Detailed introduction of carbon nanotube - preparation method and development

It is beneficial to improve the energy density of lithium ion battery, improve the cycle life performance of the battery, and is expected to accelerate the replacement of traditional conductive agents. This article will take you to learn more about carbon nanotube.

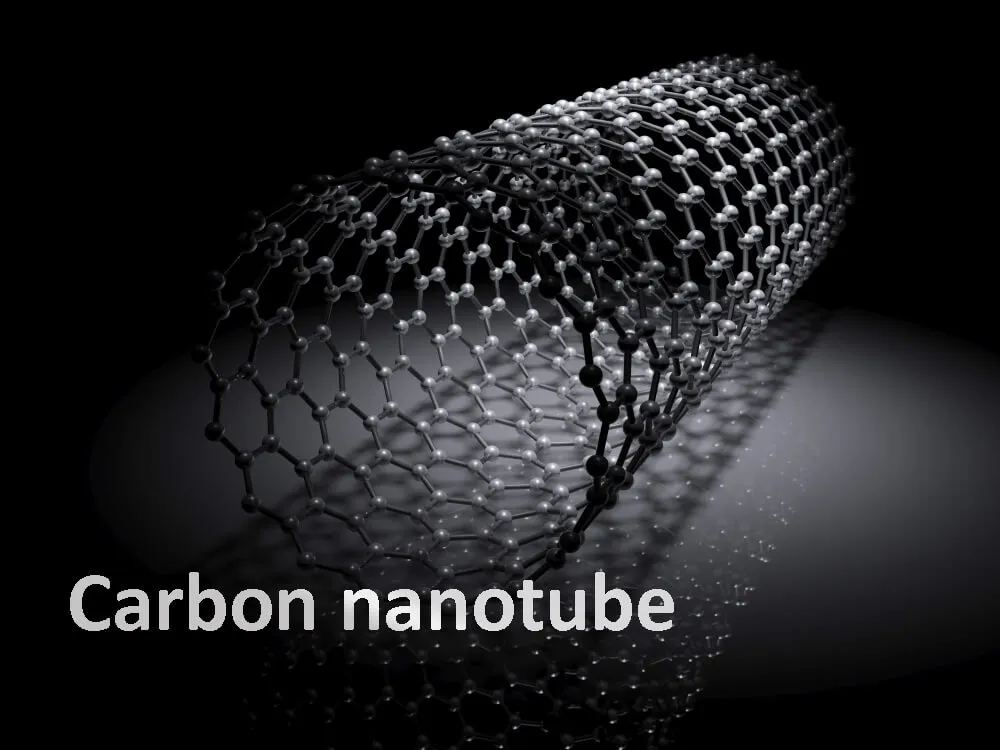

What is carbon nanotube

Carbon nanotubes (CNTs) are a typical one-dimensional nanomaterial. Carbon nanotube is an isotope of crystalline carbon, which is a honeycomb-like one-dimensional hollow nanotube in structure, in which C-C atoms are sp2 hybridized to form covalent bonds.

According to the number of walls of carbon nanotube, it can be divided into single-wall carbon nanotube (SWCNT) and multi-wall carbon nanotube (MWCNT). According to the structural characteristics of carbon nanotube, it can be divided into three types: armchair, zigzag and spiral. The helical carbon nanotubes have chirality, while the zigzag and armchair carbon nanotubes have no chirality.

Performance advantages of carbon nanotube

● Highest specific strength:

The covalent bond connecting the carbon atoms in the carbon nanotube is the most stable chemical bond in nature. Carbon nanotube has extremely high tensile strength and elastic modulus. At the same time, the density of carbon nanotube is only 1/6 of that of steel, which is the material with the highest specific strength that can be prepared at present.

● Strong flexibility:

Carbon nanotube is strong but not brittle. When bending the carbon nanotube or applying pressure on it in the axial direction, the carbon nanotube will not break even if the external force exceeds the Euler strength limit or bending strength, instead, a large-angle bending occurs first, and when the external force is released, the carbon nanotube returns to its original shape.

● Good conductivity:

The structure of carbon nanotube is the same as the sheet structure of graphite and has good electrical conductivity. The resistance of carbon nanotube has nothing to do with its length and diameter, electrons passing through carbon nanotube do not generate heat to heat carbon nanotube. The transmission of electrons in the carbon nanotube is like the transmission of light signals in the optical fiber cable, and the energy loss is small, and it is an excellent battery conductor.

● Good hydrogen storage performance:

The carbon nanotube itself has a high specific surface area, and after being treated, it has an excellent hydrogen storage capacity.

● Superior lithium intercalation properties:

The hollow lumen of carbon nanotubes, the gaps between tubes, the gaps between layers in the tube wall, and various defects in the tube structure provide abundant storage space and transport channels for lithium ions.

● Chemical stability:

The carbon nanotube is chemically stable and has acid and alkali resistance. Adding carbon nanotubes to polymer composites can improve the acid resistance and oxidation resistance of the materials themselves.

Application of carbon nanotube

From the perspective of the carbon nanotube industry chain, the upstream of the industry chain is the petrochemical industry, and the main raw materials are propylene, NMP, and dispersants. Midstream carbon nanotube conductive agents mainly include conductive paste and conductive masterbatch, which are used in lithium batteries and chemical companies respectively.

It has excellent properties of high strength and high electrical and thermal conductivity. Its downstream applications mainly cover the fields of new energy automobile industry, 3C digital industry, semiconductor industry, energy storage power station and power infrastructure, as well as conductive plastic enterprises of chemical enterprises.

The large-scale commercial application demand of carbon nanotube mainly comes from the fields of lithium batteries and conductive plastics, of which more than 80% of the demand comes from lithium batteries. Carbon nanotube and graphene belong to new conductive agent materials. Carbon nanotube forms a line-contact conductive network between active materials, and graphene forms a surface-contact conductive network between active materials.

According to the proportion of the downstream demand structure of carbon nanotubes, the lithium battery service industry accounts for a relatively heavy proportion, reaching 86%; the conductive plastic enterprises account for a relatively low proportion, accounting for only 14%.

Preparation method of carbon nanotube

There are three main synthesis methods of carbon nanotube: arc discharge method, laser evaporation method and chemical vapor deposition method. Among them, the arc discharge method has a high reaction temperature, a fast growth rate of carbon nanotubes, and the preparation parameters are not easy to control, so it is difficult to control its fine structure.

Due to the expensive and complicated equipment, the laser evaporation method is less used now. Chemical vapor deposition (CVD) is to decompose carbon-containing compounds to provide carbon sources, and then realize the growth of carbon nanotubes under the action of metal catalysts. The method has low growth temperature, easy adjustment of parameters, high product yield and high carbon purity, and is currently the most widely used technology in the industry.

Arc method

The arc method is the earliest method used to prepare carbon nanotubes, and it is also the most important method. Its main technique is: filling a vacuum container with inert gas or hydrogen under a certain pressure, and using graphite doped with catalyst (metal sharp, drill, iron, etc.) as the electrode. When the anode graphite is evaporated and consumed during the arc discharge, carbon nanotubes are deposited on the cathode graphite electrode, thereby producing carbon nanotubes.

Laser evaporation method

The principle is to use the laser beam to irradiate the graphite target containing the gold ring to evaporate it, and at the same time combine with a certain reaction gas to deposit the carbon nanotube on the substrate and the wall of the reaction cavity.

Catalytic Pyrolysis

Also known as chemical vapor deposition, the carbon-containing gas is decomposed to generate carbon atoms when it flows through the surface of the catalyst nanoparticles, and carbon nanotubes are formed on the surface of the catalyst. The catalytic pyrolysis method is also divided into the matrix method and the floating method according to the different ways of catalyst existence.

The matrix method uses graphite or ceramics as a carrier, attaches the catalyst to it, and passes carbon-containing gas at high temperature to decompose it and grow carbon nanotubes on the catalyst particles. The flotation method is to directly heat the catalyst precursor to make it gaseous, and at the same time, it is introduced into the reaction chamber together with gaseous hydrogen, and decomposes separately in different temperature zones, the decomposed catalyst atoms gradually aggregate into nano-sized particles, and the decomposed carbon atoms floating in the reaction space are precipitated on the catalyst particles to form carbon nanotubes.

Market pattern of carbon nanotube

Judging from the global carbon nanotube market demand, the carbon nanotube market demand continues to increase. According to data, the global demand for carbon nanotube powder and carbon nanotube slurry in 2019 is 10,000 tons and 30,000 tons respectively.

In 2020, the global demand for carbon nanotube powder and slurry is 20,000 tons and 40,000 tons respectively. In 2021, the global demand for carbon nanotube powder and slurry will be 4,000 tons and 90,000 tons respectively. It is estimated that by 2025, the demand for carbon nanotube powder in the global market will reach 24,000 tons, and the demand for carbon nanotube slurry will reach 590,000 tons.

Core technical indicators of carbon nanotube

Two core indicators: aspect ratio (length to diameter ratio) of carbon nanotube and carbon purity. The increase of the aspect ratio of carbon nanotube is conducive to improving its electrical conductivity, which can further improve the rate performance of lithium batteries, and can increase the content of positive active materials through less addition, thereby increasing the energy density.

Carbon purity: Metal impurities (especially iron) will increase the self-discharge of the power lithium battery and increase the safety hazard of the battery. Therefore, the power lithium battery requires higher purity of the carbon nanotube conductive agent.

Obstacles to the rapid development of carbon nanotube

At this stage, the price of carbon nanotube is relatively high, and downstream acceptance requires a process. In the future, with the improvement of market acceptance and the popularization of large-scale industrialization, the continuous decline in the price of carbon nanotube conductive agent is expected to accelerate the substitution process of carbon nanotube for carbon black. It is predicted that by 2025, the market share of carbon nanotube will surpass carbon black and become the mainstream of the market.