Vanadium redox flow battery industry report - wide space for LDES

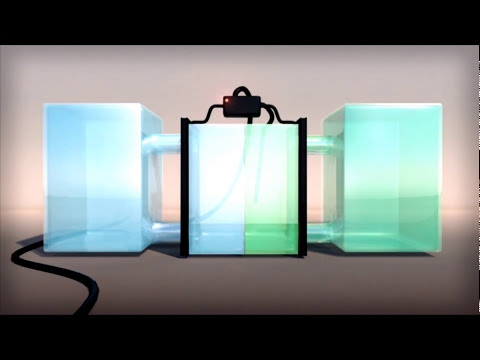

When vanadium redox flow battery is charged and discharged, the battery electrolyte of cathode and anode electrode performs redox reactions on both sides of the ion exchange membrane. At the same time, through the action of the reactor external pump, the electrolyte in the storage tank is constantly sent into the cathode chamber and anode chamber to maintain the concentration of ions and realize the charge and discharge of the battery.

Advantages of vanadium redox flow battery

High security and easy capacity expansion are the biggest advantages

The working principle of the flow battery determines that it is the safest technical route in the current electrochemical energy storage technology route. Different from the lithium battery, the electrolyte of the flow battery is separated from the stack. Since the electrolyte ions of the vanadium redox flow battery exist in the aqueous solution, thermal runaway, overheating, combustion and explosion will not occur. At the same time, the vanadium redox flow battery supports frequent charging and discharging, and can be charged and discharged hundreds of times a day.

The liquid electrolyte makes overcharge and overdischarge without causing explosion and battery capacity reduction. Compared with lithium batteries, the water-based electrolyte properties of vanadium redox flow battery prevent them from burning and exploding. Vanadium batteries use chemically reversible vanadium ions in aqueous solution, and their function is independent of electrode structure, so they are very flexible even at high currents, and there is no safety problem with overcharging.

On the other hand, the power and capacity of the vanadium redox flow battery are independent of each other, the power is determined by the specification and quantity of the stack, and the capacity is determined by the concentration and steps of the electrolyte. The capacity expansion can be achieved by increasing the capacity of the vanadium electrolyte, so it can still be safe on a large-capacity installed scale.

The stack of the vanadium redox flow battery is separated from the storage tank for storing the electrolyte as the place where the reaction occurs, which fundamentally overcomes the self-discharge phenomenon of the traditional battery. The power only depends on the size of the stack, the capacity only depends on the electrolyte storage and concentration, and the design is flexible.

When the power is constant, to increase the energy storage capacity, it is only necessary to increase the volume of the electrolyte storage tank or increase the volume or concentration of the electrolyte, without changing the size of the stack. At the same time, the power can be increased by increasing the reactor power and the number of reactors, and the storage power by increasing the electrolyte, which facilitates the expansion of the battery scale, and can be used to build kilowatt to 100 megawatt energy storage power stations, which is very adaptable.

Long cycle life, basic full recovery, low full cycle life cost

Vanadium batteries have long cycle life. The cathode and anode active materials of vanadium redox flow battery exist in the cathode and anode electrolytes, respectively. There is no phase change that is common in other batteries during charging and discharging, and it can be deeply discharged without damaging the battery. During the charging and discharging process, the vanadium ion as an active material only changes its valence state in the electrolyte, does not react with the electrode material, and does not produce other substances.

After long-term use, it still maintains good activity. Therefore, the vanadium battery has a long service life. The vanadium redox flow battery has a charge-discharge cycle of more than 10,000 times, and some can reach more than 20,000 times. The full cycle life cost of vanadium batteries is already lower than that of lithium batteries. At present, the initial installation cost of vanadium redox flow battery energy storage is high, but due to the long cycle life of vanadium battery, the cost of vanadium redox flow battery energy storage is lower than that of lithium battery from the perspective of the whole cycle life.

We compared the costs of vanadium redox flow battery projects and lithium battery energy storage projects with complete investment data. If calculated according to the whole cycle life, the cost of vanadium redox flow battery is 0.3-0.4 RMB/Wh, which is already lower than the cost of lithium battery (about 0.5 RMB/Wh). At the same time, the vanadium electrolyte solution can be recycled and reused after the battery life expires.

The cost of the electrolyte solution accounts for 40% of the total cost of the energy storage system. After the energy storage system is scrapped, the residual value is relatively high. The full cycle life cost of vanadium redox flow battery for long-term energy storage is already competitive. Moreover, vanadium batteries are still in the early stage of industrialization, and there is still room for further cost reduction after technological progress and large-scale application.

China’s vanadium resource production and reserves are the world’s largest, independent and controllable

From the perspective of resources, China ranks first in the world in terms of vanadium reserves and production, and the resources required for the development of vanadium batteries can be controlled independently.

● Resource reserves: Vanadium resources in China ranks first in the world. According to statistics, as of the end of 2021, the global reserves of vanadium metal are 63 million tons, of which more than 24 million tons of vanadium metal reserves have been identified as meeting the current mining and production requirements. More than 99% of the world’s vanadium reserves are concentrated in China, Australia, Russia and South Africa; China’s vanadium reserves are about 9.5 million tons, accounting for 39% of the world’s vanadium reserves, ranking first in the world.

● Vanadium production: Vanadium is fully self-sufficient. China’s vanadium production accounts for 68% of the world’s total, and the resources can be completely self-sufficient. The main countries producing vanadium in the world are China, Russia, South Africa and Brazil. According to USGS data, the global vanadium production in 2021 will be 107,000 metal tons, of which China will produce 73,000 tons, accounting for 68%.

● Vanadium static mineable life is comparable. According to USGS statistics, with the global vanadium output in 2021 of about 107,000 metal tons (equivalent to 191,000 tons of vanadium pentoxide), the static mineable life of global vanadium resources is about 224 years.

Disadvantages of vanadium redox flow battery

The initial installation cost of vanadium battery is more than 2 times that of lithium battery

The biggest disadvantage of vanadium batteries is the high cost of initial installation, which is more than twice that of lithium-ion batteries. According to the specific investment cost of vanadium battery project, the total investment cost of the project is 3.8-6.0 RMB / Wh; among which, the four-hour energy storage system cost is 3.8-4.8 RMB / Wh, and the 2-3-hour energy storage system cost is slightly higher, at 4.65-6 RMB / Wh, which is still higher than that of lithium battery.

Vanadium battery rapid development or drive vanadium price rise

● New energy storage is growing rapidly, and the size of the vanadium redox flow battery market is expected to increase rapidly. According to relevant data, as of the end of 2021, the cumulative installed capacity of global energy storage projects that have been put into operation is 209.4GW, a year-on-year increase of 9%. Among them, the largest is pumped hydro storage, with a cumulative installed capacity of about 180.5GW, accounting for 86.2%, down 4.1 percentage points from the end of 2020.

The cumulative installed capacity of new energy storage (including lithium-ion batteries, lead batteries, sodium-sulfur batteries, compressed air, flow batteries, supercapacitors and flywheel energy storage, etc.) was 25.4GW, a year-on-year increase of 67.7%, accounting for 12.2%. Among the new energy storage, lithium-ion batteries still dominate, accounting for 90.9% of the cumulative installed capacity. By the end of 2021, China’s cumulative installed power is 46.1GW, ranking first in the world. Among them, the installed capacity of pumped storage is 39.8GW, accounting for 86.3%.

The cumulative installed capacity of new energy storage is 5729.7MW, accounting for 12.5%, and the cumulative heat storage of molten salt accounts for 1.2%. Among the new energy storage capacity, lead acid battery vs lithium ion, lithium ion batteries accounted for 89.6%, lead acid batteries for 5.9%. And the compressed air energy storage for 3.2%, flow batteries for 0.9%, and other electrochemical energy storage (ultracapacitors and flywheel energy storage) accounted for 0.4%.

● Policies help the energy storage market develop. The Chinese government has issued relevant documents that on the way to the carbon peak and carbon neutrality, it is necessary to build a safe, efficient, clean and low-carbon energy system, and promote the realization of the comprehensive market-oriented development of new energy storage.

● The rapid growth of vanadium redox flow battery scale may drive vanadium demand. The year 2021 is the first year for China’s energy storage to enter the large-scale development, and the 100-megawatt-level level of vanadium redox flow battery project is also under construction. According to CNESA statistics, in 2021, the penetration rate of global flow battery (basically vanadium redox flow battery) in China’s new energy storage field reached 0.9%.

Benefiting from the multiple advantages of resources, safety, environmental protection and policy, with the gradual implementation of many large vanadium battery projects, the installed capacity of vanadium redox flow battery will achieve leapfrog growth. According to the conservative and ideal two scenarios and the 10%, 20% and 30% penetration rate of vanadium batteries in the new energy storage, the annual installed capacity of vanadium batteries in 2026 is 1.48GW-7.06GW.

According to USGS, China’s vanadium metal production capacity is about 131,000 tons in 2021. If the subsequent development of vanadium resources is not as expected, or the vanadium price is obviously pulled, and then affect the cost of vanadium redox flow battery electrolyte.

Low energy density and conversion efficiency, high maintenance requirements for consumables

● The energy density and conversion efficiency are low. The vanadium redox flow battery has high requirements on the ambient temperature during operation, and also needs a pump to maintain the flow of the electrolyte, so its loss is large, and the energy conversion efficiency is lower than that of the lithium battery, which is 70-75%. Limited by vanadium ion solubility and stack design, compared with other batteries, vanadium redox flow batteries have a lower energy density of only 12-40Wh/kg.

● Consumables require timely maintenance. The graphite plate should be etched by the positive solution. If the user operates properly, the graphite plate can be used for two years. If the user does not operate properly, the graphite plate can be completely etched by a single charge, and the stack can only be scrapped. Under normal use, it needs to be maintained by professionals every two months. This high-frequency maintenance is expensive and laborious.

Potential: LDES is a great use

LDES is one of the keys to achieving the dual carbon goal

As the penetration rate of renewable energy continues to increase, the demand for energy storage time is also increasing. In the context of the continuous global promotion of carbon neutrality, LDES(Long duration energy storage) is one of the keys to achieving the dual carbon goal. Under the background of vigorous development of renewable energy, LDES plays an important role in enhancing power storage capacity, ensuring peak regulation and stable operation of the power system, and power supply in extreme situations.

● Enhance power storage capacity: In the context of the dual-carbon target, the proportion of traditional fossil fuel sources such as thermal power generation will gradually decrease, renewable energy (photovoltaic, wind energy, etc.) will gradually replace thermal power as the main source of power generation, and LDES as a supporting construction of renewable energy is of great significance.

● To ensure peak regulation and safety and stability of power system: LDES can adjust the fluctuation of new energy generation in a longer time dimension with long cycle and large capacity characteristics, avoid grid congestion when clean energy is excess, and release and increase power supply at peak load.

● Power supplement in extreme cases: The suspension of power supply and energy supply tension caused by force majeure factors (natural disasters such as wildfires, rainstorms, floods, severe cold, conflicts among major energy supply countries, etc.) will lead to the increase of electricity costs of the whole society. LDES can guarantee the power supply in extreme cases, ensure the stable operation of the power system of the whole society and reduce the electricity cost.

Flow battery has huge application space in LDES field

LDES is still in the initial stage of R&D and demonstration. Among the various solutions, the construction scale of pumped storage is relatively large. With the advantages of mature technology, high efficiency and low cost, pumped storage power plants have become the solution with the largest energy storage capacity in the world. Large-scale pumped-storage power plants can provide low-cost, dispatchable power and serve as a major solution for grid stability due to their fast response times.

But the biggest limitations of pumped storage are site constraints, long construction times, and environmental concerns. In the long run, due to the promotion of the power battery industry, electrochemical energy storage is not restricted by the geographical environment, and is in a relatively favorable competitive position. In terms of electrochemical energy storage, lithium ion battery, sodium sulfur battery, sodium ion battery and flow battery all have great application potential; while vanadium redox flow battery can be used in LDES system due to their long life and easy expansion.

● Lithium ion battery: lithium battery has high energy density and high conversion efficiency, which are widely used in the field of energy storage.

● Sodium-based battery: sodium-sulfur battery has installed precedent, sodium and sulfur raw materials from a wide range, but the process requirements are very high, and the operating temperature is about 300-350 degrees, and the melting state of sodium and sulfur activity is great, there are certain safety risks.

However, sodium ion batteries have the advantages of safety, rich resources and low cost, and also have the disadvantages such as low cycle times and electrode material side reactions affecting battery life. At present, they have not been promoted on the energy storage industry on a large scale, and their advantages still remain to be verified.

● Flow battery: flow battery has the advantages of high safety and stability, long cycle life, strong expansion capacity, recycling and environmental protection, but it also has the disadvantages of high initial installation cost.

Based on the advantages of high safety and stability, long cycle life, strong capacity expansion, recycling and environmental protection, it is expected that liquid flow batteries will have a huge application space in the field of LDES, and will compete with pumped storage / hydrogen energy storage and compressed air energy storage.

Vanadium batteries commercialized faster in flow batteries

At present, flow battery routes mainly include more than 20 technical routes such as vanadium redox flow battery, iron-chromium flow batteries, zinc-bromine flow batteries, and zinc-iron flow batteries. At present, the first three technical routes are discussed more. Vanadium redox flow battery is a relatively mature flow battery route for commercialization. Vanadium redox flow batteryhas the advantages of running demonstration projects for many years, the industrial chain is gradually formed, and the cost of the whole life cycle is low. It is expected to be widely used in long-term energy storage systems.

● Safe operation of multiple demonstration projects: Vanadium redox flow battery has been operating for many years in the world, and the industrialization effect and reliability verification are significantly higher than those of iron-chromium flow batteries and zinc-bromine flow batteries. According to relevant data, in February 2022, the world’s largest 100MW vanadium redox flow battery energy storage peak shaving power station has entered the single module commissioning stage in Dalian.

● The whole industry chain is gradually taking shape: The supply chain of raw materials such as electrolyte, diaphragm and membrane electrode for vanadium redox flow battery has been initially formed, and the process of localization in China is accelerating, which has been able to support the design and development of 100-megawatt projects , and its industrial supporting facilities are more mature.

● Cost advantage in the whole cycle life: The whole cycle life cost of vanadium redox flow battery is already lower than that of lithium battery, and it has conditions for large-scale commercial application.

To sum up, the vanadium redox flow battery has the advantages of high safety, long life, strong capacity expansion, and high efficiency. We are optimistic about the potential of all-vanadium redox flow battery in the field of energy storage applications, especially the application space in the direction of long-term energy storage.

Policy and technology promote vanadium redox flow battery cost reduction

Policy support is an important impetus for the development of vanadium batteries

● Formulate relevant subsidies for the development of vanadium redox flow battery. Most of the existing vanadium redox flow battery projects are demonstration projects promoted by local governments, and a small number are independent construction projects of enterprises. The whole cycle life cost of vanadium redox flow battery has been lower than that of lithium battery, but the initial construction cost is too high, resulting in the investment motivation of enterprises is not strong. In the future or still need to promote at the government level, and formulate effectively implemented price compensation mechanism and LDES industry policies.

● Strengthen resource development and expand production capacity of steel companies. As China’s main vanadium production comes from vanadium slag in the vanadium titanomagnetite steelmaking process, allowing corresponding steel companies to expand production capacity is also one of the ways to increase the source of vanadium resources. At the same time, policies to support the development of vanadium resources can also be introduced to increase the development of vanadium resources in China.

Technological advancements are expected to continue reducing costs

The entire vanadium battery energy storage system is mainly composed of stack, electrolyte, inverter, intelligent control, storage tank, container, tube pump valve sensor. The most important core components of a vanadium battery are the stack and electrolyte. The electrolyte is generally composed of vanadium pentoxide, which is also the main use of vanadium products in the entire vanadium battery system.

According to IRENA, the cost of vanadium batteries is mainly divided into three parts: reactor, electrolyte and peripheral equipment costs. Reactor and electrolyte are the main costs, accounting for about 75%, vanadium electrolyte cost cost about 40%, reactor cost about 35%, and other components cost about 25%.

● Technology has driven the cost of electric reactors down continuously. The cost of lithium batteries has fallen rapidly after commercial application, falling from $7,523 / KWh in 1991 to $181 / KWh in 2018. Referring to the cost reduction approach of lithium battery, it can be predicted that the cost of vanadium battery still has a large downward space after mass production.

Vanadium redox flow battery is still in the early stage of commercialization, and there is a large space for cost reduction brought about by technological progress. For example, by reducing the use area of membrane materials to reduce the cost of batteries.

● Substitution of domestically produced materials in China drives down costs. With the gradual promotion of China’s domestic ion exchange membranes, there is still a lot of room for cost reduction in products such as membranes. It is expected that there will be room for cost optimization in other stack materials (bipolar plates, carbon felt, etc.) in the future.

Supply and demand of vanadium

Supply: China’s vanadium reserves and production ranks first in the world

● Resources: In 2021, China’s vanadium product reserves and production proportion will rank first in the world. As mentioned above, by the end of 2021, China’s vanadium ore reserves will account for 39% of the world’s total. In 2021, China’s production will account for 68% of the world’s total, ranking first in the world.

● Raw materials and processes: Vanadium-titanium magnetite is the main source in the world, and vanadium slag is the main source in China. Although the crustal abundance of vanadium is high, it mainly forms symbiotic or composite ores with other minerals, and independent vanadium ores are rare. China uses vanadium slag as a raw material for vanadium production, accounting for 86.9% of vanadium slag raw materials, and only 0.3% of vanadium-titanium magnetite raw materials are used directly.

The proportion of output of vanadium extraction from stone coal has declined due to environmental problems. Stone coal is a low-quality anthracite with low carbon content and low calorific value, and it is also a low-grade polymetallic symbiotic ore. More than 60 associated elements have been found in stone coal resources in China. Among them, vanadium can form industrial deposits.

However, the grade of vanadium in stone coal is very low, and the content of vanadium pentoxide is mostly below 0.8%. The proportion of vanadium extraction from stone coal has dropped significantly since 2017. In recent years, some companies have made breakthroughs in the process and realized green vanadium extraction from stone coal. The production proportion of vanadium extraction from stone coal may increase slightly in the future.

● Production capacity: Pangang Group Vanadium Titanium & Resources production capacity is first. More than 70% of the world’s vanadium comes from byproduct steelmaking vanadium slag. The main vanadium production companies with large production capacity include Pangang Group Vanadium Titanium & Resources, Evraz of Russia, Chengde Street, Beijing Jianlong Heavy Industry, etc. Among them, the vanadium and titanium production capacity of Pangang Group Vanadium Titanium & Resources is 40,000 tons / year, ranking the first in the world.

Application of vanadium: more than 90% of applications in steel industry

Vanadium is an important alloy element, mainly used in steel, titanium alloy additives, chemical catalysts, and energy storage field. The common vanadium compounds found in industry include VO, V2O3, V2O5, FeV ferric vanadium, and NH4VO3 ammonium partial vanadate.

● Steel: Metal vanadium is added to steel production in the form of ferrovanadium and vanadium-nitrogen alloys to improve the strength, toughness, ductility and heat resistance of steel. Vanadium-containing alloy steel has high strength, high toughness and good wear resistance, and is widely used in the production and construction of oil/gas pipelines, buildings, bridges, rails, etc. The steel industry accounts for the largest proportion of the downstream applications of vanadium, and its consumption accounts for more than 90% of vanadium consumption.

● Titanium alloy: About 2% of vanadium forms titanium alloy in the form of titanium-aluminum-vanadium alloy. Vanadium can be used as a stabilizer and strengthening agent in titanium alloy, which makes titanium alloy have good ductility and plasticity. Mainly used in aircraft engines, aerospace cabin skeletons, missiles, steam turbine blades, rocket engine casings, etc. In addition, vanadium alloys are also used in magnetic materials, hard alloys, superconducting materials and nuclear reactor materials.

● Chemical industry: In the chemical industry, vanadium is mainly used as a catalyst for the manufacture of sulfuric acid and vulcanized rubber, and is also used to inhibit the production of nitrous oxide in power plants. Other chemical vanadium products are mainly used as catalysts, ceramic colorants, developers, desiccants, etc.

● Energy storage: At present, the use of vanadium in the production of all-vanadium redox flow batteries has also become a research hotspot in the energy storage industry. If you want to learn more about the energy storage industry, you can also read the article top 5 energy storage battery companies on our website to help you. In the energy storage industry, great progress has been made in the research of vanadium redox flow batteries in clean energy in recent years. Vanadium redox flow battery has broad market prospects in wind power generation, photovoltaic power generation, grid peak regulation, distribution power stations, communication base stations and other fields, and have been used in commercial energy storage systems.

1 thought on “Vanadium redox flow battery industry report – wide space for LDES”

Dear manager

I hope you are doing well.

I would like to know please if you have some products depending on vanadium redox flow batteries stacks and their specifications.

Regards.