Home » battery news » Not only tesla 4680 battery, which battery manufacturers are in the layout of 4680

Not only tesla 4680 battery, which battery manufacturers are in the layout of 4680

2022 will be a critical year for the development of the power battery industry, and a turning point year for battery companies to release production capacity and iteratively upgrade technology. A major concern of the market is whether the 4680 battery can be mass-produced to further reduce battery costs.

From the battery side process, Tesla will take the lead in mass production of in 2022. And tesla 4680 battery will not stand alone in the battery market, various battery manufacturers are also speeding up their active deployment in preparation for mass production of 4680 batteries.

To match the rhythm of downstream mass production, material and equipment companies at the supply chain end are also preparing in advance for the large-scale mass production of 4680 batteries.

4680 battery vs 18650 and 21700, why 4680 battery is stronger?

First of all, the large-scale use of cylindrical power batteries is also Tesla. European car companies such as Daimler, Nissan, Renault, Volkswagen, and Hyundai mainly use soft pack batteries. China car companies mostly use square batteries.

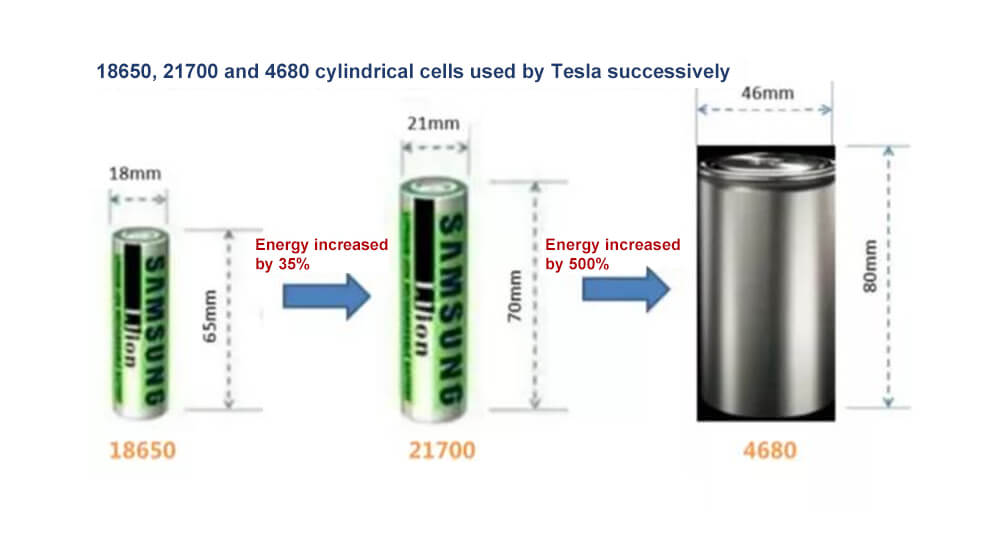

The new 4680 battery launched by Tesla on Battery Day last year, the number 46 refers to the diameter of the cylindrical battery 46mm, and 80 means the height of the battery is 80mm.

The 4680 is still essentially a cylindrical wound cell, and the overall structure is the same as that of the 21700 and 18650. It can be simply understood as a “roll paper” cell. The metal outside the cell and the middle part of the internal diaphragm are common ternary/LFP/graphite components used to store electrical energy. In terms of volume, if the 2170 and 18650 batteries are similar to the 7th and 5th batteries that are common in our daily life, then the 4680 is a “fat battery” that is even larger than the 1st battery!

We mentioned in 4680 battery vs 18650, 21700 battery vs 18650 articles earlier, compared with the 18650 and 21700 cylindrical lithium batteries used by Tesla before, the advantages of the 4680 battery are reflected in battery capacity, production cost and efficiency.

The reason for the increase in 4680 cell capacity is the increase in size. This is not a special case of the 4680 itself. The previous 21700 battery has 50% more capacity than the 18650 battery.

The 4680 cell capacity has 5 times of the 21700 capacity(not 5 times the energy density), the increase in 4680 cell capacity will also lead to an increase in cruising range (up 16%) and a 4x increase in peak performance.

The improvement of production efficiency and the reduction of cost (down 14%) are reflected in the large cells, which are also used in 75KWh electric vehicles. The old version of 18650 needs about 7100 cells, and the 21700 cylinder needs 4400+ cells. , while the new battery 4680 adopts a module-free design.

Only 950 cells are required, and the smaller number of cells means that the space utilization rate during PACK is improved, the difficulty of battery thermal management and the manufacturing cost are greatly reduced, and the time required for production and assembly is reduced, so the grouping efficiency is greatly improved.

Which companies are currently deploying 4680 batteries

Tesla

Among the battery companies in the industry that advocate pushing 4680, Tesla is among the best. The ideal tesla 4680 battery, in addition to non-electrode ears, dry electrodes, silicon anodes, new high-nickel and cobalt-free cathode materials, and CTP/CTC integration solutions.

Tesla’s electrodeless ear solution directly leaves a part of the material on the copper foil and aluminum foil for the electrode ear, which is rolled into a circle and welded directly to the cover plate, as shown in the following figure:

The last one is dry electrode technology, which is also a very unknown technology at present. It saves the solvent and directly forms the powder into a film and presses it on copper foil and aluminum foil to prepare positive and negative electrode sheets. The process has changed, and the corresponding equipment may be different. .

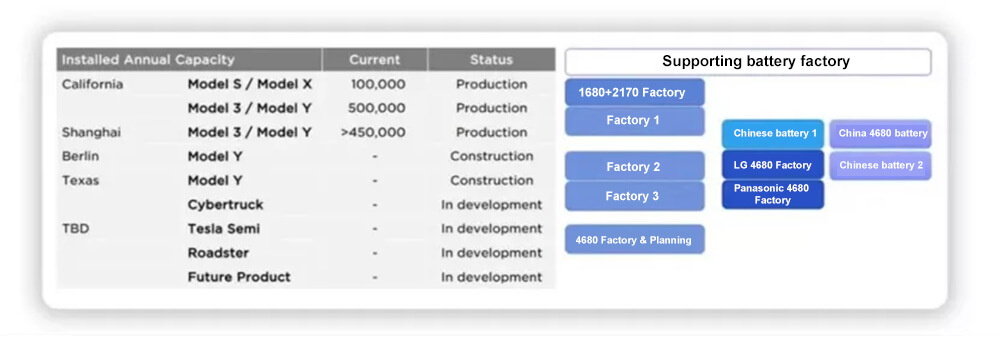

In terms of production capacity, Tesla has an overall planned production capacity of 100GWh for tesla 4680 battery. The original delivery time was set for 2022, but the large-scale delivery has been delayed until 2023.

A few days ago, Tesla CEO Elon Musk confirmed the news that the tesla 4680 battery has been deployed on a prototype. He said that at Tesla’s Texas factory, tesla 4680 are already being used to produce the Model Y, but they need to complete relevant product certification before they can be delivered to the market.

According to previous news, Tesla’s supporting factory in Texas will also produce this new type of battery, and when the production technology matures, it will further increase the number of factories producing batteries. Other suppliers, including Panasonic, will also supply Tesla with 4680 cells.

Therefore, at the earnings conference, Tesla’s vice president of engineering, Drew Baglino, said that the supply of 4680 batteries will not be limited this year, and expects to deliver the first Model Y with tesla 4680 by the end of the quarter.

That is to say, Tesla’s first models equipped with tesla 4680 batteries will be mass-produced in the first quarter.

As of November 2021, the yield rate of Panasonic and LG New Energy’s 4680 cells is around 80-90%, and the yield of two other companies has also reached around 80%.

According to the improvement plan, before June this year, it is expected that the yield rate of leading companies that have invested heavily in the development of 4680 batteries in the early stage will increase to more than 90%.

The 90% overall yield will undoubtedly accelerate the mass production process of tesla 4680 battery.

Panasonic

The latest news from Panasonic shows that the test production of the 4680 batteries that will be supplied to Tesla is scheduled to start in Japan in March 2022, but mass production will have to wait until Tesla places an order, which is expected by the end of 2022.

Panasonic also said that since Tesla has a strong demand for this battery, it will give priority to meeting Tesla’s requirements after mass production. Tesla’s business accounts for about 60 percent of revenue from Panasonic’s energy business, which earned $1.69 billion in the last quarter of last year, according to Panasonic’s financials. Tesla contributed $1 billion in revenue.

Panasonic plans to invest 80 billion yen (about 700 million U.S. dollars) to build a 4680 battery plant in Kayama Prefecture, Japan. It will start small-scale production this year, and after confirming the technical safety and efficiency, it will be put into mass production in 2023. Once the 4680 battery can be delivered, Panasonic will first supply Tesla, which is also the first time Panasonic has mass-produced the 4680 battery.

The production capacity target has not yet been confirmed, but the annual production capacity is expected to be about 10 GWh, which is equivalent to the demand for 150,000 car batteries.

At present, the total monthly production capacity of Panasonic cylindrical batteries is 50 GWh/year (including 2170 batteries from the Nevada plant and 1865 batteries from Japan).

The aforementioned 10 GWh may only be an initial production capacity plan, and the company plans to build factories in other countries such as the United States to expand the scale of mass production.

LG

According to reports, Samsung SDI and LG Energy Solutions have completed the development of “4680” battery cell samples. The “4680” is the battery cell Tesla first launched last year, and the two South Korean battery companies are apparently trying to win Tesla’s orders.

LG Energy also hinted at developing 4680 cells during a conference call last year. LG Energy later announced plans to invest more than 5 trillion won to build at least two new battery factories in the U.S. by 2025 to produce pouch and “cylindrical” batteries and batteries for energy storage systems.

LG Energy currently supplies 2170 cells for Tesla Model 3 and Model Y vehicles made in China. LG’s planned supply time is 2023, and it is considering supplying Tesla from factories in the United States and Europe.

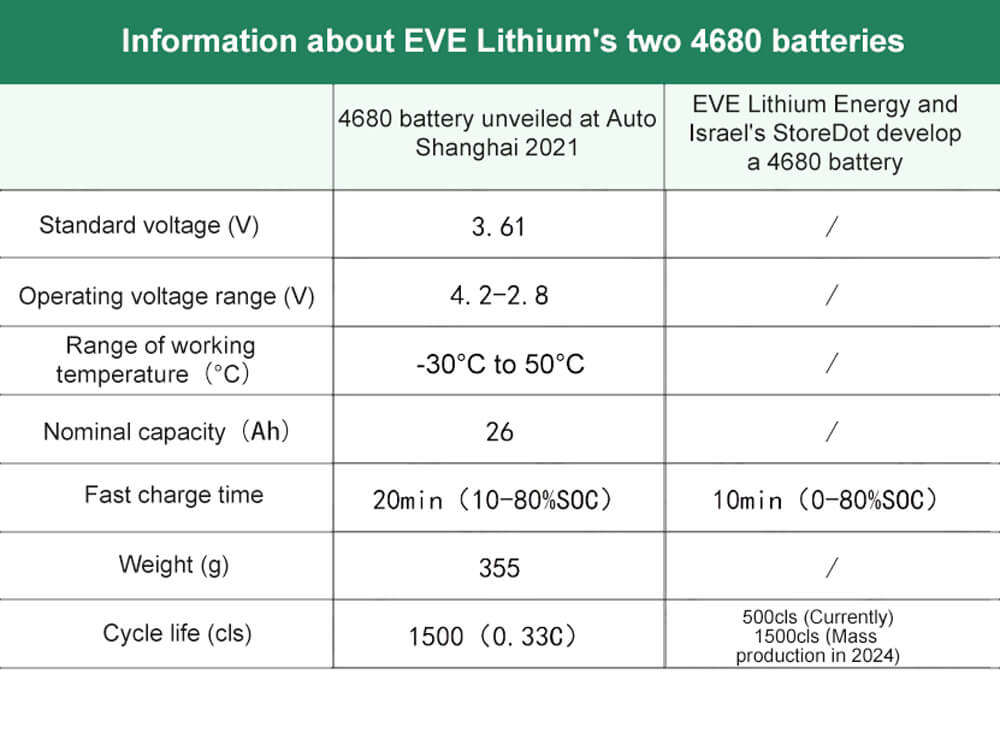

EVE

Regarding the 4680 battery, EVE mainly takes the route of 4680 and 4695, of which 4680 is a standardized battery, and 4695 should be a customized product for car companies.

The joint development of EVE and StoreDot plans to mass-produce 4680 batteries in 2024. The production capacity of 20GWh of 4680 batteries will start construction in 2022 and will be shipped in small batches. It will not be fully completed until the second half of 2023.

On the basis of the 4680 battery, EVE optimized the pole, shell, winding core and cover plate. In order to apply CTP and CTC, the positive and negative poles are on the same side, and the electrical connection and the pressure relief channel are separated.

The high-strength shell is used to ensure the strength and reduce the expansion of the cell. The structure of the all-pole ear reduces the impedance by 10 times compared with the traditional cylindrical battery, and enhances the thermal conductivity.

The cover plate features a high-efficiency VENT design to provide quick pressure relief access. From the perspective of these optimized designs, Yiwei Lithium Energy is essentially different from the 4680 cylindrical battery that Tesla wants to build.

BAK

BAK Battery is the No. 1 supplier in the field of cylindrical batteries in China, with three parallel lines of small cylindrical, large cylindrical and square. Among them, in terms of 4680 battery capacity planning, the civil construction of the industrial park next to BAK Battery’s Zhengzhou factory has been basically completed, and this production line will officially enter the factory in the second half of next year.

It is expected that BAK will achieve mass production of 4680 batteries in the next two years. Among them, the first batch of mass production lines will be located in Zhengzhou No. 2 Plant, with an overall production capacity of 15Gwh. If the cooperation with the car factory reaches the platform-designated stage, the production capacity of a single platform is estimated to be more than 10Gwh.

BAK stated at the China International Battery Technology Exhibition held in March 2021 that it is cooperating with customers to develop 4680 batteries with full tabs. At present, BAK’s 4680 battery is mainly customized and developed in conjunction with the OEM.

Dr. Lin Jian, chief scientist of BAK Battery, revealed that BAK Battery’s 46X0 series of large cylindrical batteries cover 80mm to 120mm, of which 4680 batteries are expected to be mass-produced in 2022.

In BAK’s understanding, the 4680 battery is not limited to 4680, and the height may be 90 or 100mm, but it is more inclined to the size of 4680, because if most companies in the industry make 4680 batteries, it is better to standardize , but also conducive to promotion.

Similarly, BAK has also deployed all-tab technology on the 4680 battery, and the large-cylindrical battery with all-tabs for high-end models will become the core product in the field of BAK’s automotive electric applications.

CATL

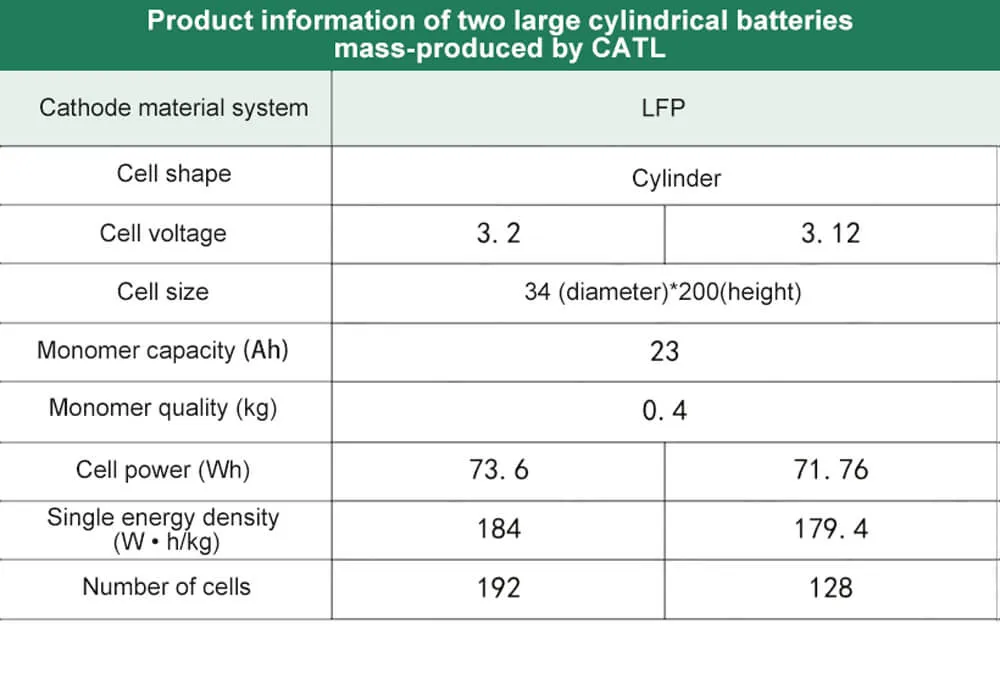

CATL has currently mass-produced two large cylindrical batteries, both of which are 34 (diameter) * 200 (height) mm in size.

According to this size, two different lithium iron phosphate batteries were made and used in Hongguang MINI and QQ ice cream models.

It is reported that CATL is also developing a 4680 battery project, the project name is ‘Golden Hoop Bar’. The company has planned 8 lines on the 4680 battery, with a total of 12GWh. At present, the 4680 battery of CATL in the field of two-wheelers has been offline for application.

CATL has signed a contract with the Shanghai Municipal Government to build a super battery factory in Lingang, which will produce Tesla’s 4680 batteries, which means CATL will soon become Tesla’s largest power battery supplier in the world.

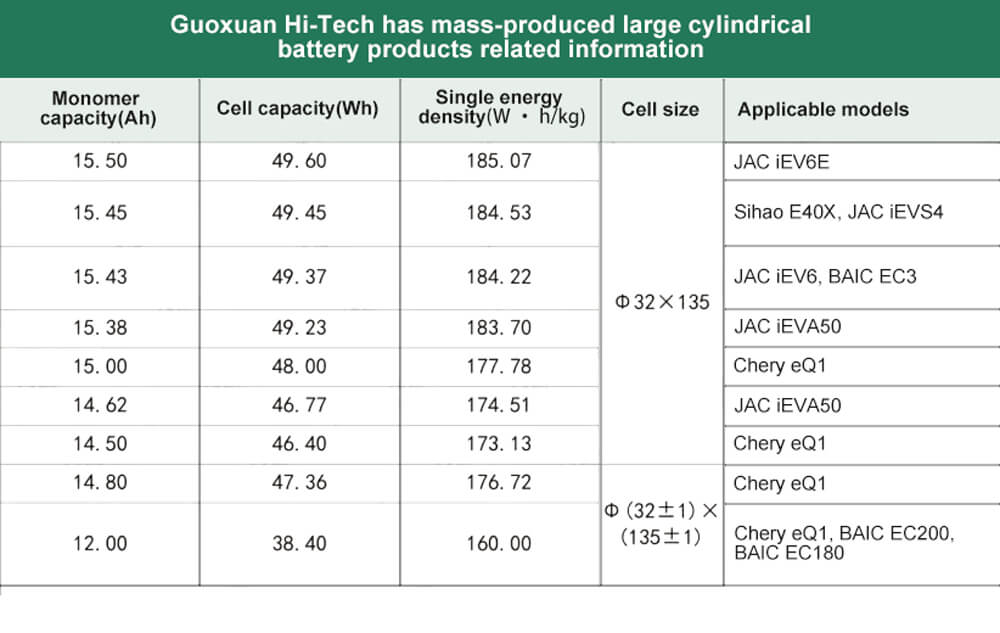

GOTION High Tech

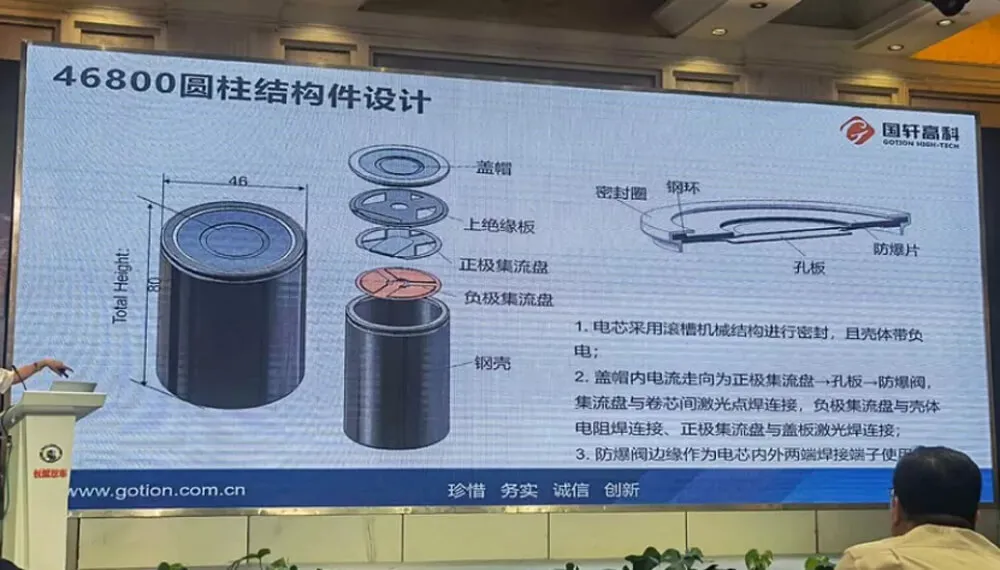

Guoxuan disclosed some information about the 4680 cylindrical battery in August 2021, and refined it to the step of structural design, but it is not known which technologies will be applied and whether there is a corresponding production capacity layout.

SVOLT

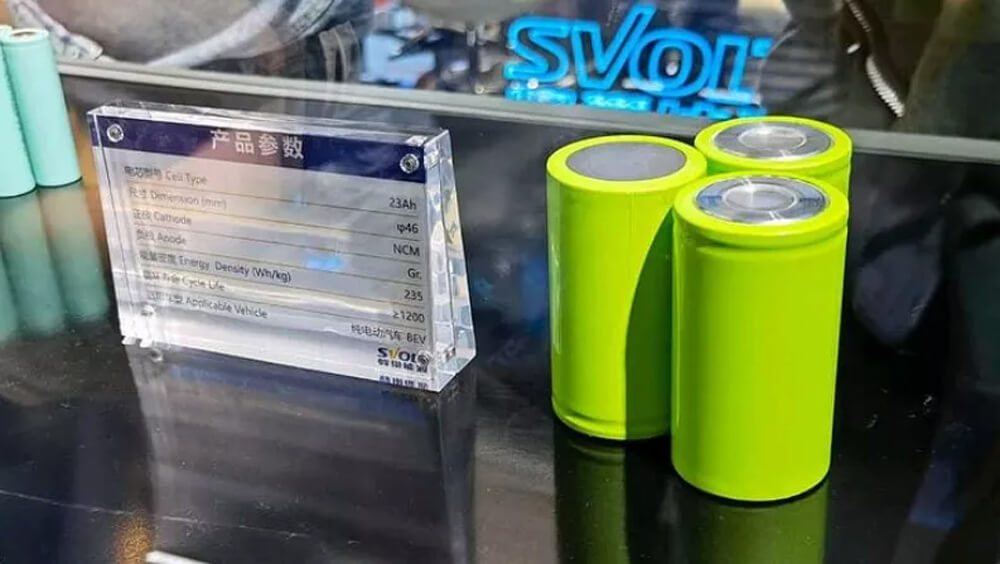

SVOLT exhibited a 23Ah 4680 battery at the 2021 Shanghai Auto Show, NCM positive electrode, the planned energy density is 235Wh/kg, and the cycle life is higher than 1200 times for pure electric vehicles.

And, BMW Brilliance will participate in the research and development of its 4680 battery.

Samsung SDI

The latest news shows that Samsung SDI has started trial production of next-generation 4680 batteries at its plant in Cheonan, South Chungcheong Province, and is in the final stage of finalizing the new product standards. The product is similar to a 4680 battery, but the exact specifications have not yet been determined.

For this 4680 battery, Samsung SDI plans to add factories in Malaysia, Hungary and the United States. In addition to winning Tesla’s orders, Samsung SDI and Hyundai are also developing next-generation cylindrical batteries, the size of which is larger than 2170 but smaller than 4680, mainly for hybrid vehicles.

Vision AESC

Vision AESC also has a 4680 battery layout, which is currently in the experimental verification stage.

LISHEN

LISHEN also exhibited corresponding samples at the 2021 Shanghai Auto Show, and it is not yet known which stage it has reached.

In addition to the above companies, the advantages of 4680 battery in terms of single capacity, output power, cost, etc. are attracting more battery companies to join, prompting the transformation and upgrading of 4680 battery technology, and further promoting the mass production process of 4680 battery.

4680 battery impacts the industry pattern

From the perspective of mass production time, the real mass production of 4680 batteries may still be in 2023. However, it can be seen that, on the one hand, Japanese and Korean companies are fighting for the right to supply Tesla, and Panasonic is expected to gain the supply share.

On the other hand, the R&D and production of various China leading battery companies will help cylindrical batteries return to the electric vehicle track and increase the market share of cylindrical batteries. Now many Chinese lithium battery companies have a good performance. You can check out our top 10 lithium ion battery manufacturers in China article for readers to learn more about China’s lithium battery companies

From the perspective of the supporting industry chain, the core innovative technologies of the 4680 battery are: electrodeless ear mode, dry electrode technology, and the application of silicon-based negative electrodes. With the acceleration of mass production, 4680 batteries will drive the iterative upgrade of equipment and materials in the industrial chain.

On the cathode material side, according to the plans announced by various battery factories, 4680 batteries are currently dominated by high nickel. In 2021, the lithium iron phosphate battery is on fire, and the market is worried about the full replacement of NCM by LFP, while 4680 further promotes the development of high nickel and ultra-high nickel.

However, with the maturity of the 4680 battery technology, the iron-lithium version of the 4680 battery is likely to be launched, and it will be used in low-cost models, light vehicles, energy storage and other fields, focusing on high cycle performance.

For example, CATL / EVE has announced the large cylindrical lithium iron phosphate battery solution for two-wheeled vehicles, and is currently promoting production capacity.

On the negative electrode material side, when the 4680 battery is officially released, the permeability of the silicon-based negative electrode will continue to increase. At present, Chinese anode manufacturers have expanded their investment in silicon carbon anodes, and Biteray, Shanshan, Guoxuan Hi-Tech, and Zhengtuo Energy can achieve mass production.

Among them, Beitri silicon carbon anode supplies Panasonic power batteries and enters the Tesla industry chain. Some battery companies such as CATL, BYD, Guoxuan Hi-Tech, BAK and Lishen are all actively deploying in silicon carbon.

In addition, in terms of high-performance materials, 4680 batteries will also promote the growth of demand for carbon nanotubes and LiFSI, and leading companies such as Tianna Technology and Tianci Materials are expected to continue to benefit.

On the equipment side, the progress and changes in the manufacturing process of the 4680 battery shell and the welding of the tabs will also drive the increase in the demand for related equipment.

Yinghe Technology said that the company has become the first enterprise in China to provide high-efficiency winding equipment for large cylinders, and has now started to supply customers in batches with key equipment that meets the production of 4680 large-cylinder batteries.

Huaguan Technology said that the company has successfully developed winding equipment for 4680 batteries.

Ningbo Jingda said on the investor interactive platform on February 7 that the company’s first 4680 shell stamping production line in China has been delivered.

Lian Ying Laser said that the company has 4680 welding process technology reserves. Hangke Technology’s 2021 semi-annual report revealed that 4680 and other large cylindrical styles have completed prototype production.