NCA battery characteristics and comparison - NCA vs NCM

NCM refers to the combination of three materials of nickel, cobalt and manganese in a certain proportion. The energy density of the battery has also been improved accordingly. The cathode material of NCA is composed of nickel-cobalt-aluminum, and the usual ratio of the three materials is 8:1.5:0.5. The large-scale application of NCA with relatively higher energy density is dominated by Japan and South Korea.

Because of the excellent capacity of NCM battery to meet the needs of consumers, many car manufacturers currently use NCM batteries, but their lifespan is not as good as that of NCA battery systems. This article will introduce NCA battery characteristics and compare the differences between NCM battery and NCA battery.

What is an NCA battery

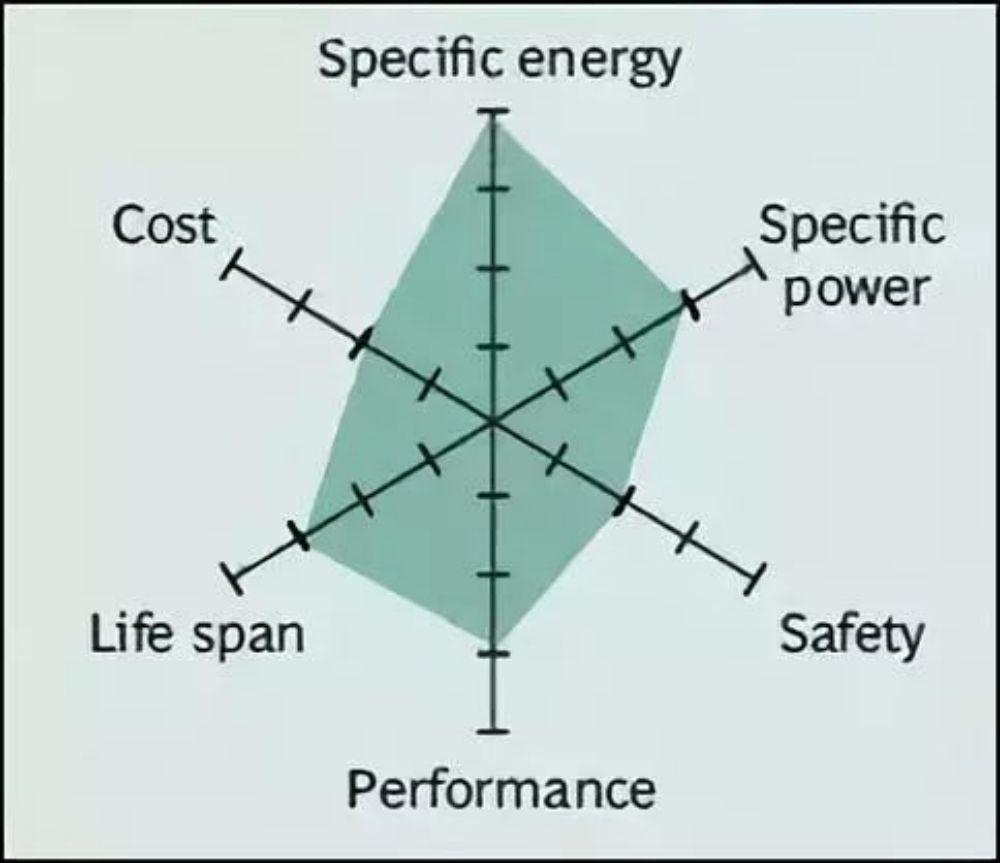

Lithium Nickel Cobalt Aluminate or NCA has been used since 1999. It has high specific energy, fairly good specific power and long service life which are similar to NMC. Less flattering are safety and cost. The six key characteristics are summarized below, along with the main parameters of NCA cells.

Characteristics of lithium-nickel-cobalt-aluminate

Characteristics of lithium nickel-cobalt aluminate (NCA battery) | |

| Voltage | Nominal value is 3.60V; typical operating range is 3.0-4.2V |

| Specific energy | 200-260Wh/kg; Predicted to reach 300Wh/kg |

| Charge | 0.7C, charging to 4.20V (most batteries), typical 3 hours charging, some leakage can charge quickly |

| Discharge | 1C typical; cut off at 3.00V; high discharge rate will shorten battery life |

| Life cycle | Over 1000 times (related to discharge depth and temperature) |

| Thermal runaway | Typical value is 150°C (302°F), high charge can cause thermal runaway |

| Application | Portable Medical Devices, Industrial, Electric Powertrain (Tesla) |

NCA is a further development of lithium nickel oxide; adding aluminum gives the battery better chemical stability. High energy and power density and good service life make NCA a candidate for EV powertrain. High cost and marginal safety have negative effects.

NCA battery is also a lithium-ion battery, compared with NCM, its chemical composition is changed from manganese to aluminum, which is characterized by a longer life. NCA battery was developed by Tesla and Panasonic in 2019. However, due to high technical barriers, most car manufacturers have not put it into use. NCA batteries are currently installed on Tesla electric vehicles.

In September 2020, Tesla released its new 4680 large cylindrical battery at the Battery Day event. The 4680 battery adopts NCM cathode, non-tab (full-tab) technology, and dry electrode technology, which greatly reduces the manufacturing cost. It only takes 15 minutes to charge from 10% to 80%.

What is the difference between NCM and NCA

NCM refers to the English abbreviation of nickel (NI), cobalt (CO), and manganese (Mn) in the ternary lithium cathode material. NCA refers to the English abbreviation of nickel (NI), cobalt (CO), and aluminum (Al) in the ternary lithium cathode material.

● NI——Increase and increase the volumetric energy density of the material.

● CO—stabilizes the layered structure of the material while enhancing the cycle and rate performance of the material.

● Mn——Reduce material cost, improve material safety and structural stability.

● AI——It can suppress the structural collapse of the material in the high delithiation state.

Comparison of NCM vs NCA battery

| NCM battery | NCA battery | |

| Represents the type of battery | The current mainstream types are NCM523 and NCM622, NCM811. | Panasonic, LG, Samsung, Jiangsu Tianpeng’s 18650, 21700 series. |

| Main production manufacturers | CATL, LG, SK, Samsung SDI, BYD, etc. | Panasonic, LG, Samsung SDI, Jiangsu Tianpeng, Lishen, Delangeng, etc. |

| Energy density | The upper limit of theoretical energy density of NCM811 battery is 300wh/kg. | The upper limit of theoretical energy density of NCA battery is 350wh/kg |

| cost | With the continuous reduction of nickel content, the current cost is less than NCA battery | NCA battery production process requirements are higher, and the cost is slightly higher than NCM when the amount of cobalt used is similar. |

| Production process | The production process of NCM811 is simpler than that of NCA, but more difficult than that of NCM523 and 622. | The tightness requirements for production equipment are high, and NCA is highly sensitive to temperature. The temperature and humidity of the production environment need to be controlled below 10%, which increases the cost of production and management. |

| Cycle life description | 1000-2000 times, it must be used frequently to ensure its lifespan, once it is not used, it will decay quickly if it is played for a long time. | 1000-2000 times, NCA battery will not have the problem that NCM needs to be used frequently to ensure its life. |

| Safety performance | The higher the nickel content, the lower the safety performance, which requires a good BMS management system and battery pack design | Good EMS management and battery pack design are required, but there are obvious advantages in safety under some extreme abuse conditions. |

| Downstream applications | Electric vehicles, consumer products, energy storage, etc. | Electric vehicles, electric tools, garden tools, etc. |

Development status of NCA battery

At present, the main reasons why China has not produced NCA battery on a large scale are as follows:

1. The research and development of NCA by Chinese battery companies started later than that of Japan and South Korea, and there is still a certain gap with Japanese and Korean companies in terms of manufacturing process, patents, and material use.

2. The production process of NCA battery is stricter than that of NCM811. For example, NCA requires the humidity to be controlled below 10% during the manufacturing process, while NCM and other types of batteries currently only need to strictly control the humidity during the liquid injection process. This high-standard production environment poses a great challenge to domestic enterprises.

3. There is serious gas production during the charging and discharging process, which will cause the battery to bulge and deform, and the cycle and shelf life will be reduced. The battery has potential safety hazards. Therefore, NCA battery is usually made of pressure-resistant cylindrical battery cases, which reduces the gas production to control the problem of battery swelling and deformation.

4. The thermal stability of high-nickel materials in the state of charge is poor, which leads to a decrease in the safety of the battery, making battery manufacturers and end product users have concerns about the safety of NCA battery. It is necessary to carry out a reliable safety design of the system from the aspects of battery cell design, power system design, and power use.

Development direction of NCM and NCA

● China is dominated by the NCM route.

● Japan is mainly based on the NCA route.

● South Korea is the joint development of NCM and NCA

NCM vs NCA battery – which is better

In NCM battery, according to the content of the three, NCM materials can be divided into NCM111, NCM523, NCM622, NCM811, etc., and the numbers behind them represent the ratio of the three. With the increasing demand for cruising range, the specific energy of the battery needs to be higher, and the price of cobalt as a rare metal continues to rise, the high-nickel system NCM811 will become an important development trend in the future. NCM811 related company information is top 5 NCM811 high nickel ternary cathode material companies.

The common ratio of nickel-cobalt-aluminum in NCA is 8:1.5:0.5, and the content of aluminum is relatively small, so it can be understood that it is close to a binary material, and Al (transition metal) is used instead of manganese. It is to modify lithium nickel cobalt manganese oxide through ion doping and surface coating. Ion doping can enhance the stability of the material and improve the cycle performance of the material. However, in the production process, since Al is an amphoteric metal, it is not easy to precipitate, so there is a threshold in the production process of NCA materials.

Conclusion

Both NCM and NCA are high-nickel ternary lithium batteries. The biggest advantage is their high specific energy, which can provide more sufficient power for vehicles. If but from the perspective of energy demand, NCA battery still seem to have more advantages. However, considering the manufacturing process, cost, and current technical conditions, Chinese battery companies are currently mainly focusing on the production of NCM.

However, almost all large battery companies are actively researching and developing NCA. It can be expected that China will be able to break through technical barriers and mass-produce NCA batteries in the future. NCM and NCA battery will simultaneously become the main structure of ternary lithium battery.