Application of powder technology in lithium-ion battery electrode material processing

Powder properties are directly related to battery performance, so the design and processing of electrode material are very important. This article will introduce the application of powder technology in lithium battery electrode material.

Electrode material and powder technology

Control the particle size of the electrode material

The particle size of the electrode material plays a decisive role in the performance of lithium-ion batteries. Generally, the particle size of the electrode material will directly affect the preparation of battery slurry and pole piece. The slurry with large particle size has low viscosity and good fluidity, can use less solvent and has high solid content. When the particle size of the powder is reduced, the compaction density and capacity can be improved to a certain extent.

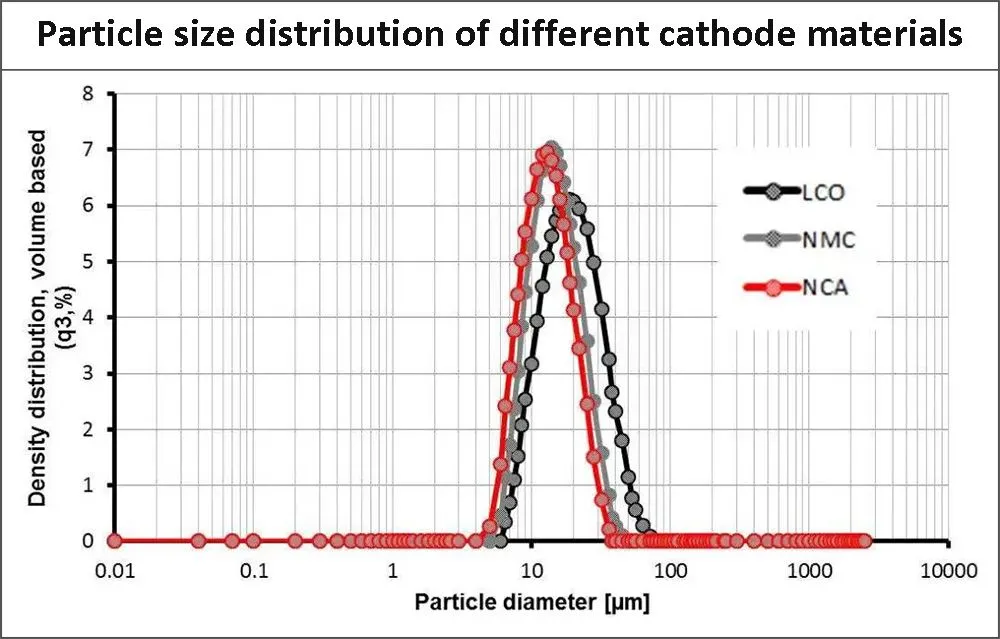

The particle size of the electrode material is usually tested by a laser particle size analyzer, and the equivalent diameter D50 of the largest particle in the particle size distribution curve when the cumulative distribution is 50% is regarded as the average particle size of the electrode material. Taking the cathode material as an example, the particle size and distribution of the cathode material are closely related to the preparation, sintering, and crushing processes of the precursor.

For example, lithium cobaltate is generally prepared from tricobalt tetroxide and lithium carbonate as raw materials, and its sintering characteristics are very good, so the requirements for raw materials are relatively low. Lithium manganese oxide mostly uses the same raw material as the alkaline manganese battery – electrolytic manganese dioxide (EMD). Its production process is to deposit a whole piece of MnO2 plate by electrolysis process, and then obtain it by peeling and crushing.

Usually, there are large irregular particles in the raw material itself, so the spherical manganese source precursor is used to control the particle size distribution. When materials such as lithium nickel cobalt oxide, lithium nickel cobalt manganese oxide, and lithium nickel cobalt aluminate are industrialized, chemical co-precipitation is usually used to achieve atomic-level mixing of elements such as Ni, Co, Mn, and Al. And achieve high density by controlling crystallization, these are the technical category of powder particle size process control.

Control the specific surface area of the electrode material

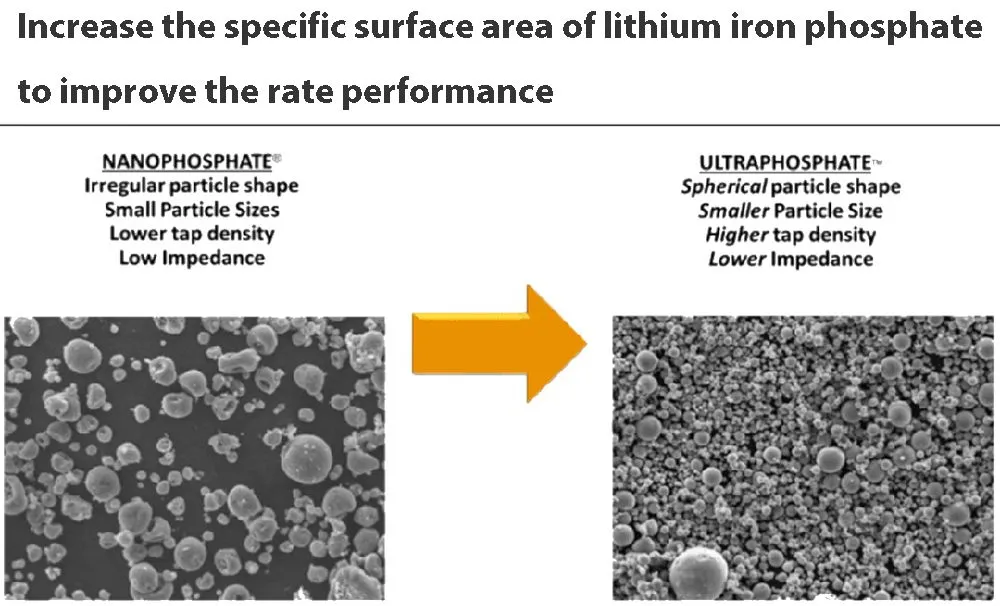

Generally, when the specific surface area of the electrode material is large, the rate characteristic of the battery is better. However, it is usually more likely to react with the electrolyte material, making the cycle and storage worse, and its specific surface area is closely related to the particle size and distribution, surface porosity, surface coating, etc. In the lithium cobalt oxide system, the specific surface area corresponding to the small particle rate electrode material product is the largest.

Due to the poor conductivity of lithium iron phosphate, the particles are designed in the form of nano-aggregates, and the surface is coated with amorphous carbon, resulting in the highest specific surface area of the electrode material among all cathode materials. Compared with cobalt-based materials, manganese-based materials are inherently difficult to sinter, and their specific surface area is generally larger.

How to control the specific surface area that meets the needs of the battery based on the performance characteristics of the material is also the application of powder technology research in the preparation of electrode material.

Control particle morphology of electrode material

A typical application of improving the performance of electrode material through particle morphology is the spheroidization of natural graphite. At present, the application of lithium-ion battery anode material manufacturers is gradually developing in the direction of low cost, so the global research on natural graphite is very important. Although natural graphite has the advantages of large specific capacity and stable discharge voltage as the anode, it also has obvious disadvantages:

● During the charging process, the solvent molecules will co-embed the graphite sheet with the lithium ions and cause the graphite layer to “peel off”, resulting in structural damage and resulting in a rapid deterioration of the electrode cycle performance;

● At the same time, ordinary natural graphite is flake due to the developed layered structure, and it is easy to arrange parallel to the pole piece when filling, which makes the diffusion distance of lithium ions longer, increases the diffusion resistance of lithium ions, and reduces the charge and discharge performance.

When the natural graphite particles are spheroidized, the layers of graphite particles are arranged and distributed in all directions, and there will be a smaller preferred orientation and a more uniform distribution. Lithium ions have a shorter diffusion path, which improves discharge efficiency.

Similarly, other material types can also be modified and modified through proper spheroidization. At the same time, the spheroidization treatment can make the powder material have better filling and uniform distribution, and further improve the volume energy density and cycle performance of the lithium-ion battery.

Surface modification by coating other powder materials

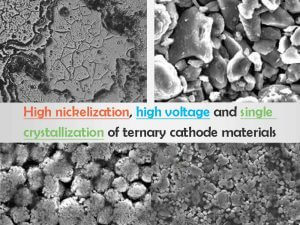

Nickel-cobalt-manganese ternary materials are currently the most widely used cathode materials for power batteries. With the increasing demand for high energy density, problems such as poor structural stability and moisture sensitivity after high-nickelization pose challenges to practical applications. Surface coating is often used in the lithium top 100 industry to regulate the performance of materials.

Surface coating can effectively stabilize the structure of high-nickel materials. The surface coating technology reduces the contact area between the electrode material and the electrolyte, thereby reducing the side reaction of impurities on the surface of the material and the electrolyte, improving the electronic conductivity of the surface of the ternary cathode material, and improving the cycle stability of the material. Common surface coating materials include metal oxides, phosphates and other stable electrode materials, etc., which are currently used coating materials.

Mixing and dispersion of various powder materials

In the production of lithium-ion battery electrodes, various components such as active materials, binders, solvents and additives need to be added and stirred to form a slurry. Therefore, the dispersion of particles and the uniformity of composition become very important. Electrode material has very complicated changes in the actual stirring process, in addition to strong physical effects, there are also certain chemical effects.

Even if the homogeneity is achieved macroscopically, there are still some material particle agglomerates under the microscope. Therefore, the stirring of electrode material is not only macroscopically homogeneous, but more importantly, microscopically relatively homogeneous. The more uniform the mixing, the more beneficial it is to improve the performance of the battery.

In addition, the uniform mixing of two or more electrode materials can also improve the performance of the battery, or achieve a certain cost optimization. With the continuous updating and upgrading of battery technology, production equipment such as lithium battery homogenization system and powder conveying are also constantly being innovated and modified.

Many lithium battery equipment suppliers have studied the mixing and dispersion mechanism in depth to achieve higher production line integration, higher efficiency, lower energy consumption, and more intelligent production line construction. These are the basis for improving the process and realizing the manufacture of higher quality products, and they are also the embodiment of the industrialization of powder technology.

Conclusion

There are many applications of powder technology in the processing of lithium battery electrode materials and even in the battery manufacturing process. Powder processing technology has become a key technology in the process of preparation, post-processing and electrode production of lithium battery products such as motorcycle battery, fish finder battery, etc., and plays an important role in improving the performance of lithium-ion batteries. It is worth discussing from the perspective of powder technology.

The powder industry covers a variety of industries, and its equipment and process principles are often cross-connected. A new understanding of lithium battery electrode materials from the perspective of powder will help to integrate the key points of material preparation and application technology, so as to find new innovation points and further promote the development of lithium battery industry.