed capacity of lithium iron phosphate batteries was 49.0GWh, accounting for 58.9%, up 17.6 pct compared with 2021; The cumulative installed capacity of ternary batteries was 34.0GWh, up 186.1% year on year, accounting for 40.9%.

The installed amount of power battery installed in the European market is mainly ternary materials. From 2017 to 2020, the installed capacity of power batteries in Europe increased from 16.5 GWh to 98.1 GWh, and the CAGR reached 81.4%. Among them, the installed capacity of ternary power batteries always occupies a dominant position, accounting for more than 90% in 2020. From January to November 2021, the power battery capacity installed in Europe reached 144.9 GWh, up 92.1% year on year. Ternary power battery is still dominant, accounting for 95.4%; the installed capacity of 8 series ternary has reached 30.2GWh, up 495.2% year on year, and the proportion has significantly increased from 6.7% to 20.9%.

Benefiting from the increased demand for electric vehicles, the shipments of ternary materials continued to rise. In 2021, global ternary cathode materials shipped 718,000 tons, up 70.95% year on year, with a compound growth rate of 48.66% from 2017 to 2021; in 2021, Chinese ternary cathode materials shipped reached 422,000 tons, up 79.57% year on year, and with a compound growth rate of 41.25% from 2017 to 2021. In 2021, China’s market accounted for 58.8% of the world, becoming the main force driving the growth of the global ternary material market.

Ternary cathode materials technology continues to iterate

Ternary cathode material pattern is still relatively scattered

China’s market pattern is relatively scattered, the gap between the head companies is not obvious. According to statistics, the CR5 / CR10 in 2021 is 52.6% and 78.6% respectively. From the perspective of companies, RONBAY TECHNOLOGY, B&M and EASPRING are the top three. In 2022, the CR5 / CR10 reached 55.7%. The overall concentration of the industry is increased, and the share of the industry is still relatively dispersed.

Ternary cathode materials technology promotes the continuous optimization of the factor

A variety of cathode materials routes coexist, and the performance elements differ between the material systems. At present, cathode materials can be mainly divided into four categories: lithium cobalt oxide, lithium manganese oxide, lithium iron phosphate and ternary materials, among which ternary cathode materials can be subdivided into lithium nickel-cobalt-manganese oxide (NCM) and lithium nickel-cobalt-aluminate (NCA).

According to product characteristics and downstream application scenarios, lithium cobalt oxide and lithium manganese oxide batteries are mainly used in consumer electronics, while lithium iron phosphate and ternary batteries are mainly used in new energy vehicles.

Cost reduction and efficiency increase continue to drive research and innovation, and ternary cathode materials are constantly optimized in terms of energy density, safety performance and cost performance. The intelligent development trend of new energy vehicles has become the mainstream. The richer cockpit experience and intelligent driving function have both proposed the requirements of longer range and higher energy density for power batteries. At the same time, the safety and cost performance requirements of the battery systems accompanied by higher capacity and higher load are equally rigid, giving rise to the further exploration of the ternary cathode energy density, safety performance and cost performance.

● Energy density upgrade: ternary high nickel / high voltage trend is obvious

Solve the range anxiety, high nickels and high voltage to improve the energy density of ternary cathode materials. At present, the industry mainly improves the energy density of ternary cathode materials by raising the charging voltage upper limit (high voltage) and increasing the nickel content (high nickel content).

The proportion of high nickel 8 series ternary gradually increased, and ultra high nickel further enhances the competitiveness of high nickel ternary. High nickelization of ternary cathode materials refers to increasing the content of nickel elements in ternary materials, thus increasing the energy density, and correspondingly reducing the dependence on cobalt elements.

In 2021, China’s high nickel ternary production was 152,000 tons, up 110.2% year on year, accounting for 38.3% of the total production of ternary cathode materials. At present, the top cathode material companies in the industry have been gradually developing, verifying and producing 9 series of ultra-high nickel cathode materials, to further improve the energy density, solve the problem of battery lightweight, and enhance the competitiveness of high nickel ternary.

With the rise of medium nickel voltage platform, the energy density performance of high voltage route tends to be consistent with high nickel ternary. The high voltage route increases the battery charging stop voltage for the cathode material to remove more lithium ions at a higher voltage, so as to increase the capacity and working voltage at the same time, thus achieving the purpose of increasing the energy density.

● Further improvement of safety performance: the application of ternary single crystal system is increased

Polycrystal ternary cathode system is mature, and the single crystal ternary cathode characteristic is prominent. In terms of crystal structure, ternary cathode materials can be divided into single crystal type and polycrystalline type ternary cathode materials. Single crystal refers to by a crystal core equilibrium growth in all direction of the crystal. Its internal structure is basically a complete lattice, and polycrystalline is composed of many different orientation single crystal particles, the whole crystal structure is not by the same lattice, regular polycrystalline ternary cathode material is in the form of secondary spherical particle agglomeration.

Single crystal technology through the use of special precursor and sintering process, realize the ternary cathode material crystal special structure, in maintaining the existing capacity and charge and discharge platform, on the basis of trying to improve the single grain size of cathode material, so as to improve the vibration density, improve the volume capacity of lithium battery, and greatly improve the safety of lithium battery, make the quality of lithium battery is greatly improved.

The world is mainly polycrystalline ternary technology, China’s single crystal ternary and polycrystalline ternary technology in parallel. Single crystal ternary materials have been studied for a long time, but due to the early material system research and development route and patent reserve focus, the mainstream ternary materials of Japanese and Korean battery factories are mainly polycrystalline ternary materials, and gradually introduced into the domestic market by Chinese head cathode material enterprises. In the second half of 2017, as Ningde Times and other head battery enterprises began to apply them in power batteries, single crystal materials gradually realized the volume in the domestic market.

Single crystal ternary cathode material is more stable, which can be used as one of the material systems with higher voltage, and has certain advantages in safety performance and cycle performance. At high voltage, with the increasing internal resistance of the cycle number, the battery capacity will decay quickly, and the cycle performance will become worse.

Single crystal ternary cathode material is usually directly composed of one or several large particles (2~5 m) an irregular block particles, material internal no crystal boundary, microscopic surface is smooth, has better structure stability and high temperature resistance. And its material after compaction and high temperature cycle, not easy to break, so as to obtain more excellent high temperature cycle stability. Therefore, the single crystal ternary cathode material has better safety performance, which can better avoid the above problems of the polycrystalline ternary cathode material.

The permeability of single crystal ternary cathode material is gradually increased. Since 2018, China’s output of single crystal ternary materials has increased rapidly, with the annual output jumping to about 49,000 tons, of which more than 90% of single crystal ternary materials are used in the field of power battery. With the gradual introduction of downstream power battery enterprises, the total production of domestic single crystal ternary materials jumped to 144,000 tons in 2021, up 89.5% year on year; it is expected that the market share of single crystal ternary materials in China is expected to rise to more than 40% in 2022.

Single crystal high voltage technology iteration in medium nickel field, and single crystal introduction in high nickel field is accelerated. In the first quarter of 2022, the single crystal material system accounted for more than 50% of the medium nickel 5 series and medium and high nickel 6 series ternary materials. At present, high nickel 8 series ternary materials are still mainly based on polycrystalline system, but since the market penetration rate of single crystal high nickel in 8 series ternary materials, China’s head power battery enterprises began to introduce high nickel single crystal in 2021.

● Cost-performance breakthrough again: ternary watt-hour cost is expected to fall

In recent years, China’s new energy vehicle industry subsidies showed an overall downward trend, before the policy subsidy advantage brought by high energy density has been weakened.In this context, Chinese car companies reconsider the cost and benefits, balance between ensuring high energy density and cost performance, and rationally select the battery configuration combined with the actual costs and benefits of the products.

Ternary high nickel / high voltage drives watt-hour costs down. From the cost end, high nickel ternary cathode material to ultra high nickel development, reduce the use of cobalt metal, and high voltage ternary cathode materials relying on higher voltage platform can be realized in the same nickel material cost system of energy density, both in further improve the battery energy density at the same time, also brought the ternary lithium battery tile when effective cost reduction.

● Difficulty of technical iteration increases, and the concentration of market segmentation is higher

From the current technical level and product application, high nickel, high voltage, single crystal drive ternary cathode material industry technology iteration, also to ternary cathode material enterprises proposed higher process difficulty:

In the direction of high nickel conversion, the higher the nickel content, the higher the specific capacity under the same voltage conditions, but the radius of nickel ion and lithium ion is close, the higher the possibility of cation mixing in its structure, which is easy to reduce the specific capacity of the material. The ratio performance is weakened, and the reduction of the material surface stability is more likely to cause safety problems. At the same time, the process of high nickel ternary cathode materials above 8 series has special requirements for kiln equipment, box bowl, reaction atmosphere, etc., and it is more difficult to ensure the batch stability and consistency of products.

In the direction of single crystal, the production and synthesis of large single crystal ternary cathode materials need to overcome the negative impact of large single crystal on capacity and power performance, and also need to solve the problem of large DC internal resistance. At present, the industry mainly through doping and surface modification technology, to reduce the product free lithium, improve the material slurry adjustment stability, reduce the DC internal resistance, improve the cycle stability of single crystal ternary materials in high temperature, high nickel and high voltage environment.

In the direction of high voltage, although the high voltage ternary cathode materials can effectively improve the energy density of the material, it faces a series of challenges such as crystal structure stability, phase change, interface side reaction and oxygen release in the application scenario of the voltage of 4.4V and above, which makes the material development has extremely high technical barriers.

The market concentration of high nickel and single crystal ternary cathode materials is higher than that of the overall concentration of ternary industry. In 2020-2021, CR3 / CR5 was 35% / 52% and 38% / 55% respectively, compared with the CR3 / CR5 / 93.6% and 68.6%, and CR3 / CR5 was 53.5% / 73.8% and 53.9% / 73.4% respectively, which is more concentrated than the overall competition pattern.

The leading ternary cathode companies lead the development of the industry

ZEC: the ternary single crystal leader of the primary particle large single crystal technology, and the ternary cathode material enterprise with the first single crystal shipment.

XTC: high voltage series of products accumulated rich experience in the field of cathode materials industry leader. In terms of ternary materials, the company fully draws lessons from the high voltage battery technology research and development advantages formed in the field of lithium cobalt oxide, and actively develops high voltage ternary materials with downstream battery manufacturers, so that the main products have both safety and cost advantages while improving the energy density.

EASPRING: the global layout of the leading head three yuan material suppliers, with the global customer card advantage of the head three yuan cathode material enterprises. The company’s business scope covers the whole world, and it has become one of the few domestic enterprises that simultaneously sell power cathode materials to Japan, South Korea, Europe and the United States.

RONBAY TECHNOLOGY: focusing on the high nickel track ternary cathode material leader, China ternary cathode leader, focusing on the high nickel ternary cathode material.

MINMETALS: a head ternary cathode enterprise with outstanding advantages in industrial chain integration. The company has entered the field of ternary cathode materials since 2011, and has the mass production capacity of ternary cathode materials such as NCM523, NCM622, NCM811 and NCA.

Related post

Lfp vs nmc battery – comparative analysis of materials and batteries

1 thought on “High nickelization, high voltage and single crystallization of ternary cathode materials”

Keep on writing, great job!