Home » lithium ion battery knowledge » Battery swapping connector – why it is so important

Battery swapping connector - why it is so important?

Electric vehicles are developing rapidly every year, but range anxiety and charging anxiety are still concerns for many people.

In order to solve these problems, there are two kinds of energy supplementary technologies that are currently developing rapidly: car fast charging/super fast charging technology and car battery replacement technology.

These two technologies are closely related to connectors, which play a vital role in battery swapping technology.

This article will discuss the energy replenishment method of electric vehicles and the importance of battery swapping connector in battery swapping technology.

Electric vehicle energy supply

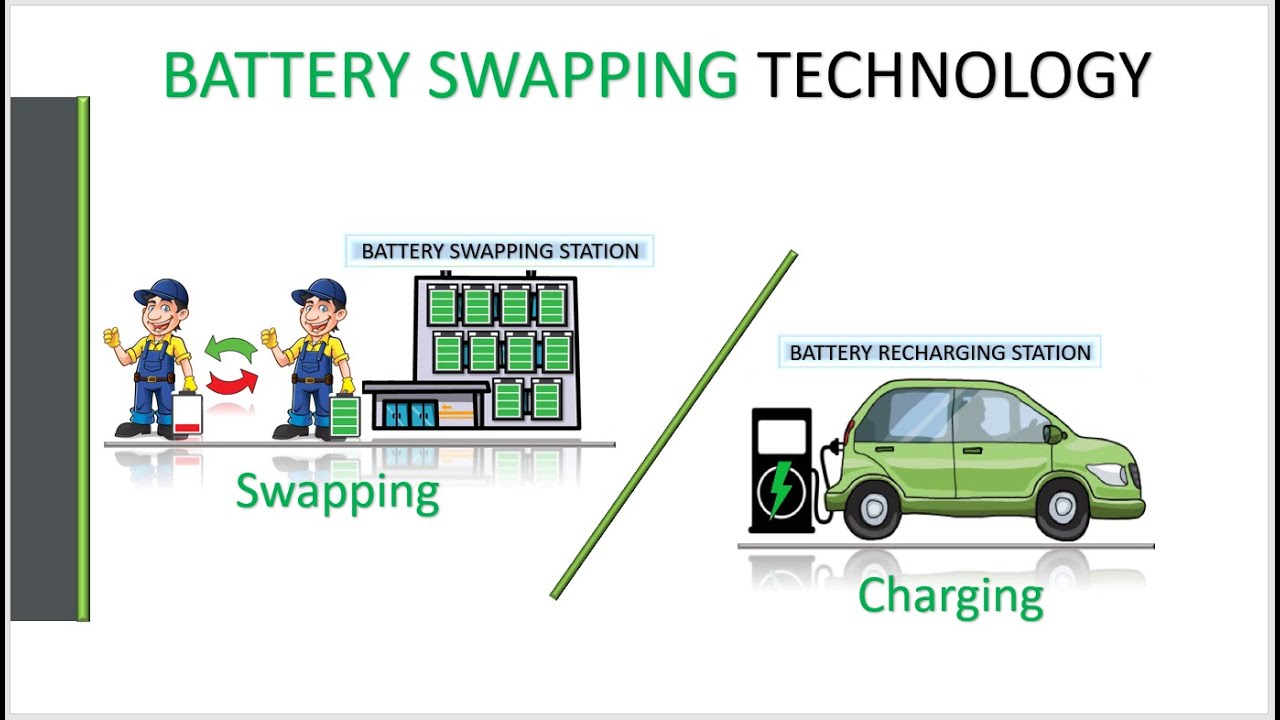

Energy supply has always been a very important link in the electric vehicle industry chain. The vigorous development of electric vehicles has a great relationship with the evolution of energy supply models. At present, the two mainstream routes are plug-in charging and battery replacement.

The car battery replacement technology is to quickly remove the whole battery from the electric car and install another battery. It is completely different from the charging of the whole car, which is an energy supplement solution that separates the car from the battery.

In the plug-in charging mode, the battery is deeply bound to the vehicle, and the battery itself is also expensive. The battery swap mode can separate the vehicle from the battery, which has another advantage.

For now, the battery replacement time is much shorter than the charging time.

The battery swapping mode can save some time costs and avoid waiting for too long charging time. To a certain extent, it can solve the mileage anxiety of electric vehicles and help reduce the load on the power grid.

Battery swapping technology will not require as much technical requirements for charging and battery as fast charging technology, and the replaced battery will be handled at the swap station for unified processing, which is also more trouble-free and convenient.

However, the cost of battery swapping infrastructure construction is too expensive, and the battery swapping mechanism will significantly increase the difficulty of vehicle design, including reliability, seating space, weight increase, etc. Therefore, this route is not as popular in passenger cars as it is in commercial vehicles.

In general, the advantage of the battery swap mode at this stage is that it can realize rapid energy replenishment, reduce the cost of car purchase, and the battery under centralized management can prolong a certain lifespan.

Relevant data show that in 2025, the scale of power stations in China will exceed 15,000. Automakers such as NIO, BAIC, SAIC, and Geely are all representative companies in the battery swap market.

Among them, battery swapping connector is an essential core component of the battery swapping technology, which is used to connect the power battery and the vehicle interface.

According to the data, the battery swapping connector market will grow at a compound annual growth rate of 83%, reaching 2.7 billion yuan in 2025.

What is battery swapping connector?

In the battery replacement mode, the battery swapping connector is an important component.

It is a special connector used to realize the electrical quick connection and separation between the whole vehicle and the quick-change battery system, strictly speaking, it belongs to the category of high-voltage connectors.

The battery swapping connector consists of quick-change plugs, sockets and related cables. It is the only electrical interface of the battery pack and needs to be able to provide mixed connections of high voltage, low voltage, communication and grounding at the same time.

Battery swapping connectors have different application standards in passenger cars and commercial vehicles.

Commercial vehicles generally have longer strokes and heavier loads, and have more requirements for plugging and unplugging performance and battery pressure-bearing performance for battery swapping connectors. Passenger cars have relatively looser requirements on power replacement connectors.

Judging from the current development, thanks to the maturity of the battery swapping station business model, the development of battery exchange connectors has also maintained rapid growth.

Moreover, the unit price of battery swapping connector has been decreasing year by year since 2020, and the unit price of battery swapping connectors in 2022 has dropped by about 10% compared with 2020. Subsequent further price reductions are also conducive to the promotion of the point-for-point model.

Requirements for battery swapping connector

The battery swapping connector should have large floating compensation capability, long life, and low maintenance cost.

In the process of quick battery replacement, there is generally a matching error during the connection and mating process between the battery and the vehicle end.

The floating compensation design of the battery swapping connector is a technical difficulty. It is required that the battery swapping connector must have floating compensation capabilities, and within a certain tolerance range, it can still complete the mixed connection of high voltage, low voltage, communication and grounding.

The battery replacement frequency of the whole vehicle is generally 1-15 times/week for passenger cars, and 7-70 times/week for commercial vehicles. The battery replacement connector life generally requires 3,000-10,000 times and lower maintenance costs.

Therefore, the core technology of the power exchange connector is reflected in technical indicators such as large floating compensation capability and long life.

Development of electric motorcycle connectors

Lithium battery is increasingly popular as electric motorcycle battery. Simultaneously, power exchange cabinets are becoming increasingly common in cities.

The requirements for electric motorcycle connectors are getting higher and higher, and high-quality connectors have gradually become a new market direction.

Electric motorcycle connector products are used in electric motorcycles, the main function is to transmit current and signals, but also to prevent wire contact and short circuit, and protect electrical components.

Electric motor connectors can be used in various electrical equipment and circuits, such as battery packs, motors, controllers, etc. They play a vital role in the proper operation of electric motorcycles as they ensure the safety and reliability of the electrical circuit.

Summary

It is a good technical route to adopt the battery replacement mode to greatly shorten the energy replenishment time of electric vehicles, and to a certain extent solve battery life anxiety and mileage anxiety.

This also puts high demands on connectors, and the high growth of the battery replacement market has also made global manufacturers increasingly competitive on the new track.