Application and development of solid oxide fuel cell

This article introduces the principle and application scenarios of solid oxide fuel cell, as well as its development in China, the United States, Japan, Europe, and South Korea.

What is solid oxide fuel cell

Solid oxide fuel cell (SOFC) is currently the most efficient fuel cell, also known as ceramic fuel cell, it is an all-solid-state fuel cell that efficiently converts the chemical energy of various fuel gases (natural gas, landfill gas, coal gas, methanol, etc.) into electrical energy at medium and high temperatures.

The structure of the solid oxide fuel cell group is mainly: tubular, planar and unique. Among them, the planar type has become the development trend of solid oxide fuel cell due to its high power density and low manufacturing cost.

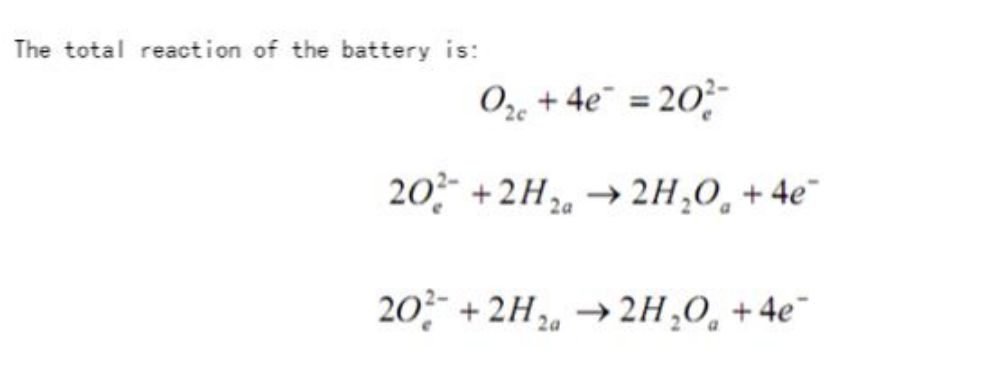

The working principle of solid oxide fuel cell is the same as that of other fuel cells, which is equivalent to the “reverse” device of water electrolysis in principle. Its single cell is composed of anode, cathode and solid oxide electrolyte.

The anode is the place where the fuel is oxidized, and the cathode is the place where the oxidant is reduced. Both electrodes contain catalysts that accelerate the electrochemical reaction of the electrodes. When working, it is equivalent to a DC power supply, its anode is the anode pole of the power supply, and the cathode is the cathode pole of the power supply.

Advantages and characteristics of solid oxide fuel cell

The advantages of solid oxide fuel cells are in line with the liberalization of the energy market, the strengthening of environmental awareness and the trend of distributed power generation. The most attractive features of the solid oxide fuel cell system are high efficiency, strong fuel adaptability and almost no particulate matter, NOx, SOx emissions.

Benchmarking the economic and technical specifications set by competitive systems such as gas engines, gas turbines and combined cycle plants, the solid oxide fuel cell combination system has more obvious advantages than the existing technology in terms of electrical efficiency, part load efficiency and emission. The specific characteristics of solid oxide fuel cell are as follows.

(1) The working temperature of solid oxide fuel cell can reach 1000 degrees Celsius, which is currently the highest working temperature of all fuel cells. Combined heat and power generation through heat recovery technology can obtain a combined heat and power efficiency of more than 80%.

(2) The electrolyte of solid oxide fuel cell is solid, so there is no problem of electrolyte evaporation and leakage. In addition, there is no problem of corrosion of the electrode, and the operation life is long. In addition, since the cell materials that make up the material are all solid, the shape of the battery is flexible.

(3) The forward operation of solid oxide fuel cell can generate electricity, and the reverse operation is the solid oxide electrolytic cell (SOEC). SOEC can utilize waste heat and renewable electricity. At the same time, high-temperature water vapor and high-temperature CO₂ can be used in large-scale applications of SOEC technology. The electrolysis efficiency is as high as 85% to 95%, which is much higher than other electrolysis water technologies.

(4) SOFC reacts chemically at high temperature, so there is no need to use precious metals as catalysts, and it has the ability of internal reforming, and can directly use hydrogen, hydrocarbons (methane), methanol, etc. as fuel, which simplifies the battery system.

(5) SOFC can provide high-quality waste heat, realize cogeneration of heat and power, have high fuel utilization rate, and the energy utilization rate is as high as about 80%. It is a clean and efficient energy system.

(6) Solid oxide fuel cell has high current density and power density.

(7) The system design of solid oxide fuel cell is simple, the power generation capacity is large, and the application is relatively extensive.

(8) SOFC is an all-solid structure, which can avoid problems such as corrosion and electrolyte loss caused by the use of liquid electrolytes. The all-solid-state structure is also conducive to the modular design of the battery, improves the volume specific capacity of the battery, and reduces design and production costs.

(9) Solid oxide fuel cell is compatible with traditional fuels, but its start-up time is long, so it is suitable as an auxiliary power unit for luxury cars, recreational vehicles and heavy trucks.

Application scenarios of solid oxide fuel cell

Solid oxide fuel cells can be applied to distributed power generation, backup power and cogeneration, and can be used in hydrogen production, comprehensive energy supply stations, energy storage, chemical energy conservation, transportation applications (mainly used in commercial vehicle range extenders and ship auxiliary power), etc.

The micro power generation system based on solid oxide fuel cell is also expanding to the field of portable power supply, it is related to our product portable battery station, this is mainly because the solid oxide fuel cell has a higher specific power density, which describes the ability of the battery to release a large amount of energy in an instant. The micro-tubular solid oxide fuel cell can meet the requirement of rapid start-up.

At present, solid oxide fuel cell is mainly used in household combined heat and power projects, and it cannot be applied to large-scale power stations. This is related to the many shortcomings of solid oxide fuel cell itself, such as: high operating temperature, long start-up time, high material requirements, persistent sealing problems, high component manufacturing costs, etc.

Development of solid oxide fuel cell

At present, solid oxide fuel cell technology has matured day by day in developed countries represented by the United States and Japan, and has begun to enter the initial stage of commercial application.

United States

The United States mainly supports large-scale industrial/commercial fuel cell power generation. The representative company Bloom Energy is the largest solid oxide fuel cell company in the world, with a total installed capacity of more than 350MW.

It has provided hundreds of sets of fuel cell distributed power generation systems for companies such as Google, eBay, and Wal Mart. It is currently recognized as the company with the strongest technical force and the most successful operation in the solid oxide fuel cell industry. The power generation efficiency of its main products can reach 65%. According to statistics, the global solid oxide fuel cell and SOEC market size will reach 2 trillion US dollars.

Japan

The development of solid oxide fuel cells in Japan is mainly promoted by NEDO (New Energy and Industrial Technology Development Organization Japan). The goal is that by 2024, the power generation efficiency of solid oxide fuel cell will exceed 65% (low heat), and the service life will reach 130,000 h. The main project is the development and industrial verification of key technologies of the solid oxide fuel cell system. The main R&D institutions include Aisin Seiki, Osaka Gas, Kyocera and Toyota Motor.

Europe

The development direction of European solid oxide fuel cell is mainly based on SOEC electrolysis, and renewable electricity is used to produce hydrogen through SOEC. The representative company is Sunfire in Germany, which has built a SOEC water electrolysis hydrogen production equipment with a total power of 2.6MW, which is the world’s largest electrolysis water hydrogen production equipment.

The solid oxide fuel cell in Europe mainly supports the domestic fuel cell CHP (Combined Heat and Power) project mainly based on solid oxide fuel cell, and Europe mainly conducts research and development of flat solid oxide fuel cell battery stack and power generation system. At present, Germany has released more than 50,000 sets of Micro-CHP, and provides subsidies of 7050-28200 euros for the installation of the device according to the size of the output power. It is the country with the most Micro-CHP in Europe.

Korea

At present, South Korea’s solid oxide fuel cell is mainly used in the public utility field. The mainstream technologies on the market come from two companies, Ceres Power of the United Kingdom and Bloom Energy of the United States, and are introduced and promoted by Doosan and SK E&C respectively.

South Korea has become a global leader in the use of fuel cells for utility-scale power generation, with deployments of 370.7MW, 464MW, and 605MW in 2019, 2020, and 2021, respectively. According to the power supply demand plan issued by the Ministry of Trade, Industry and Energy (MOTIE), it is expected that the deployment of fuel cells in South Korea will further expand to 800MW by 2022.

China

Since China’s solid oxide fuel cell technology and industry have been blockaded to China, China can only take the route of independent development. China’s fuel cell research institutions are mainly universities and research institutes. In recent years, large enterprises such as one of the top 10 fuel cell manufacturers in China WEICHAI, CGN, and Jinneng have joined the solid oxide fuel cell research and development array to accelerate the pace of commercialization. As of the end of 2020, there were 8,187 solid oxide fuel cell-related patent applications, and China ranked first with 5,100.

The solid oxide fuel cell industry chain mainly includes single cells and upstream materials, stacks and auxiliary equipment (BOP), system integration and application parts. At the battery level, several units in China have mastered the large-area single-cell mass production technology, and the durability can reach tens of thousands of hours, Chaozhou Three-Circle is particularly outstanding. In terms of battery stacks, Chinese companies are still relatively extensive in terms of battery structure design and single-cell assembly.

The battery seal and the bonding strength of the connector still have problems such as instability in the long-term operation of the battery, which largely affects the service life of the solid oxide fuel cell system. For example, the current level in China is about thousands of hours to 10,000 hours, but the expectation of commercialization of solid oxide fuel cell systems is more than 10 years.

On the stack auxiliary system (BOP), including pre-reformer, heater, compressor, voltage regulator, inverter, heat exchanger, etc., At present, there is no professional production company in China, the main reasons are: the solid oxide fuel cell market has not yet started, the enthusiasm of setting foot in enterprises is not high, and there are not many enterprises participating in the development and industrialization of solid oxide fuel cell;

There is a lack of corresponding supporting policies, and the subsidy is less than that of countries such as Europe and the United States. In addition to the supporting parts (BOP) industry chain issues, there are also system efficiency optimization issues, high-power system construction issues, and battery life issues.