How thick electrode improve lithium-ion battery energy density

Thick electrode architecture design, without changing the battery chemical system, increasing the active material content per unit volume of the battery, thereby thick electrode increasing the energy density of the battery system. Compared with the previous two approaches, thick electrode architecture design has the advantage of being compatible with various electrode materials. Therefore, increasing the energy density of batteries through thick electrode architecture design has received extensive attention.

Advantages and challenges of traditional thick electrode

Building thick electrode can reduce the content of inactive materials at the battery device level, increase the energy density of the battery, and reduce the cost of the battery. However, the slow ion and electron transport and poor mechanical stability of traditional thick electrode lead to poor rate performance and cycle performance.

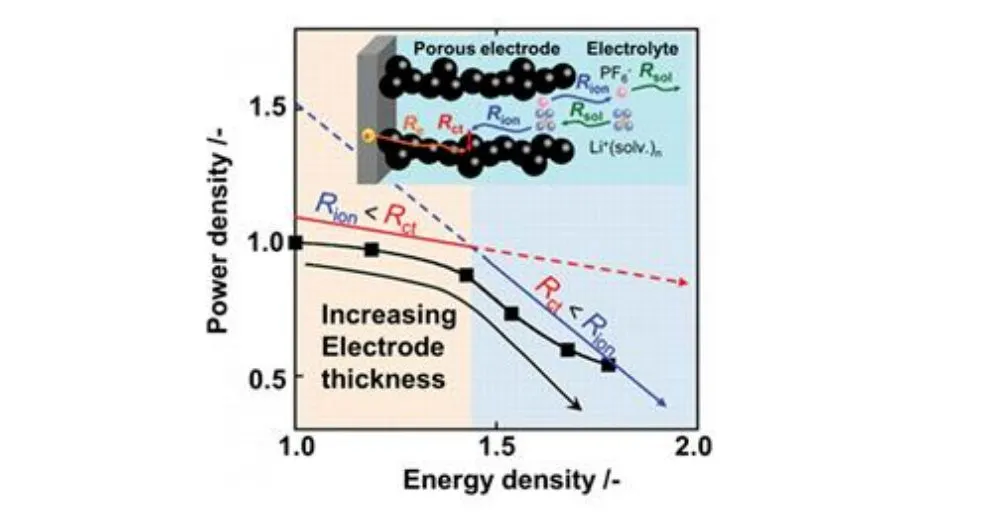

There are four main steps in charge transport in porous electrodes:

(1) Li-ion transport in the electrolyte; (2) Charge transport at the interface; (3) Li-ion diffusion in the bulk phase of the electrode; (4) Charge transport at the interface between the current collector and the electrode. Therefore, the impedance in thick electrode can be divided into corresponding four parts: electronic impedance, charge transport impedance, bulk phase impedance of electrolyte, and lithium ion transport impedance in porous electrodes.

In thin-electrode batteries, the charge transfer impedance is the rate-controlling step of the kinetic reaction of lithium-ion batteries, while with the increase of electrode thickness, the lithium-ion transport impedance in porous electrodes gradually becomes the rate-controlling step of the kinetic behavior in lithium-ion batteries.

Charge transport in porous electrodes compared with electrodes of different thick electrode

Therefore, in order to simultaneously increase the energy density and power density of lithium-ion batteries, it is necessary to construct high-power thick electrode with efficient lithium-ion transport channels and good electronic conduction networks.

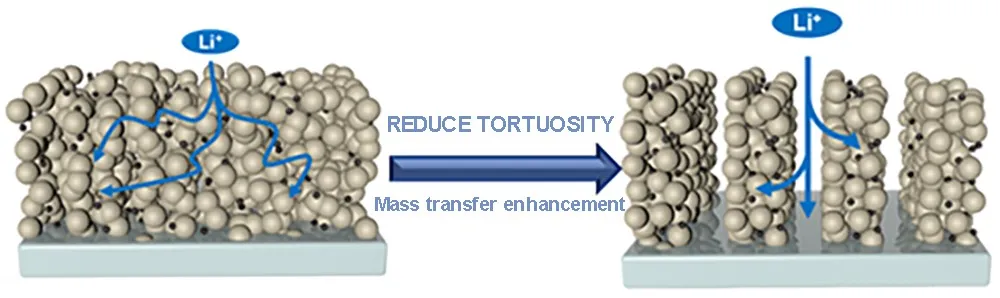

At present, the main strategy for constructing high-power thick electrode is to construct low-tortuosity thick electrode with straight-through channels to promote lithium ion transport in thick electrode, reduce concentration polarization, and improve battery performance. In addition, Professor Xie Jia from Huazhong University of Science and Technology also proved that low tortuosity electrodes can effectively alleviate the degradation of active material materials.

Design ideas for thick electrode

Methods for constructing thick electrode

At present, the methods of constructing thick electrodes mainly focus on:

(1)Construct a 3D current collector, using 1D carbon fiber/carbon nanotubes with high specific surface area, 2D graphene, and 3D porous conductive framework as the thick electrode substrate. The thick electrode constructed by the 3D current collector method has a good electronic conduction network;

(2) Template method, common methods include sacrificial template method (alumina template), natural cellulose (wood), ice template method, etc. The thick electrode prepared based on the template method has a certain pattern and a straight-through ion transport channel;

(3) Advanced manufacturing technology, mainly including laser etching and 3D printing, the prepared pole piece has a regular pattern and a lithium ion transmission channel perpendicular to the direction of the current collector;

(4) Low-temperature sintering. After low-temperature sintering treatment, densified pole pieces can be obtained, which reduces the porosity and thickness of the electrodes, which is conducive to improving the volumetric energy density of thick electrodes;

(5)Other methods, such as introducing foaming agent and phase inversion method during electrode preparation.

Research status of thick electrode

In order to realize the batch preparation of high-power thick electrodes, academia and industry focus on the design and preparation of gradient electrodes. In academia, the double-gradient electrode (porosity and material particle size) designed by the team of Academician Yu Shuhong of the University of Science and Technology of China can achieve a volumetric energy density of 701 Wh▪L for graphite electrodes at a 6C rate.

The team of Professor Yu Guihua from the University of Texas also designed a low tortuosity gradient thick electrode capable of stable cycling by combining the phase inversion method and the magnetic template method. In the industry, most enterprises adopt multi-layer coating method to carry out large-scale production of high-power thick electrodes.

Gradient electrode design

The study of thick electrodes involves complex engineering and scientific issues. First of all, it should have good mechanical properties to adapt to the electrode lamination, winding and other processes. Secondly, efficient ion and electron transport networks should be constructed to accelerate the reaction kinetics of thick electrodes, reduce ohmic polarization and concentration polarization, and improve rate performance and cycle stability.

Combining experimental methods and theoretical simulations to establish the structure-activity relationship between the architecture design and electrochemical performance of thick electrode is an important idea to promote the practical application of thick electrode. In order to further improve the cycle performance of thick-electrode batteries, the pre-lithiation technology can be combined with the structural design of thick electrodes to obtain lithium-ion batteries with long cycle life and high energy density.

The template method, laser etching method and 3D printing technology can all realize the characteristic structure with low tortuosity, shorten the lithium ion transmission distance and improve the rate performance. The electron transport network plays an important role in improving the electrochemical performance of lithium-ion batteries.

The self-supporting structure introduces one-dimensional and two-dimensional carbon materials into the thick electrode to effectively improve the electronic conductivity of the thick electrode. However, the preparation process of one-dimensional and two-dimensional carbon materials is very complicated, and it is difficult to carry out large-scale output in the laboratory. Natural raw materials such as wood are rich in resources and can reduce manufacturing costs, so they have great development potential.

Thick electrodes involve multidisciplinary problems, requiring the participation of scholars with various professional backgrounds such as materials, electrochemistry, chemistry, and engineering, and the cooperation, communication, and joint efforts of the scientific and industrial communities. In addition, the design principle of thick electrodes is to construct a good charge transport network, and this research idea can also be extended to all solid state battery, lithium-air battery systems, and sodium-ion battery systems.