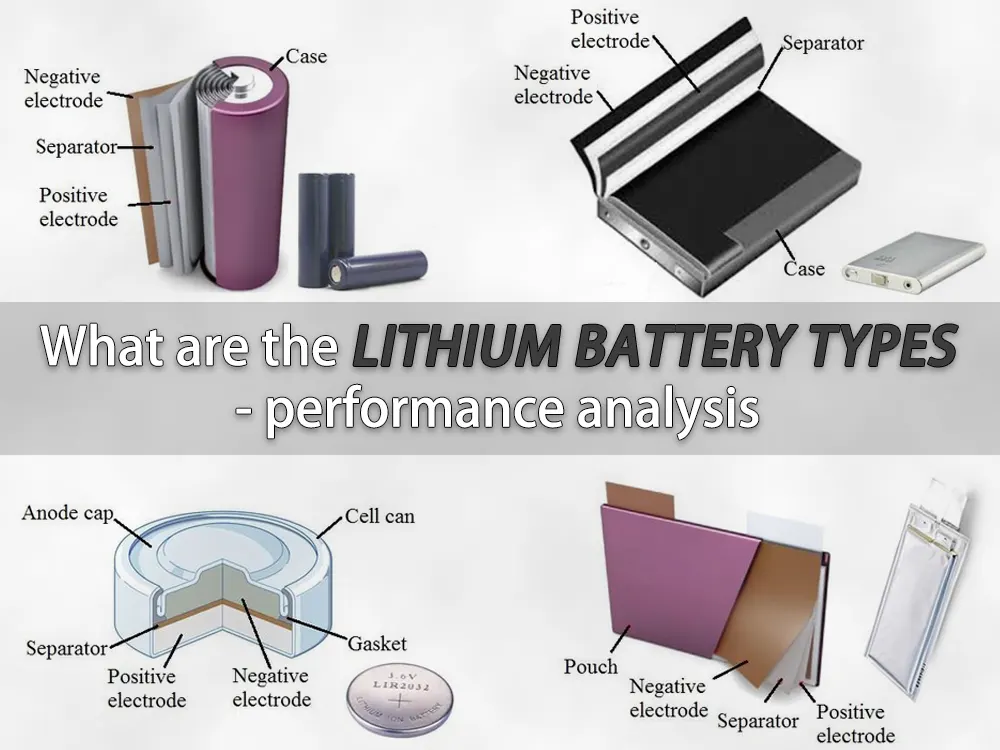

What are the lithium battery types - performance analysis

The ternary lithium battery or iron-lithium battery that is often mentioned is named after the cathode active material. This article summarizes six common lithium battery types and their key properties. There are six lithium battery types, including lithium cobalt oxide battery, lithium manganese battery, NMC battery, NCA battery, LiFePO4 battery and LTO battery.

Lithium cobalt oxide battery

Its high specific energy makes lithium cobalt oxide a popular choice for cell phones, laptops and digital cameras. Among the lithium battery types, the battery consists of a cobalt oxide cathode and a graphitic carbon anode. The cathode has a layered structure, and lithium ions move from the anode to the cathode during discharge and in the opposite direction during charge.

The disadvantages of lithium cobalt oxide are relatively short lifetime, low thermal stability and limited load capacity. Like other cobalt-hybrid lithium-ion batteries, lithium cobalt oxide uses a graphite anode. Its cycle life is mainly limited by the solid electrolyte interface (SEI), which is mainly manifested in the gradual thickening of the SEI film, and the problem of anode lithium plating during fast charging or low-temperature charging.

Lithium cobalt oxide should not be charged and discharged with a current higher than the capacity. This means that an 18650 battery with 2,400mAh can only be charged and discharged at ≤2,400mA. Forcing a fast charge or applying a load higher than 2400mA can cause overheating and excessive stress.

Due to the high cost of cobalt and the obvious performance improvement brought about by mixing materials with other active cathode materials, lithium cobalt oxide is gradually being replaced by lithium manganese oxide in lithium battery types, especially in NMC and NCA batteries. In the lithium battery types, lithium cobalt oxide is excellent in terms of high specific energy, but can only provide mediocre performance in terms of power characteristics, safety and cycle life.

Lithium manganate battery

As one of the lithium battery types, the spinel lithium manganate battery was first published in a 1983 material research report. In 1996, Moli Energy Company commercialized lithium-ion batteries with lithium manganese oxide as the cathode material.

The architecture forms a three-dimensional spinel structure that improves ion flow on the electrodes, resulting in lower internal resistance and improved current-carrying capability. Another advantage of spinel is high thermal stability and improved safety, but limited cycle and calendar life.

Low battery internal resistance enables fast charging and high current discharging. 18650 cells, lithium manganate battery can be discharged at a current of 20-30A, and have moderate heat accumulation. Lithium manganate battery is used in power tools, medical equipment, and hybrid and pure electric vehicles.

Most lithium manganese oxides are mixed with lithium nickel manganese cobalt oxide (NMC) to increase specific energy and extend life. This combination brings out the best performance of each system, and in most EVs, LMO (NMC) is chosen. The LMO part of the battery can reach about 30%, which can provide a higher current during acceleration; the NMC part provides a long cruising range.

Li-ion battery research tends to combine lithium manganate with cobalt, nickel, manganese and/or aluminum as the active cathode material. In some architectures, a small amount of silicon is added to the anode, which provides a 25% capacity boost. However, silicon expands and contracts with charge and discharge, causing mechanical stress, and capacity enhancement is usually closely linked to short cycle life.

These three active metals along with silicon enhancements can be conveniently selected to improve the specific energy, specific power or lifetime.

NMC battery

In lithium battery types, one of the most successful Li-ion systems is the cathode combination of nickel manganese cobalt (NMC). Similar to lithium manganate, this system can be tailored for use as an energy or power battery. For example, an NMC in an 18650 battery under moderate load conditions has a capacity of about 2,800mAh and can provide a 4A to 5A discharge current.

The same type of NMC when optimized for a specific power has a capacity of only 2,000mAh but can deliver a continuous discharge current of 20A. Silicon-based anodes will reach more than 4000mAh, but the load capacity will be reduced and the cycle life will be shortened. The silicon added to the graphite has the defect that the anode expands and contracts as it is charged and discharged, making the battery mechanically stressed and structurally unstable.

The secret of NMC lies in the combination of nickel and manganese. Nickel is known for its high specific energy but poor stability, and the manganese spinel structure can achieve low internal resistance but low specific energy. The two active metals have complementary advantages.

Among the six lithium battery types, NMC has good overall properties and excels in terms of specific energy. This battery is the battery of choice for power tools, e-bikes, and other electric powertrains, with the lowest self-heating rate.

Due to the relatively good economic performance and comprehensive performance of the system, NMC hybrid lithium-ion batteries have received more and more attention. The three active materials, nickel, manganese and cobalt, can be easily blended to accommodate a wide range of applications in automotive and energy storage systems (EES) that require frequent cycling.

LiFePO4 battery

In 1996, the University of Texas discovered that phosphate could be used as a cathode material for rechargeable lithium batteries. Lithium phosphate has good electrochemical performance and low resistance. This is achieved through nanoscale phosphate cathode materials.

The main advantages of LiFePO4 battery are high rated current and long cycle life; good thermal stability for enhanced safety and tolerance to abuse. Lithium phosphate is more resistant to full charge conditions and is less stressed than other lithium battery types systems if kept at high voltage for extended periods of time. On the downside, the lower 3.2V battery nominal voltage makes the specific energy lower than cobalt-doped Li-ion batteries.

For most lithium battery types, low temperatures will reduce performance, and elevated storage temperatures will shorten service life, and lithium phosphate is no exception. Lithium phosphate has a higher self-discharge than other Li-ion batteries, which can cause aging and equalization problems. Although it can be compensated by choosing a high-quality battery or using an advanced battery management system, both of these methods increase the cost of the battery pack.

People would like to use lithium battery replacement lead acid. Four batteries in series produce 12.8V, similar to six 2V lead-acid batteries in series. In addition, lithium phosphate has good safety and long life, moderate specific energy, and enhanced self-discharge ability.

NCA battery

Nickel cobalt lithium aluminate battery or NCA battery has been used since 1999. It has high specific energy, fairly good specific power and long service life which are similar to NMC. Less flattering are safety and cost. NCA, one of the lithium battery types, is a further development of lithium nickel oxide, adding aluminum to give the battery better chemical stability.

High energy and power density and good service life make NCA a candidate for EV powertrain. High cost and marginal safety have negative effects.

LTO battery

Batteries with lithium titanate anodes have been known since the 1980s. Lithium titanate replaces graphite in a typical lithium-ion battery anode, and the material forms a spinel structure. The cathode can be lithium manganate or NMC.

Lithium titanate has a nominal battery voltage of 2.40V, can be charged quickly, and provides a high discharge current of 10C. The cycle times are said to be higher than those of conventional Li-ion batteries. Lithium titanate is safe and has excellent low-temperature discharge characteristics, achieving 80% capacity at -30°C.

LTO battery has zero strain, no SEI film formation and no lithium plating phenomenon during fast charging and low temperature charging, so it has better charge and discharge performance than traditional cobalt-doped Li-ion and graphite anodes. The thermal stability at high temperature is also better than other lithium battery types.

However, LTO batteries are expensive. Low specific energy, only 65Wh/kg, comparable to NiCd. Lithium titanate is charged to 2.80V and 1.80V at the end of discharge. Typical uses are electric powertrains, UPS and solar street lights. Lithium titanate is excellent in safety, low-temperature performance and lifespan, and efforts are being made to increase specific energy and reduce costs.

Conclusion

While NCA is the clear winner by storing more capacity than other systems, it’s only good for scenario-specific power usage. Among six lithium battery types, lithium manganate and lithium phosphate are excellent in terms of specific power and thermal stability. Lithium titanate may have a lower capacity, but it outlasts most other batteries and has the best low-temperature performance.