What is battery meter and its classification

It can measure and report many key aspects about the battery pack, such as voltage, temperature, charge/discharge current, and remaining capacity prediction. These chips can be discrete or integrated with the battery protection IC . This post will explain in detail what a battery meter is, how it works, etc. About the production of the battery pack, you can refer to the video of odm lithium ion battery pack manufacturer.

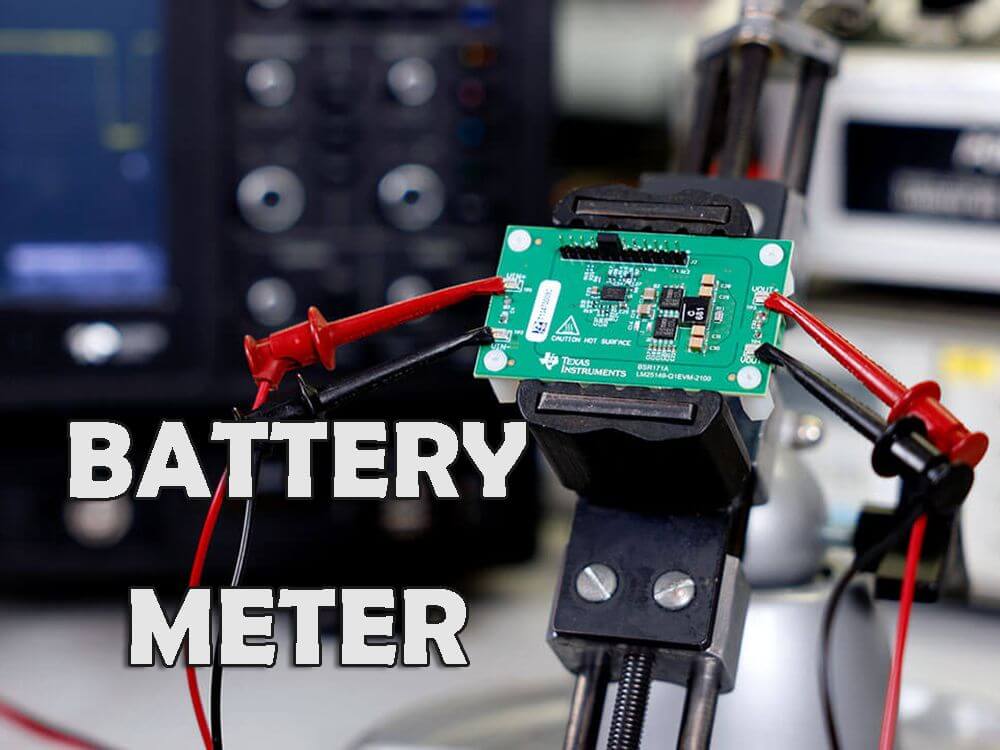

What is battery meter

The battery meter chip, as the core of the intelligent battery system, is supported by battery material information data, user battery big data and battery encryption system to carry out algorithm evolution and underlying data analysis to achieve all-round battery safety, prolong battery life, and improve user experience. The use experience is called the “brain” of the battery in the industry.

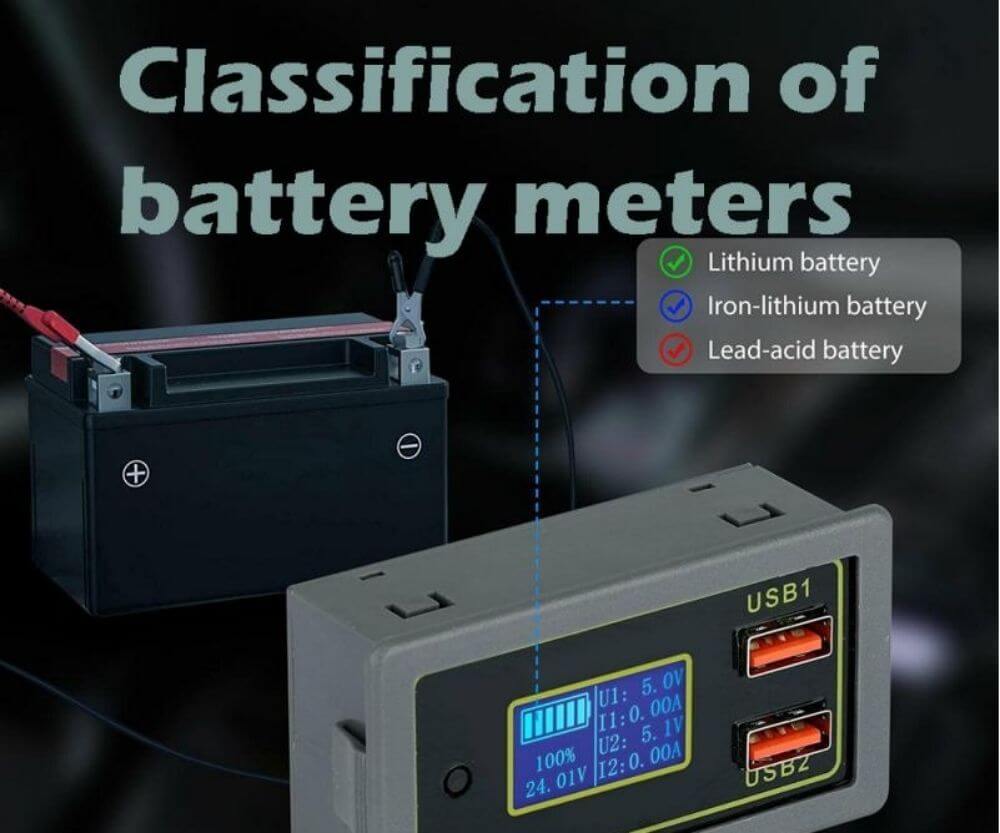

Classification of battery meters

For different application scenarios, battery meter makes a basic classification:

Number of batteries

One string of batteries has a wide range of applications, such as mobile phones, smart watches, POS, tablet computers, etc., and the difference in accuracy and circuit area is relatively large. Therefore, there are many fuel gauge solutions for one string of batteries. Many 1-series batteries are relatively small, so there are usually certain requirements for package size. Because there is only one string, there is no unbalanced battery, and no equalization function is required.

For batteries with more than 2 strings, it is usually necessary to consider the balancing function. 2~4 series battery meter are widely used in notebook computers and other fields, so the integrated protection function is generally adopted to reduce the overall cost.

For batteries with more than 4 strings, due to the large difference in battery voltage, it is difficult to develop dedicated chips for different applications. You can use the method of monitoring the total voltage of the battery after dividing the voltage, or use the method of cooperating with the analog front-end chip.

Type of battery

Many models of battery meter are mainly aimed at the application of lithium battery, especially the impedance tracking algorithm, but the CEDV algorithm is based on coulomb counting and can also be used for nickel-metal hydride batteries and lead-acid batteries. The discharge platform of the LiFePO4 battery is flat, and a small error in the voltage detection may cause a large error in the power calculation. Therefore, the accuracy of the impedance tracking algorithm will be affected to a certain extent, and some battery meter have been optimized for the application of LiFePO4 batteries.

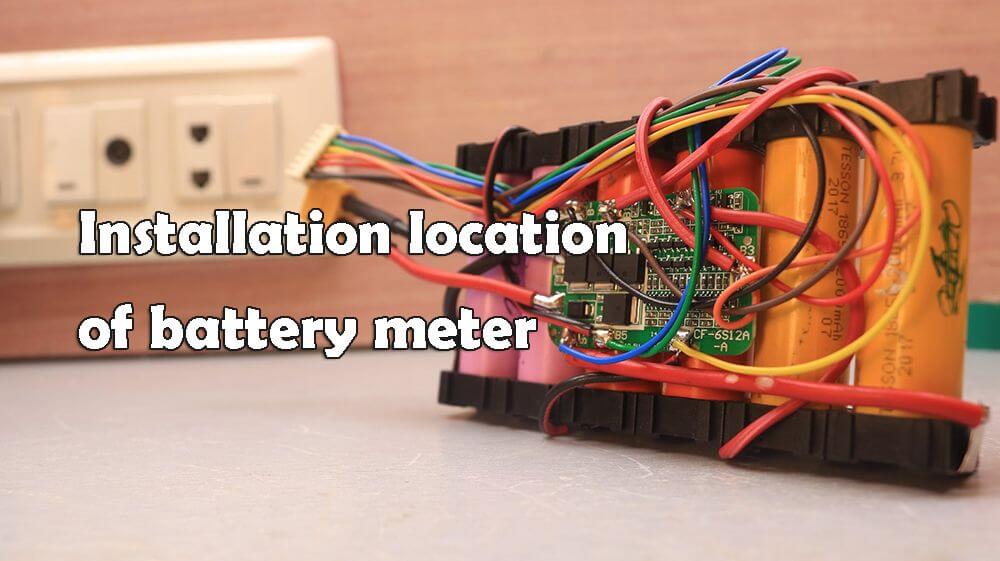

Installation location of battery meter

Usually, the battery meter can be placed in the battery pack to achieve higher accuracy, and can realize data encryption and battery identity identification, avoiding potential dangers caused by counterfeit and shoddy batteries.

The battery meter of 1 series battery can also be placed on the system motherboard, but due to the introduction of MOS, the influence of wiring impedance, and the inconvenience of calibration, the power accuracy will be affected, especially after the battery is replaced, the battery meter on the system side will be affected. The parameter settings of the battery may not match the actual battery cells, resulting in large errors;

On the other hand, system board manufacturers usually do not have battery meter calibration, battery test experience and equipment, which brings potential risks. 2~4 strings of batteries, if the battery meter is placed on the system side, because it is inconvenient to lead, it is usually not convenient to monitor the voltage of each cell, and the equalization function of the battery meter may not work, and it must be There is an extra protection circuit in the bag, so it is usually recommended to put 2~4 series of battery meter in the battery pack.

For battery meters with more than 4 strings, it is usually impossible to monitor the voltage of each cell independently. It needs to cooperate with the analog front-end chip or only monitor the average voltage of the battery. The equalization and protection functions are completed by the analog front-end chip or the protection chip. The location of the battery meter depends on the architecture of the system.

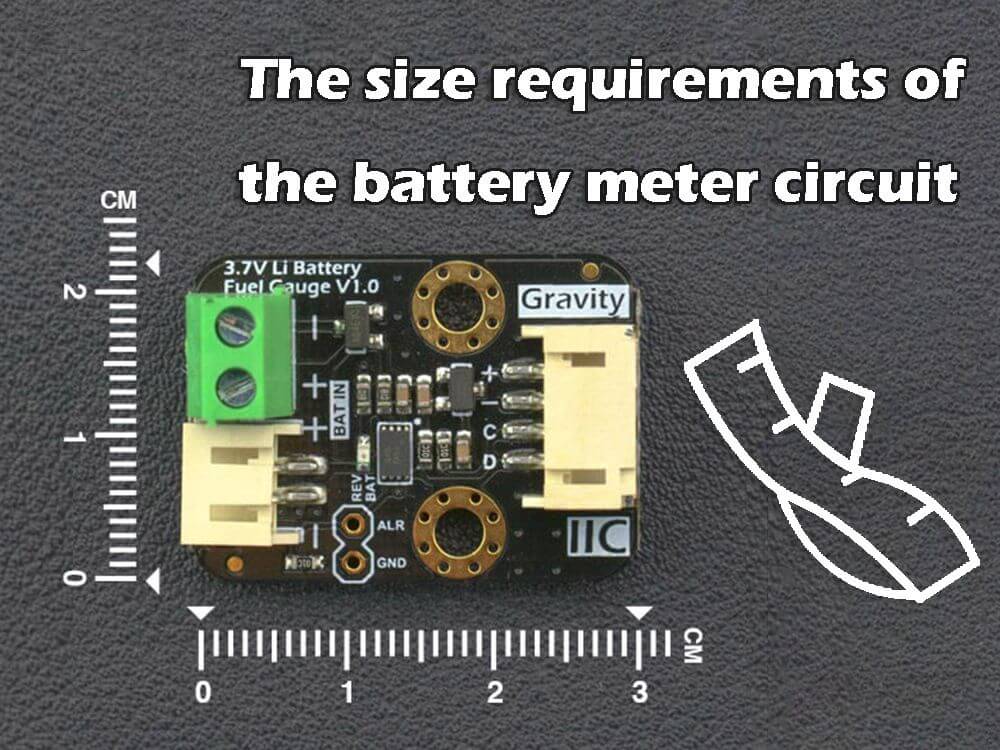

The size requirements of the battery meter circuit

For applications such as smart watches, batteries with small capacity, due to the small size of the battery, have higher requirements on the area of the battery meter circuit, and a battery meter with a small package (such as BGA) can be used;

Further, the purpose of reducing the circuit area can be achieved by reducing external circuit elements by means of a fuel gauge chip integrating a protection function and an integrated current detection resistor.

Communication interface of battery meter

In the application of battery meter, usually the system needs to read information such as battery power, voltage, temperature, etc., so the battery meter needs to communicate with the system;

For battery meters with 2 strings or more, the most commonly used communication interface is SMBus (usually compatible with MCU communication with I2C interface);

For battery meters with 1-2 strings of batteries, I2C and single-wire communication interface HDQ are often used.

Cost requirements for battery meter

Usually the accuracy requirements are high, and the cost of the fuel gauge will be slightly higher; For some applications that require less precision, a low-cost model can be selected.

How does a battery meter work

In order to calculate basic battery pack information, the metering system needs to measure charge and discharge progress, battery pack voltage and temperature.

Take a pure coulomb-counting metering system as an example. In such a system that mainly relies on the integration of charge and discharge to determine the state of charge, the resolution and accuracy of the analog-to-digital converter are critical. With this type of metering chip, the converter must integrate all charging and discharging activities, including those that occur when the system is in sleep, standby, or off.

If the system shuts down and discharges very frequently, and the metering chip does not accurately integrate the range of low discharge levels, significant flow errors can occur over time. Therefore, devices with high robustness and high resolution ensure reliability and accuracy throughout the process.

Final thoughts

We know that European and American companies have always had the upper hand in BMS chips, and the same is true in the battery metering chip market. In the field of power batteries, Chinese manufacturers of chips are still in the preliminary layout stage, but localized substitution in the field of consumer electronics is developing very quickly. Relevant Chinese manufacturers are top 10 battery management system suppliers.