Will hard carbon anode material be a rookie for energy storage

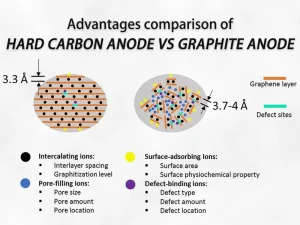

Hard carbon is carbon that will not be graphitized after high temperature treatment, and its internal crystal arrangement is disordered and the interlayer spacing is large. This allows the hard carbon anode to store more charge in the same volume, improving the energy density and endurance of sodium-ion batteries.

The expansion and contraction of the hard carbon anode are more uniform during the discharge process, which increases its cycle stability, charge and discharge performance, and prolongs the cycle life of the sodium-ion battery.

With the rapid expansion of renewable energy such as solar energy and wind energy, the research on new materials for energy storage batteries is also deepening. China is rich in sodium resources, and sodium-ion batteries are considered to be the most suitable new batteries for large-scale energy storage solutions, and are expected to alleviate the limited development of energy storage caused by the shortage and uneven distribution of lithium resources.

What are the advantages of hard carbon materials compared with other anode materials for sodium-ion batteries? What is the development status of China’s hard carbon material industry? How far is it from large-scale application? With these questions in mind, read this article.

Why hard carbon is the first choice for sodium-ion battery anode materials

Sodium-ion batteries are mainly composed of cathode, anode, electrolytes, separators, etc., and their working principles are similar to lithium-ion batteries. The anode material of sodium ion battery is the main body of sodium storage in the battery, and it realizes the intercalation or extraction of sodium ions during the charging and discharging process.

Therefore, the capacity of the battery is positively correlated with the ability of the anode to store sodium ions, and the selection of anode materials plays a decisive role in the development of sodium ion batteries.

From the perspective of the classification of anode materials for sodium-ion batteries, they can be roughly divided into five categories.

● One is carbon-based anode materials, mainly including graphite, amorphous carbon, nano-carbon, etc. Among them, amorphous carbon is most likely to be the first to achieve industrialization;

● The second is the alloy-type anode material, which has a high theoretical capacity, but the volume expansion is serious after the electron intercalation of sodium, and the cycle performance is poor;

● The third is metal oxide and sulfide-based anode materials, which have high theoretical capacity but poor conductivity;

● Fourth, the embedded titanium-based anode material has small volume change but low capacity;

● Fifth, organic anode materials are low in cost, but have poor conductivity and are easily soluble in electrolyte.

Carbon-based anode materials have excellent electrical conductivity, flexible preparation methods, low cost, and environmental friendliness, making them the first choice for anode materials for sodium-ion batteries. Among them, hard carbon and soft carbon materials in amorphous carbon are considered to be potential anode materials for sodium-ion batteries.

Hard carbon has a larger pore structure that can accommodate more sodium ions. Therefore, the expansion and contraction of the electrode are more uniform during the discharge process, which increases the cycle stability and charge-discharge performance of the hard carbon anode, and prolongs the cycle life of the sodium-ion battery.

By comparing the properties of different types of carbon anode materials, it can be found that hard carbon is the preferred solution for anode materials in the commercial application of sodium-ion batteries, and is expected to be the first to achieve industrialization.

Biomass has become the mainstream for the preparation of hard carbon materials

The raw materials of hard carbon precursors are rich in sources, and the selection of precursors and the accumulation of process technology are the key factors in the development of hard carbon anode materials. Common precursors for the preparation of hard carbon materials include biomass, synthetic polymers, and fossil fuels.

The hard carbon materials prepared by different precursors have significant performance differences. Due to the different sources of precursor raw materials, the cost structure of hard carbon materials is also significantly different.

Among them, biomass raw materials come from a wide range of sources, such as coconut shells, fruit shells, grapefruit peels, animal and plant tissues, etc., and the cost is relatively low, making it the first choice for the preparation of hard carbon materials. At present, the preparation process of hard carbon is parallel in multiple ways, and hard carbon anode materials have been developed continuously.

Hard carbon anode material industry market size will continue to grow

Sodium-ion batteries have become a hotspot in current global research and industrialization. Relevant departments in China have proposed to develop high energy density energy storage technologies such as sodium-ion batteries, liquid metal battery, lithium-ion solid state battery, metal-air battery, and lithium-sulfur battery.

Professionals said that at present, researchers have proposed a variety of models for the sodium storage mechanism of hard carbon, but a unified understanding of the sodium storage mechanism has not yet been reached. Therefore, further research is needed to reveal the structure-activity relationship between hard carbon materials and the electrochemical reaction mechanism, and provide theoretical guidance and scientific basis for improving the performance of hard carbon.

In addition, the influence of physical parameters of hard carbon materials such as particle size, tap density, and mass loading on electrochemical performance needs to be further explored to synergistically improve the performance of materials when they are applied to sodium-ion battery systems. With China’s support for the development of new energy vehicles and energy storage equipment, the market size of China’s hard carbon anode material industry will further grow.

According to market forecasts, in 2025, the market size of China’s hard carbon anode material industry will reach 8.65 billion RMB, and the average annual growth rate of the hard carbon anode material industry will reach 15.3% in the next five years.

At present, due to the short development time of China’s hard carbon anode material industry, most companies and research institutions are still in the stage of technology research and development and optimization. However, major Chinese top 10 anode material manufacturers are actively planning the production of hard carbon anode materials.

Professionals believe that sodium-ion batteries perform better than lithium-ion batteries in terms of performance indicators such as low temperature, safety, and fast charging. Although there is still room for improvement in its energy density, cycle life, etc., considering the rich sources of materials for sodium-ion batteries, it still has great development potential.

With breakthroughs in key technologies of sodium-ion batteries such as hard carbon anode materials and rapid growth in energy storage demand, the application scenarios and scale of sodium-ion batteries will also develop rapidly.