Home » lithium ion battery knowledge » Module level power electronics – key innovations and emerging trends

Module level power electronics - key innovations and emerging trends

What is module level power electronics?

Module level power electronics refers to power electronic equipment that can perform fine control of single or several photovoltaic modules in a solar photovoltaic system. It mainly implements functions such as inversion, monitoring, power optimization, and shutdown, and performs functions on photovoltaic modules. Fine control. The existing product series includes three solutions: micro-inverter, optimizer, and component-level shutdown.

There are two main paths to module level power electronics technology:

1) Directly replace the string inverter with a micro inverter. The system DC voltage is generally below 80V. It has the highest safety and power generation efficiency, small footprint, and flexible installation. The cost per watt is about 0.5~1.8 yuan/W, which is suitable for cost control. Small and medium-sized distributed systems that are insensitive and have high requirements on security and power generation;

2) Configure an optimizer/shutdown device for each component in the photovoltaic string to achieve rapid shutdown at the component level, eliminate DC high voltage in critical situations, and reduce operation and maintenance risks; at the same time, the component power can be adjusted in real time, thereby improving the overall power generation efficiency. The cost per watt is about 0.35 yuan/W, and as the system capacity increases, the cost per watt gradually decreases, so it has more advantages in medium and large systems.

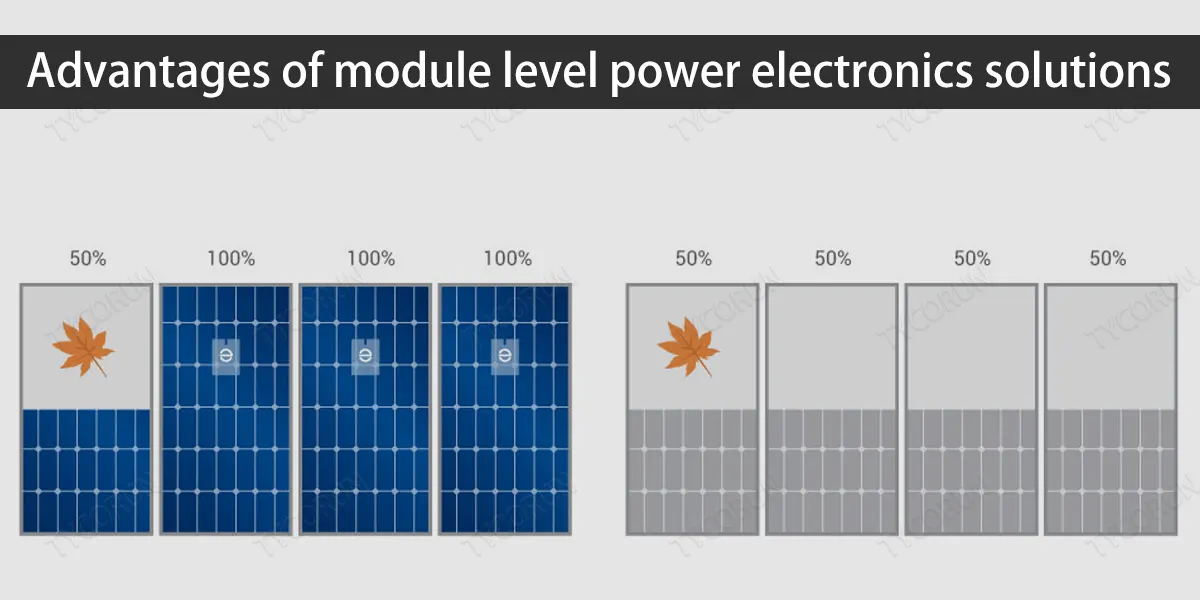

Advantages of module level power electronics solutions

- Eliminate safety hazards

The rapid growth of module level power electronics is due to the increasing policy requirements for the safety of photovoltaic power generation systems. The increase in the proportion of distributed photovoltaics has led to frequent safety issues, and safety has inevitably become a systemic factor that local governments and users need to consider. The cumulative DC voltage of the entire string of photovoltaic strings can reach a high voltage of 600V~1500V, resulting in two major safety hazards: “DC high voltage risk” and “rescue risk”.In response to this type of safety hazard, many countries around the world have successively promulgated mandatory regulations or standards, requiring component voltages to be reduced to a safe range within a short period of time. The United States was the first country to propose the concept of component-level shutdown and implement relevant mandatory regulations. Subsequently, Canada, Germany, Mexico, Australia and other countries have successively introduced policies and regulations. Module level power electronics solutions will gradually become the standard for global distributed photovoltaics. - Improve system power generation efficiency

For photovoltaic systems using centralized or string inverters, once a module causes a power drop due to failure, shading, etc., the output power of the entire string of modules will be reduced. Since Module level power electronics can achieve refined output power adjustment at the component level, it can still achieve higher power generation and extend power generation time even under poor lighting conditions. According to calculations by relevant companies, under the same conditions, compared with traditional inverter systems, systems using Module level power electronics can increase power generation by 5-25%. - Intelligent and precise monitoring

Another major advantage of Module level power electronics is the precise monitoring of individual components. In centralized and string inverter scenarios, once a component fails, operation and maintenance personnel need to conduct large-scale inspections to locate the faulty component, which takes a long time. Current Module level power electronics products can achieve rapid positioning at the component level through remote monitoring systems, which can minimize the shutdown time of photovoltaic systems and greatly improve operation and maintenance efficiency. - Flexible expansion, low-cost operation and maintenance

Distributed photovoltaic systems are mostly installed on the roofs of residential and industrial and commercial buildings. The length, specification, and orientation of the strings are relatively flexible, and the capacity of a single household also varies greatly. The advantages of Module level power electronics such as “modular design and plug-and-play” can be fully utilized. space, adapts to different installation directions and angles, and lowers the threshold for installation and expansion. During the operation and maintenance process, because Module level power electronics is independent and connected to the grid in parallel, a single inverter can be replaced and repaired without interrupting the entire pv system.

Module level power electronics technology application scenarios

- Rooftop photovoltaic: For rooftop photovoltaic systems, where there are usually shadows or uneven illumination, Module level power electronics technology can maximize the power generation efficiency of photovoltaic modules.

- Complex terrain: In complex terrain environments, MLPE technology can better cope with photovoltaic modules of different slopes and orientations, improving the power generation efficiency of the entire system.

Photovoltaic power station maintenance: For large-scale photovoltaic power stations, the fault isolation and real-time monitoring functions of MLPE technology help reduce maintenance costs and improve operation and maintenance efficiency. - Module-level monitoring: MLPE technology can provide data monitoring of each photovoltaic module to facilitate system operation management and performance optimization.

- Places with high safety requirements: In some places with high voltage and current safety requirements, such as schools, hospitals, etc., MLPE technology can provide safer and more reliable photovoltaic power generation solutions.

Module level power electronics industry trends

- “High current” and “high power” bring cost-effective advantages

Technological innovation directly brings about a substantial improvement in product performance. The upgrade of new DC boost topology circuits and software control algorithms drives the development of “one-to-n” products and enables large current input.”One-to-N” technology connects a single micro-inverter to multiple photovoltaic components. While ensuring that each component achieves AC-DC conversion through independent input, it also reuses some devices (transformers, AC terminals, etc.) to comprehensively reduce the micro-inverter cost. The cost per watt of the inverter helps improve product cost performance. As the power of supporting photovoltaic modules increases, the rated output power of module level power electronics inverters also continues to increase. The increased power of a single module improves product compatibility, directly leading to the expansion of application scenarios and scope of MLPE products, and accelerating the continued penetration of the product.

- “High current” and “high power” bring cost-effective advantages

- “Intelligence” greatly improves operation and maintenance efficiency

The intelligent application of MLPE can accurately monitor individual components in real time. With the further integration of intelligent technology, once the system fails, operation and maintenance personnel only need to quickly locate it through the component-level monitoring interface and perform remote operations to solve the problem. The entire process realize intelligent management, continuously improve operation and maintenance efficiency, and ensure end-to-end system security. - “Integration” may become a mid- to long-term development trend

In the medium to long term, in order to reduce the demand for raw materials and components and reduce assembly, integration and operation and maintenance costs, direct integration of module level power electronics components into photovoltaic modules has become a new possibility. Judging from current market dynamics, the integration of MLPE and components may become a mainstream product development trend in the future.