Will sodium replace lithium - technological innovation of CATL sodium ion battery

The data shows that it is expected that by 2025, the domestic demand for three scenarios of electric two-wheeled, low-speed electric vehicles including Lithium ion Motorcycle Battery and energy storage will reach 123GWh.

At present, in addition to the share of lead-acid batteries for two-wheeled vehicles, lithium iron phosphate batteries in these three fields basically show a dominant trend. Because not only the energy density of lithium ion battery has advantages, but also safety and environmental protection.

The complete sodium ion battery system is the appropriate choice

Sodium ion battery cell energy density

On the one hand, sodium ion battery monomer energy density (70~200Wh/kg) overlaps with that of lithium iron phosphate batteries (150~210Wh/kg):

The cost advantage of sodium ion batteries

On the other hand, the theoretical cost advantage overflows the screen: taking the calculation data of Zhongke Haina as an example, according to the watt-hour cost of a pouch battery of the same capacity, The theoretical cost of sodium ion battery BOM is about 30% lower than that of lithium ion battery.

Safety and performance

Furthermore, the safety and performance aspects are not lost to iron and lithium at all. benefit from

● Relatively low energy density and exothermic enthalpy.

● It is not easy to release oxygen and has no flammable risk.

● The instantaneous current and temperature rise are relatively small in a short period of time. At present, the sodium-ion battery has no fire and explosion phenomenon due to overcharge, over-discharge, short circuit, acupuncture and extrusion.

Benefit from low temperature conditions

1) Better interfacial ion diffusion ability due to lower solvation energy of sodium ions.

2) Large aperture transmission channels brought about by the open-frame three-dimensional framework of special cathode materials such as Prussian blue.

3) At present, the electronic conductivity is greatly improved by the micro-nano structure and carbon coating, and the discharge power is relatively excellent.

However, the ambition of the Ningde era is obviously broader, not only to improve energy density, layout supply chain, it involves three major scenarios of electric two-wheel, electric vehicle and energy storage, and also requires lithium and sodium to combine with each other to make up for the shortcomings of ground and air to reduce temperature and high power scenarios

Technological innovation

Chemical innovation

Different from the O3-type Nax[Li-Cu-Fe-Mn]O2 oxide of Li-doped transition metal of Zhongke Haina, the Ningde era took the route of sodium-based Prussian Blue Analogue (hereinafter referred to as PBA) derivatives .

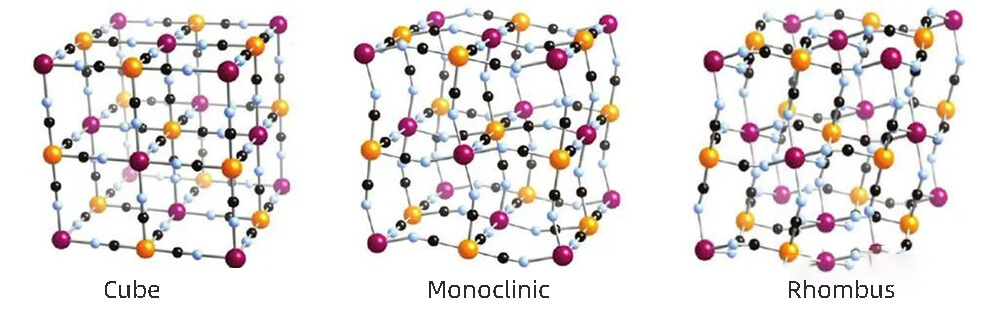

Both have the advantages of high gram capacity and voltage platform, which means high energy density. The difference is the high kinetic advantage brought by the special crystal structure of PBA. The general chemical formula of PBA should be written as AMa[Mb(CN)6]1-y⎕y·nH2O, where A is an alkali metal element, Ma and Mb are transition metal elements coordinated to C and N, respectively, and ⎕ is a defect vacancy.

It is very ornamental that the Ma and Mb and —C≡N—are arranged in a three-dimensional cubic structure according to the Ma—C≡N—Mb configuration, and Ma and Mb are located at the vertices of the face-centered cube, respectively.

Connected by -C≡N- on the edge, Na+ occupies the position of the cubic void, and crystal water usually exists on the surface and inside of the crystal.

Such a face-centered cubic open-frame framework and three-dimensional giant channels are very beneficial to the rapid migration of sodium ions, and can reversibly maintain structural stability after a certain amount of deintercalation.

Of course, due to the difference in the preparation process, the content of sodium element and the content of crystal water are also different, so the final crystal will be twisted to a certain extent to form a single crystal or a rhombohedral system.

In 2015, several cutting-edge laboratories in the United States worked closely with J.B. Goodenough to develop a sodium-ion battery cathode material called Prussian white: Na1.92Fe[Fe(CN)6].

This is actually a specific component of sodium-based Prussian blue. Because the sodium content is as high as 1.92, the powder is in a white state, so it is called Prussian white. In 2018, a company called Novasis Energies introduced a soft-packed sodium-ion battery based on NaxMnFe(CN)6 positive electrode by replacing Fe element in Ma position with Mn element. For the selection of Ma and Mb, a more reasonable solution is to use Mn and Fe elements.

Among them, Mn and N are in a high-spin state, and Fe and C are in a low-spin state, showing multiple pairs of reversible redox reactions during the charge and discharge process.

But this material also has quite fatal flaws, which is why it has not been able to achieve commercial applications for a long time:

1) Too much crystal water in the crystal will occupy the sodium ion site and block the migration channel of adjacent sodium ions, and will also be freed into the electrolyte, and a side reaction occurs with it, causing electrolyte consumption, instability of the negative electrode SEI film, and increase in impedance.

2)Too many vacancies in the crystal will hinder the migration of electrons and cause lattice distortion and destroy the Ma-C≡N-Mb bridge bond, this in turn leads to the collapse of the three-dimensional framework of PBA, which leads to the degradation of battery performance.

In this context, CATL has innovatively designed and improved from the material and pole piece process levels:

(1)Material level

In the invention patent CN108946765B, the CATL research team added one or more neutral ligands L. Partially or completely replace the crystal water, thereby reducing or even removing the crystal water content at the powder level. It has been verified that the water absorption can be reduced by up to 60%.

In order to maximize the gram capacity of Prussian white materials and increase the contact surface with the electrolyte to reduce the internal resistance of charge transfer, the specific surface area of the powder particles is generally increased.

However, if the specific surface area is too large, the adsorption capacity of the material will be significantly improved, so that the water absorption destroys the configuration and enriches the side reaction products during the charging and discharging process, so that the material loses its activity, resulting in the deterioration of electrical properties.

In the invention patent CN109728296B, the research team of CATL introduced sodium carboxymethyl cellulose in the preparation of Prussian white materials to adjust the viscosity and precipitation rate of the mother liquor, and formed particles with very suitable particle size and specific surface area, and obtained a relatively optimized rate and cycle performance.

At the same time, in order to ensure that the material will not be exposed to the risk of side reaction corrosion of the electrolyte due to the excessive porosity, and will not have poor wettability due to too small porosity and the broken band and light transmission during the cold pressing of the pole piece, etc. processing problems.

The CATL research team made the most appropriate design for particle size and porosity in the invention patent CN109841832B, and ensured the cycle stability.

During the charging and discharging process of sodium charge, alkali metal cations will inevitably cause the change of lattice constant when they are extracted and inserted into the three-dimensional structure of PBA. It is easy to cause the cycle stability of the PBA overall skeleton to decrease and the life to decay.

In order to improve the cycle performance of Prussian white materials in the non-aqueous electrolyte system, the CATL research team introduced a special type of electrolyte additives in the invention patent CN109088068B: the charge/radius ratio of cations is smaller than that of sodium ions. charge/radius ratio and optimized for its addition content.

During the charging and discharging process of the sodium-ion battery, the cation will preferentially intercalate and deintercalate into the PBA material. Because the cation has a small charge/radius ratio, it has less structural damage to the Prussian blue material during the intercalation and deintercalation process. The three-dimensional skeleton structure of Prussian blue-like materials can be stabilized, so that the sodium-ion battery has good cycle performance.

(2) Pole piece level

The Prussian blue material itself has poor electronic conductivity and low electrical conductivity. Conventional conductive agents cannot reduce the resistance of the membrane, resulting in a complete collapse of the electrical properties. In this invention patent CN109841806B.

The CATL research team introduced a suitable proportion of one-dimensional carbon nanomaterials with a diameter of 5nm to 100nm and good flexibility. A good conductive network was formed on the surface of the Prussian blue material particles and the interior of the secondary particles. The problem of “dead zone” in local areas is reduced, and the resistance of the membrane is greatly reduced, so that the positive electrode sheet has good conductivity.

In the invention patent CN109920979A, the CATL research team even optimized the ratio of conductive polymer and conductive agent, which reduced the membrane resistance by 70% and obtained a very excellent 2C rate performance.

In addition, the CATL research team also improved the stirring and coating process of the Prussian white cathode slurry, improved the tortuosity of the cathode active layer and the roughness in the direction away from the current collector, and optimized the active material thickness d1 and The ratio of the current collector thickness d2 to obtain excellent cycle performance.

In order to specifically improve the problem of low compaction density inherent in small particle powders, the CATL research team adopted a unique Bimodal mixing and matching method with a primary particle size of 1~5μm and a secondary particle size of 0.02~0.8μm. The compaction density of the Prussian white cathode sheet was increased to 2.0g/cc, which maximized the volume and mass energy density as much as possible.

(3) Chemical system level

In terms of chemical system matching, the CATL research team has optimized the three key design indicators of positive and negative electrode median particle size A/B, porosity P1/P2, and areal density C/D ratio. Thus, the capacity loss in the first charge and discharge of the battery is controlled, and the battery has high charge and discharge performance at high rates. As a result, the sodium-ion battery has high first Coulomb efficiency and rate performance.

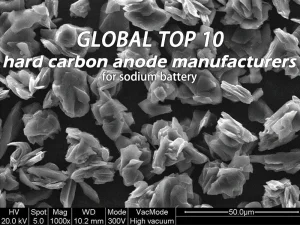

The CATL research team has developed a hard carbon material with a unique pore structure that can store a large amount of sodium ions and quickly pass through. The gram capacity can reach 350mAh/g, and it has excellent cyclability.

Based on the integration of highly innovative technical capabilities, CATL has developed a sodium-ion battery with unique advantages.

●Cell energy density: 160Wh/kg, the world’s current head level

●Charging at room temperature for 15 minutes, the power can reach more than 80%, excellent fast charging characteristics

●In the low temperature environment of -20 °C, the discharge retention rate of more than 90% is maintained, and the low temperature power is excellent.

●System integration efficiency can reach more than 80%

•Excellent thermal stability, and exceeds the safety requirements of the national power battery strong standard

To sum up, the energy density of the first-generation sodium-ion battery products of CATL is slightly lower than that of commercial lithium iron phosphate batteries, but its obvious advantages in low-temperature performance and fast charging are clearly seen, which are very suitable for high-power application scenarios in alpine regions.

Structural innovation

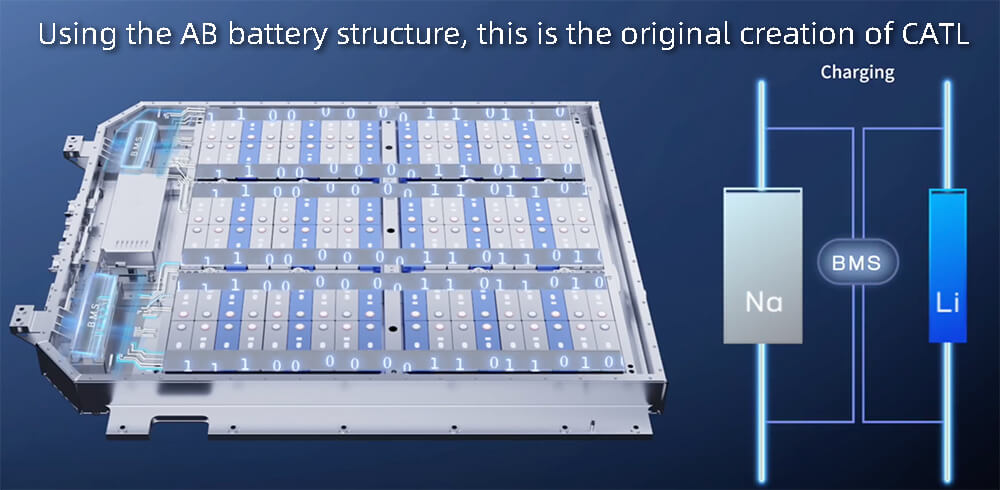

Using the AB battery structure, this is the original creation of CATL, which complements each other and complements each other. The buff bonus of 1+1>2.

The integration of the two batteries in series and parallel can quickly solve the problem of low energy density of the first-generation sodium-ion batteries. Of course, this also tests the BMS system very much.

Although it can be matched over the full cell voltage range (2.5~4.2V), the current Prussian white + hard carbon electrochemical curve (at least two plateau potentials) is significantly different from any existing Li-ion battery chemistry. (ternary slash, iron-lithium single platform), coupled with the inherent voltage hysteresis of sodium-based cathodes, this is bound to bring considerable complexity to SOC management.

However, based on the powerful computing power of the current CATL high-throughput simulation platform and the experience iteration of the battery cell development team and the combination of different systems in the field of lithium batteries, Shanren should have their own clever ideas.

The combination of AB and double swords can well make up for the energy density shortcomings of Gen1 sodium batteries. The energy density of the battery pack is increased by 25%, and the advantages of high power and low temperature performance are exerted, which can be adapted to more scenarios.

Judging from the route plan announced by CATL, Gen2 sodium battery products will surge to 200Wh/kg. In fact, the working principle of sodium-ion batteries is the same as that of lithium-ion batteries.

The processing properties can completely refer to the physical and chemical indicators of lithium-ion battery chemical materials, and the mass production lines of the two can be completely compatible, which is a test of the firm’s ability to ramp up production capacity and quality control.

In terms of standardization and quality assurance of new energy batteries in China, CATL is already doing its part. Carbon neutrality has spawned the demand for TWh-level batteries, and diversified application scenarios are emerging.