Home » Lithium battery technology » Aluminum air battery – how it works and applications

Aluminum air battery - how it works and applications

What is an aluminum air battery?

Aluminum air batteries are a type of special fuel cell that uses aluminum as the positive electrode active material and oxygen in the air as the cathode active material.

Compared with ternary lithium battery, aluminum-air battery has higher energy. Its theoretical specific energy can reach 4000 Wh·kg-1, and the actual specific energy can generally reach 320-400 Wh·kg-1, which is about 6-8 times that of lead-acid batteries and 5 times that of nickel-metal hydride batteries.

Aluminum-air batteries have the advantages of large capacity, high specific energy, light weight, and long life. It can meet the needs of electrical equipment for high-current and high-power battery systems.

Principle of aluminum air battery

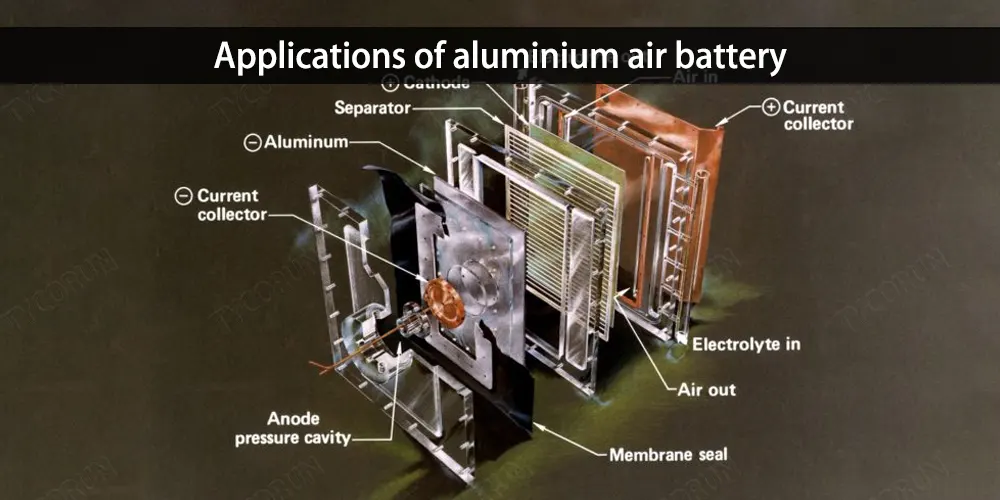

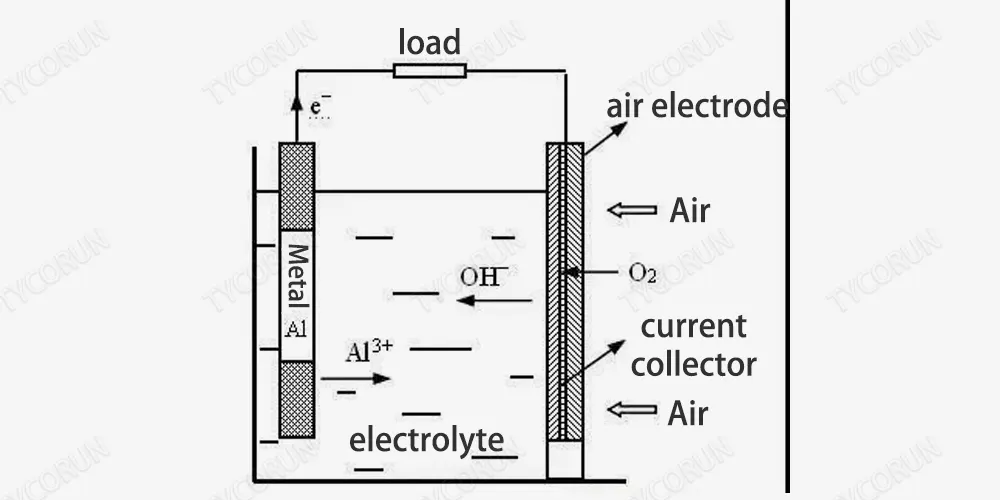

Aluminum air battery is composed of aluminum alloy negative electrode, air electrode (positive electrode), neutral or alkaline electrolyte and battery casing. Its structure is shown in Figure 1.

During the battery discharge process, aluminum is continuously consumed and Al(OH)3 is generated, and oxygen diffuses to the three-phase reaction interface of the air electrode to undergo a reduction reaction. Its basic reaction equation is:

Negative electrode: Al 3OHˉ → Al(OH)3 3eˉ (1)

Positive electrode:O2 2H2O 4eˉ→ 4OHˉ (2)

Total battery reaction: 4Al 3O2 6H2O → 4Al(OH)3 (3)

Aluminum air battery structure

Aluminum-air batteries have high discharge power and are accompanied by the generation of Al(OH)3 and heat. A reliable and reasonable battery structure is required to ensure safe and stable operation of the battery.

In recent years, researchers have designed a variety of new modular battery structures that can achieve uninterrupted battery output. It can easily recycle metal electrodes and replace electrode components, and can also drain the electrolyte in the battery when the battery is not working.

At the same time, it eliminates battery self-discharge and hydrogen evolution and extends battery life. In addition, through the optimized design of the battery structure, the weight of the battery is reduced and its specific energy density is increased, striving to meet the requirements of commercial applications.

Applications of aluminum air battery

In recent years, new research results have been continuously obtained in aspects such as oxygen reduction catalysts, aluminum alloy modification, and battery structural systems. The performance of aluminum-air batteries has been further improved, and its applications have gradually developed.

At present, European and American countries have applied aluminum-air batteries with neutral electrolytes in portable equipment, communication base stations, and marine engineering facilities.

Alkaline aluminum-air batteries are used in motor vehicles, underwater monitors, long-range torpedoes and diving facilities.

Norway’s HUGIN3000 underwater robot uses oxygen produced by the decomposition of hydrogen peroxide as the reaction gas for aluminum-air batteries. The underwater robot only needs to carry 18-20 kg of hydrogen peroxide to operate continuously for 48 hours under a rated load of 900W.

The United States has launched aluminum-oxygen batteries for submarine unmanned operating vehicles and torpedo propulsion, with a specific energy of 440 Wh/kg, reaching a practical level.

In addition, aluminum-air batteries also have broad application prospects in the field of electric vehicles.

Preliminary estimates indicate that an average truck will consume 14 kg of aluminum and 25 L of water for every 400 km traveled.

If the aluminum block in the negative electrode weighs 68 kg, and the aluminum utilization rate is 85%, the negative electrode can run 1,600 km. Water is added every 400 km, similar to refueling a fuel vehicle during the same driving time.

At present, European and American countries are vigorously developing aluminum-air batteries as power sources for electric vehicles, allowing them to give full play to the advantages of fuel cells and batteries and promote the development of the electric vehicle industry.

Technical breakthroughs required for aluminum air battery

About 20 years ago, scientists predicted that the combination of aluminum-air batteries and xEVs would be one of the most promising technologies for future passenger cars in terms of range, purchase price, fuel costs and life cycle costs.

The performance and cost-effectiveness of batteries make them an economical alternative to fossil fuels. Aluminum-air batteries have a range similar to that of gasoline-powered cars, currently estimated at 1,600 kilometers per tank.

Why has this technology been so slow to gain public attention?

For a long time, the main factor hindering the commercialization of this technology has actually been the technology itself. Because of engineering application problems such as anode corrosion or pore clogging.

There are still some technical difficulties in the practical application of aluminum-air batteries, which require continued in-depth research in aspects such as aluminum anode modification, oxygen reduction catalyst development, air electrode preparation, and battery structure design optimization.

In 2020, scientists still believe that poor performance and high cost of the cathodes, anodes, electrolytes and other battery components make the technology unsuitable for scaling and commercialization.

Conclusion and outlook

As a new battery solution with high specific energy, aluminum-air batteries can be widely used in military and civilian fields such as backup power supplies, portable power supplies, electric vehicles, and underwater vehicles.

In order to meet the requirements for the promotion and use of aluminum-air batteries, it is necessary to focus on the development of non-noble metal catalysts with high catalytic activity. Related research work can continue on both metal organic chelates and manganese oxide catalysts.

Among them, alloying methods have bright prospects for improving the activity and corrosion resistance of aluminum. It is necessary to continue to improve the doping formula, and supplement it with aluminum alloy heat treatment technology to improve the comprehensive properties of aluminum.

In the future, the performance of aluminum-air batteries will likely be gradually improved, and its industrial application may also be gradually realized.