A detailed introduction for best battery pack

In battery pack industry, people call batteries that are not assembled into batteries that cannot be used directly, and batteries that are connected to PCM boards and have functions such as charge and discharge control are called batteries. Cells are an important part of batteries in best battery pack assembly.

Batteries and cells

The most commonly used cells for best battery pack: polymer, lithium-ion aluminum shell, lithium-ion steel shell, cylindrical cells (lithium-ion, nickel metal hydride).

Types of cells

| Features | Lithium cobalt oxide (LCO) | Lithium manganese oxide (LMO) | Lithium iron phosphate (LFP) | Lithium nickel cobalt manganate (NCM) | Lithium nickel cobalt aluminate (NCA) |

| Voltage platform(V) | 3.7-3.9 | 3.8 | 3.2 | 3.6-3.9 | 3.6 |

| Specific heat capacity(mAh/g) | 140-160 | 110-120 | 130-150 | 150-220 | 170-200 |

| Energy density(Wh/kg) | 160-220 | 80-100 | 90-120 | 160-200 | 180-240 |

| Cycle life (Times) | 500-1000 | 500-1000 | 4000 | 800-2000 | 500-1000 |

| Cost | High | Low price | Low price | Relatively high price | Relatively high price |

| Advantages | Stable charging and discharging and simple process | Rich manganese resources, low price and good safety performance | High security, environmental protection and long life | Stable electrochemical performance and good cycle performance | High energy density, good low temperature performance |

| Disadvantages | Cobalt is expensive and has low cycle life | Low energy density and poor electrolyte compatibility | Poor low temperature performance and low discharge voltage | Using some metal cobalt, high price | Poor high-temperature performance, poor safety, and high technical threshold |

Cell model and specification naming method

According to the battery electrochemical system + size, such as square lithium-ion 383450 model, refers to the battery cell body part width 34mm thick 3.8mm long 50mm; Cylindrical type 18650 model, refers to the cell diameter 18mm long 65mm polymer. Object (soft package) 383450 model, refers to the physical part of the battery cell width 34mm thick 3.8mm long 50mm. If you want to know more detailed information about 18650 battery, you can read the article 18650 vs 14500 batteries in our website.

Main cell models

■ IFR18650-1.5Ah

■ IFR22650-2.3Ah

■ IFR26650-3.6Ah

■ IFR32700-5.5Ah

■ IFR32700-6.0Ah

■ IFP2270160-20Ah

■ IFP2270160-24Ah

Electrochemical system

■ Cathode electrode:

P1: Lithium Cobaltate LCO, Lithium Manganate LMO, Lithium Nickelate LNO, Binary Material NCA, Ternary Material NCM;

P2: Lithium Iron Phosphate LFP

■ Anode electrode:

N1: graphite, hard carbon;

N2: lithium titanate LTO,

■ 3.7V system: P1+N1 ICP/ICR INR/INP

■ 3.2V system: P2+N1 IFP/IFR (IFR32700-6.0Ah IFP2270160-20Ah)

■ 2.4V system: P1+N2 ITP/ITR

■ 1.9V system: P2+N2 is not currently used

Cell connection process

Resistance welding, bolt and screw connection, laser welding connection, aluminum wire welding bonding connection

Common series and parallel forms

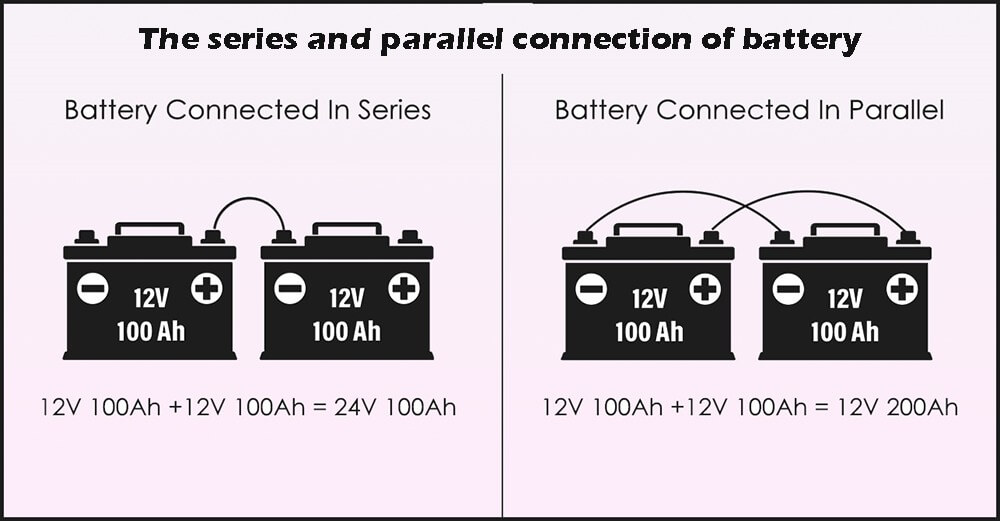

Through the series and parallel connection of the best battery pack, the voltage is increased and the capacity is increased.

■ When in parallel in battery pack, the capacity is doubled; when the cells are charged or discharged at the same time, the current is distributed according to Ohm’s law, the smaller the battery impedance, the larger the current, and the larger the impedance, the smaller the current.

■ When connected in series and parallel, the capacity is doubled and the voltage is doubled for the best battery pack;

■ Problems caused by battery string and parallel to best battery pack: battery consistency

Consistency of initial state: Capacity internal resistance voltage (SOC) Self-discharge (K value)

Consistency of process state: Capacity decay rate self-discharge decay rate

Composition of the battery

The best battery pack consists of the two most important parts: the cell and the protection circuit board (usually called the PCM board).

Protection board basis: The reason why lithium batteries (rechargeable) need protection is determined by their own characteristics. Since the material of the lithium battery itself determines that it cannot be overcharged, overdischarged, overcurrent, short-circuited and ultra-high temperature charge and discharge, the lithium battery components will always appear with a delicate protection board and a current fuse.

The protection board usually includes control ICs, MOS switches and auxiliary devices NTC, ID, memory, etc. Among them, the control IC controls the MOS switch to turn on under normal circumstances, so that the cell communicates with the external circuit, and when the cell voltage or loop current exceeds the specified value, it immediately controls the MOS switch to turn off to protect the safety of the cell.

The protection range of the protective plate

The maximum charging voltage of the charger is 4.2V;

The minimum discharge voltage of electrical appliances is 3.3~3.0V;

Battery operating voltage range 4.2V~3.0V;

Protection board protection voltage range 4.30V~2.5V;

Cell NF, NE range 4.8V ~ 2.0V;

Both multi-section and single-section protective plates protect the single body.

BMS principle

BMS common functions: charge overvoltage protection, discharge low voltage protection, charge overcurrent protection, discharge low current protection, charge overtemperature protection, discharge low temperature protection, equalization function, precharge function, current limiting function, anti-reverse connection function, heating control Function, weak point switch function, dry contact function, communication function (wired, wireless), storage function

■ BMS communication function

Total battery voltage, SOC, cycle times, charge and discharge current, string voltage, battery temperature, ambient temperature, GPS positioning

SMBUS, the system management bus is a two-wire interface. It evolves based on the principle of I2C bus and can be considered as a simplified version of I2C bus. SMBus was originally applied to smart batteries, such as battery chargers and a microcontroller. It provides a system and power management related task control bus to best battery pack. Today, the types of devices that can be connected to the SMBus bus are more diverse, including power-related devices, system sensors, EEPROM capacity and other devices for information communication.

SMBus is embodied in the lower three layers of the OSI model: physical, data link, and network. The physical layer defines the electrical characteristics of SMBus; the data link layer partially normalizes the data transmission of bits and bytes, arbitration and clock signals; the network layer handles the SMBus address resolution protocol and the bus data transmission protocol.

Modbus protocol is a common language applied to electronic controllers for the best battery pack. It defines the message structure that a controller can recognize and use, regardless of the network over which they communicate. It describes the process by which a controller requests access to other devices, if it responds to requests from other devices, and how errors are detected and logged. It establishes a common format for the format and content of message fields.

RS485 used in industry is an electrical standard that specifies electrical parameters such as communication medium, voltage, resistance, etc., but does not define specific protocols. The standards that Modbus can use include RS232, RS422, RS485, TCP/IP and so on. RS485 not only supports Modbus protocol, but also supports protocols such as Profibus.

The Field Supervision Unit (FSU) of the tower base station intelligent dynamic environment monitoring unit is composed of several monitoring modules and other auxiliary equipment, data relay and other functions. Base station communication protocol: YD/T1363.2 communication bureau (station) power supply, air conditioning and environmental centralized monitoring and management system.

CANbus, as a serial data communication bus in best battery pack, is widely used in industrial field control, automotive electronic technology, medical equipment and many other fields. CANBus (ControLLer Area Net-work Bus), which is the ISO11898CAN standard, is a broadcast-oriented serial bus system that connects field devices (sensors, actuators, controllers, etc.) Used in the automotive industry, and increasingly in the manufacturing automation industry.

The CAN protocol only defines the bottom two layers of the model: the data link layer and the physical layer, which ensures error-free data transmission between nodes. The application layer protocol of CAN must be defined by the user, or adopt the standard protocol formulated by some international organizations. The most widely used are DeviceNet and CANopen, which are widely used in process control and electromechanical control respectively. However, such protocols are generally more complex in structure and are more suitable for applications in complex large-scale systems.

■ BMS wireless communication function

BLUETOOTH supports the radio technology of short-distance communication (generally within 10m) of devices, and can exchange wireless information between many devices including mobile phones, PDAs, wireless headsets, notebook computers, and related peripherals in best battery pack. Using “Bluetooth” technology, it can effectively simplify the communication between mobile communication terminal devices

The first-generation analog type of 2G/4G mobile communication technology only provides voice services; the transmission rate of the second-generation digital mobile communication system is only 9.6Kbps, up to 32Kbps; while the data transmission rate of the third-generation mobile communication system can reach 20Mbps. The fourth-generation mobile communication system is a technology that integrates 3G and WLAN and can transmit high-quality video images and the image transmission quality is comparable to that of high-definition TVs. It can transmit wireless information at a speed of 100Mbps.

Types of battery casings

■ Epoxy board + PVC (simple package)

It mainly depends on the specific needs of the customer’s products. It is necessary to add fixed brackets between the cells for the best battery pack, and after adding glass fiber board protection to the periphery, PVC heat shrinks and waterproof glue is applied.

■ Aluminum square pass or die-cast aluminum shell

Aluminum square pass main profile aluminum square pass. The profile aluminum square has a characteristic aluminum ventilation extrusion molding.

■ Male mold plastic shell

The male mold is public, that is, after the manufacturer has opened the mold (of course, the mold belongs to the mold opening manufacturer), anyone can buy the products produced by this mold.

■ Private mold plastic shell

Private mold means the mold developed by itself, the copyright is owned by itself, and the mold is customized.

■ Sheet metal box

The sheet metal box basically does not need to open the mold. It is made by bending the metal plate, splicing and welding, and then spraying powder and baking paint.

■ Sheet metal waterproof iron box

The sheet metal iron box needs to be flanged and sealed, and multiple measures such as sealing strips and waterproof nuts can be used to achieve a reliable waterproof level.

PTC

PTC: Abbreviation for Positive Temperature Coefficient in English, which means positive temperature coefficient. The higher the temperature, the resistance will increase, and it will recover after cooling. PTC in battery products can prevent the occurrence of high temperature discharge and unsafe high current of the best battery pack. According to the voltage, current density characteristics and application environment of the battery, there are special requirements for PTC. PTC is a very important safety component in battery pack products.

NTC

NTC (Negative Temperature CoeffiCient) refers to the thermistor phenomenon and material whose resistance decreases exponentially with increasing temperature and has a negative temperature coefficient. The material is a semiconductor ceramic made of two or more metal oxides, such as manganese, copper, silicon, cobalt, iron, nickel, zinc, etc., which are fully mixed, formed, and sintered. It can be made into a negative temperature coefficient (NTC) thermistor.

Instead of directly controlling a best battery pack itself, the NTC provides a temperature signal that is converted into resistance. After the charging management circuit obtains the model number, it judges whether the temperature is normal to determine whether the charging is normal or not.

Connection method of the best battery pack circuit

■ Soldering: Mainly used for the connection of wires and circuit boards; conductor reinforcement of high-current circuit boards.

■ Spot welding: Mainly used for cell connection; PCM is connected to the cell.

Characteristic expression of the best battery pack

■ Simple naming:

FB18650-2S2P 7.4V 5200mAh

■ Complex naming:

FB18650-2S2P 7.4V 5200mAh+PCM+NTC+Wire+Conn.

■ Configuration expression:

FB18650-2S2P 7.4V 5200mAh

PCB: S-8254ABC+4407+R020+NTC(10K,B=3435)

WIRE: UL1532 AWG20# L=180±5mm

Conn.: XH2.54-5P Forward

■ Performance expression:

FB18650-2S2P 7.4V 5200mAh

Add board, add wire, add plug, add NTC

Working current: 1.0A

Maximum current: 3.0A

Maximum size: 23×78×68mm

Application scenarios and specifications of battery pack

■ Application scenarios: low-speed vehicles/street lamps/lead-acid/base stations/home energy storage, etc. If you want to learn more about home energy storage, please read the article Top 10 powerwall manufacturers for home energy storage in the world in our website.

■ Appearance specifications: dimensions, shell requirements, etc.

■ Battery specification: voltage level, capacity level, energy level.

■ Power specification: working time, working current, maximum power.

■ Interface requirements: Anderson, Amphenol, fence terminals.

■ Communication requirements: SMBUS, modbus, canbus.

One of the application scenarios of lithium battery pack – solar street light

During the day, the solar panel absorbs the solar light and converts it into electrical energy after being irradiated by sunlight. Under the control of the intelligent controller, it charges the best battery pack. At night, the battery pack provides electricity to supply power to the LED light source to realize the lighting function. The intelligent controller can ensure that the best battery pack is not damaged due to overcharge or overdischarge, and has functions such as light control, time control, temperature compensation, lightning protection, and reverse polarity protection.

Introduction and main functions of key components

■ Solar modules

Due to the particularity of solar street lights, solar panels are generally installed on light poles. For light poles, they are generally more than 5 meters away, with a high center of gravity, and most of the solar panels are suspended. Wind resistance, generally choose multiple solar panels to form the required component power.

Main function: absorb sunlight, convert the light into electrical energy and charge the battery.

■ Storage battery

At present, maintenance-free, waterproof lead-acid batteries or colloidal batteries are used in the industry. However, with the development of the new energy industry and domestic policies, most of the lithium batteries have replaced lead-acid batteries.

Main function: It is to store the electrical energy converted by solar panels and provide electrical energy for street lights.