lithium battery coated electrode piece drying technology and defects

One of the core processes of lithium batteries is the preparation of electrode pieces.

After the lithium ion battery anode cathode pieces are prepared, the electrolyte is injected into the battery through winding or lamination and other processes, and the battery can be used after being activated by packaging, charging and discharging.

Introduction of battery electrode piece

Among them, the battery electrode piece is a composite material with a sandwich structure, which is mainly composed of two-sided porous coatings composed of active material particles, binders and conductive agents, and a metal current collector foil sandwiched in the middle.

After the preparation of cathode and anode electrode slurry is completed, it is coated on aluminum foil and copper foil through a coating process. For the coating process of the electrode piece, the drying of the electrode piece after coating is one of the main energy consumption units and is also the focus of research.

For relevant information, please refer to battery aluminum foil manufacturers and top 10 global lithium battery copper foil companies, I hope it will be useful to you.

The residual solvent in the electrode piece drying process has a great influence on the stability, capacity and cycle life of the electrode piece subsequent processing. The process not only affects the manufacturing cost of the battery, but also indirectly determines the manufacturing process level and the safety of the battery.

Due to the lack of in-depth research on the coating and drying process of lithium battery electrode pieces, it is generally difficult to qualitatively improve the drying efficiency at present.

Electrode piece drying technology

The immediate purpose of drying is to facilitate efficient and rapid removal of solvent from the coating slurry. There are many drying methods for electrode pieces.

Common drying methods mainly include hot air drying (convection hot air drying, double-sided air supply floating drying, circulating hot air impact drying), superheated steam drying, far-infrared radiation drying and microwave drying.

Each method has its own advantages and disadvantages, and has its application, which mainly depends on the setting of the respective process parameters and the control requirements for the residual amount of solvent.

Hot air drying

The conventional hot-air drying method is the earliest widely used method, and the equipment is simple and easy to operate. The heat in hot-air drying comes from electrical energy or steam heat.

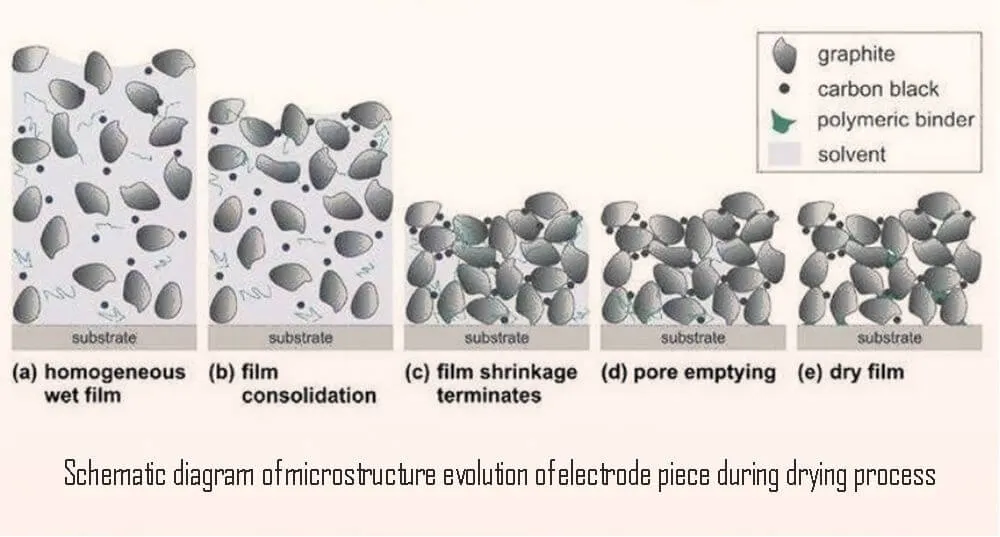

The particle size of the active material in the lithium battery electrode piece slurry is nanoscale, and the particle pore diameter is about tens of nanometers when dried, and it has the characteristics of capillary porous media.

Therefore, when the coating slurry is dried, the solvent removal method has a great influence on the uniform distribution of the electrode active material.

Generally, double-sided air supply floating drying is used to dry the sheet on both sides, which has high drying efficiency and excellent drying effect. However, the power consumption of the air supply fan is relatively large, and the uniformity of the air supply is strictly controlled.

Otherwise, the uniformity of the coating thickness will be poor, and the difficulty of the foil material will be increased, and the belt will be broken easily, resulting in downtime.

On this basis, the developed circulating hot air impingement drying has high working efficiency. This method sprays hot air onto the surface of the coating slurry at a high speed, which weakens the unevenness of the coating surface and improves the thickness consistency of the coating layer.

In practice, the drying process is adjusted by adjusting the air volume and air temperature in sections, which requires large investment and complicated maintenance.

Infrared drying

Different from hot air drying, infrared drying can remove capillary moisture and surface residual moisture in the electrode coating, which is especially suitable for high-energy electrode coatings with large thickness.

Infrared radiation drying mainly uses infrared rays to evaporate the solvent, the drying process is simple, the heat is concentrated, and the drying speed is fast.

It is usually combined with convection drying to form a hybrid drying system. Due to the difference in coating thickness, the non-uniformity of infrared drying temperature has not been completely resolved, and the slurry drying efficiency for non-aqueous solvents is insufficient.

Microwave drying

The microwave drying technology promotes the removal of moisture in the electrode piece through microwave dielectric heating. Microwave is volume heating. When drying, the free water inside the electrode piece is first vaporized, forming a high evaporation pressure gradient and accelerating the internal water migration.

Microwave mixing drying can greatly improve the drying efficiency, and the damage to the coating is small during drying, but it is easy to cause bulging and frying of the electrode pieces.

In practice, various battery manufacturers often do not use a certain drying method alone, but combine drying technologies such as infrared and microwave on the basis of hot air drying to improve drying efficiency.

Although infrared drying can make up for the shortcomings of microwave-assisted technology, the uniformity of infrared rays is poor, resulting in inconsistent drying rates of electrode pieces and reducing the capacity consistency of cells.

Drying process parameters and electrode piece defects

At present, the main drying method is still hot air drying. During drying, the hot air speed, air temperature, coating thickness, slurry characteristics and drying equipment structure all affect.

The good drying process ensures the uniform coating of the slurry fluid, improves the consistency of the power battery, ensures the good dispersion of the active material, and forms an electrolyte channel to increase the charge-discharge rate of the active material.

Poor drying may cause various defects such as agglomeration, pinholes, uneven thickness, scratches, and tailing of the coating layer.

Improper operation of the drying process will directly cause the performance of the power battery to decline, and the consistency of each batch of electrode pieces will deteriorate, which will seriously affect the yield of the matching process section and the cycle life of the module.

The overall drying time of the coating layer is short, mainly considering the influence of hot air temperature, wind speed and slurry solid content (solvent content).

Hot air temperature

In the initial stage, the temperature to be used for different solvents is different. For example, the water-based solvent is not easy to dry at low temperature, and the temperature is low, and the maintenance time of the constant speed section is longer.

Generally, when the hot air temperature of water-based slurry is 90 °C, the drying rate of the electrode piece is faster and the drying defects are less.

The study found that when the drying temperature is lower, the distribution of the binder is more uniform, and the bonding between the current collector and the active material is stronger.

The high drying temperature not only tends to cause local enrichment of the binder, but also has poor surface flatness, which reduces the yield of the winding process.

This is because the excessive temperature will harden the surface of the electrode piece, resulting in cracking and wrinkling of the electrode piece.

During the drying process, the coating solvent evaporated continuously and the viscosity increased rapidly, but the migration rate of the surface solvent was higher than that near the foil end.

Due to drastic changes in surface tension, honeycomb networks, thick edge defects or agglomeration of binder/solid particles are prone to occur.

Hot air speed

Excessive air flow speed during hot air drying will lead to uneven coating, which directly affects the performance of the power battery. Therefore, the air flow speed should be controlled at different stages.

Generally, slurries with lower viscosity are more sensitive than those with higher viscosity. In order to reduce the flow and damage of the coating layer, it is necessary to use low air speed for drying.

If the air speed of the oven is too large, the coating layer is prone to bubbles.

This is because there is a lot of dust accumulated in the air ducts in and out of the coating oven, and increasing the air volume (wind speed) is easy to roll up the accumulated dust, which is scattered on the surface of the wet coating and produces a large number of air bubbles.

The speckle defect is the formation of pattern-like speckles, which is mainly caused by the unstable flow rate of hot air.

Coating thickness

The thickness of the coating layer is mainly determined by the design parameters of the battery’s charge-discharge and capacity characteristics. The coating is thicker, the capacity is larger but the charge-discharge rate is limited.

The coating is thin, the battery charge and discharge rate is large and the capacity is correspondingly limited, and the coating dries quickly, and the coating defects are relatively few.

It is generally believed that a thicker coating layer is conducive to the release of drying stress, the coating adhesion is better, and the coating is thinner, and the segregation of inactive materials such as binders is weaker.

The interface analysis of the active material after drying shows that the current collector resistance is mainly affected by the uneven dispersion of the conductive agent, while the coating thickness is not significantly affected.

If the coating thickness is not properly controlled, it is easy to cause defects such as wrinkles and streaks.

Slurry properties

The influence of the slurry is mainly reflected in the content and type of the solvent, as well as the dispersion and adhesion characteristics of the active substance.

The drying of the electrode piece is greatly affected by the coating process, and the coating is required to be uniform and free of obvious particles.

When drying, the relative dryness of hot air is generally reduced by partial return air in the front section to avoid excessive removal of the surface solvent, while the latter section requires that the temperature can be appropriately increased to improve drying efficiency and reduce solvent residues.

In the early stage of drying, the fluidity of the slurry is large, the characteristics of the solvent affect the drying process, and the particle rearrangement process of the active substance occurs during the dispersion process.

The solvent content in the later stage of drying is low, and the coating layer basically loses its fluidity. The dispersibility of active substances and the binder are the main factors affecting the later drying.

Usually the dispersibility of the binder is affected by the drying rate, and the agglomeration is obvious if the operation is improper, which may be due to the enrichment of the binder caused by the evaporation of a large amount of solvent.

Summarize

electrode piece drying involves the transport of multiphase materials at different scales, and has the characteristics of complex physical processes and diversified drying processes.

The aggregation mode of the coating binder during the drying process is greatly affected by the drying process, and the microporous channels formed by the active material agglomerates have different transport processes at different scales.

In practice, the performance of coating slurry, coating method, and subsequent manufacturing processes such as rolling need to be comprehensively considered.

The research on the relationship between the electrode piece drying process and the cost and quality of the electrode piece is still insufficient, and there is a lack of detailed research on special drying equipment for lithium battery production.

It is necessary to continuously accumulate coating drying process data and experience to optimize the coating drying method.