Energy density of solid-state battery reached 500 Wh/kg

NASA has made a major breakthrough in solid-state batteries

NASA says it has made a breakthrough in developing solid-state batteries for aviation. According to NASA’s website, the energy density of the solid state battery developed by NASA has reached 500 Wh/kg, which is almost twice the energy density of the current best electric vehicle battery — Tesla’s 4680 lithium battery has an energy density of 300 Wh/kg.

NASA’s solid-state battery is called a selenium sulfur battery, which uses cheap and readily available sulfur as an electrolyte, and a “porous graphene” material previously developed by NASA, which is conductive and lightweight.Because solid-state lithium batteries have no liquid electrolyte, they reduce the risk of liquid fire and explosion.

In addition, unlike lithium-ion batteries that come in a single package, NASA’s solid-state batteries stack cells on top of each other in a single case, reducing battery weight by 30% to 40%.

“SABERS has experimented with new materials for batteries that have shown remarkable progress in discharging electricity. Over the past year, the team has managed to increase the battery’s discharge rate by a factor of 10, and since then by a factor of five, bringing researchers closer to the goal of powering large vehicles.” NASA said in its press release. Electric aircraft and NASA’s advanced air mobility program will be the main beneficiaries of the new battery technology, according to the presentation.

The new solid-state battery can be reused up to 10,000 times

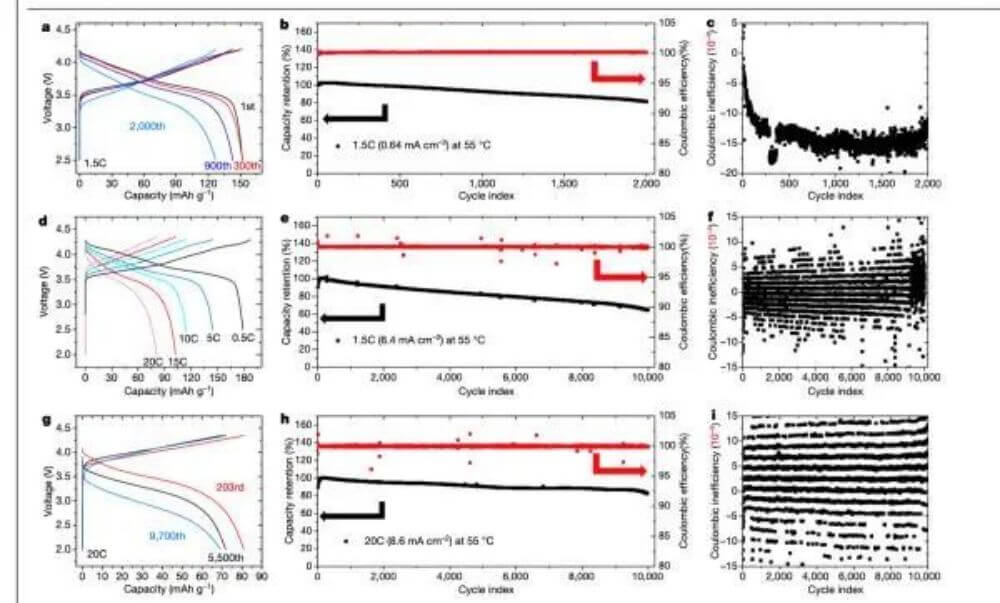

According to media reports, Li Xin, a Chinese professor at Harvard University, and Ye Luhan, a student, have developed a new solid-state battery that can be reused for 10,000 times and can be charged in three minutes at the fastest time.By comparison, the best solid-state batteries currently run for 2,000 to 10000 cycles.

A related paper published by the duo in May 2021 describes the principle of the new solid-state battery. In the paper, the researchers report that they have fabricated a multilayer lithium-metal solid state battery with interfacial stability, thus achieving stable cycling at ultra-high current densities and inhibiting dendrite penetration.

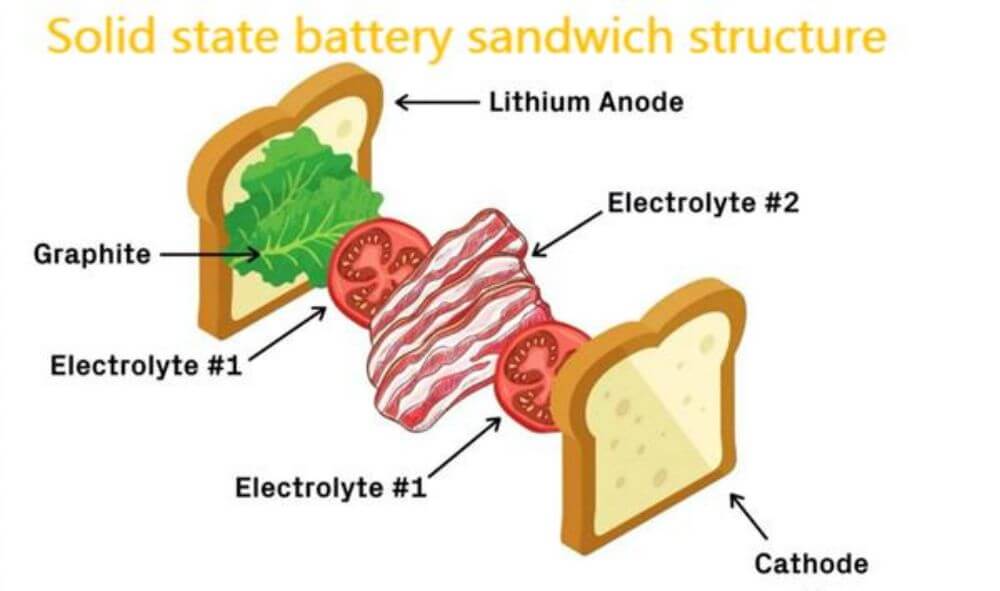

The multilayer design of the battery is characterized by sandwiched unstable electrolyte between stable solid electrolyte, forming a “sandwich” structure, and by achieving good local decomposition of cracks in the unstable electrolyte layer, the growth of any lithium dendrites is inhibited.

As shown in the figure above, from left to right, the “sandwich” battery structure is distributed as lithium metal negative electrode → graphite →LPSCI→LGPS→LPSCI→ single crystal LiNi0.8Mn0.1Co0.1O2 (nickelmanganese Cobalt 811) positive electrode.

Graphite lies between the anode of lithium metal and the first solid electrolyte layer, and is mainly used for heat insulation. As described in the paper, the first solid electrolyte sandwicketed on both sides is Li5.5PS4.5Cl1.5 (LPSCI), which is characterized by its stable performance to lithium metal, but is prone to lithium dendrite penetration. Its presence can stabilize the main interface between lithium metal and graphite layers and reduce the overall overpotential.

The second electrolyte sandwiched in the middle is Li10Ge1P2S12 (LGPS), which is less stable to lithium metal, but not easy to penetrate lithium dendrite. The intermediate electrolyte can be replaced with Li9.54Si1.74(P0.9Sb0.1)1.44S11.7Cl0.3(LSPS) to obtain similar performance.

Lithium dendrites can pass through graphite and the first electrolyte layer, but are intercepted when they reach the second electrolyte layer. Usually lithium metal solid state batteries are charged and discharged repeatedly, and micron or submicron cracks frequently occur in ceramic particles.

Once cracks are formed, lithium dendrite penetration and short circuit are unavoidable. The solid electrolyte layer in the middle of the sandwich prevents lithium dendrites from piercing the entire battery, preventing a short circuit or even a fire at the anode and cathode.

The technology not only improves safety, but also shows excellent cycling performance with lithium metal as the negative electrode and LiNi0.8Mn0.1Co0.1O2 as the positive electrode. At the discharge rate of 1.5C (0.64mAcm-2) and 20C (8.6mAcm-2), the capacity retention rate reached 81.3% and 82% after 2000 and 10000 cycles.

In addition, the battery’s micron-scale cathode material can achieve a specific power of 110.6 kW/kg and a specific energy of up to 631.1 watt-hours/kg. To further advance their research into solid-state batteries, the two researchers have founded a battery startup called Adden Energy.This year, Adden Energy is reported to have raised $5.15 million.

What is the difficulty of solid state battery industrialization

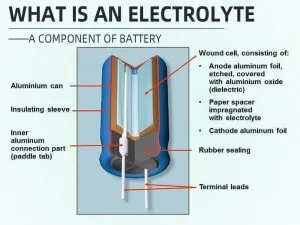

Solid-state batteries are not entirely new. In traditional liquid lithium batteries, lithium ions move from positive to negative and then to positive, and the battery completes the charging and discharging process. Solid-state batteries work in the same way, but with solid electrolytes.

Back in 2017, Fisker, an American electric vehicle company based in Anaheim, California, issued a patent for a solid-state battery that can be charged in one minute and have a range of 800k. Founder Henrik Fisker says the company’s solid-state battery could be ready for mass production by 2023 at a third of the price of conventional lithium-ion batteries. In 2021, however, Henrik Fisker announced that he had completely abandoned the solid-state battery plan.

Currently, the only company that has commercialized powered solid-state batteries worldwide is France’s Bollore Group.In October 2011, Bollore Group started to install solid state batteries manufactured by BatScap in its self-developed electric car “Bluecar” and electric bus “Bluebus”. A total of 2,900 electric vehicles were put into operation.

But the solid-state battery pack only has a 30KWh capacity and an energy density of 110 Wh/kg. In the view of the industry, the industrialization of solid state lithium battery, from the technical level, there are still no small challenges. The first is the low ionic conductivity of solid electrolytes, especially at low temperatures. Secondly, the interfacial resistance at the solid interface of electrode and electrolyte is high.

In addition, new materials such as pre-lithiated silicon carbon negatives or future metal lithium negatives, high nickel positives, and solid electrolytes for solid-state batteries, completely subvert the current liquid lithium battery system, the production cost is much higher than the current corresponding materials, the road to cost reduction is extremely arduous and long.

There are three main types of solid electrolyte materials: polymers, such as lithium hexafluorophosphate doped into PEO; Oxide, such as lithium steel zirconium oxide (LLZO), NASICON, etc. And sulfide, such as LPSX(X=Cl,Br,I). Among the three material routes, the polymer system has the advantage of high temperature ionic conductivity and easy processing. However, its ionic conductivity is very low at room temperature, which restricts its development.

For example, France’s Bolore solid-state battery uses a polymer system. In order to make the electric car work at room temperature, Bolore Group specially equipped each car with a heater, which heats the battery system to 60℃ to 80℃ before starting.

The advantage of oxide system is that the comprehensive performance is better, but the interfacial resistance between electrodes is higher than that of polymer system. Among them, thin film products have strict requirements on technology, cost and scale production is very difficult. Non-thin film products are the most reliable battery solutions for electric vehicles.

The advantage of sulphide systems is that the ionic conductivity is comparable to that of liquid electrolytes, which is the technological route chosen by Japanese and Korean firms Toyota, Honda, Samsung and Chinese one of the solid state battery companies CATL. However, sulfide systems are in the earliest stages of development, where environmental constraints and safety issues are the biggest obstacles, and the risk of not being commercialized is the highest.

Despite the difficulties, however, solid state batteries are still expected to be the key to the energy density and safety of future lithium batteries. Currently, more than 50 manufacturing companies, startups, and university research institutes worldwide are working to advance solid-state battery technology.

In Europe and the United States, BMW Group invested $130 million in Colorado-based solid-state battery startup Solid Power in 2022, aiming to launch prototype cars with solid-state batteries by 2025 and mass produce them by 2030.

Mercedes-benz reached a strategic agreement this year with Factorial Energy, a Massachusetts-based solid-state battery startup, to invest about $1 billion in solid-state battery research and development. The company will begin testing prototypes in 2022, with low-volume production within five years.

Volkswagen invested $100 million in Silicon Valle-based solid-state battery startup QuantumScape in 2018 and an additional $200 million in 2020. This year, Volkswagen announced that it would use solid-state batteries in its electric vehicles by 2025.

In Japan and South Korea, Toyota partnered with solid-state lithium-ion battery maker Ilika in 2008 and plans to launch a solid-state hybrid car by 2025. Mitsubishi, Nissan and Panasonic are also accelerating their deployment of solid-state batteries.

It is understood that at present, Toyota has 1331 solid-state battery related patents worldwide, ranking first in the world, Panasonic 272 ranked second.

In China, Nio announced a solid state battery with a lithium energy density of 150 Wh/kg at Nio Day on January 9 last year, which it plans to mass-produce in the fourth quarter of 2022.

The company’s first generation of solid-state lithium-ion batteries, which have roughly the same energy as current lithium-ion batteries, is expected to launch in 2025, with the second generation expected after 2030, the company said. In addition, Chinese lithium top 100 companies such as Fueneng Technology, SVOLT and Ganfeng Lithium have also announced plans for solid-state batteries.