Home » lithium ion battery knowledge » BYD blade battery – overall introduction and advantages

BYD blade battery - overall introduction and advantages

BYD’s self-developed blade battery has recently been frequently cited in European media reports. The local mainstream media DW and the well-known German auto media Auto Motor und Sport have made positive reports on the product evaluation of BYD Atto 3.

One of the biggest features of BYD blade battery is “super safety”. BYD had gone through long attempts and efforts to develop this battery. Today we will analyze the characteristics of BYD blade battery technology from the perspective of battery manufacturing process and its six major advantages.

What is BYD blade battery

BYD blade battery is a long battery solution (battery based on a square aluminum shell), based on the size of BYD’s original battery (BYD used more of 173 and 148 before), by reducing the thickness of the battery cell and increasing the length of the battery cell, the battery cell is designed to be elongated and thinned.

Compared with the traditional technical battery system, the number of components of the battery system using blade batteries is reduced by more than 40%, and although the specific energy density is only increased by 9%, the VCTP volumetric energy density can be increased by more than 50%, and the cost can be reduced by more than 30%.

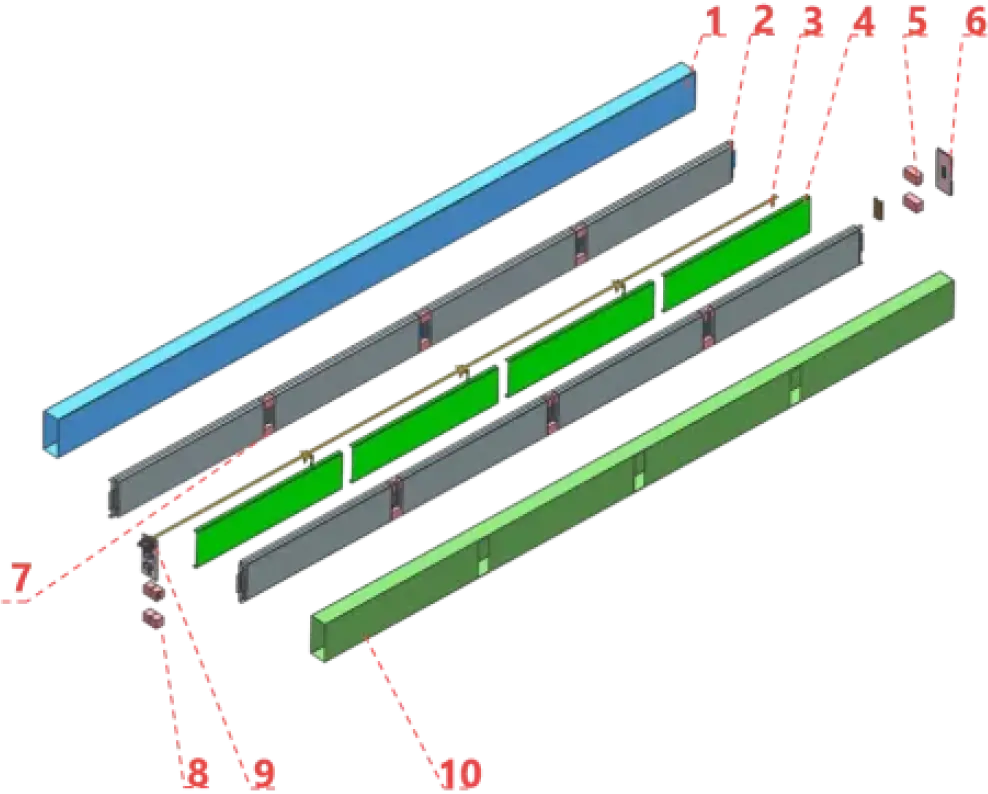

The internal structure of the multi-string blade battery is mainly composed of 1-cell aluminum shell, 2-pole core, 3-sampling harness, 4-protective film (inner), 5/7/8-insulation, 6-bottom cover, 9-composed of top cover and 10-protective film (outer).

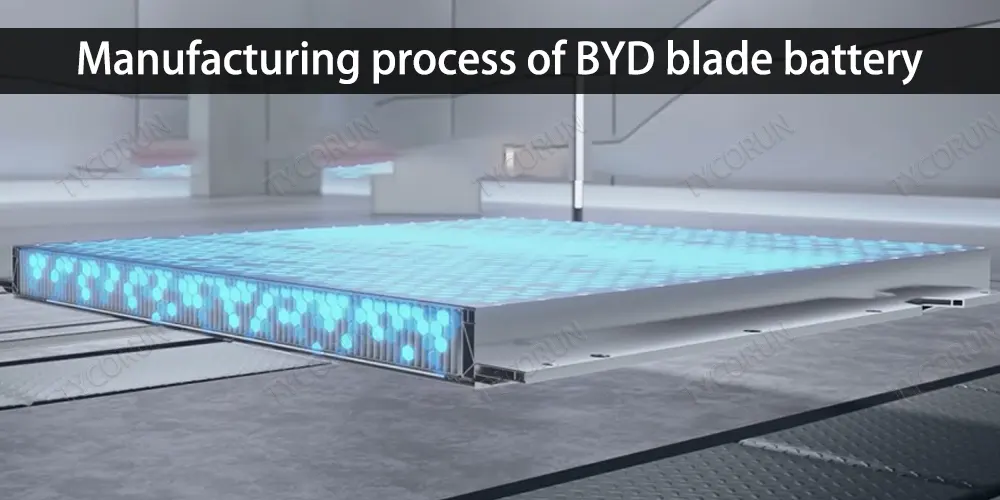

Manufacturing process of BYD blade battery

There are generally two manufacturing processes for batteries: winding and stacking processes. The blade battery adopts advanced high-speed stacking process, the length of the stacking pole piece can reach about 1000mm, the stacking alignment tolerance is within ±0.3mm, and the single stacking efficiency is 0.3s/pcs.

The stacking process of the blade battery is to cut the positive and negative pole pieces and separators into specified sizes, then stack the positive pole pieces, separators, and negative pole pieces into small battery cells, and then stack the small battery cells and connect in parallel to form a large battery cell, and then assemble the cover plate, side plate, spacer, etc. and the casing to form a single blade battery cell.

Compared with the winding process, the battery manufactured by the stacking process has better cycle characteristics and safety characteristics, which means longer life and better safety.

Generally speaking, the stacking process mainly consists of stirring, coating, roll-to-roll, die-cutting, stacking, welding, top sealing, liquid injection, pre-forming, suction sealing, forming, chemical formation and battery test. However, each battery manufacturer can properly optimize the production process to be more suitable for its own production.

Due to the particularity of the large size of the blade cell, it can only be produced by stacking technology, and the large-size high-speed stacking technology is even more difficult for all power battery manufacturers. This also reflects the advanced nature of BYD technology.

According to BYD’s introduction, the production process of BYD blade batteries is mainly concentrated in the 8 major processes: batching, coating, rolling, stacking, assembly, baking, liquid injection and testing and other production links. From the beginning of raw materials entering production, to The steps of producing each component, until the final inspection product.

The 8 major processes have covered the entire process of the actual production of blade batteries, that is to say, the innovation of blade batteries does not lie in the innovation of some links, but in the strict control of the quality of the entire field.

In addition to the high-speed stacking process, the blade battery also adopts wide-width coating, wide-width rolling and ultra-thin aluminum shell manufacturing technologies, which are basically the first in mass production.

Production environment of BYD blade battery

Before the battery is produced, the BYD blade battery has very strict requirements on the production environment, such as the dust-free design of the workshop, the constant temperature control of 26℃, and the humidity control of less than 1%.

In order to minimize the short-circuit rate of the battery, BYD has proposed a concept of dust classification control. In some key processes, it can achieve no more than 29 particles of 5 microns (1/20 the thickness of a hair) in a cubic meter of space. , which has reached the same standard as the LCD screen production workshop.

Advantages of BYD blade battery

BYD’s annual sales of electric vehicles in 2020 were only 179,054, but in 2022, it jumped to 1.86 million, completing a huge leap.

In 2022, BYD’s foreign sales of electric vehicles have reached 55,916, a year-on-year increase of 307.2%. Now, with its own strength, BYD’s electric vehicles have entered more than 35 countries and regions in the world including Europe, Japan, and Thailand.

Compared with the battery technology of other materials, BYD blade battery has the most technical advantages. Because it solves the problem of car batteries from six aspects: safety, battery life, battery strength, battery life, charging speed, and low temperature performance.

Safety

In terms of safety, BYD blade battery is “super safe”. BYD’s self-developed lithium iron phosphate material can not only make the fully charged state dissociate and release heat with high start-up temperature, slow heat release, less heat generation, and no oxygen release.

Moreover, after testing, even under the experimental environment of the furnace temperature gradient rises to 300℃(5℃/min), there were be no fire and explosion phenomenon happening to BYD blade battery. And even when up to 10V (2.6 times Vmax), there were no fire or explosion.

BYD blade battery has passed the most objective and rigorous acupuncture and extrusion tests in the industry. The acupuncture test is to use a 5mm steel needle at a speed of 25mm/s to pierce through the middle of the large surface of the battery. In the acupuncture test, BYD’s blade battery did not smoke, or catch fire.

The squeeze test is to squeeze the battery, but the BYD blade only smokes and does not catch fire. This is because the battery cell and battery pack of BYD blade battery are designed in an integrated manner, and the side impact strength is greatly improved. Moreover, the battery pack is arranged in an in-line structure + high-temperature insulating ceramic protection + smoke isolation channel, so BYD can become a “battery that is difficult to catch fire”.

Battery life

In terms of battery life, BYD blade battery is known as “super life”. The reason is that BYD blade battery is innovatively optimized from multiple technical levels.

At the cell level, the blade battery is a lithium iron phosphate battery. The lithium iron phosphate material has good reversibility, low potential, and small expansion during charging and discharging. By controlling the iron dissolution problem of the lithium iron phosphate battery, the anode material is prevented from being affected by the metal, and the capacity fading of the battery is slowed down.

At the battery pack level, the blade batteries are designed in groups, which not only maintains consistency, but also allows the overall temperature of the batteries to be very uniform.

In addition, the BYD blade battery has also innovatively made a mechanical design to ensure that the expansion force of the system’s entire life cycle is in a controllable state. Therefore, the BYD blade battery can be charged and discharged more than 3,000 times, and the mileage can reach 1.2 million kilometers.

Battery strength

In terms of battery strength, the BYD blade battery is “super strong”. This is due to the fact that BYD engineers have developed a unique honeycomb-like aluminum plate structure design. First, the original beam design at the bottom of the traditional package is removed, and then multiple blade batteries are sandwiched in the middle, so that the strength of the BYD blade battery does not decrease but increases.

Mileage

The mileage of BYD Blade has reached the level of “super mileage”. The volume energy density of the BYD blade battery is close to that of the 811 ternary lithium battery, so that the high volume density can arrange a large-capacity battery in a small space. Therefore, the maximum power of the BYD blade battery package exceeds 100KWh, and a single charge can easily achieve a cycle life of over 600km.

The endurance of 600km can be said to be a milestone, bringing the endurance of electric vehicles to a new era, completely breaking the problem of short mileage of electric vehicles in the past, and breaking the “monopoly position” of fuel vehicles in the past. Therefore, it can be said that BYD blade battery has brought electric vehicles to a new era of automobiles.

Charging rate

After testing, the charging speed of the BYD blade battery can charge a electric vehicle from 5% to 80% in 18 minutes. Moreover, with the blessing of super power, the BYD blade battery can be charged faster and safer.

In the era of fuel vehicles, many people think that the biggest shortcoming of electric vehicles is the problem of slow charging, but the super power of BYD blade battery solves this problem, and it can increase the cruising range by hundreds of kilometers in less than 20 minutes. The time is short, and the electricity price is cheaper than the fuel price. Moreover, most service areas are now equipped with charging piles, and the battery life of electric vehicles is no longer a problem.

Low temperature performance

BYD blade battery is suitable for “super low temperature”. In a low-temperature and low-battery environment, the power of BYD’s lithium iron phosphate battery is not only higher than that of the nickel-cobalt-manganese ternary battery, but at -10°C, 0.2-0.3C, 400 times, the battery capacity can still be maintained at more than 80%. Therefore, electric vehicles using BYD blade battery do not need to worry about low temperature.