Home » lithium ion battery knowledge » Inverter efficiency – making the most of power

Inverter efficiency - making the most of power

In today’s energy-conscious world, efficiency is the name of the game. One of the key players in the quest for improved energy efficiency is the inverter. There are many types of inverters such as string inverter、centralized inverter and so on.

However, the question remains: what factors contribute to inverter efficiency, and how can we ensure that we’re optimizing our power consumption to the fullest extent?

The answer to this isn’t straightforward and requires an understanding of the intricacies of inverter efficiency. So, let’s talk about the topic and get to know the complex aspects of inverter efficiency.

What is inverter efficiency?

Inverter efficiency refers to the ratio of output power to input power in an electrical inverter. An inverter is an electronic device that converts direct current (DC) power into alternating current (AC) power. Inverter efficiency is a critical parameter because it determines how much of the input power is converted into usable output power while minimizing losses in the conversion process.

In practical applications, inverters are desired to operate with high efficiency to minimize energy losses and maximize the overall system performance. Higher efficiency means that more of the input power is converted into usable output power, resulting in reduced energy waste and lower operating costs. Inverter efficiency can vary depending on factors such as the design of the inverter, its load conditions, operating temperature, and the quality of components used in its construction.

Inverter efficiency ratings are important considerations when selecting inverters for various applications, such as solar power systems, uninterruptible power supplies (UPS), motor drives, and electric vehicle (EV) powertrains.

Different inverters have different efficiencies

It is worth mentioning that although dc to ac inverter are common, the efficiency of the inverters varies.

In most cases, factors such as the power loss of the internal components of the inverter will affect the conversion efficiency of the inverter, resulting in changes in the power generation income of the photovoltaic power station.

Taking a 500W inverter as an example, under the same power, if a high-quality inverter has a 1% higher conversion efficiency than an ordinary inverter, based on working 4 hours a day, the high-quality inverter can emit nearly 20 watt-hours more energy per day. If electricity is generated, nearly 7.3 kilowatt-hours more electricity can be generated in one year, and 73 kilowatt-hours more electricity can be generated in ten years, which greatly improves users’ power generation income.

How to choose high-efficiency products among many inverters to maximize the production capacity of photovoltaic power plants? In recent years, micro-inverters have attracted much attention due to high inverter efficiency.

Taking the micro-inverter as an example, in terms of conversion efficiency, the micro-inverter system adopts a fully parallel circuit design, which can invert the DC power of each component into AC power and then integrate it into the grid, minimizing the energy loss during the inversion process. .

On the other hand, micro-inverse module-level MPPT technology will track the maximum power point of each photovoltaic module separately. This means that if a certain photovoltaic module operates poorly, it will not affect other photovoltaic modules.

For example, in the entire photovoltaic system, a module is blocked by 50% of the sunlight. At this time, the maximum power point tracks control of other modules. The machines will continue to maintain their maximum productivity and efficiency.

Factors affecting inverter efficiency

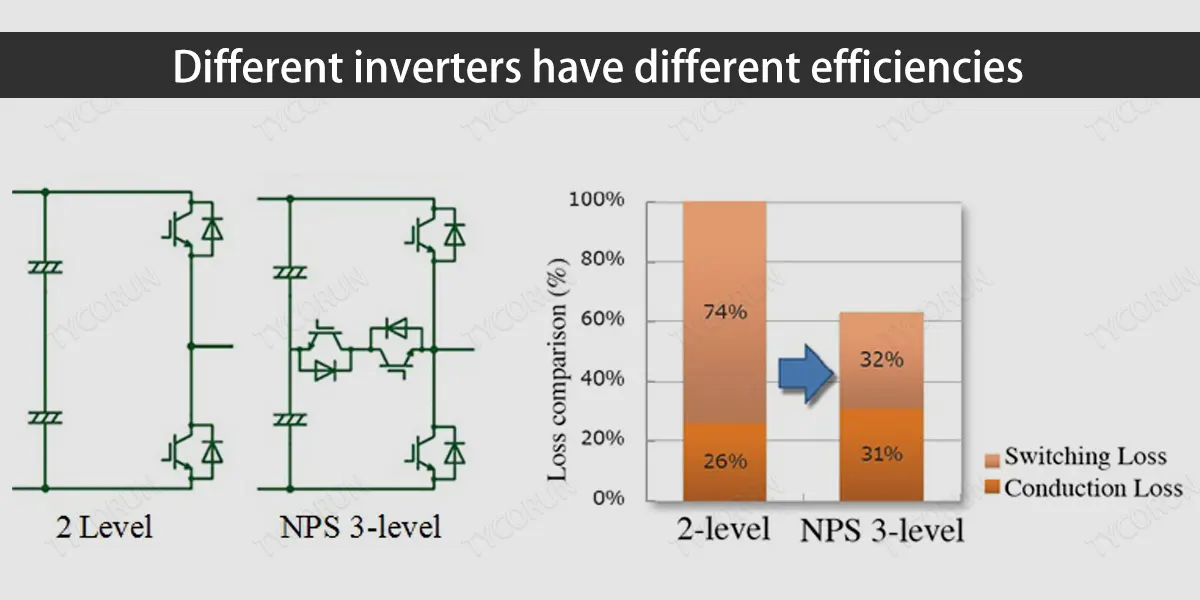

Losses have always been the most important factor affecting inverter efficiency. The main losses of the inverter come from power switching tubes such as IGBTs and MOSFETs, as well as magnetic devices such as transformers and inductors. The loss is related to the current and voltage of the components and the process of the selected materials.

The losses of IGBT mainly include conduction loss and switching loss. The conduction loss is related to the internal resistance of the device and the passing current. The switching loss is related to the switching frequency of the device and the DC voltage that the device withstands.

In addition, there are some external factors that affect the inverter efficiency:

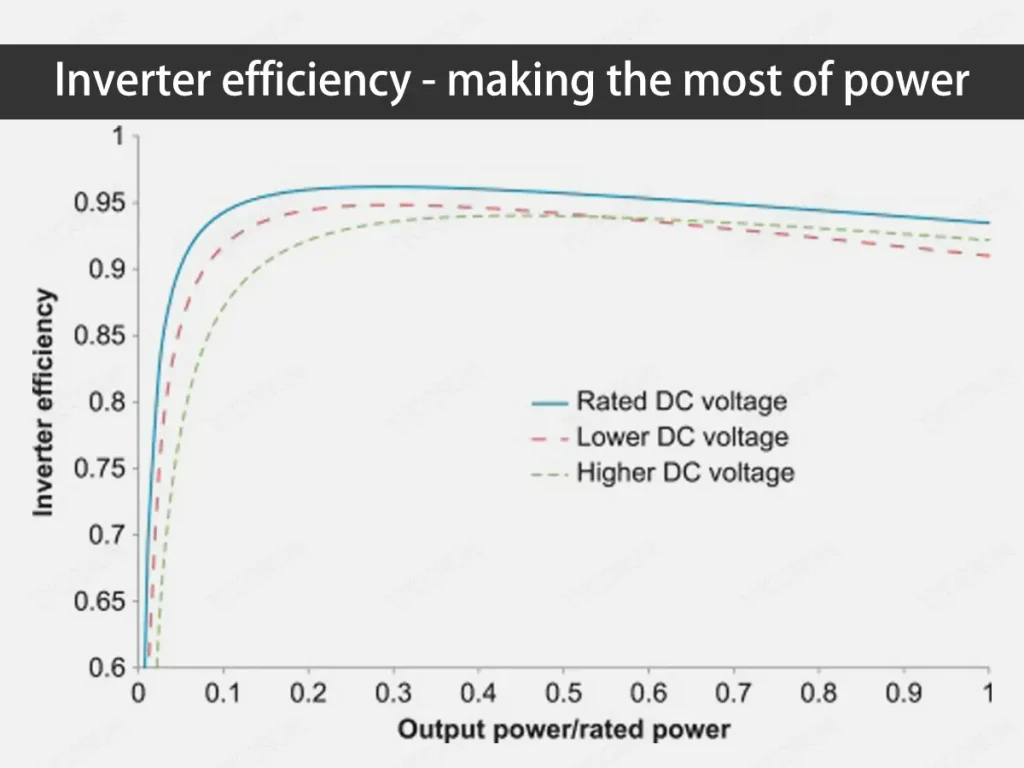

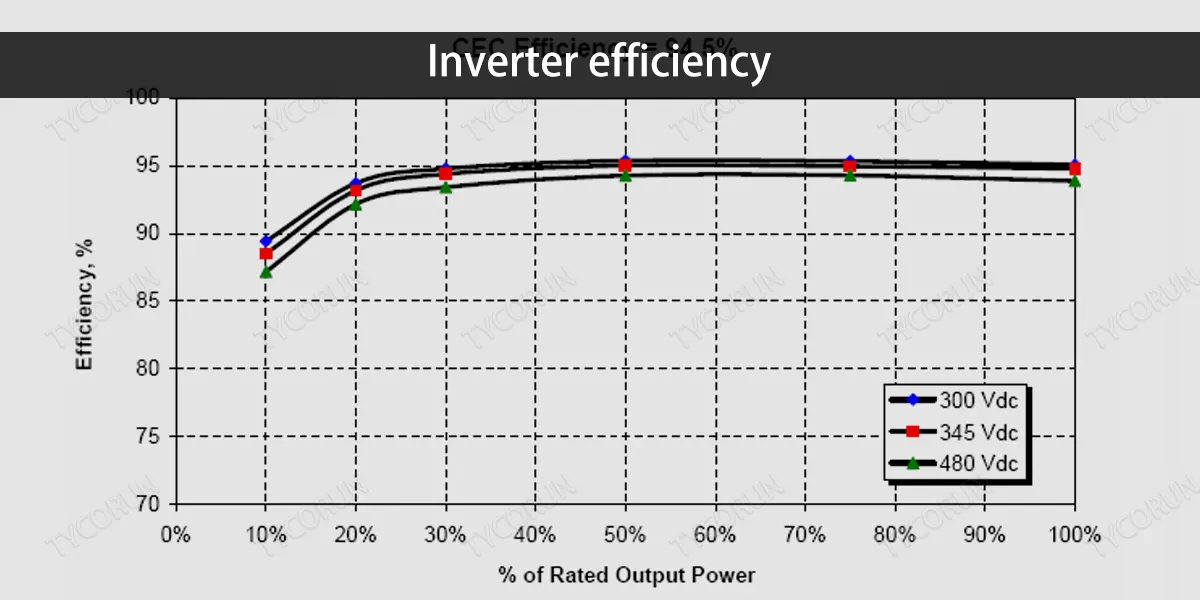

1) Voltage changes: During the power generation process, the output voltage of the solar panel may change due to illumination, temperature and other conditions, resulting in a decrease in the efficiency of the solar inverter.

2) Circuit loss: Wires and electronic components in the circuit will generate heat due to resistance, causing a certain amount of energy loss and affecting inverter efficiency.

3) Grid conditions: When the solar inverter is connected to the grid, differences in grid voltage, frequency and waveform will affect the inverter efficiency.

4) Equipment matching: The power, voltage and other parameters of the solar panel and inverter must match, otherwise the inverter efficiency will be affected.

How to improve inverter efficiency?

There are currently three technical routes to improve inverter efficiency in most inverter manufacturers:

One is to use control methods such as space vector pulse width modulation to reduce losses; the other is to use silicon carbide material components to reduce the internal resistance of power devices; the third is to use three-level, five-level and other multi-level flat electrical topology and soft switching technology reduce the voltage across the power device and reduce the switching frequency of the power device.

Voltage Space Vector Pulse Width Modulation (SVPWM)

This is a fully digital control method that has the advantages of high DC voltage utilization and easy control, and is widely used in inverters. The DC voltage utilization rate is high, and a lower DC bus voltage can be used under the same output voltage, thereby reducing the voltage stress of the power switching device, the switching loss on the device is smaller, and the conversion efficiency of the inverter is improved to a certain extent.

Components using silicon carbide materials

The resistance per unit area of silicon carbide devices is only one percent of that of silicon devices. The on-state resistance of power devices such as IGBT (Insulated Gate Bipolar Transistor) made of silicon carbide material is reduced to one-tenth of that of ordinary silicon devices.

Silicon carbide technology can effectively reduce the reverse recovery current of the diode, thereby reducing the switching losses on the power device, and the current capacity required by the main switch can also be reduced accordingly. Therefore, using silicon carbide diodes as anti-parallel diodes of the main switch is a way to improve the efficiency of the inverter.

Soft switching and multi-level technology

Soft switching technology uses the principle of resonance to make the current or voltage in the switching device change sinusoidally or quasi-sinusoidally. When the current naturally crosses zero, the device is turned off; when the voltage naturally crosses zero, the device is turned on. This reduces switching losses and greatly solves problems such as inductive turn-off and capacitive turn-on.

When the voltage across the switch tube or the current flowing through the switch tube is zero, it is turned on or off, so that there is no switching loss in the switch tube. Under the same output harmonic content, the three-level inverter can use a lower switching frequency than the two-level structure, the device switching loss is smaller, and the conversion efficiency of the inverter is improved.